Patents

Literature

40results about How to "Improve the quality of electroplating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

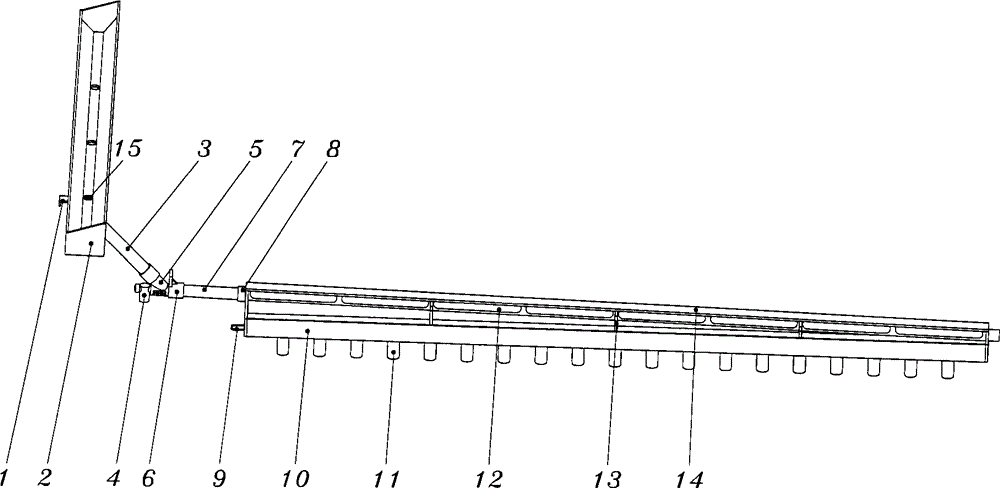

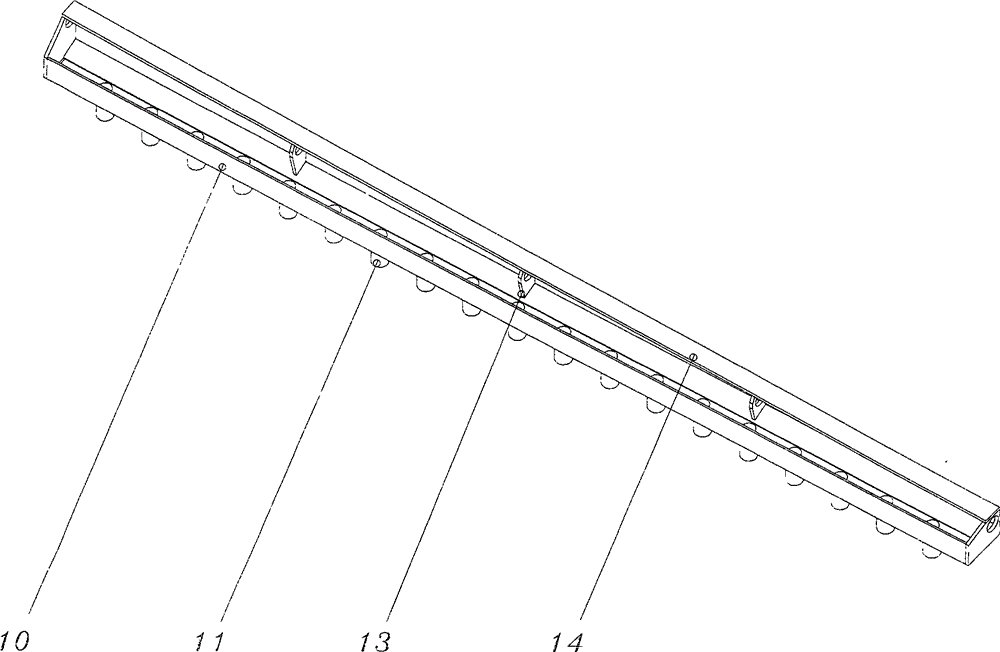

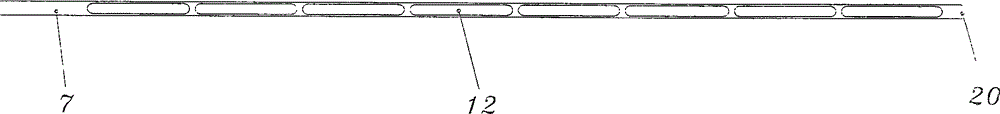

