Fuel supply limiter for carburetor

A fuel supply and limiting device technology, which is applied to carburetors, idle speed devices, charging systems, etc., can solve problems such as difficulty in ensuring fuel tightness, fuel leakage, and troublesome assembly, achieve good space utilization, and improve fuel efficiency. Consumption and excellent responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

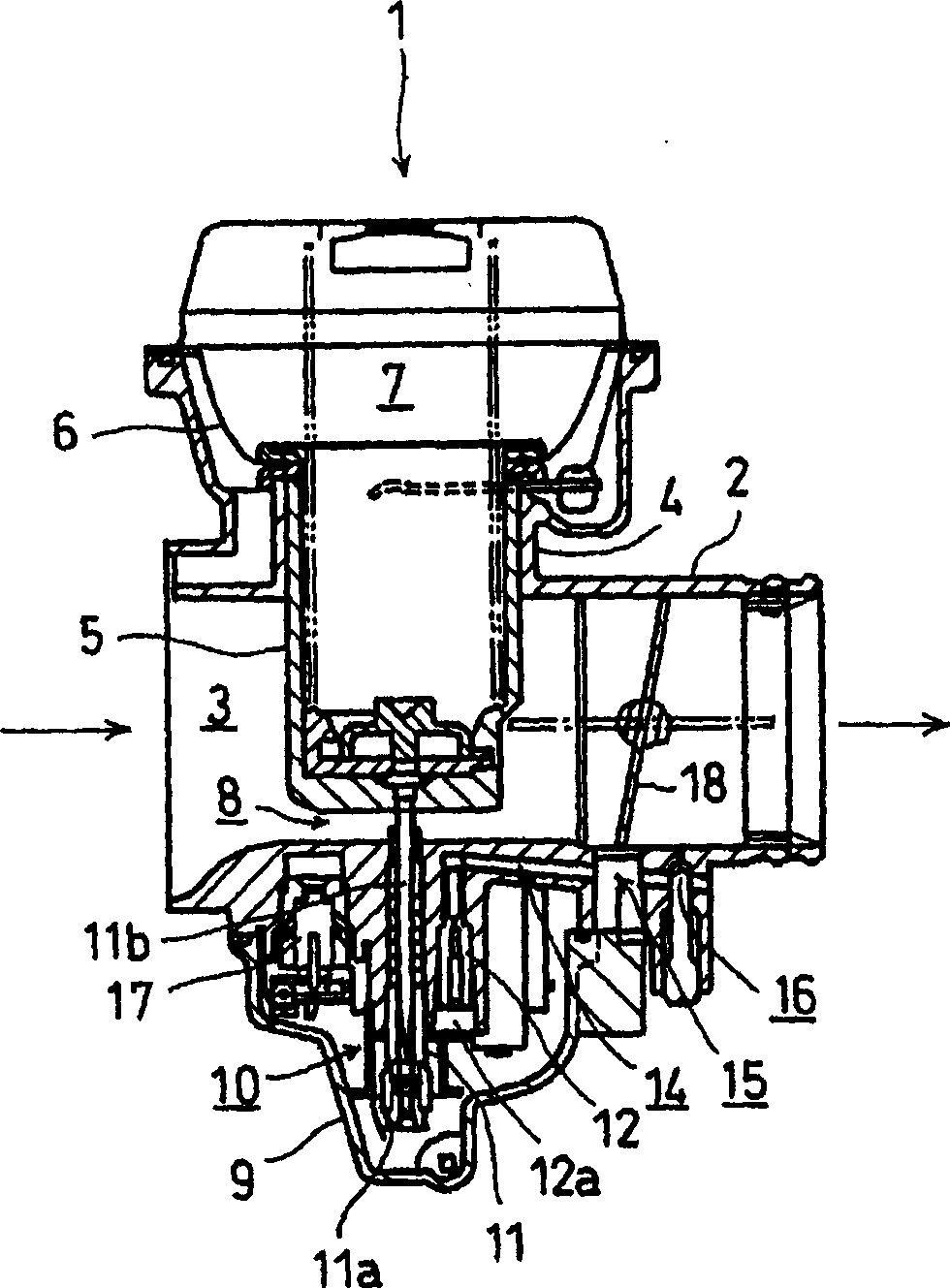

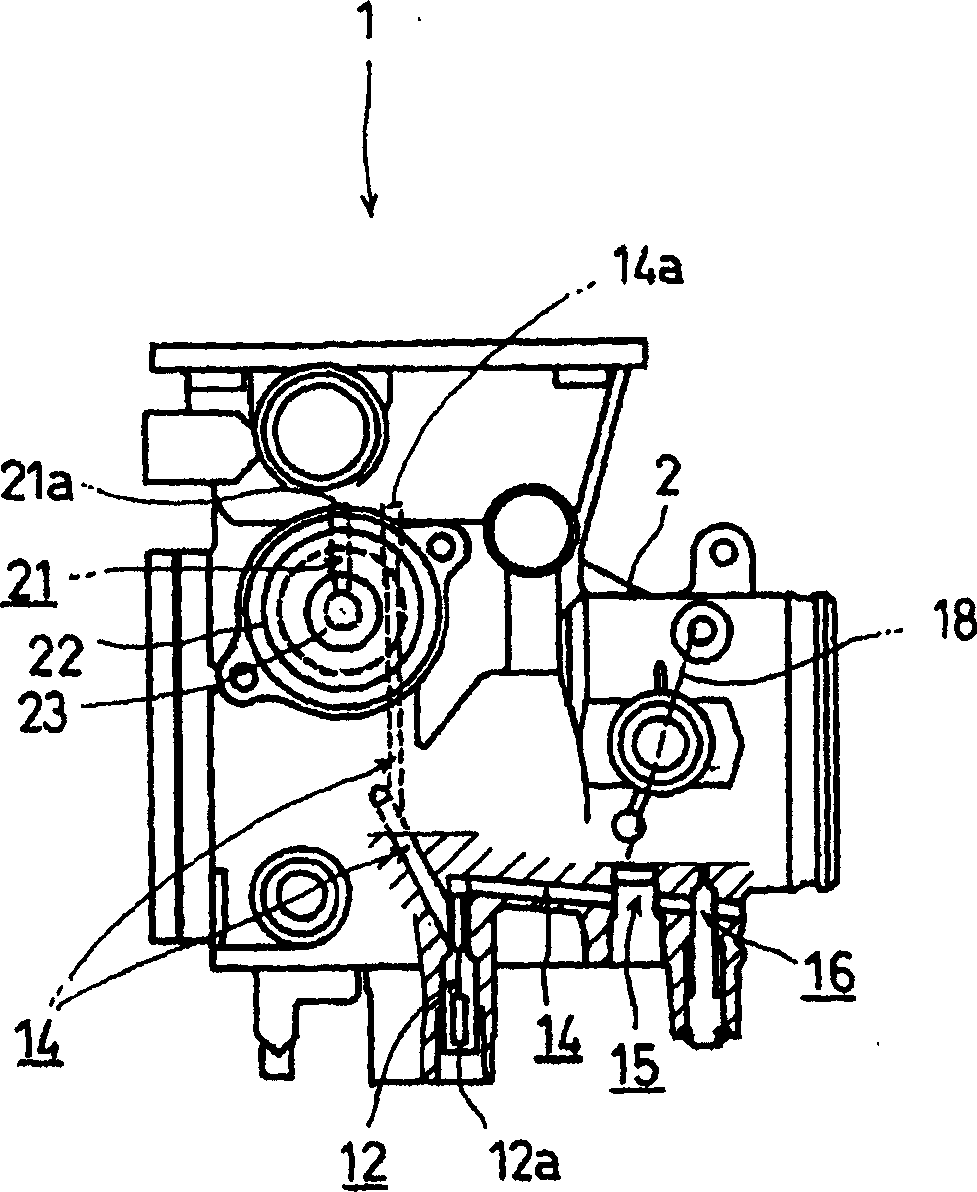

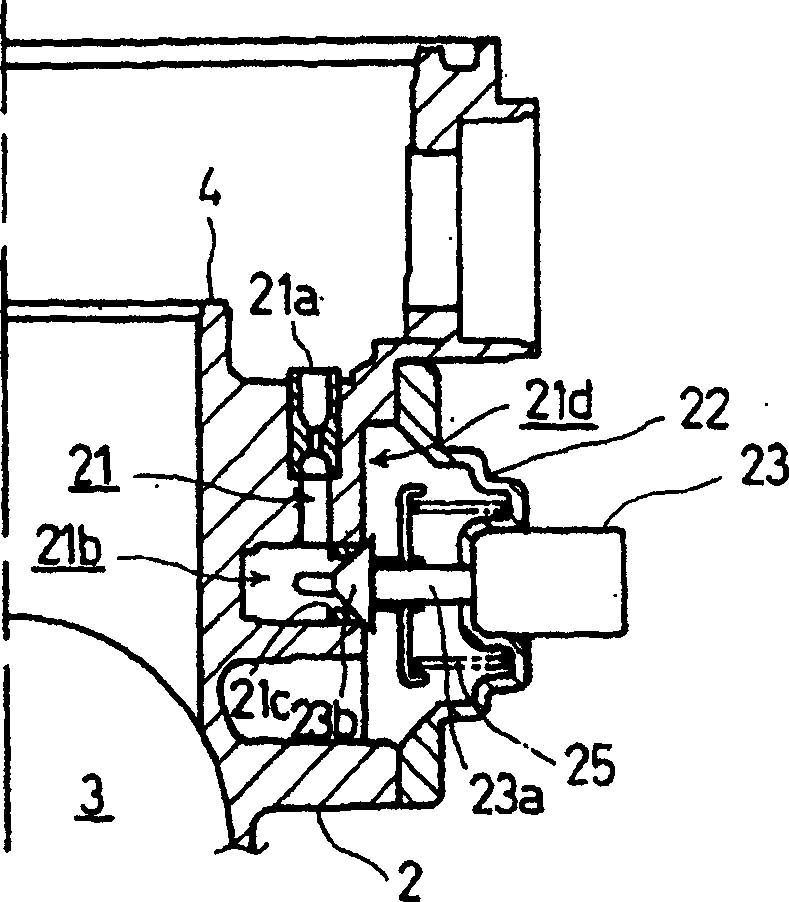

[0038] Below, refer to Figure 1 to Figure 6 An example of the present invention will be described.

[0039] figure 1 A sectional view showing the carburetor of this embodiment, figure 2 Shows a side view in partial section.

[0040] The carburetor body case 2 of the carburetor 1 is mainly composed of a main air passage 3 and a cylindrical portion 4 slidably fitted with a piston valve 5 in a direction perpendicular to the main air passage 3 . A piston negative pressure chamber 7 is provided above the diaphragm 6 supporting the upper part of the piston valve 5 fitted in the cylindrical part 4, and a venturi part 8 is formed between the bottom wall of the piston valve 5 and the main air passage 3 .

[0041] By installing a float tank 9 under the carburetor body shell 2, a float chamber 10 temporarily holding fuel is formed below the Fenchuli 8, and a main nozzle 11 and a low-velocity nozzle 12 are arranged in the float chamber 10. The main injection hole 11a of its lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com