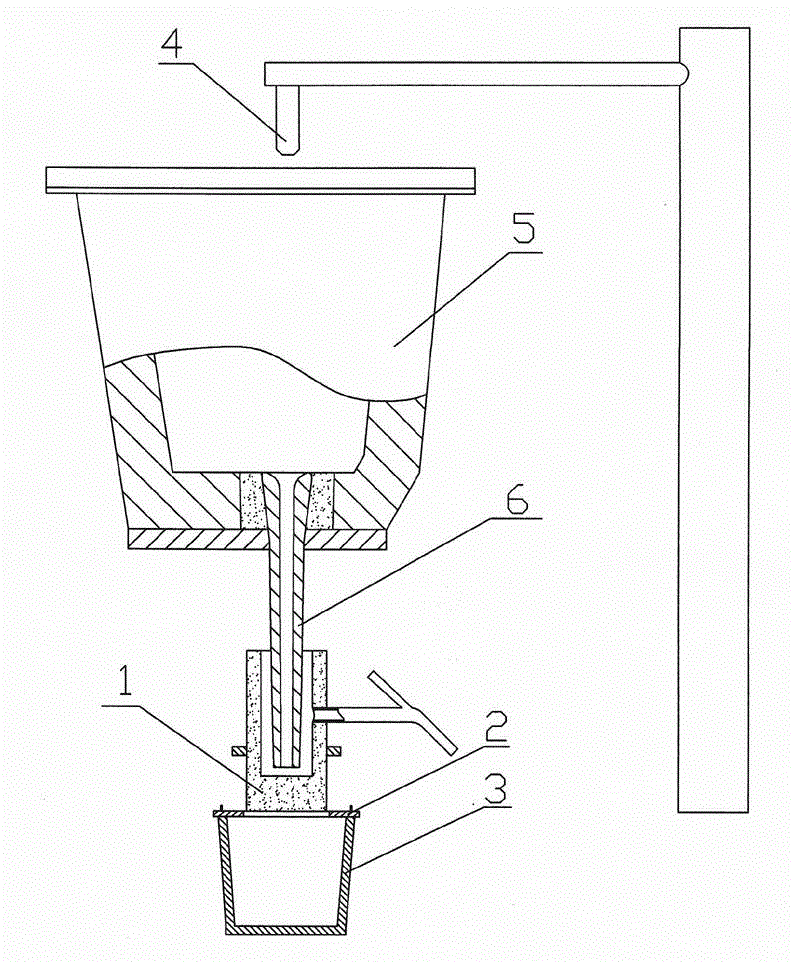

Baking device and method for integral water gap of continuous casting tundish

A continuous casting tundish and baking device technology, which is applied to casting equipment, casting molten material containers, metal processing equipment, etc., can solve the problems of continuous casting production impact, achieve low pressure and flow requirements, ensure baking effect, Easy to operate and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

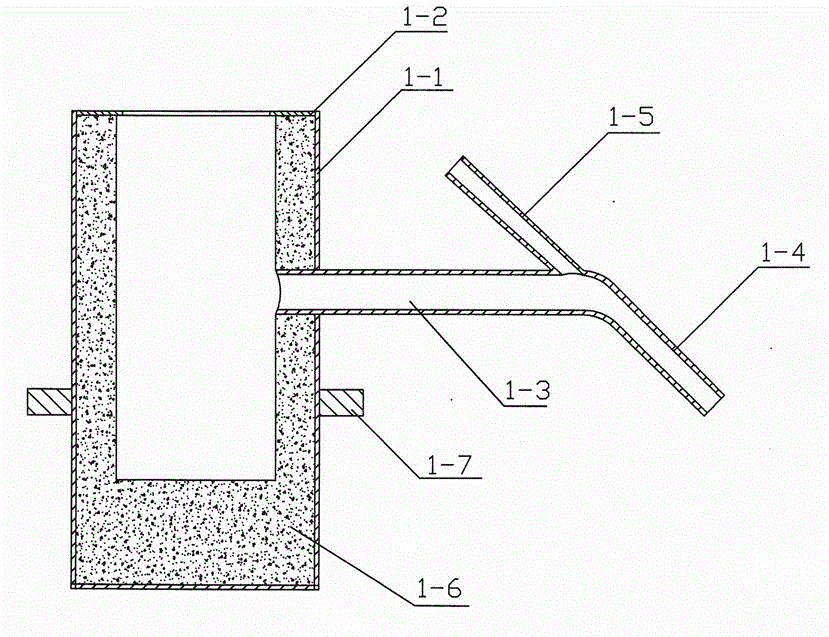

[0017] A continuous casting tundish integral nozzle baking device, which includes a cylindrical baking barrel 1-1 with a closed bottom and an open upper end, and a refractory material layer 1-6 is provided on the inner wall and bottom of the baking barrel 1-1 , two symmetrical supports 1-7 are welded on the outer wall of the baking barrel 1-1. A ventilation duct 1-3 is arranged on the cylinder wall of the baking barrel 1-1, and one end of the ventilation duct 1-3 is welded on the outer wall of the baking barrel 1-1, and is connected with the inner cavity of the baking barrel 1-1. In the same way, the other end of the ventilation pipe 1-3 is welded with an exhaust pipe joint 1-4, the angle between the exhaust pipe joint 1-4 and the air pipe 1-3 is 150 degrees, and the diameter of the exhaust pipe joint 1-4 is less than The diameter of the air duct 1-3 adopts an arc transition at its junction. Also welded with a blowing pipe joint 1-5 on the vent pipe 1-3, the diameter of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com