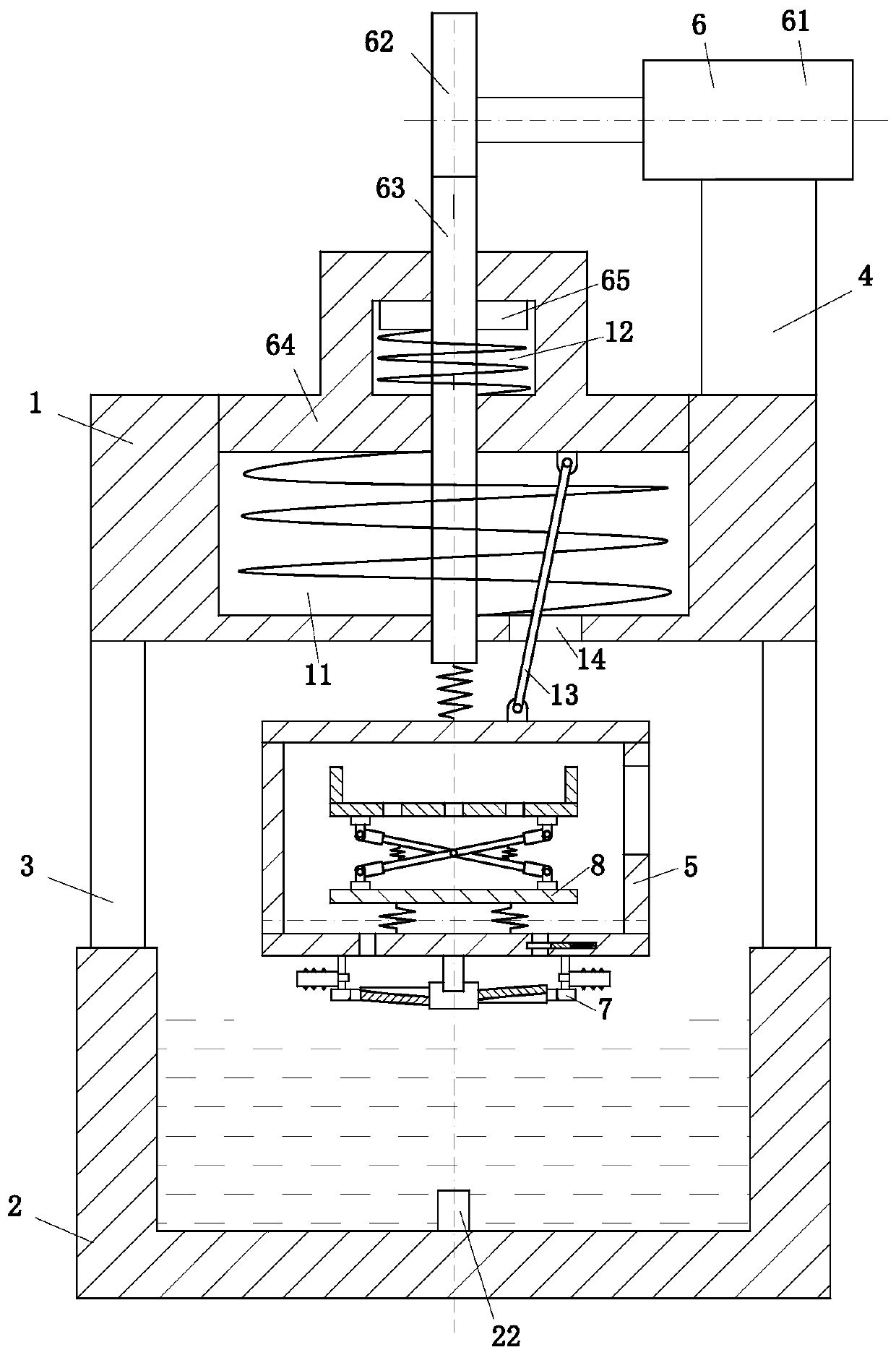

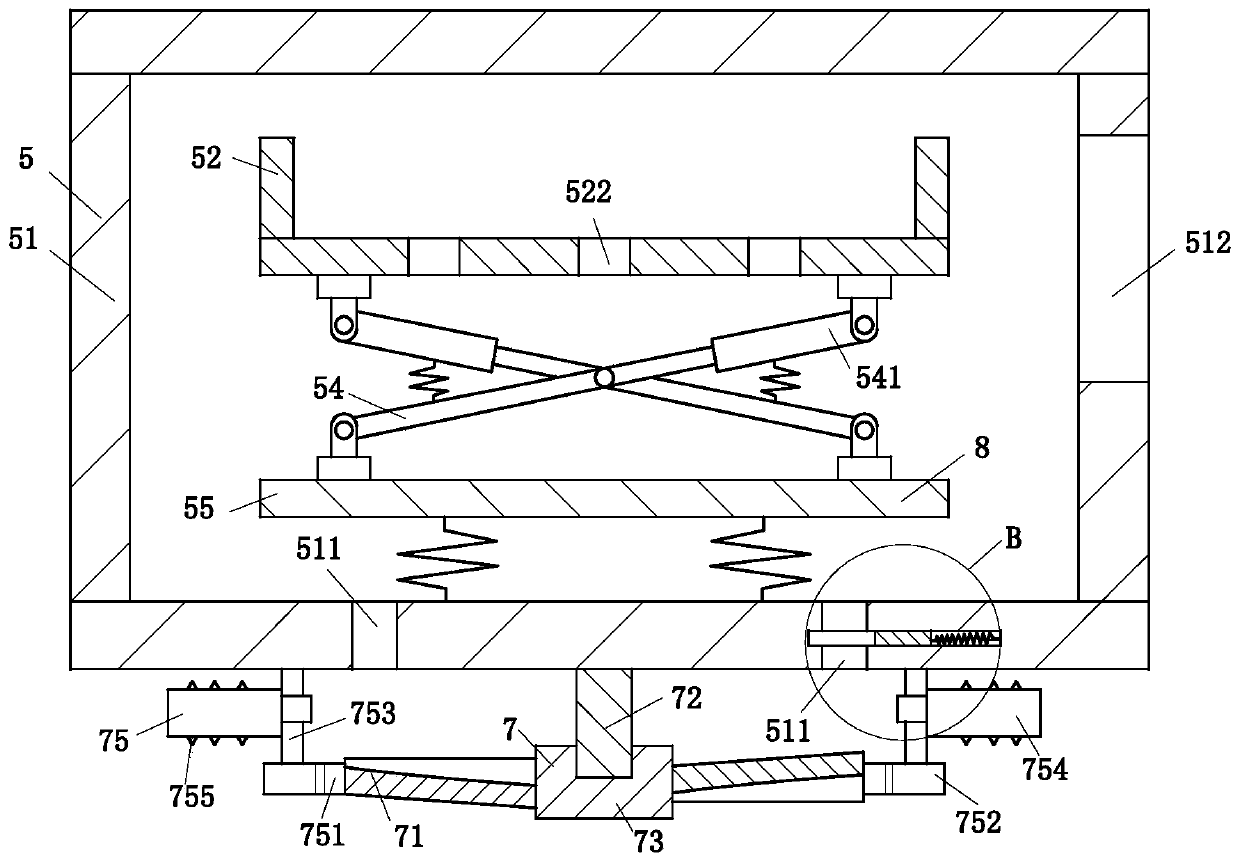

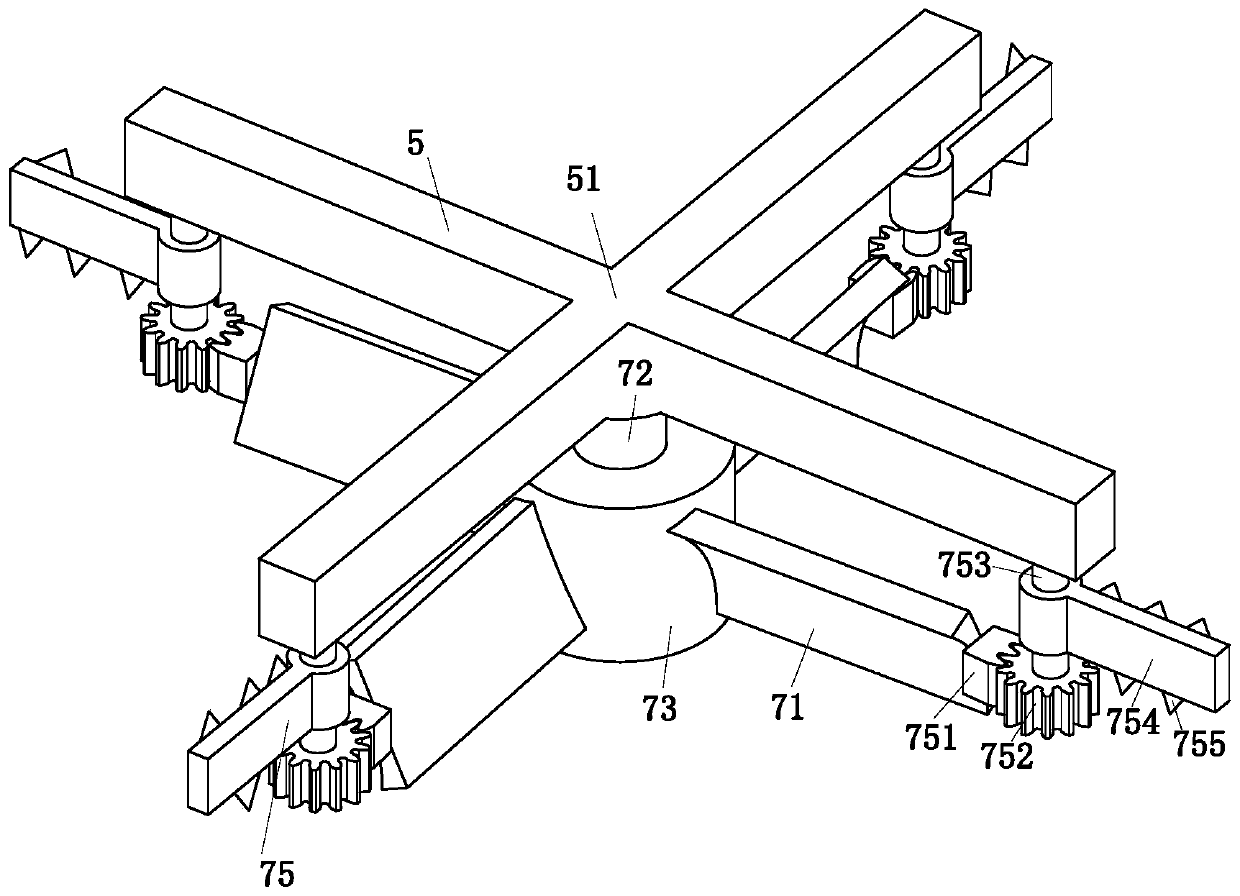

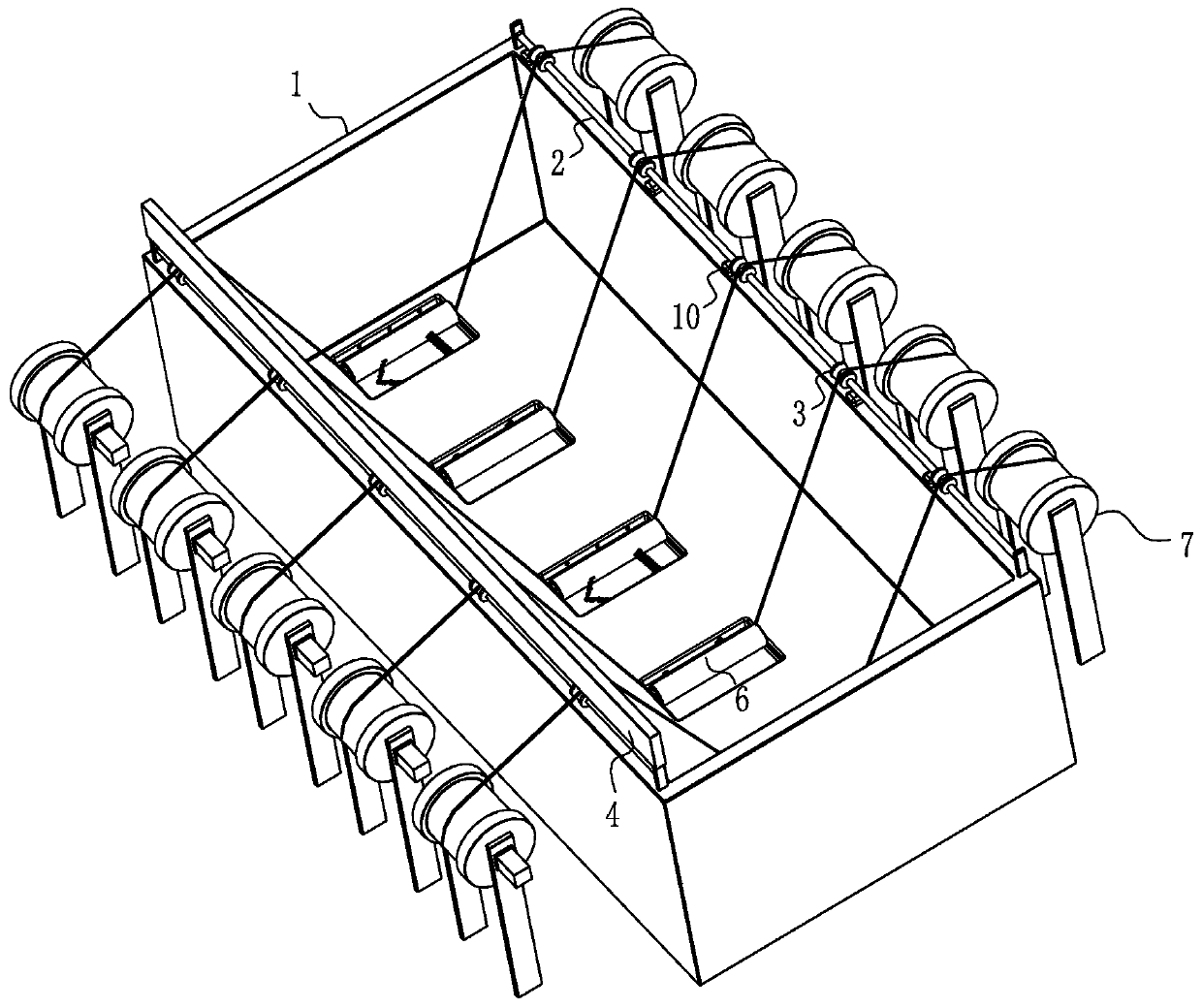

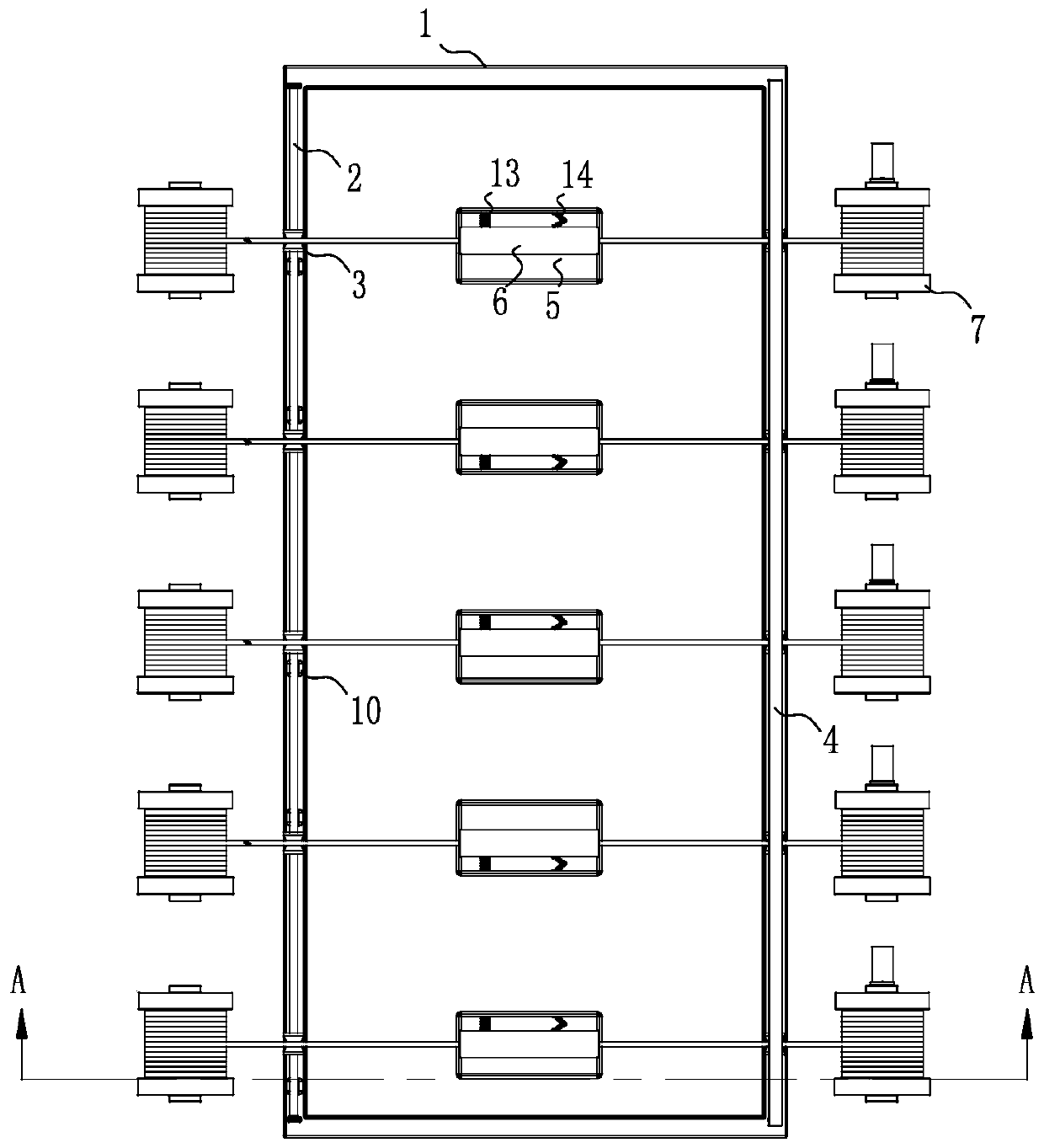

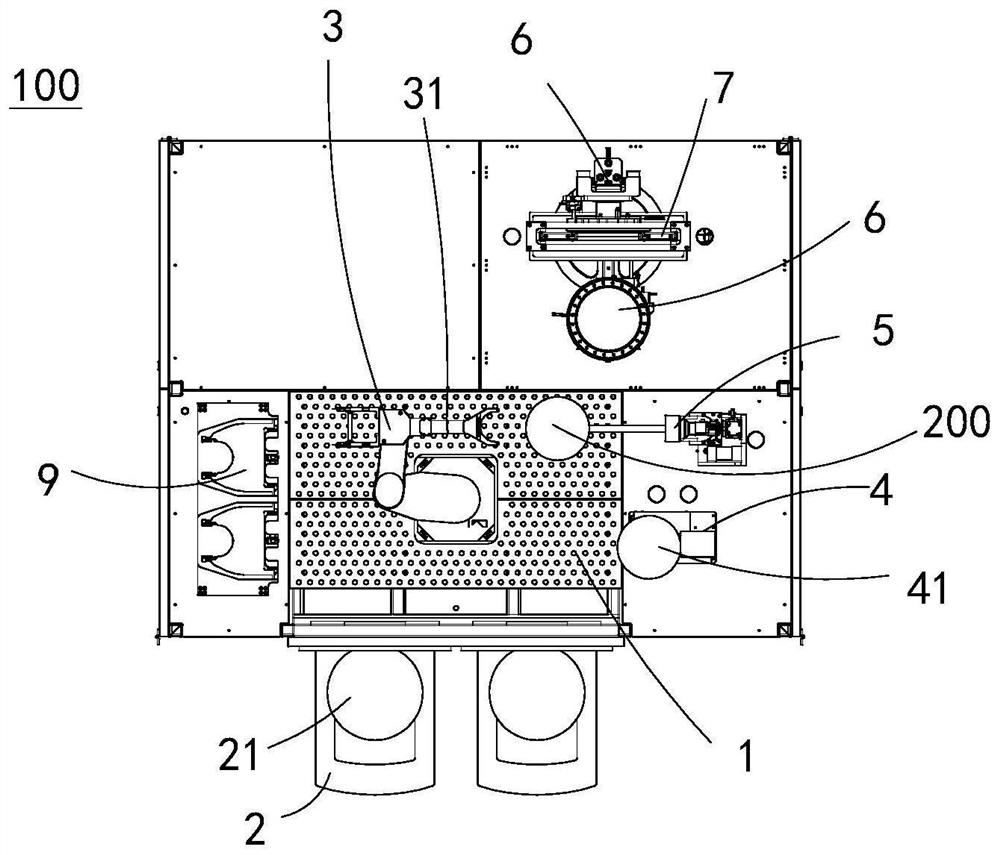

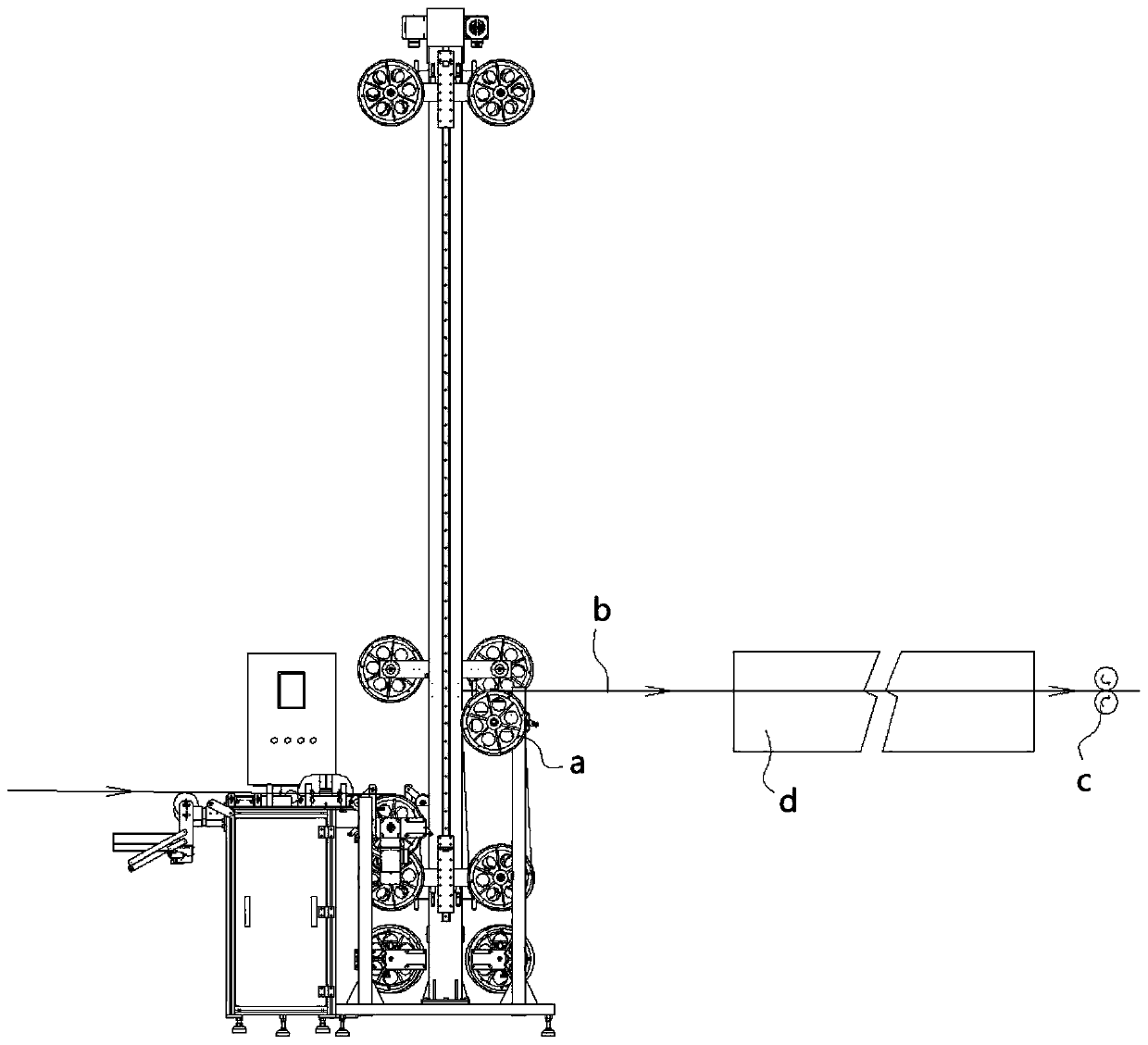

