An electric coal mixed flue-cured tobacco heating device

A technology of heating device and electric heater, which is applied in the direction of tobacco, tobacco preparation, application, etc., to achieve the effect of ensuring quality, reducing the generation of toxic gas, and avoiding physical health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a heating method for mixed flue-cured tobacco with electricity and coal. During the temperature-rising period of flue-cured tobacco, the temperature of the flue-cured tobacco room is uniformly raised to the target temperature value by means of electric heating or electric-coal hybrid heating; The heating method stabilizes the temperature of the flue-curing room at the target temperature value.

[0023] In the process of applying the electric-coal mixed flue-cured tobacco heating method to flue-cured tobacco, the electric heating method has the characteristics of easy power adjustment, and the air can be directly heated stably through the electric heating method, or the electric coal mixed heating method can be used (this Time-electric heating is the main method and coal-fired heating method is auxiliary), the instability provided by the coal-fired heating method is dynamically compensated by power control (for example, the instant heating power of t...

Embodiment 2

[0026] The second embodiment provides a flue-cured tobacco process that implements the electric-coal hybrid heating method described in the first embodiment. In the yellowing stage of the three-stage flue-cured tobacco process, the temperature of the flue-curing room is firstly increased to 34~34 by electric heating. At 38 degrees Celsius, the temperature of the flue-curing room is stabilized at 34-38 degrees Celsius through electric heating. When 80% of the tobacco leaves become 80% yellow, the temperature of the flue-curing room is increased to 40-42 degrees Celsius uniformly through electric heating. The temperature of the flue-curing room is still stabilized at 40-42 degrees Celsius through electric heating; and / or, during the color fixation phase of the three-stage flue-curing process, the temperature of the flue-curing room is first uniformly increased to 46-48 by electric heating Celsius, the temperature of the flue-curing room is stabilized at 46 to 48 degrees Celsius by...

