Method for aging smoking material by using oak barrel, and smoking article manufactured using same

A technology of smoking products and oak barrels, which is applied in the field of smoking products, can solve problems such as type restrictions, and achieve the effects of reducing irritation, increasing aging efficiency, and rich flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

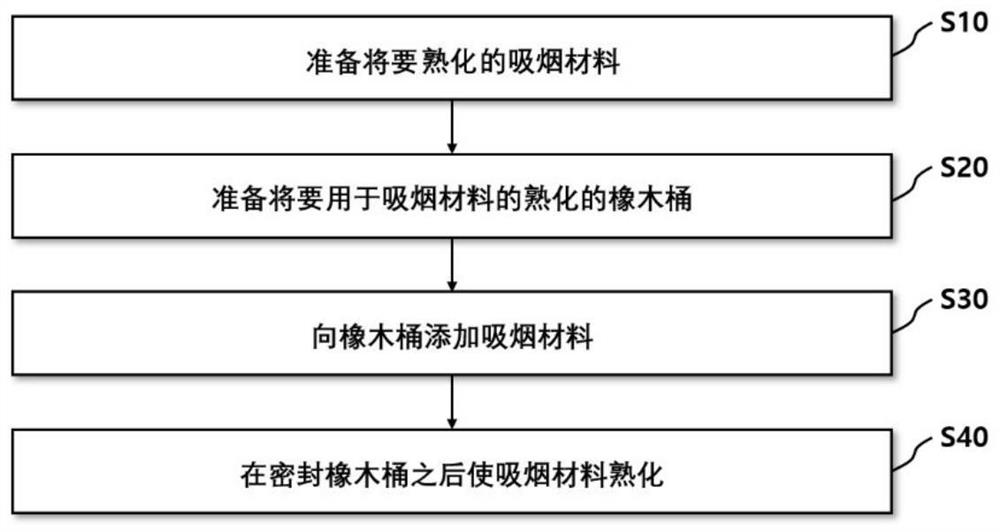

Method used

Image

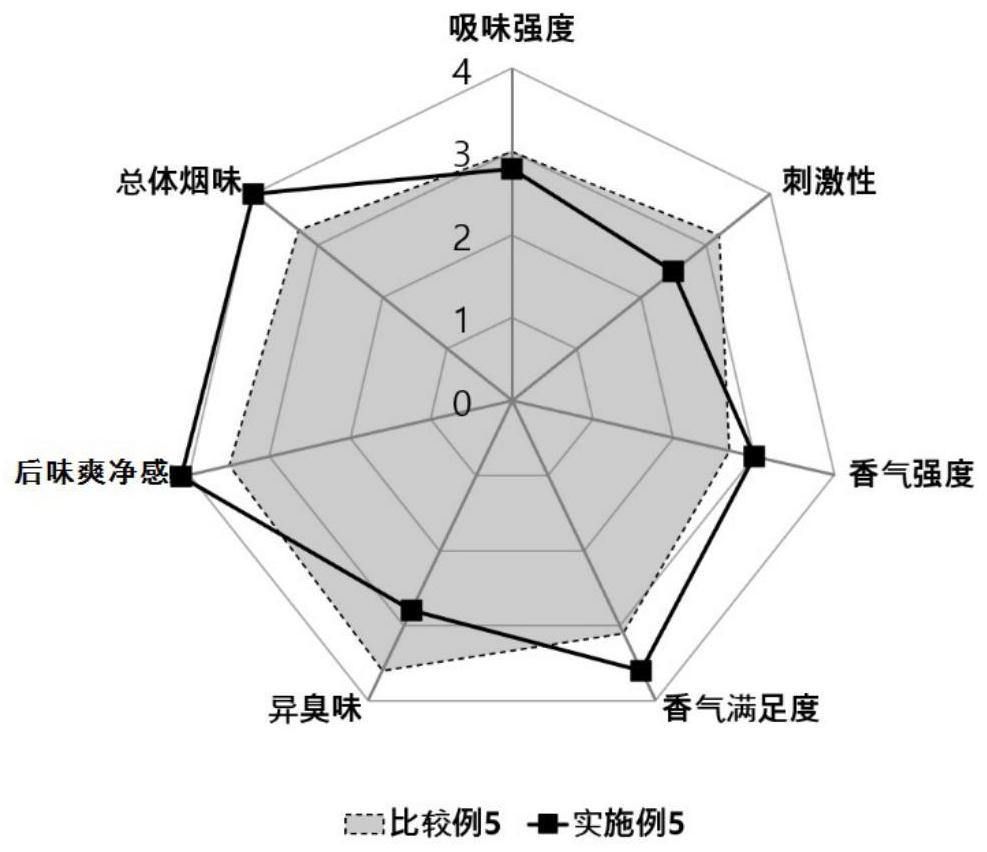

Examples

Embodiment 1

[0071] After deveining the same yellow seed leaves as in Comparative Example 1, it was added to In a new (new) oak barrel, the outside of the oak barrel was sealed with packaging materials, and then stored at a temperature of 72° C. and 20% tobacco leaf moisture for about 2 weeks to prepare cured leaves.

