Coal bunker maintenance device

A technology for overhauling devices and coal bunkers, applied in transportation and packaging, lifting equipment in mines, etc., can solve problems such as protection without manhole cover doors, difficulty in overhauling, and threats to personal safety, saving labor costs, shortening maintenance man-hours, The effect of avoiding accidental injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

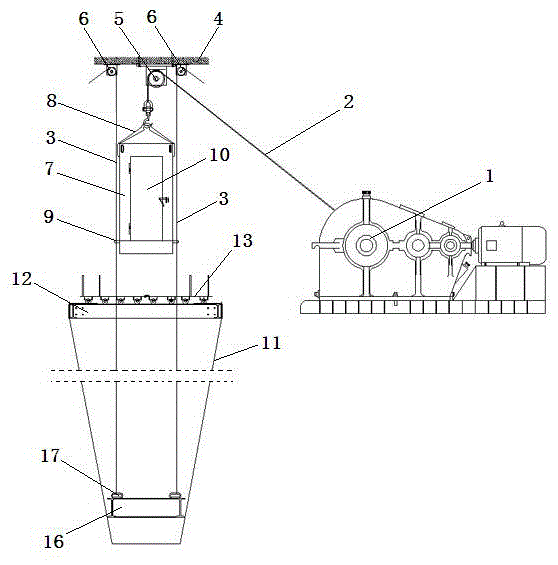

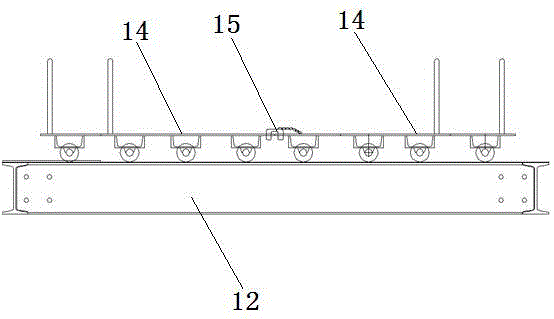

[0025] Below in conjunction with accompanying drawing, the present invention is further described, as figure 1 and figure 2 A coal bunker maintenance device shown includes a traction mechanism 1, a sky wheel suspension mechanism, a cage mechanism, a sealing plate mechanism, a rope-stabilizing base mechanism, a traction rope 2 and two ropes 3; the traction mechanism 1 For the return column winch.

[0026] The sky wheel suspension mechanism is arranged on the shaft wall 4, and includes a lifting reversing pulley 5 and two rope-stabilizing reversing pulleys 6 arranged on both sides of the lifting reversing pulley 5;

[0027] The cage mechanism includes a cage main body 7 with an end cover, which can be opened to transport long materials; the tank cover is provided with a semicircular arc-shaped anti-drenching rain shed to prevent personnel from being injured by falling objects; The upper part of the side wall of 7 is provided with hook frame 8, and the lower part of cage main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com