Post-processing method of quantum dot light-emitting diode

A quantum dot light-emitting and diode technology, which is applied in the direction of organic semiconductor devices, semiconductor devices, electrical components, etc., can solve the problems of quantum dot light-emitting diode device efficiency is not obvious, the post-processing method takes a long time, etc., to improve the luminous efficiency of the device, The effect of shortening the production cycle and improving the external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] As another specific implementation method, the quantum dot light emitting diode is placed in an environment provided with a light source, the cathode and anode of the quantum dot light emitting diode are energized, and the method of performing light treatment on the quantum dot light emitting diode The method is: energize the cathode and anode of the quantum dot light emitting diode, and perform light treatment on the quantum dot light emitting diode in a closed cavity, and the material of the inner wall of the closed cavity is a material with light reflection performance. Through the reflection of the reflective material on the inner wall surface of the airtight cavity, the light emitted by the light source can be irradiated on the surface of the quantum dot light emitting diode as much as possible, so as to improve the irradiation rate of the quantum dot light emitting diode, thereby improving the appearance of the quantum dot light emitting diode. Quantum efficiency, ...

Embodiment 1

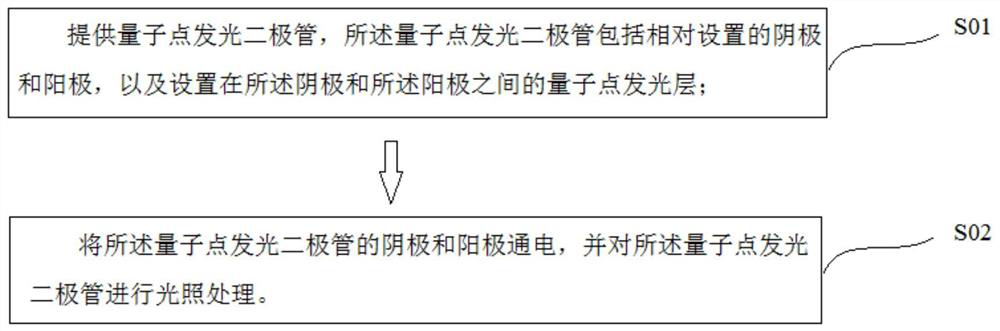

[0034] A post-processing method for quantum dot light-emitting diodes, comprising the following steps:

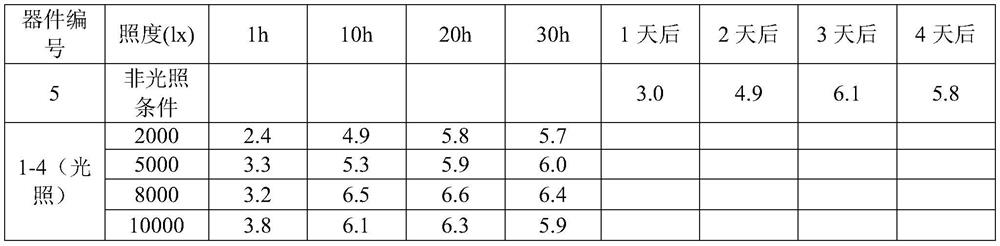

[0035] Provide 5 quantum dot light-emitting diodes (respectively numbered 1, 2, 3, 4, 5) with the same structure and specifications. A functional stacked structure between the anode and the cathode, the functional stacked structure includes a hole injection layer (PEDOT:PSS) and a hole transport layer (TFB) stacked in sequence from the anode to the cathode , a quantum dot light-emitting layer (CdSe / ZnS QDs), an electron transport layer (ZnO), and an electron injection layer (LiF), wherein the anode is arranged on a glass substrate.

[0036] The five quantum dot light emitting diodes are connected to an external power supply, and the cathodes and anodes of the quantum dot light emitting diodes are energized. The quantum dot light-emitting diodes numbered 1-4 are subjected to light treatment, and the light source used in the light treatment is selected from blue light with a...

Embodiment 2

[0042] A post-processing method for quantum dot light-emitting diodes, comprising the following steps:

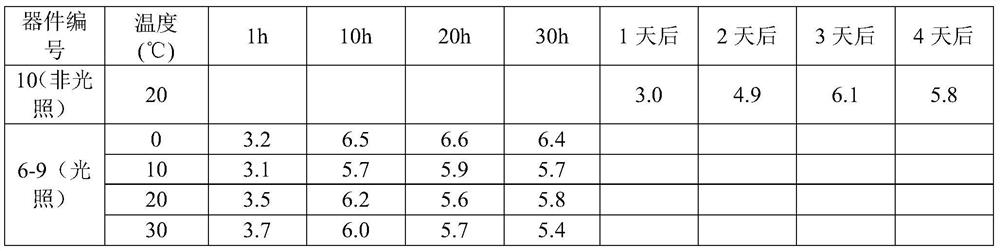

[0043] Provide 5 quantum dot light-emitting diodes (respectively numbered 6, 7, 8, 9, 10) with the same structure and specifications. A functional stacked structure between the anode and the cathode, the functional stacked structure includes a hole injection layer (PEDOT:PSS) and a hole transport layer (TFB) stacked in sequence from the anode to the cathode , a quantum dot light-emitting layer (CdSe / ZnS QDs), an electron transport layer (ZnO), and an electron injection layer (LiF), wherein the anode is arranged on a glass substrate.

[0044] The cathode and anode of the quantum dot light-emitting diode are energized. Perform light treatment on the quantum dot light-emitting diodes numbered 6-9, and the light source used in the light treatment is selected from blue light with an emission wavelength of 400nm, and the illuminance of the light source used in the light treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| illuminance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com