Banana ripening acceleration device

A banana ripening technology, applied in food preservation, fruit and vegetable preservation, food processing, etc., can solve the problems of uneven fruit ripening, affecting fruit quality, affecting banana sales, etc., to improve the effect, increase the flow range, The effect of velocity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

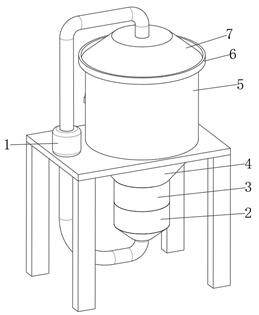

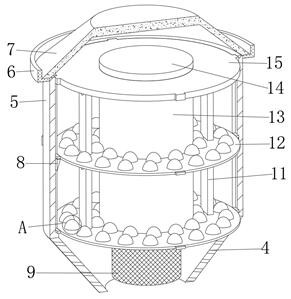

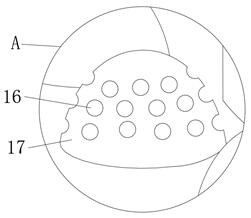

[0031]Refer toFigure 1-6, A banana ripening device, including a workbench, the top outer wall of the workbench is fixed with a ripening cylinder 5 by screws, and the circumferential inner wall of the ripening cylinder 5 is provided with two placement plates 12 of the same size, and the top of the placement plate 12 The outer wall is provided with uniformly distributed protrusions 17, and the outer wall of the protrusions 17 is provided with uniformly distributed air outlet holes 16, the circumferential inner wall of the placement plate 12 is fixed with an outer tube 13 by screws, and the inner wall of the outer tube 13 is fixedly installed with an inner tube 9 , The circumferential inner wall of the outer cylinder 13 is fixed with equidistantly distributed air guide plates 24 by screws, and the outer circumferential outer wall of the outer cylinder 13 is provided with equidistantly distributed rectangular holes 23, and the bottom end of the ripening cylinder 5 is fixedly installed w...

Embodiment 2

[0042]ReferenceFigure 6 A banana ripening device. Compared with the first embodiment, this embodiment further includes a mounting frame 22 fixed on the inner wall of the second reducing pipe 10 by screws, and a heating wire 21 is fixedly installed on the circumferential inner wall of the mounting frame 22.

[0043]Working principle: When the banana is ripening, the heating wire 21 is energized, the heating wire 21 heats up, and the air enters from the bottom of the second reducer 10 and is heated by the heating wire 21 to increase the temperature of the air and accelerate the ripening of the banana.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com