Quick plugging kit for clamping-type pipeline

A clamping and kit technology, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as economic loss, complicated production and installation, and sealing leakage, so as to reduce economic loss and save maintenance man-hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the technical solution of the present invention, a specific description is given in conjunction with the accompanying drawings.

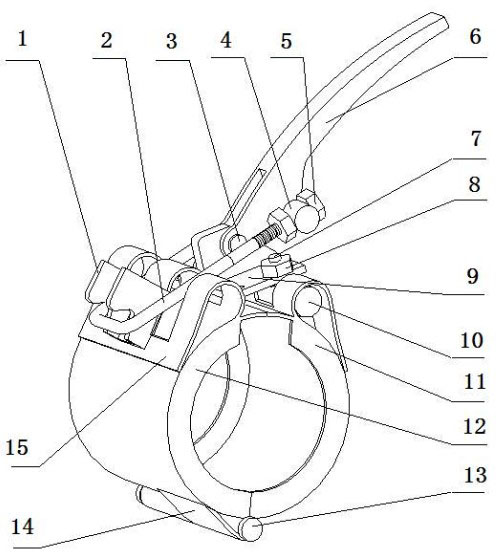

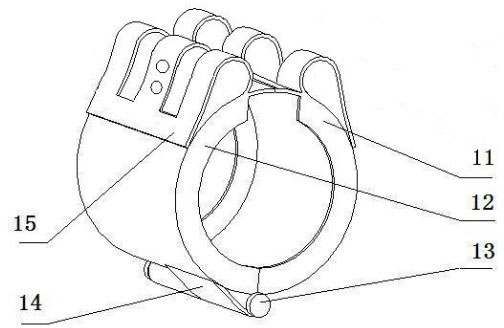

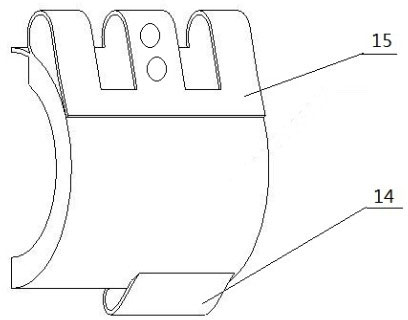

[0022] figure 1 Among them, 1 is a hook; 2 is a U-shaped elastic pull rod; 3 is a rivet, through which the handle and the handle base are connected, and can be rotated up and down around the handle base; 4 is the handle pin; 5 is the adjusting nut; 6 is Handle; 7 is the fixing bolt of the handle base; 8 is the fixing nut of the handle base fixing bolt; 9 is the handle base; 10 is the base pin; 11 is the right half ring; 12 is the left half ring; 13 is the king pin; 14 It is the left half-ring 12 that is re-rolled under the lug, the king pin 13 is located therebetween, and the bottom of the right half-ring 11 and the left half-ring 12 are connected through the king pin 13. When the gap between the pipeline to be blocked and the peripheral gap is very small, it is also The kingpin shaft 13 can be pulled out, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com