Corrugated plate welding track data smoothing method and system

A trajectory data and smoothing technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to obtain geometric shape information of corrugated plates, small trajectory length, automatic welding of container corrugated plate welding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

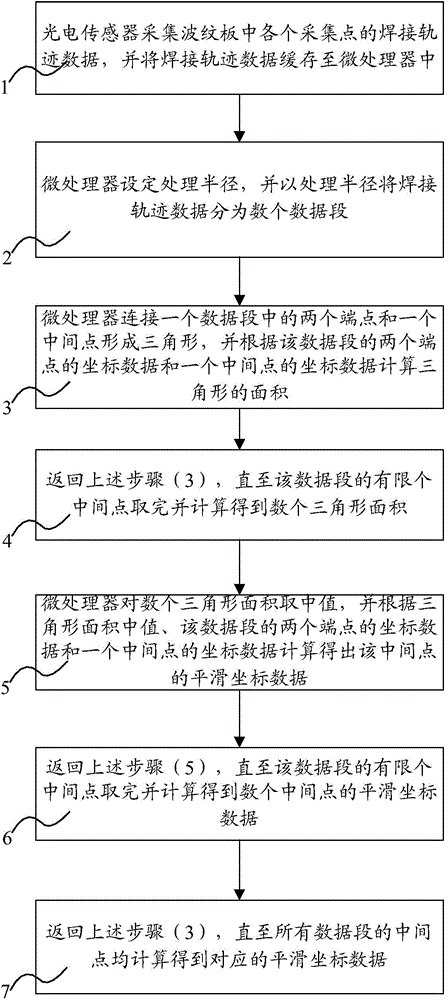

[0059] see figure 1 , in one embodiment, the method for realizing smooth processing of corrugated plate welding trajectory data includes the following steps:

[0060] (1) The photoelectric sensor collects the welding trajectory data of each collection point in the corrugated plate, and caches the welding trajectory data in the microprocessor;

[0061] (2) The microprocessor sets the processing radius, and divides the welding track data into several data segments with the processing radius;

[0062] (3) described microprocessor connects two endpoints in a data segment and an intermediate point to form a triangle, and calculates the area of the triangle according to the coordinate data of the two endpoints of the data segment and the coordinate data of an intermediate point;

[0063] (4) Return to the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com