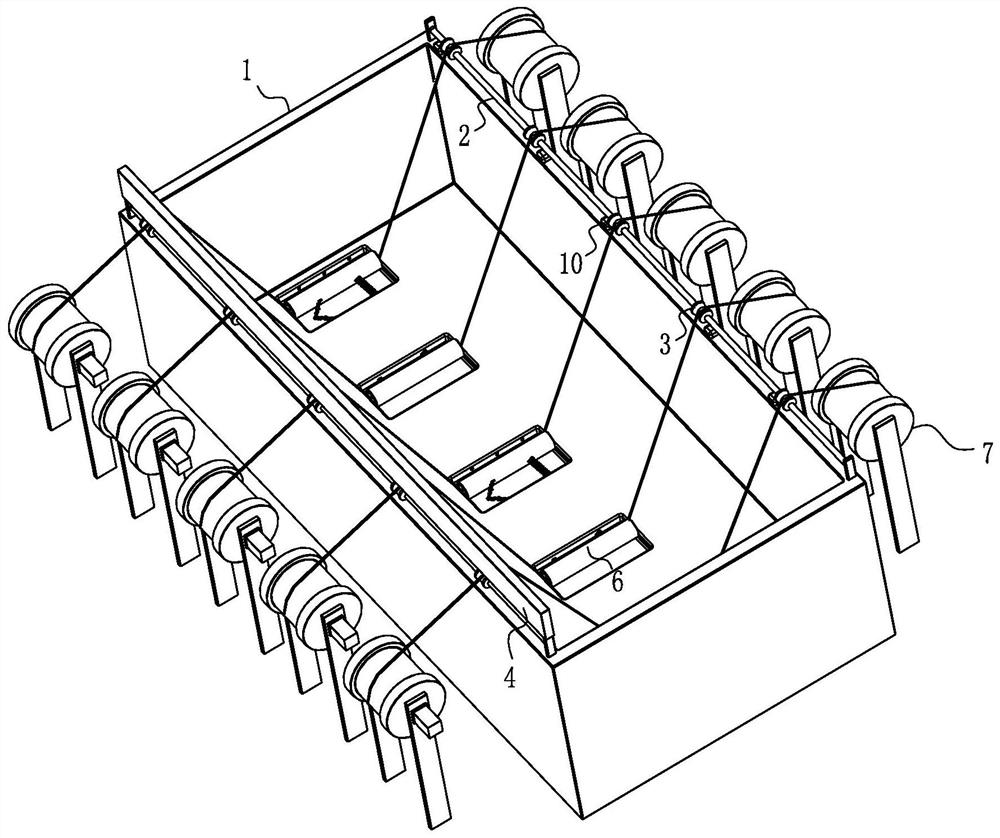

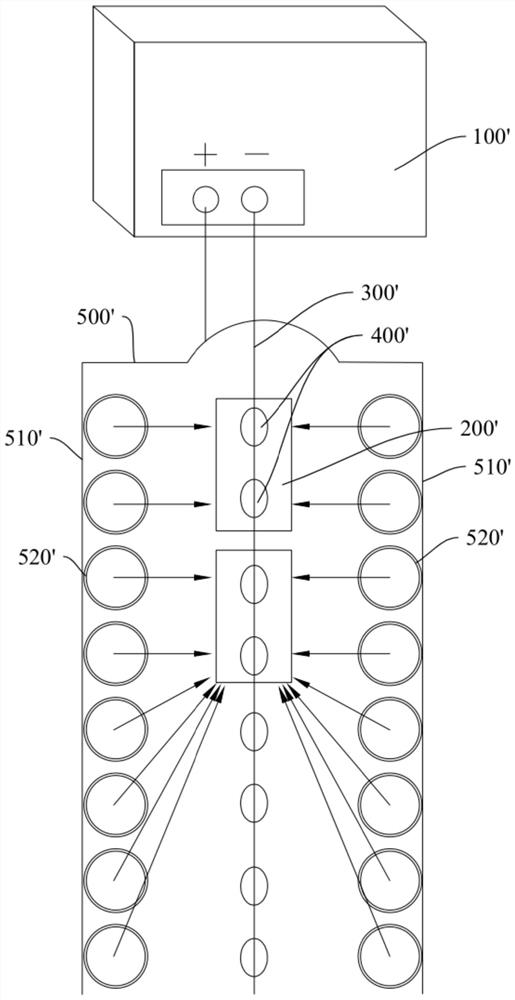

Automatic electroplating equipment for zipper head

ActiveCN103469270AImprove the quality of electroplatingImprove plating qualityCellsSlide fastenersControl systemEngineering

