Outer layer material of composite roll for rolling and composite roll for rolling

一种外层材料、复合辊的技术,应用在轧辊、金属轧制、金属轧制等方向,能够解决耐表面粗糙性降低、辊表面损伤加深、辊寿命变短等问题,达到耐表面粗糙性优异、降低磨削频率、降低消耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

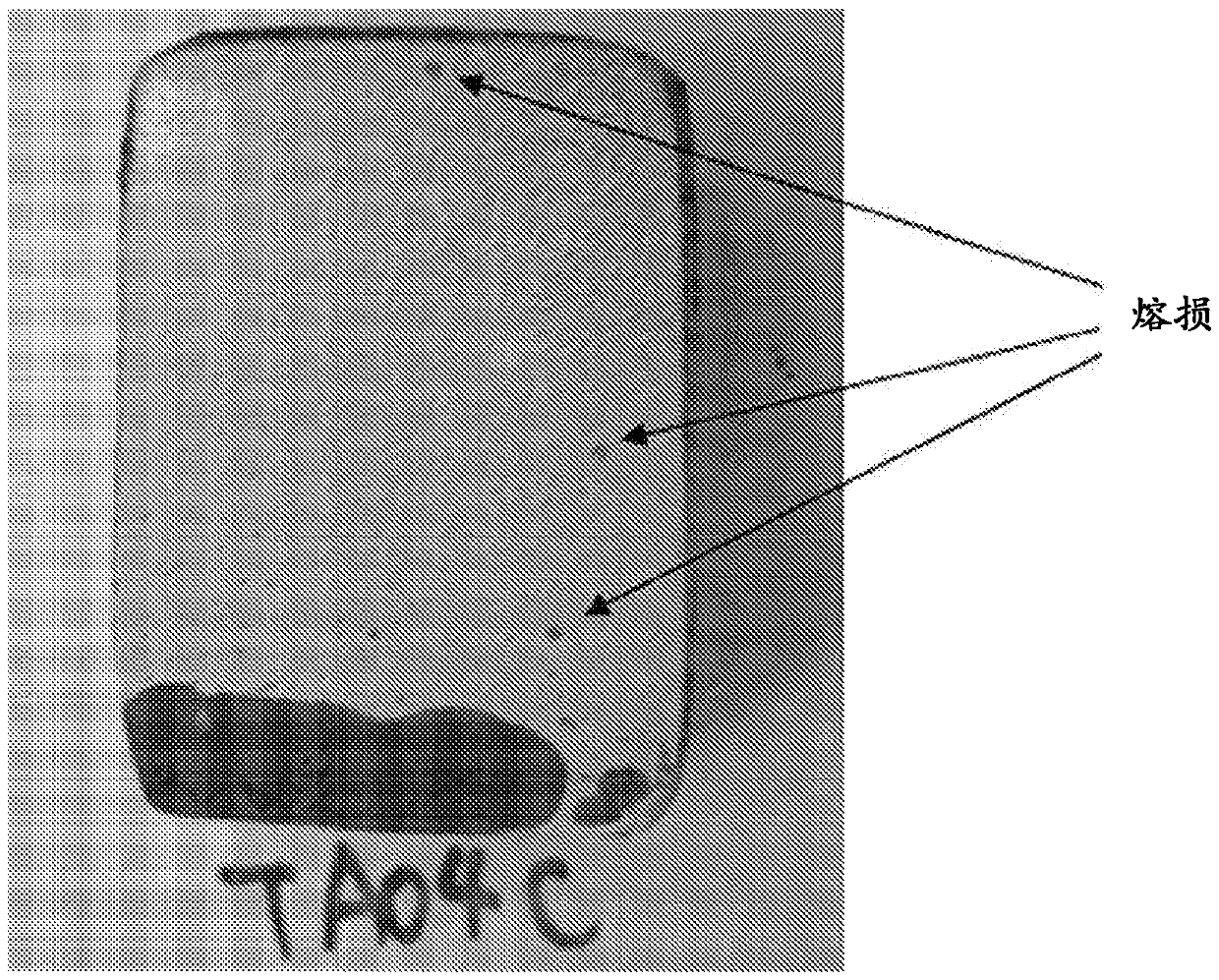

[0069] Alloy melts with various components shown in Table 1 were melted in a high-frequency induction furnace and subjected to centrifugal casting. Adjustment is made so that the solidification rate of the outer layer material during casting is 8 mm / min or more. In Table 1, Embodiments 1 to 5 are invention examples. In addition, Comparative Example 1 and Comparative Example 2 are outer layer materials in which the amount of B exceeds 0.01%.