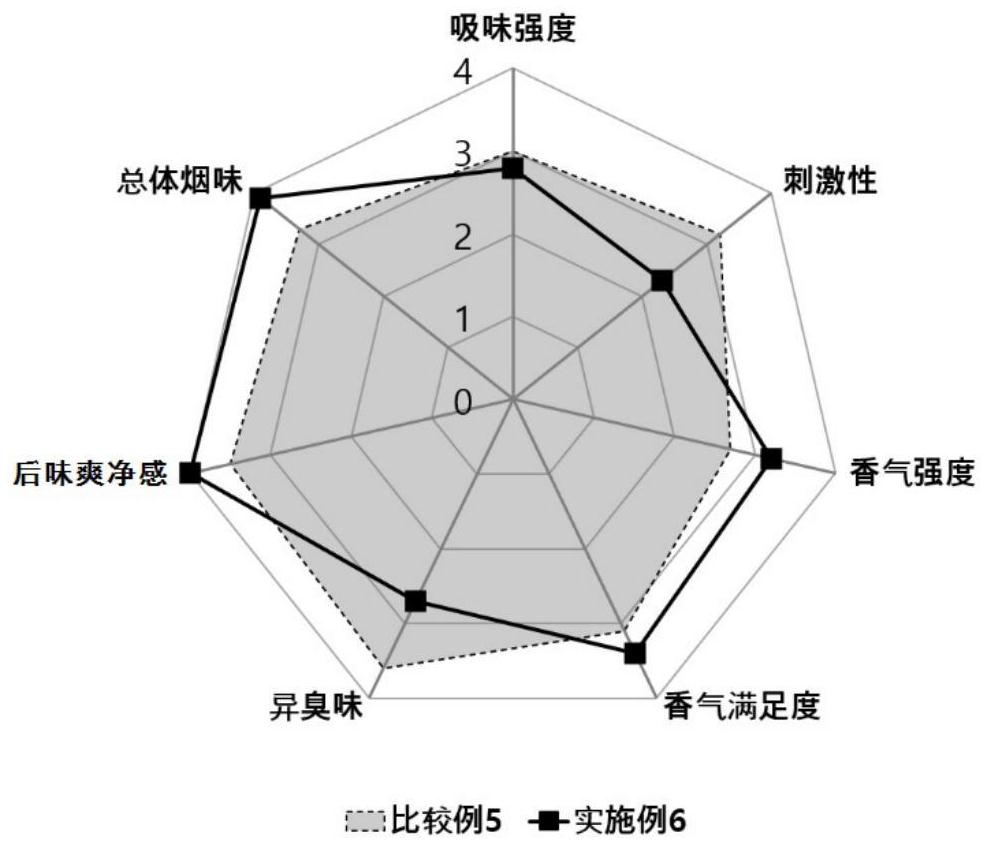

Embodiment 2

[0073] After deveining the same yellow seed leaves as in Comparative Example 1, they were added to wine oak barrels of 225 l for aging wine for about 1 week, and the outside of the barrels were sealed with packing materials, and then heated at a temperature of 72°C and 20% Tobacco leaves were stored under moisture conditions for about 2 weeks to prepare cured leaves.

Embodiment 3

[0075] After deveining the same flue-cured tobacco leaves as in Comparative Example 1, add them to a 225l brandy oak barrel that aged brandy for about 1 week, seal the outside of the oak barrel with packing material, and then place it at a temperature of 72°C with 20% tobacco leaves Store under moisture for about 2 weeks to prepare mature leaves.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com