Embodiment 3

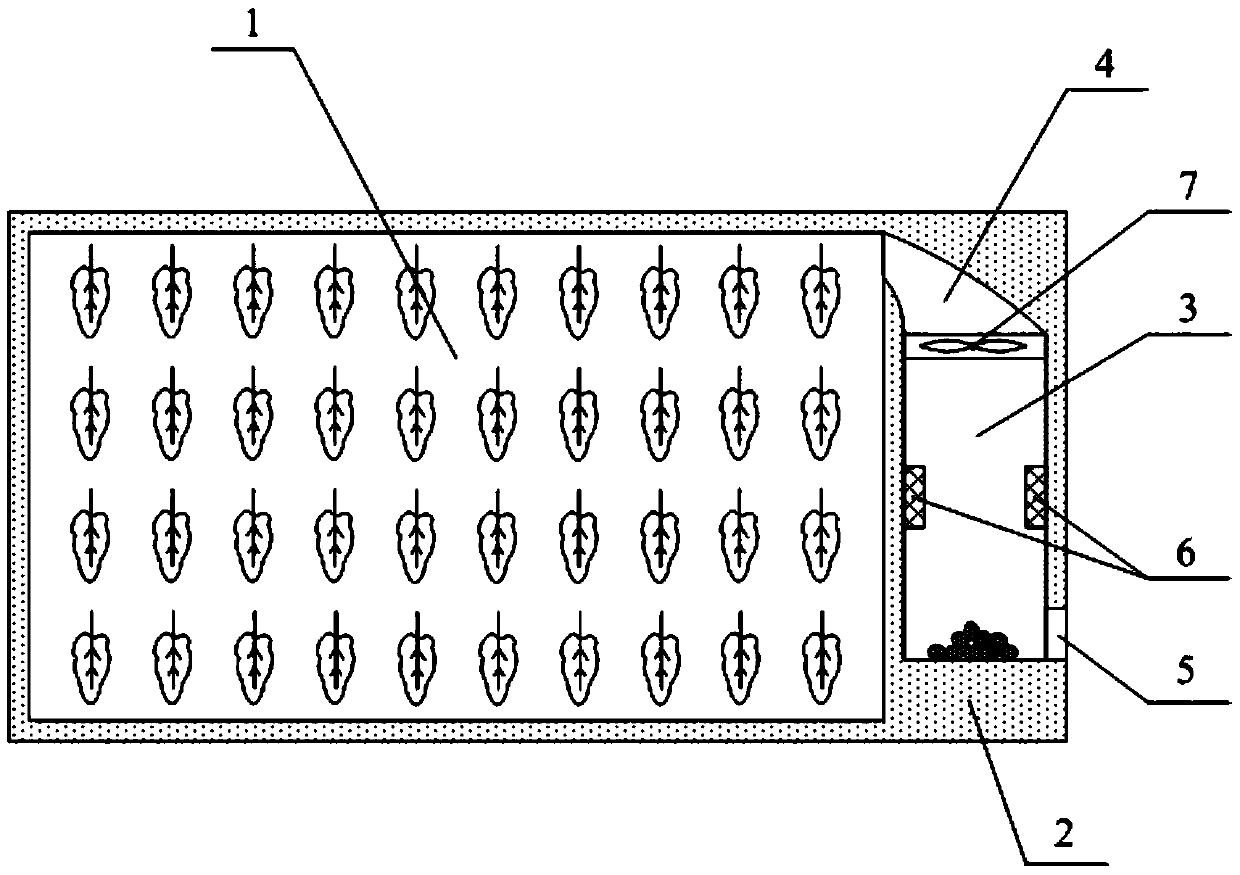

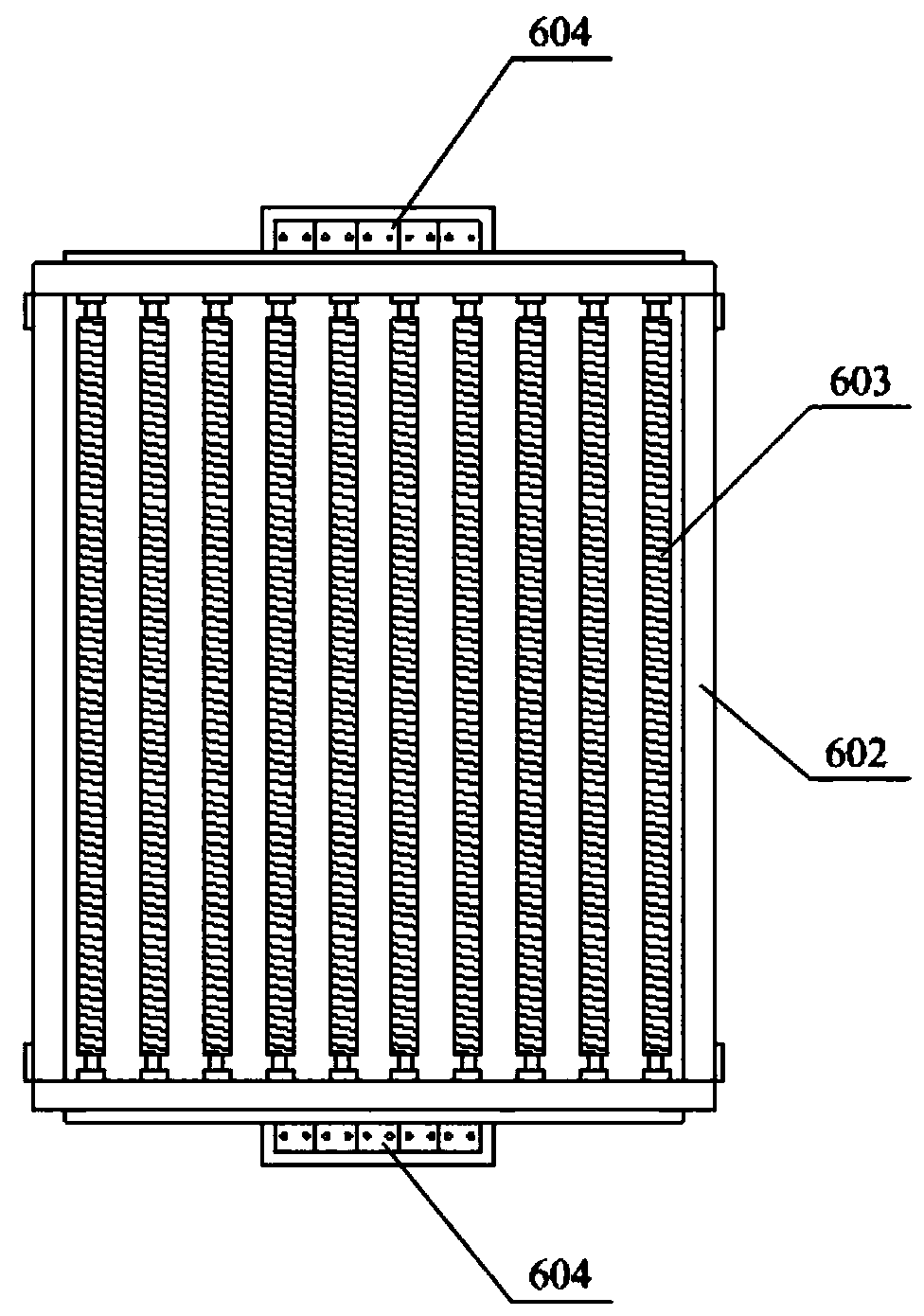

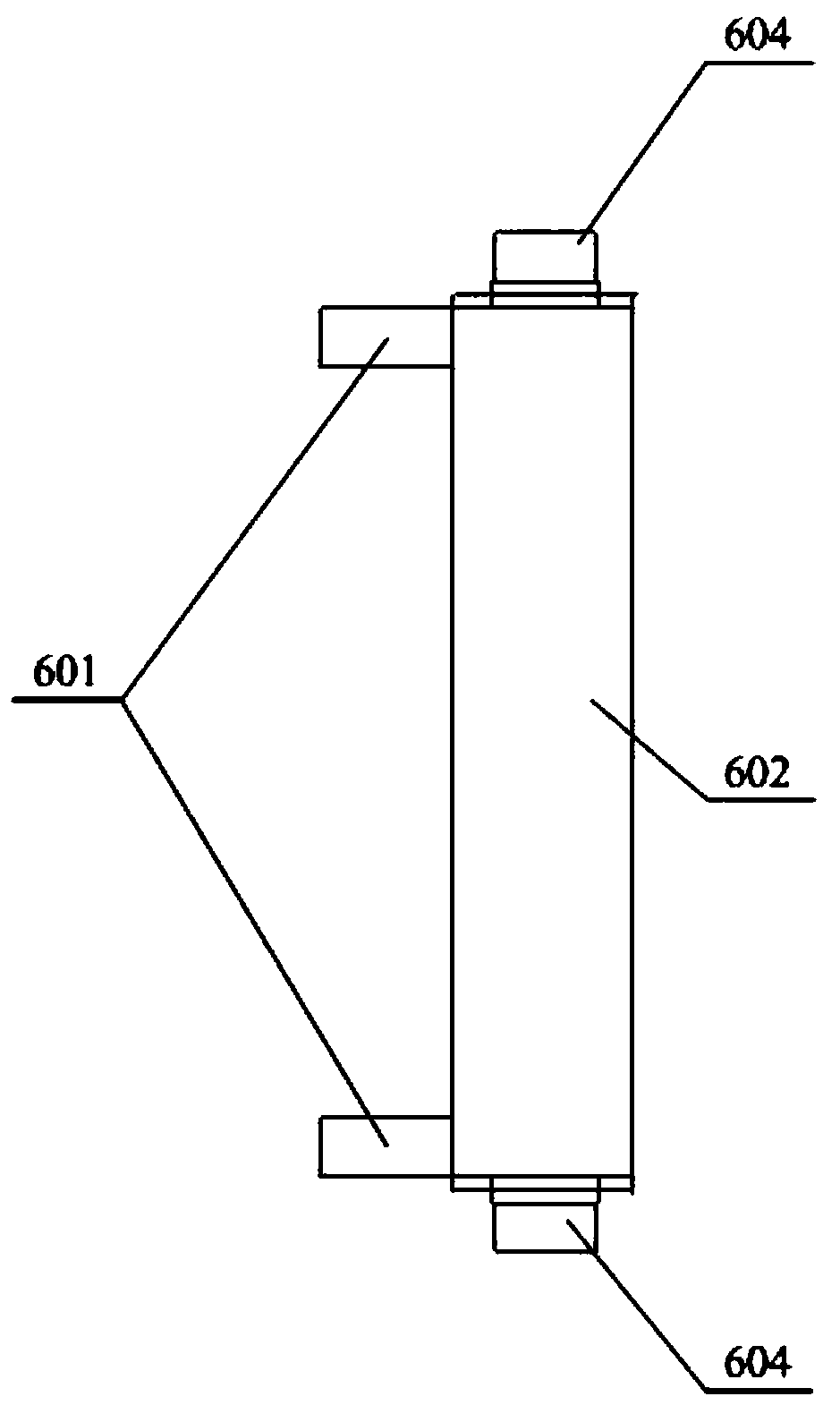

[0032] figure 1 Shows a schematic cross-sectional view of the heating device for electric-coal mixed flue-cured tobacco provided by the present invention, figure 2 Shows a schematic diagram of the front structure of the electric heater in the electric coal mixed flue-cured tobacco heating device provided by the present invention, image 3 The left side structural diagram of the electric heater in the electric coal mixed flue-cured tobacco heating device provided by the present invention is shown. This embodiment provides a heating device for realizing the heating method of electric-coal mixed flue-cured tobacco in the first embodiment. The heating device includes a flue-curing room 1 and a heating room 2. The heating room 2 is provided with a coal-fired furnace cavity 3 and a coal-fired furnace. The top of the furnace cavity 3 communicates with the air duct 4 of the flue-curing room 1; the coal-fired furnace cavity 3 has a coal inlet 5 at the bottom of the cavity wall, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com