[0070] [Table 1]

[0071]

[0072] After molding the outer layer material, the inner layer is molded to make a composite roll for rolling.

[0073] Quenching was given to the obtained composite roll for rolling. During quenching, forced air cooling was performed using a large fan, and the cooling rate of the roll surface from the austenitizing temperature to 700°C was 900°C / h or more.

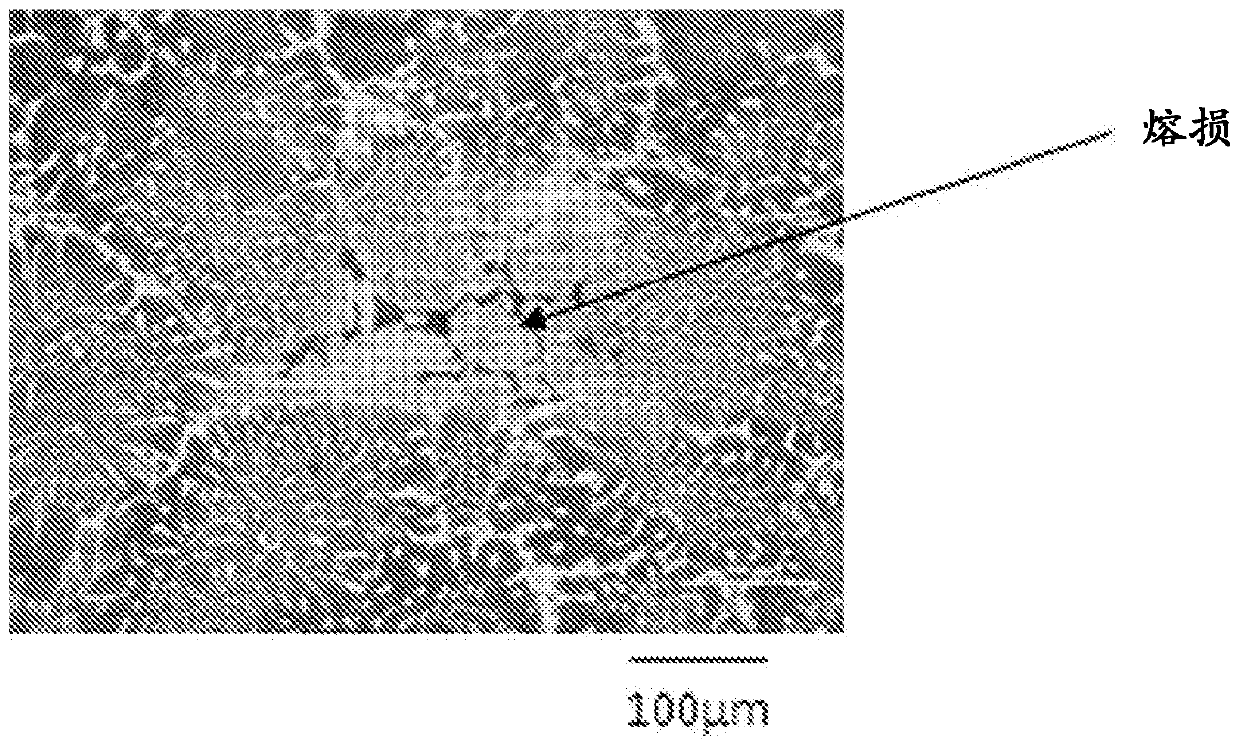

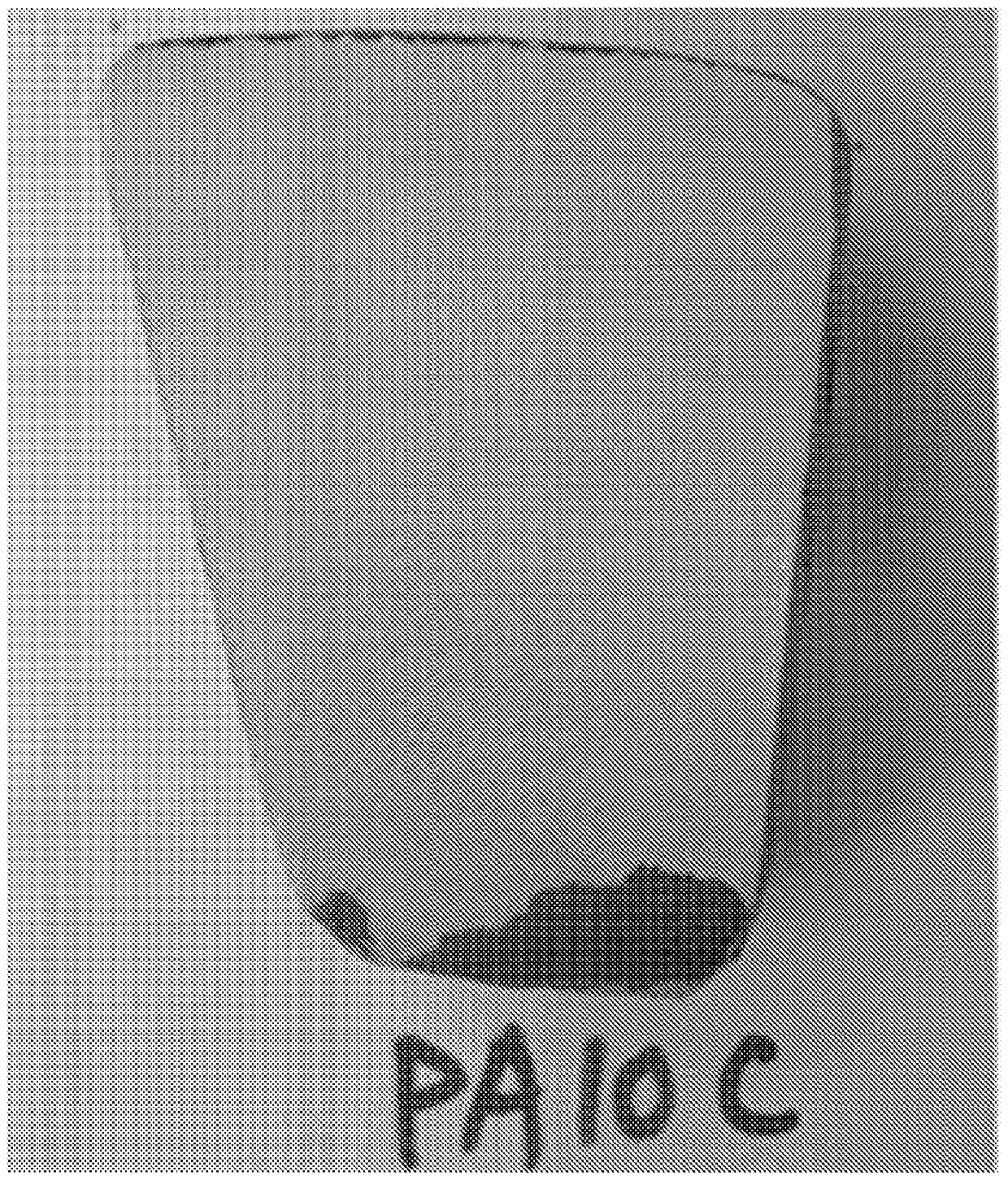

[0074] For the rolling composite rolls of Examples and Comparative Examples that have been quenched, after mechanical processing, a plurality of te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com