Continuous temperature measuring device for tundish molten steel

A technology of temperature measuring device and tundish, which is used in the configuration of indicating equipment/measuring equipment, casting melt containers, manufacturing tools, etc. problems such as low life, to prevent erosion and melting loss, ensure the effect, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

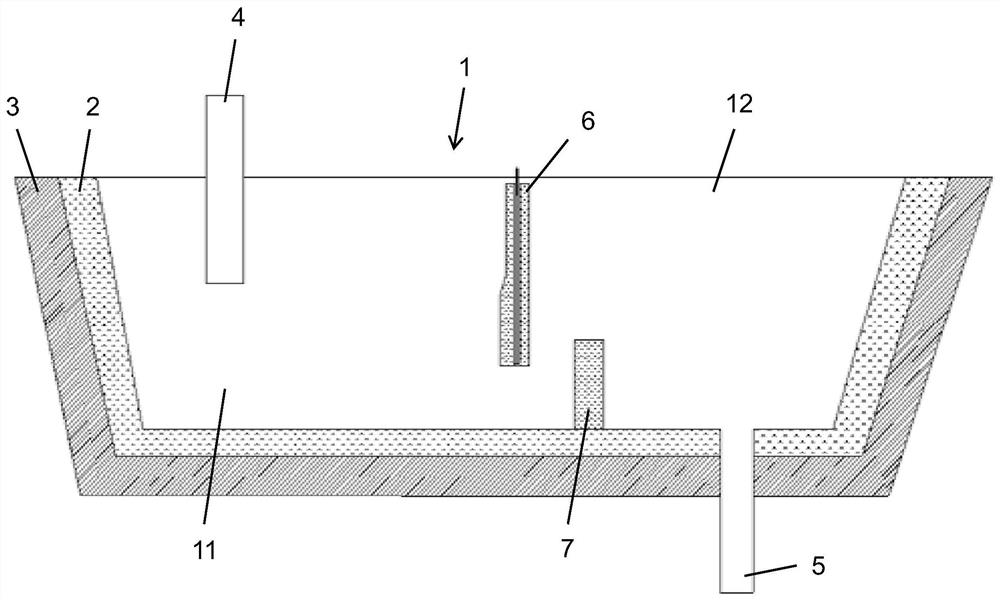

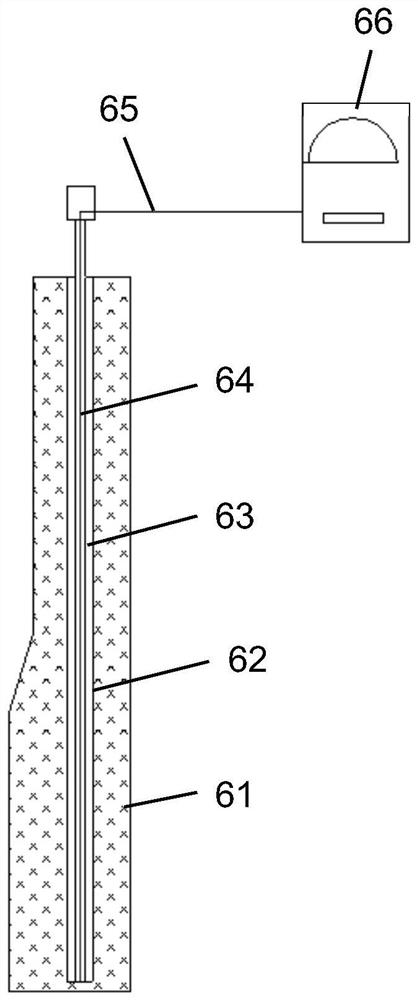

[0031] Please combine figure 1 and figure 2 As shown, embodiment one of a continuous temperature measuring device for molten steel in a tundish provided by the present invention includes:

[0032] The tundish 1 is composed of the tundish refractory material layer 2 and the tundish shell 3. The long nozzle 4 is installed on the top of the tundish 1, the submerged nozzle 5 is installed on the bottom of the tundish 1, and the temperature measuring weir plate is installed in the middle of the tundish 1. 6. A dam 7 is installed between the temperature measuring weir plate 6 and the submerged nozzle 5 . The temperature measuring weir plate 6 is installed in the middle of the tundish 1, including: the weir plate refractory body 61, a temperature measuring hole 62 is opened in it, and a temperature measuring refractory protective sleeve 63 is installed in the temperature measuring hole 62, and the temperature measuring refractory A temperature-measuring thermocouple 64 is installed...

Embodiment 2

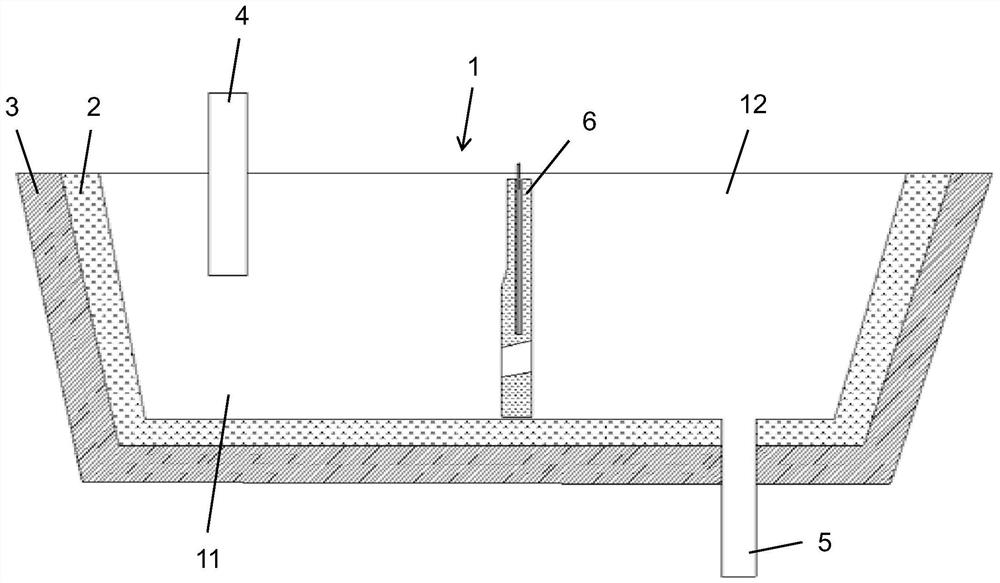

[0037] Please combine image 3 and Figure 4 As shown, a second embodiment of a continuous temperature measuring device for molten steel in a tundish provided by the present invention includes:

[0038] The tundish 1 is composed of the tundish refractory material layer 2 and the tundish shell 3. The long nozzle 4 is installed on the top of the tundish 1, the submerged nozzle 5 is installed on the bottom of the tundish 1, and the temperature measuring weir plate is installed in the middle of the tundish 1. 6. A dam 7 is installed between the temperature measuring weir plate 6 and the submerged nozzle 5 . The temperature measuring weir plate 6 is installed in the middle of the tundish 1, including: the weir plate refractory body 61, a temperature measuring hole 62 is opened in it, and a temperature measuring refractory protective sleeve 63 is installed in the temperature measuring hole 62, and the temperature measuring refractory A temperature-measuring thermocouple 64 is inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com