Automatic resetting method of barrel and feed harvesting machine

An automatic homing and barrel technology, applied in the field of harvesters, can solve the problems of inability to accurately homing the barrel, waste of feed, damaged barrel, etc., to achieve high homing efficiency, save time and cost, and homing the position Accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

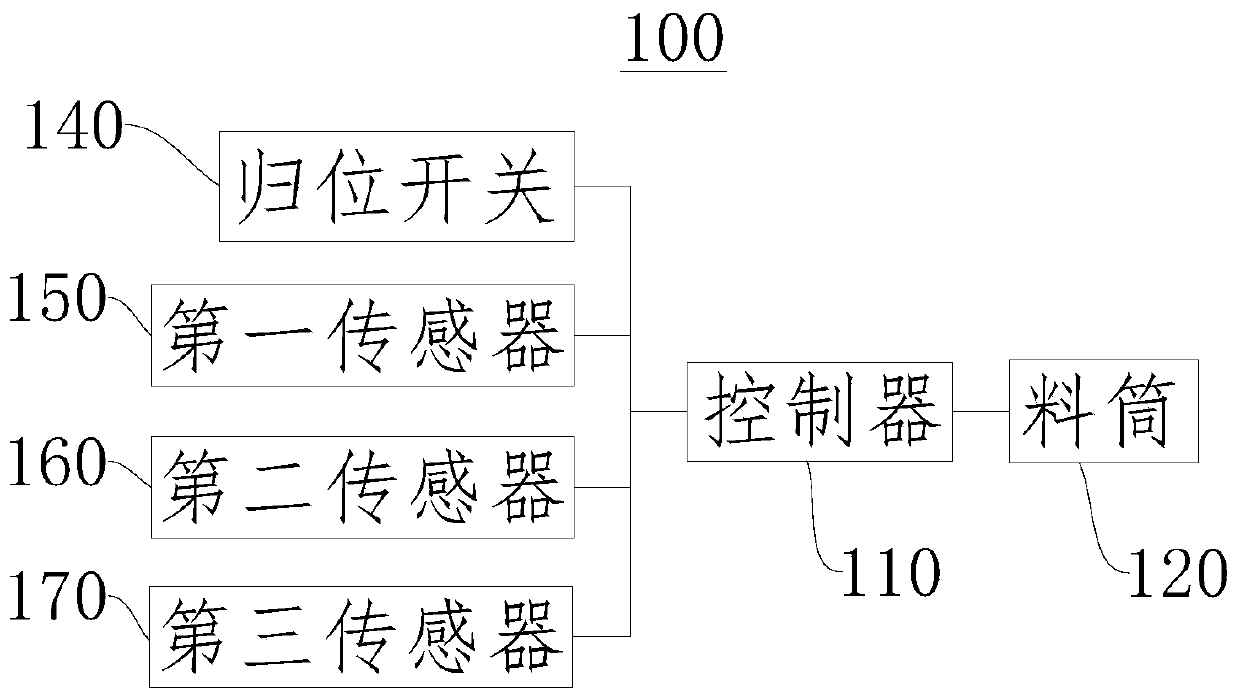

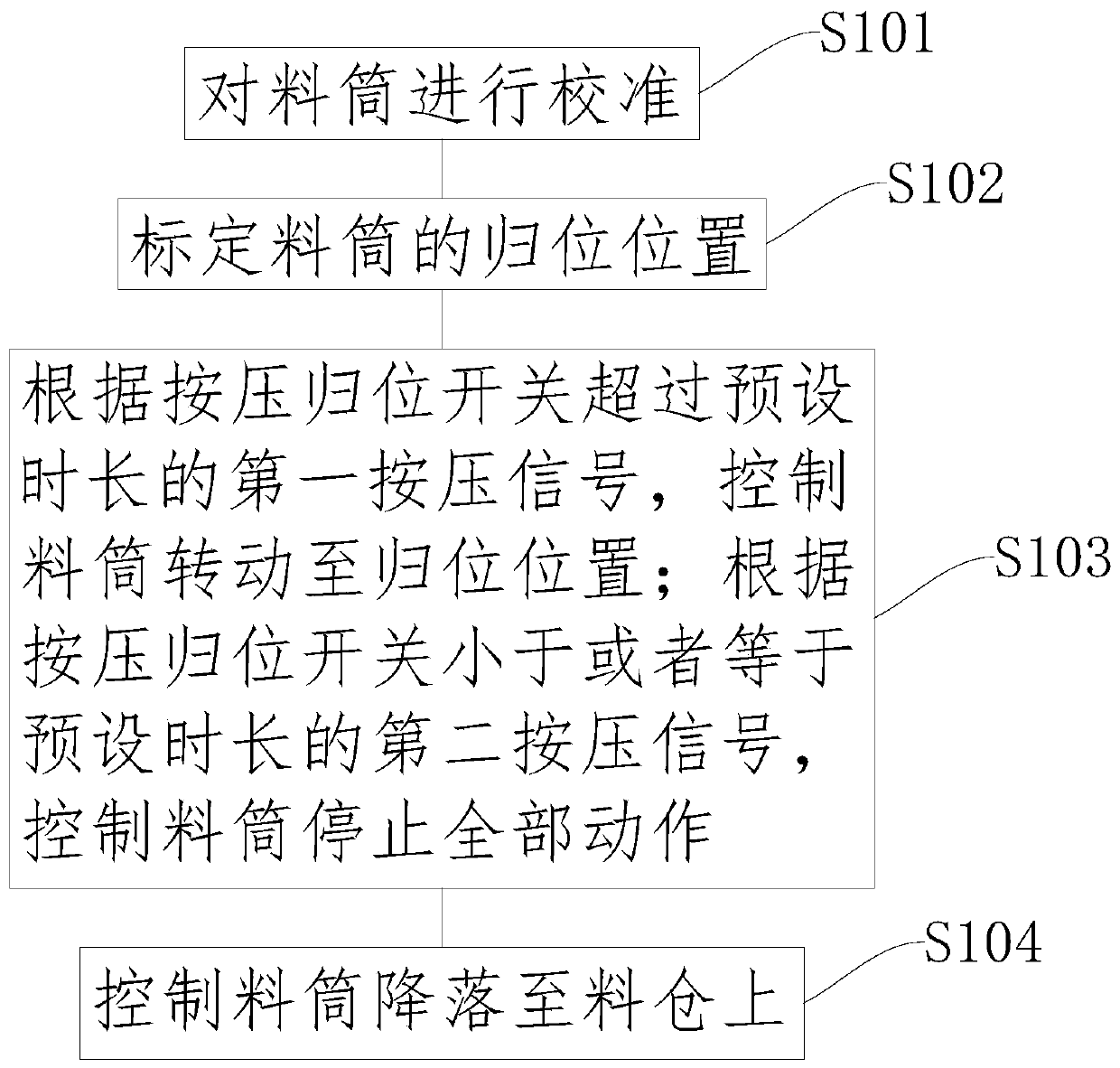

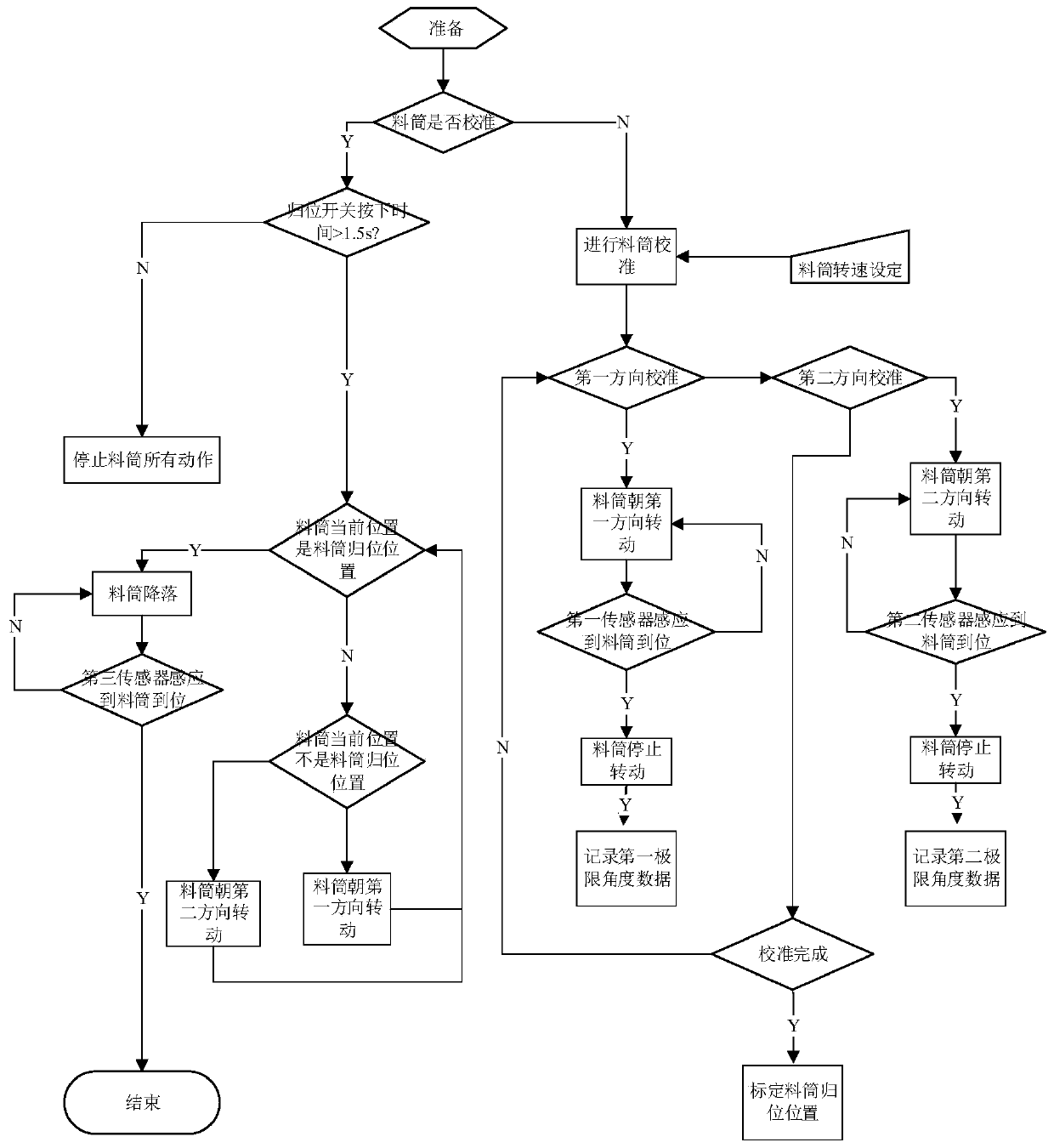

[0032] Please refer to figure 1 , figure 2 with image 3 The embodiment of the present invention provides a forage harvester 100 for harvesting straw fodder. The operation is simple, the automatic homing of the barrel 120 can be realized, the homing position is accurate and reliable, the homing efficiency is high, time and cost are saved, and the user experience is good.

[0033] The forage harvester 100 includes a controller 110, a barrel 120, a silo (not shown), a home switch 140, a first sensor 150, a second sensor 160, a third sensor 170, and a body (not shown). Among them, the controller 110, the barrel 120, the silo, the home switch 140, the first sensor 150, the second sensor 160, and the third sensor 170 are all installed on the body. The hopper 120 is movably connected with the machine body, and the silo is fixedly connected with the machine body. The hopper 120 is used to transport the straw into the silo. The barrel 120 can rotate or translate relative to the machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com