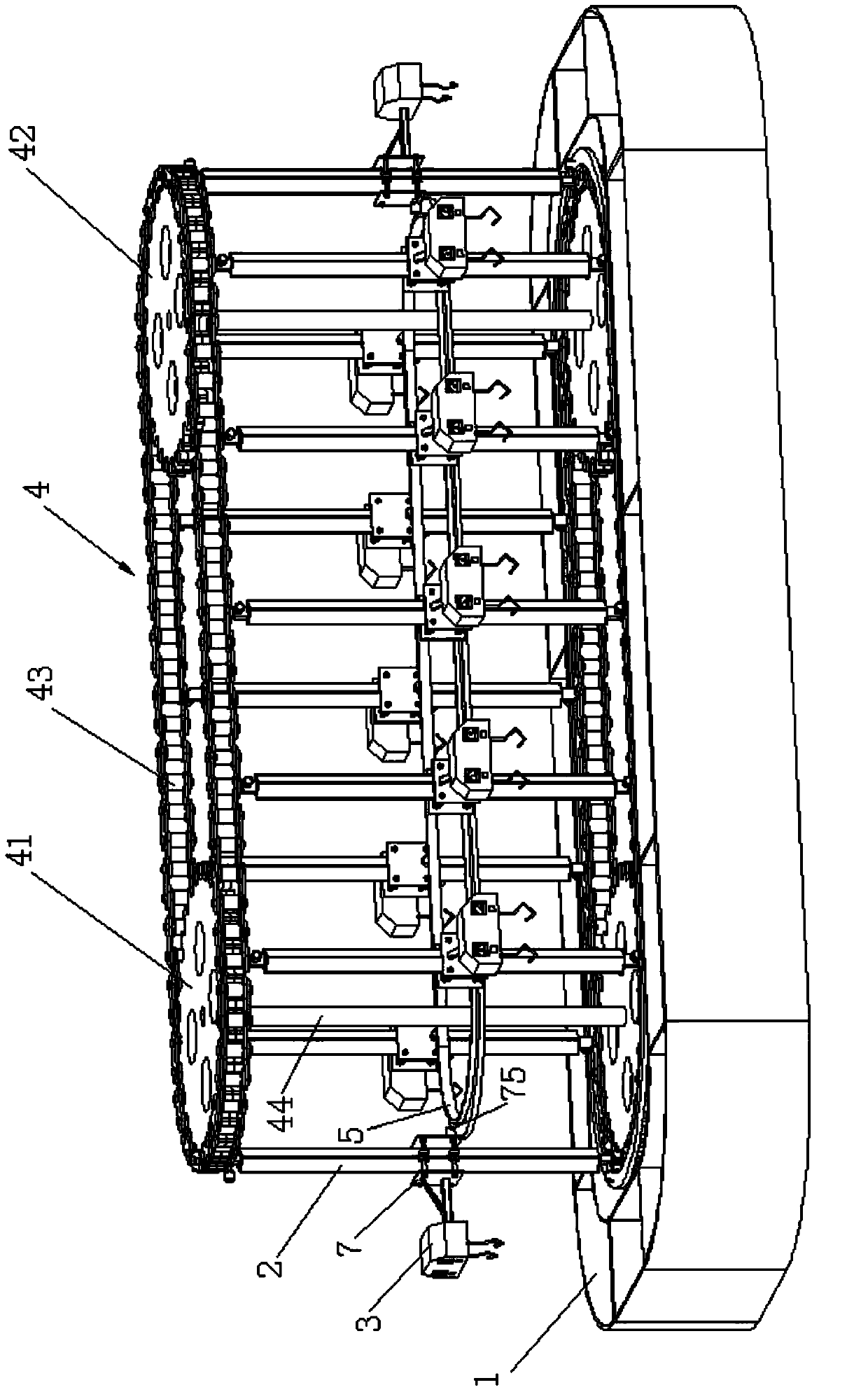

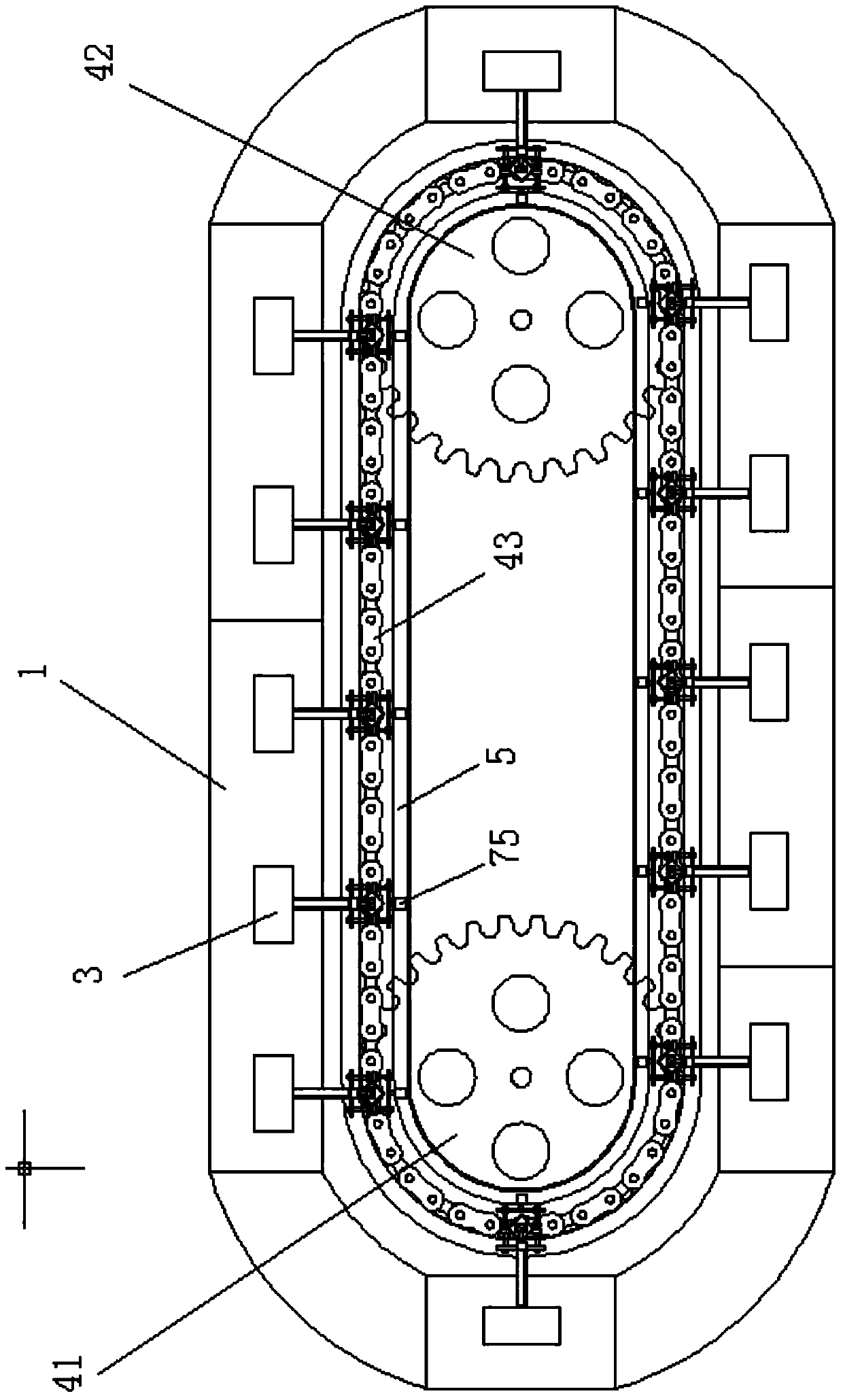

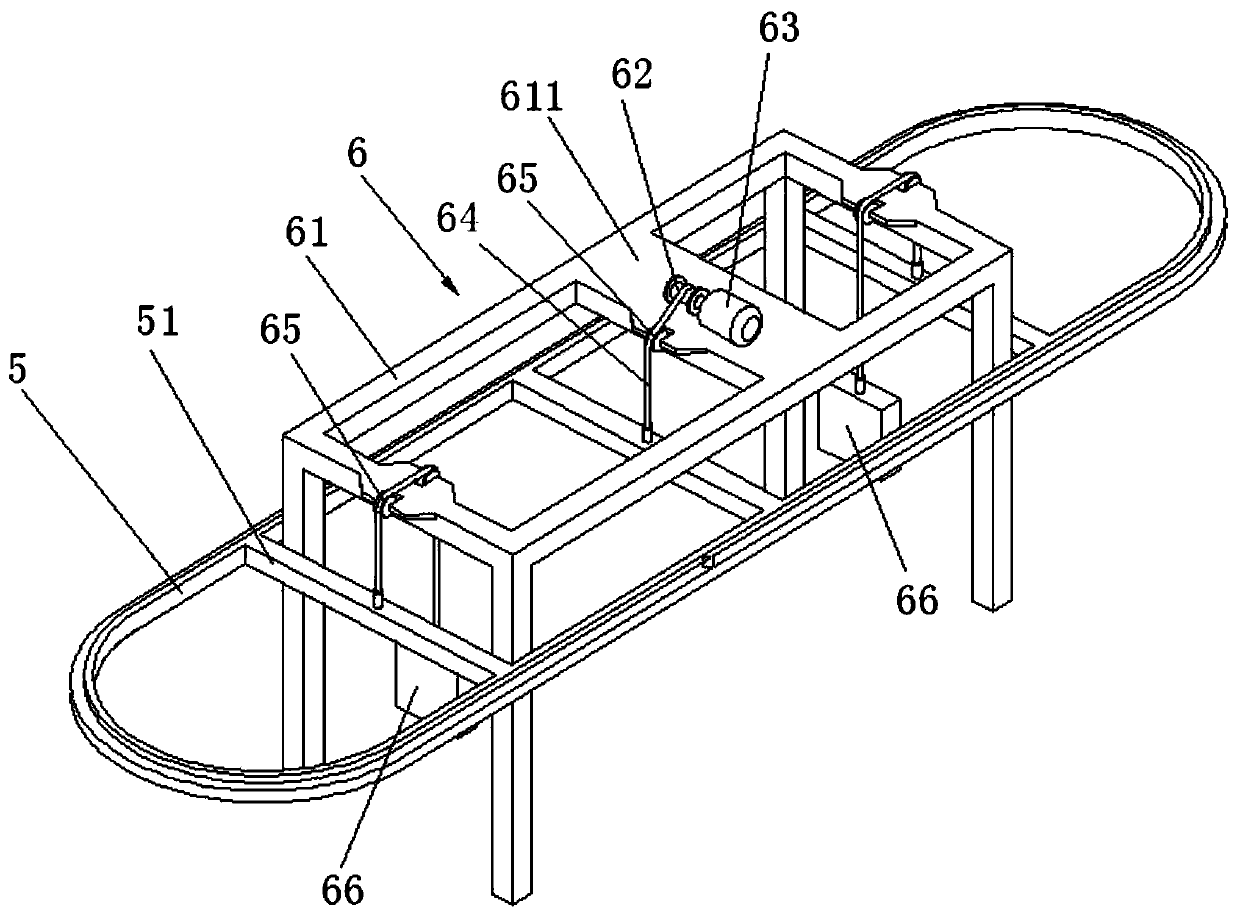

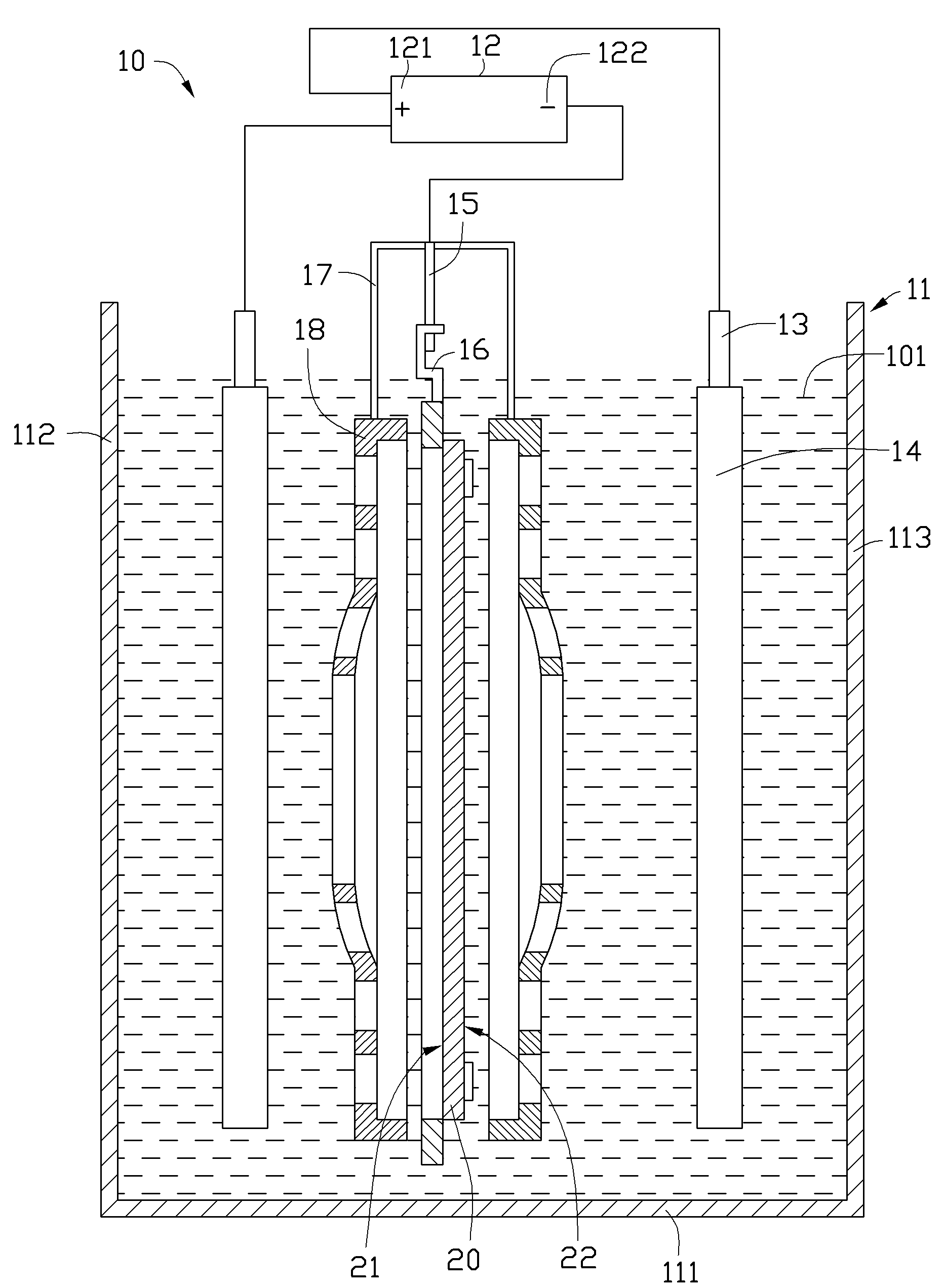

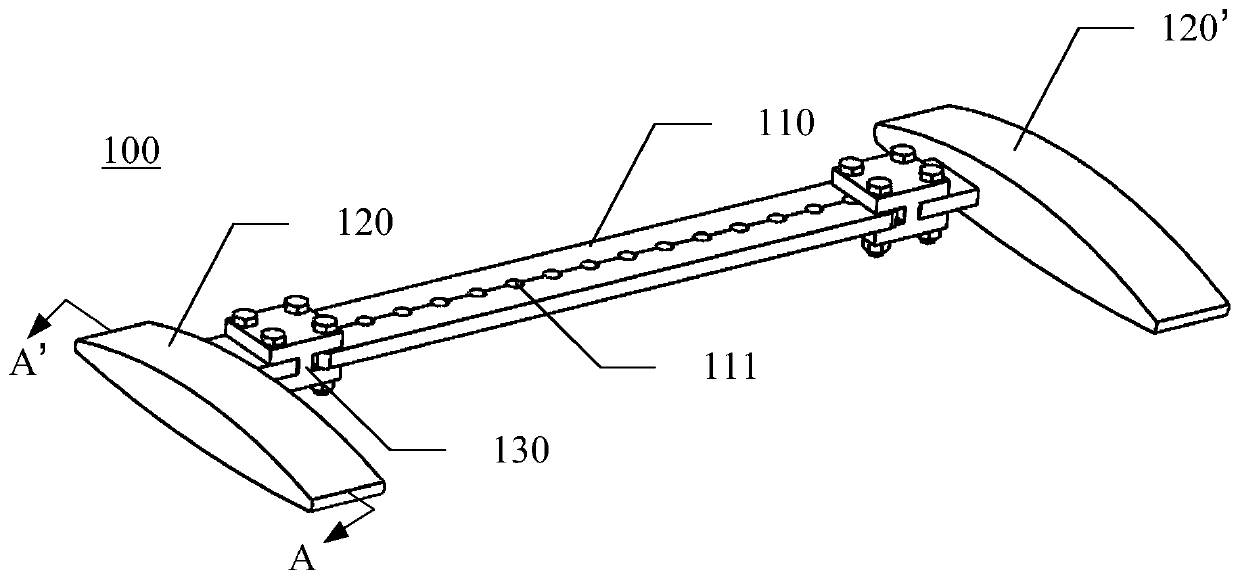

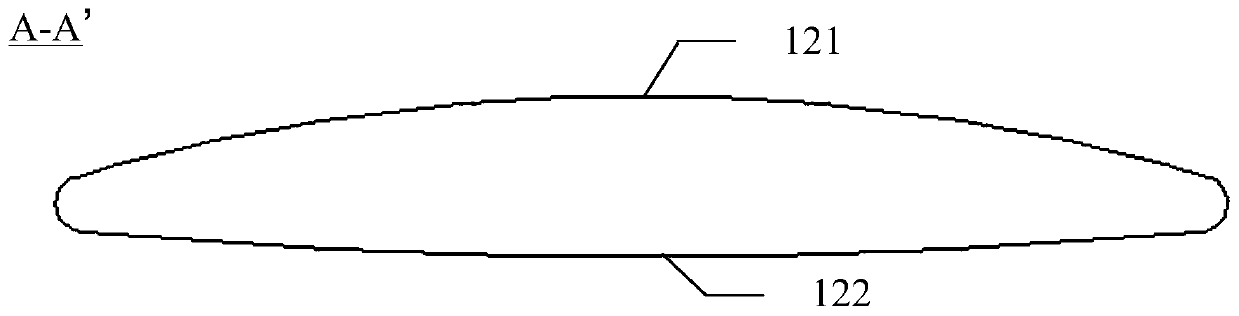

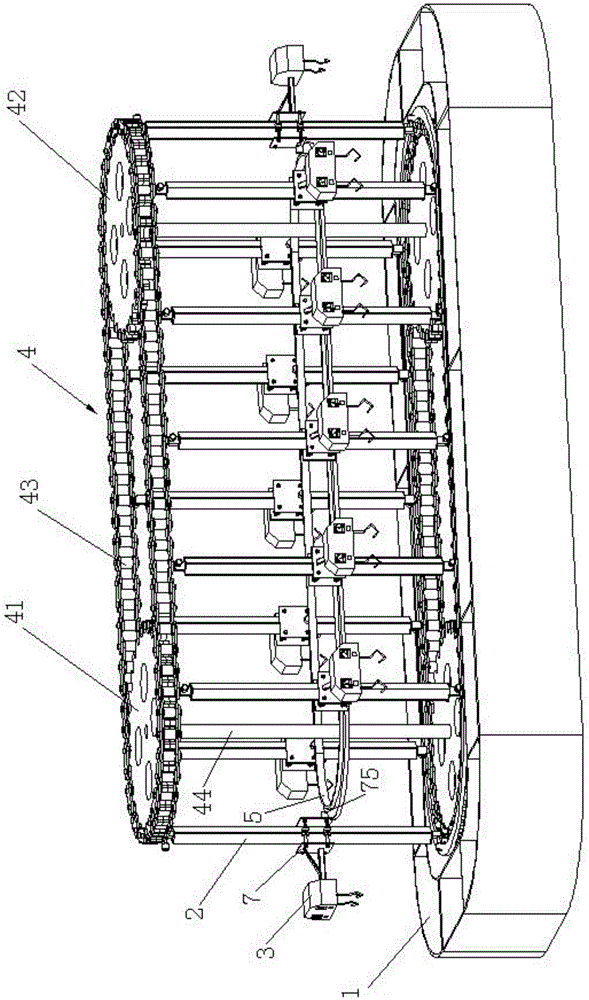

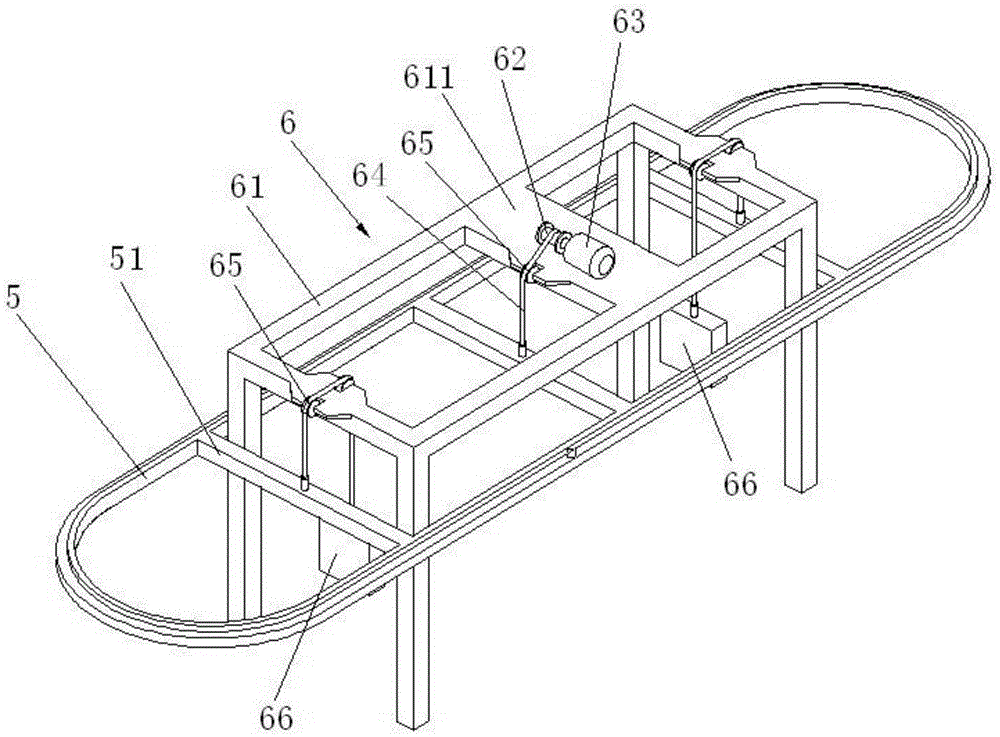

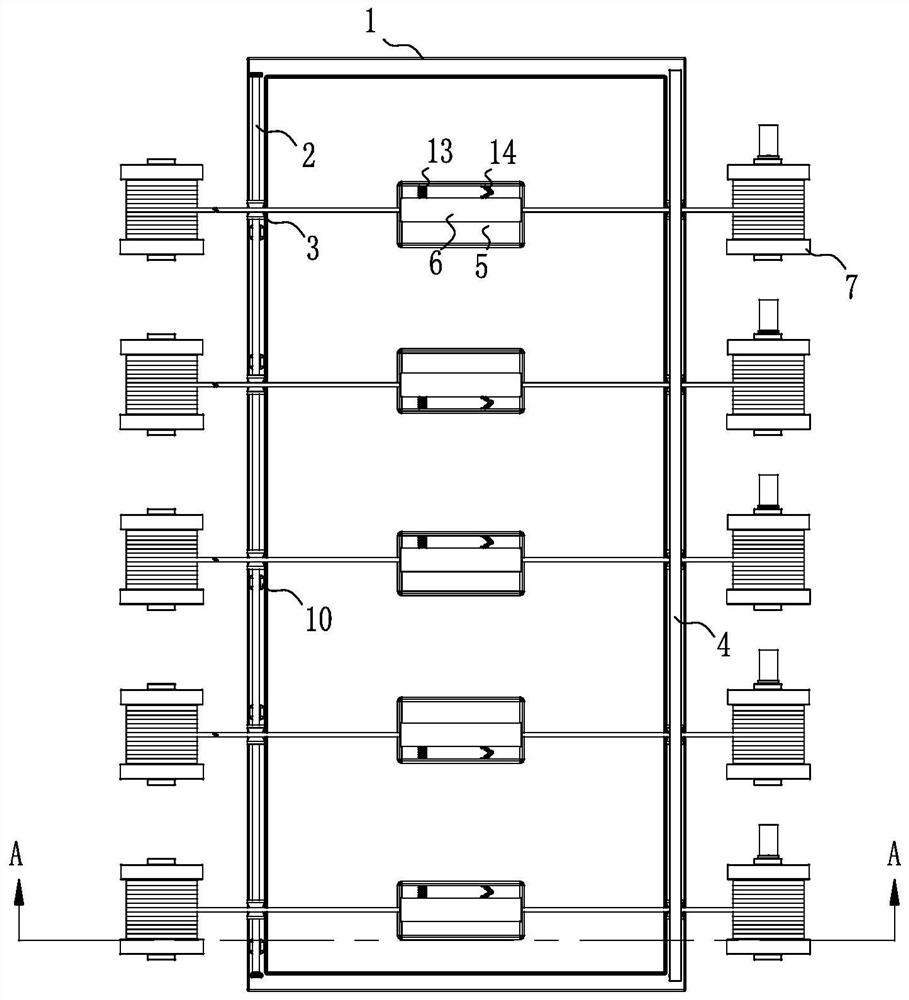

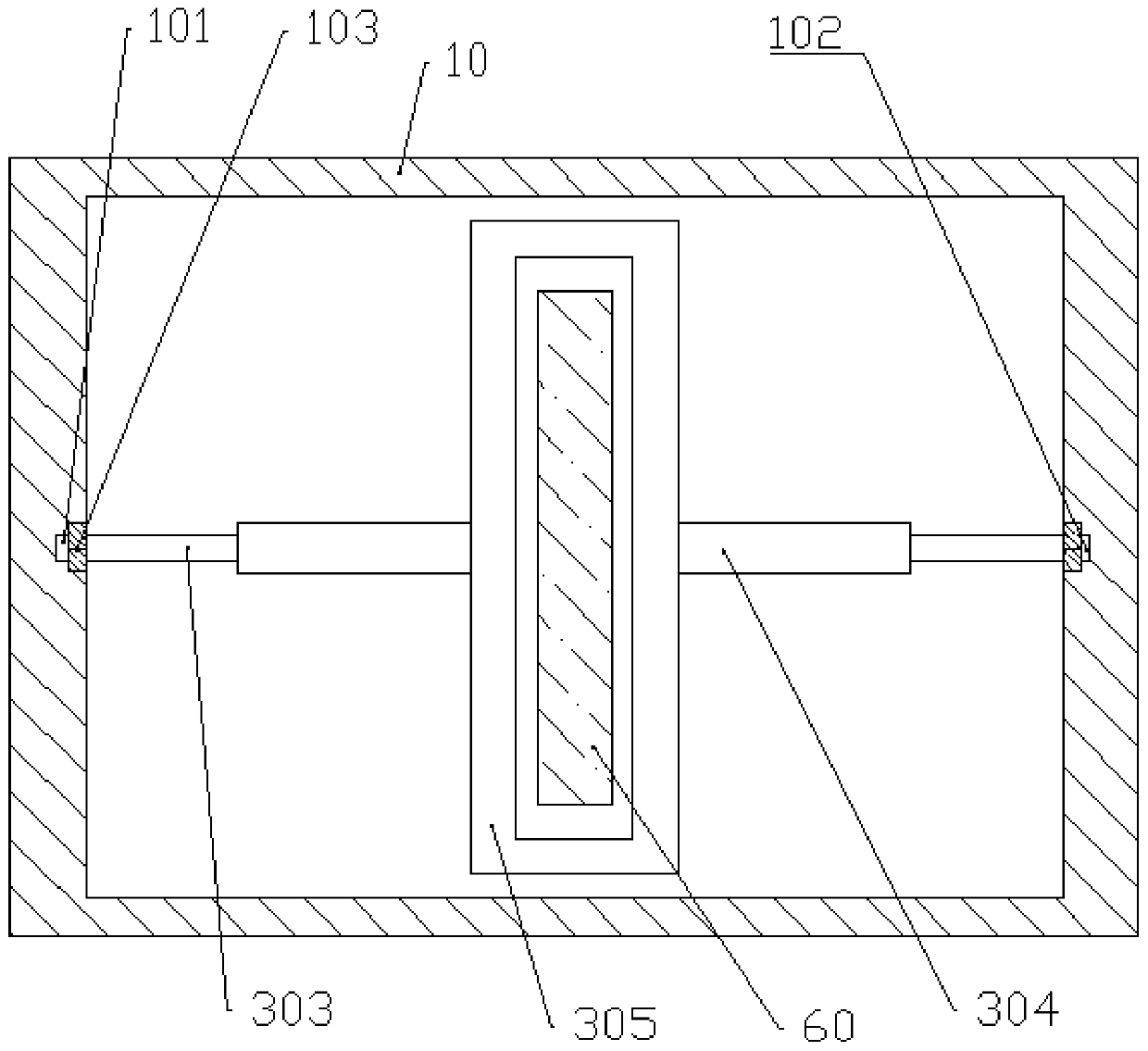

The invention provides automatic electroplating equipment of a zipper head. The equipment consists of electroplating grooves which are formed by a pre-electroplating treatment groove, an electroplating treatment groove and a post-electroplating treatment groove and are connected head-to-tail to form a closed ring, wherein an anode generator is installed on a vertical guide rail which is connected with a chain of a traveling device, the anode generator is further provided with an idler wheel which is placed on a horizontal circular track, and the circular track driven by a lifting device can ascend and descend. Under the effects of a control system, the traveling device and the lifting device, the anode generator intermittently travels on the circular track and circulates according to a sequence of ascending, traveling, descending and stopping. According to the invention, the zipper head is continuously electroplated through the automatic equipment, so that the electroplating production efficiency is greatly improved. Times of the steps are controlled through intelligent programs, so that the electroplating quality is high and the electroplating quality of the zipper head is enhanced. Meanwhile, the labor intensity of the workers is further reduced, and the field environment is improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

