Baking curve construction method and baking method of lithium ion battery pole pieces

A lithium-ion battery and battery pole piece technology, which is applied in the field of lithium-ion battery processing and manufacturing, can solve problems such as difficult to ensure qualified moisture, re-baking, and difficult to optimize the baking time, so as to save baking time and energy consumption, The effect of improving baking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

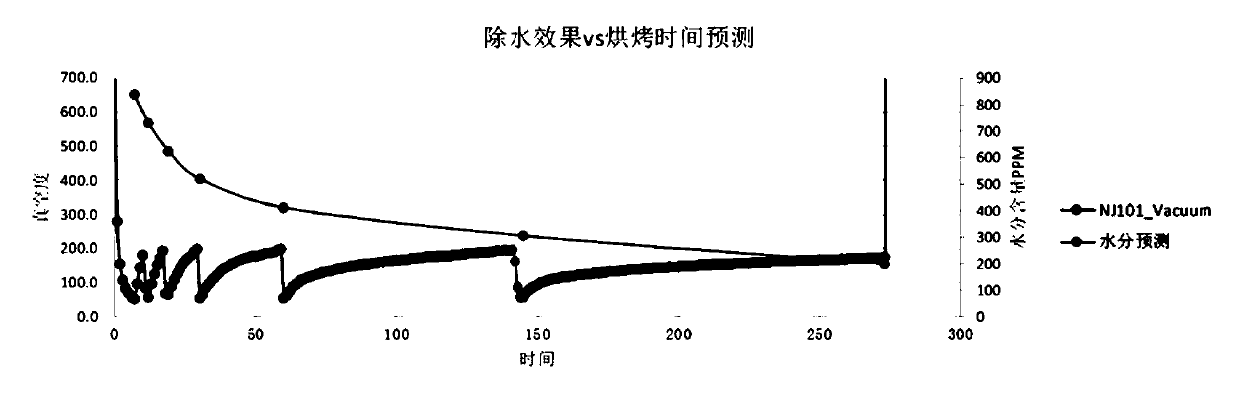

[0034] This embodiment is aimed at baking the lithium-ion battery pole piece of graphite negative electrode material.

[0035] Take a sample of the negative pole piece to be baked, the size of the sample has no effect, use the Karl Fischer moisture tester to test the initial moisture content of the pole piece before baking, and record it as A0 = 838ppm; and take the same batch and the same The pole pieces preserved under storage conditions were loaded into a high-vacuum oven according to the predetermined baking quantity of 27,000 pieces, and set aside. In this embodiment, the pole piece baking setting conditions with different initial moisture contents are exactly the same, and the temperature, pressure, and quantity conditions are completely consistent with the initial curve construction, so that they can be used as the cut-off conditions for subsequent baking processes, and There is no special requirement for the initial moisture content in the curve construction stage, and...

Embodiment 2

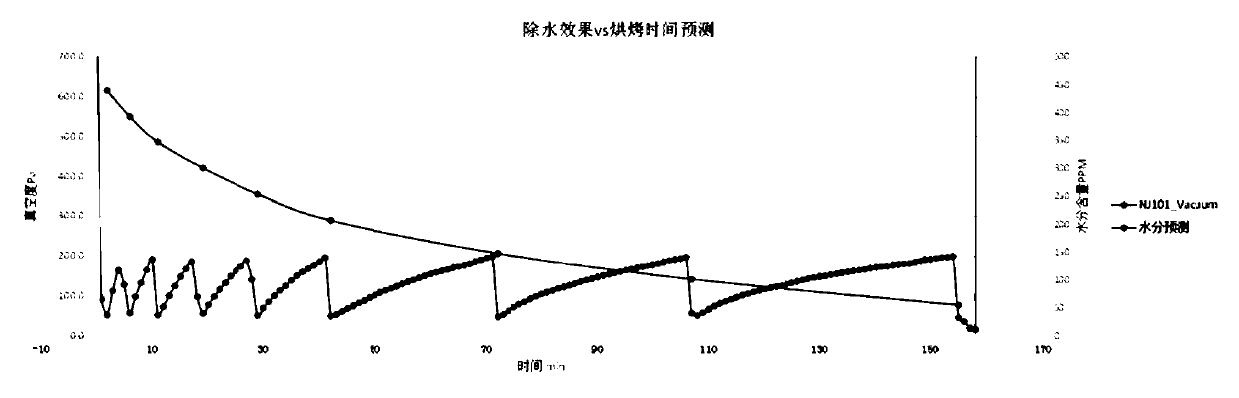

[0048] This embodiment is aimed at baking the lithium-ion battery pole piece made of nickel-cobalt-manganese ternary material.

[0049] Take a sample of the positive pole piece to be baked, use the Karl Fischer moisture tester to test the initial moisture content of the pole piece before baking, and record it as A0=440ppm; 27,000 pieces are loaded into a high-vacuum oven according to the predetermined baking quantity and set aside.

[0050] Vacuumize the drying chamber of the oven to ≤200Pa, fill it with nitrogen, and preheat at a preheating temperature of 130°C for 5 hours under the protection of nitrogen, so that all pole pieces in the drying chamber reach a drying temperature of 130°C.

[0051] Under the condition of 130°C heat preservation, the drying chamber was further evacuated to an initial pressure value of 50Pa. At this time, the pole piece had begun to dewater, and the pressure in the drying chamber gradually increased to 200Pa. During this process, the pressure was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com