Drafting frame and operating process

A technology of harnessing and harnessing, which is applied to the field of harnessing and operation technology, can solve the problems of warp thread confusion, easy to fall off, easy to be pulled off, etc., so as to improve the on-site environment, improve the efficiency of harnessing, and is not easy to touch inverted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

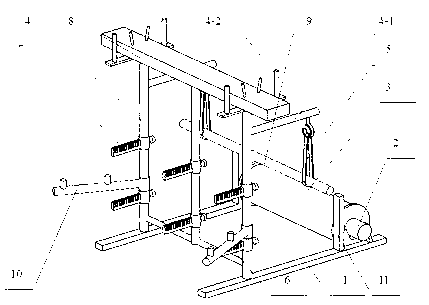

[0031] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0032] The present invention designs a heald threading frame and its operating process, and improves the overall structure and operating process of the threading frame, thereby saving space in the threading heald area, reducing operating procedures, and improving operating efficiency.

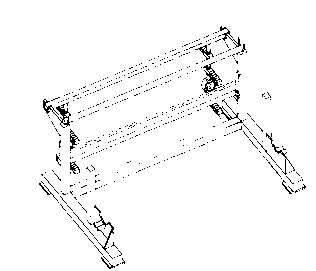

[0033] As a specific embodiment of the invention, the present invention provides a structural schematic diagram such as figure 2 Shown is a heddle frame, which includes two underframes 1, a weaving shaft support 2, a heald frame support 4, a drawstring 5, a heald bracket, a reed pallet 8, and a warp yarn support rod 9. Reed support plate movable bracket 10 and weaving shaft limiter 11, each of the heald frame chassis 1 rear end has a weaving axis limiter 11, and the weaving axis limiter 11 has a weaving axis support 2, Warp yarn 3 is housed in the weaving shaft support 2, and the heald...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com