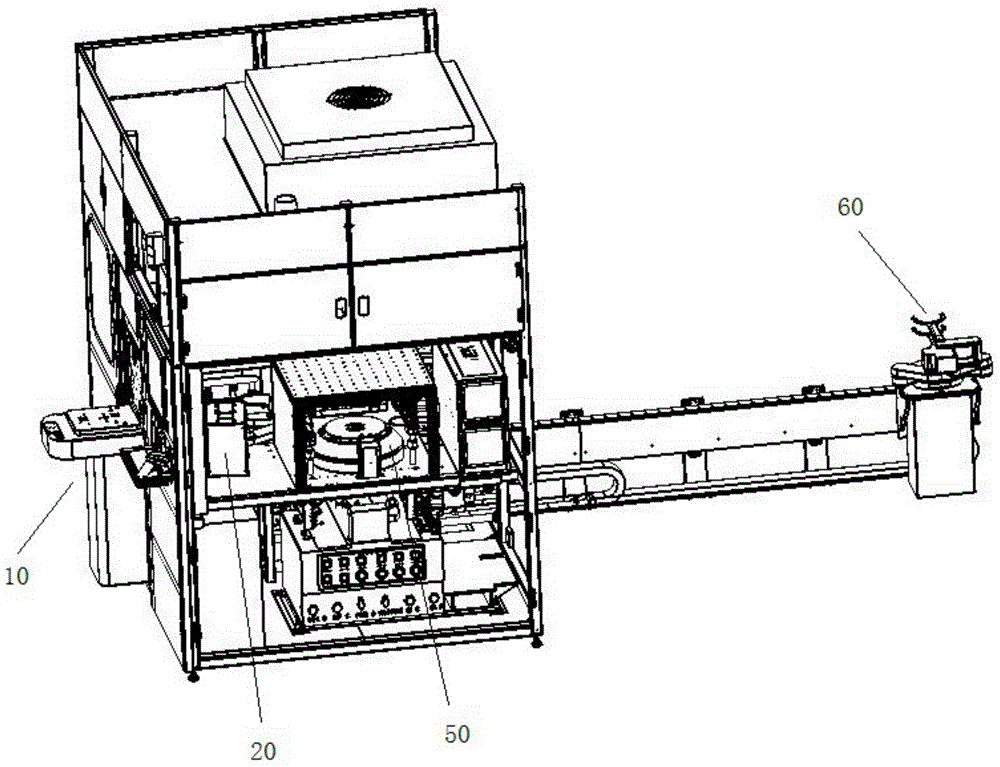

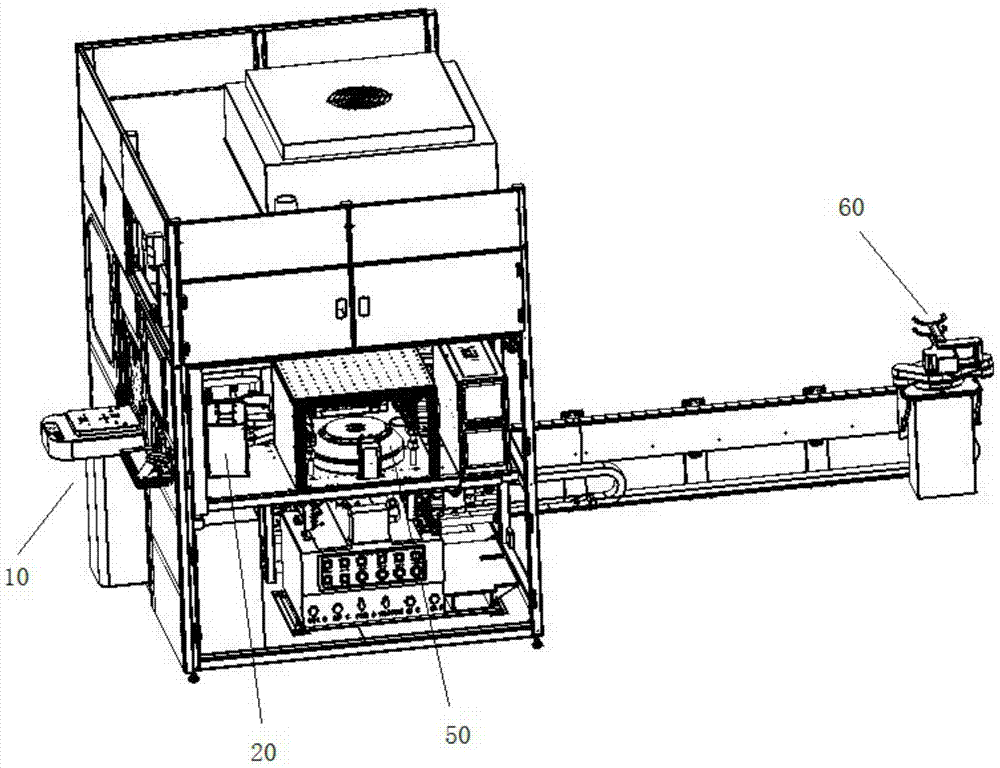

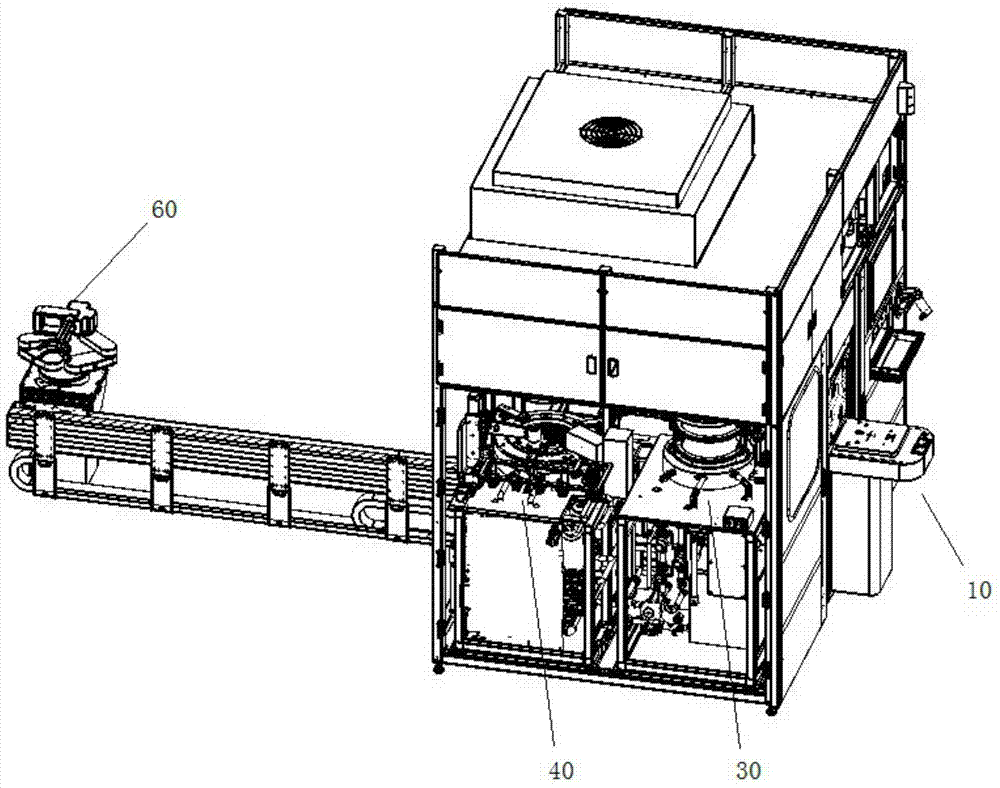

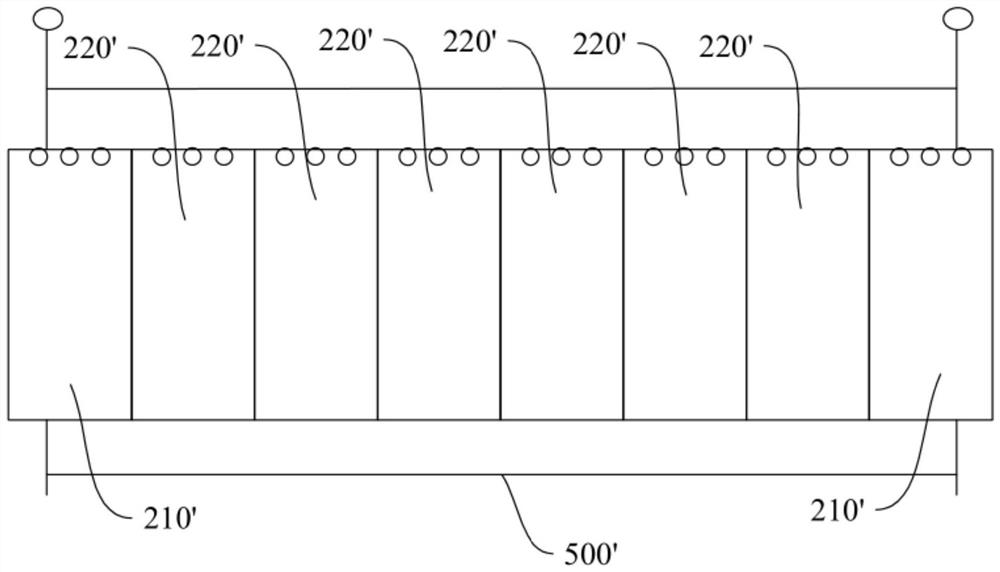

Wafer processing unit

ActiveCN104617016AImprove shipping stabilityImprove work efficiencySemiconductor/solid-state device manufacturingEngineeringRejection rate

The invention discloses a wafer processing unit, which is characterized by comprising a wafer electroplating pretreatment device for pre-treating wafers before electroplating, a wafer electroplating device for electroplating the wafers, a wafer cleaning device for cleaning the wafers after electroplating and a manipulator for conveying the wafers from one device to another device. According to the wafer processing unit, the wafer electroplating pretreatment device, the wafer electroplating device and the wafer cleaning device are combined organically; the wafers are conveyed by the manipulator, so that the working efficiency is improved greatly, the manpower is saved, the conveying stability of the wafers is improved, and the damage and rejection rate of the wafers is reduced.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

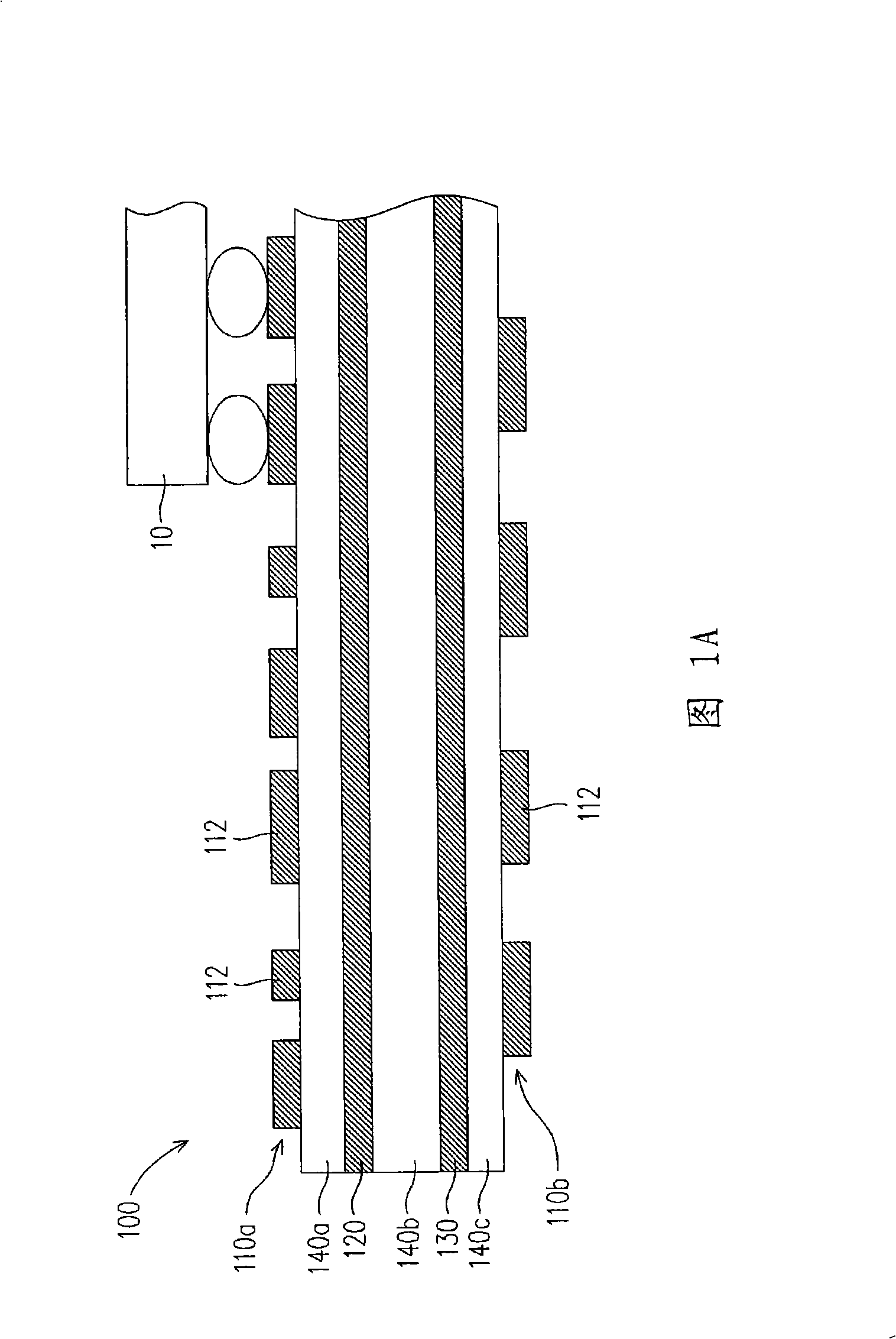

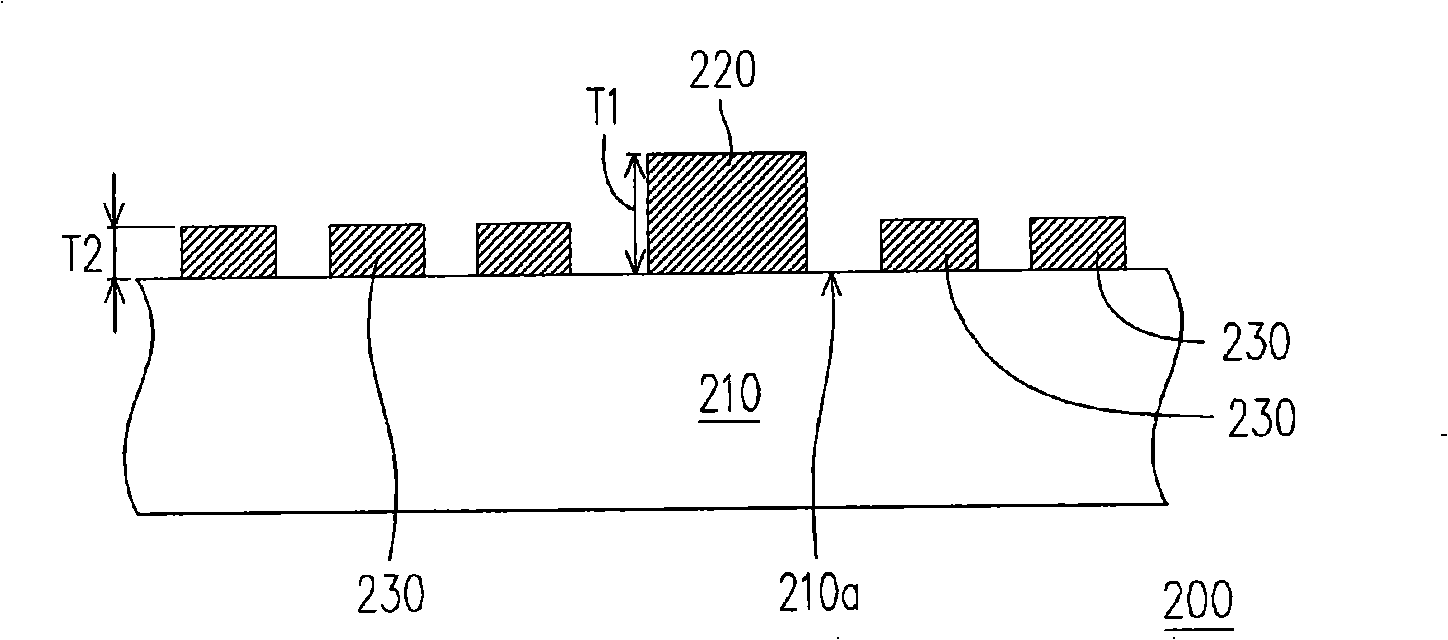

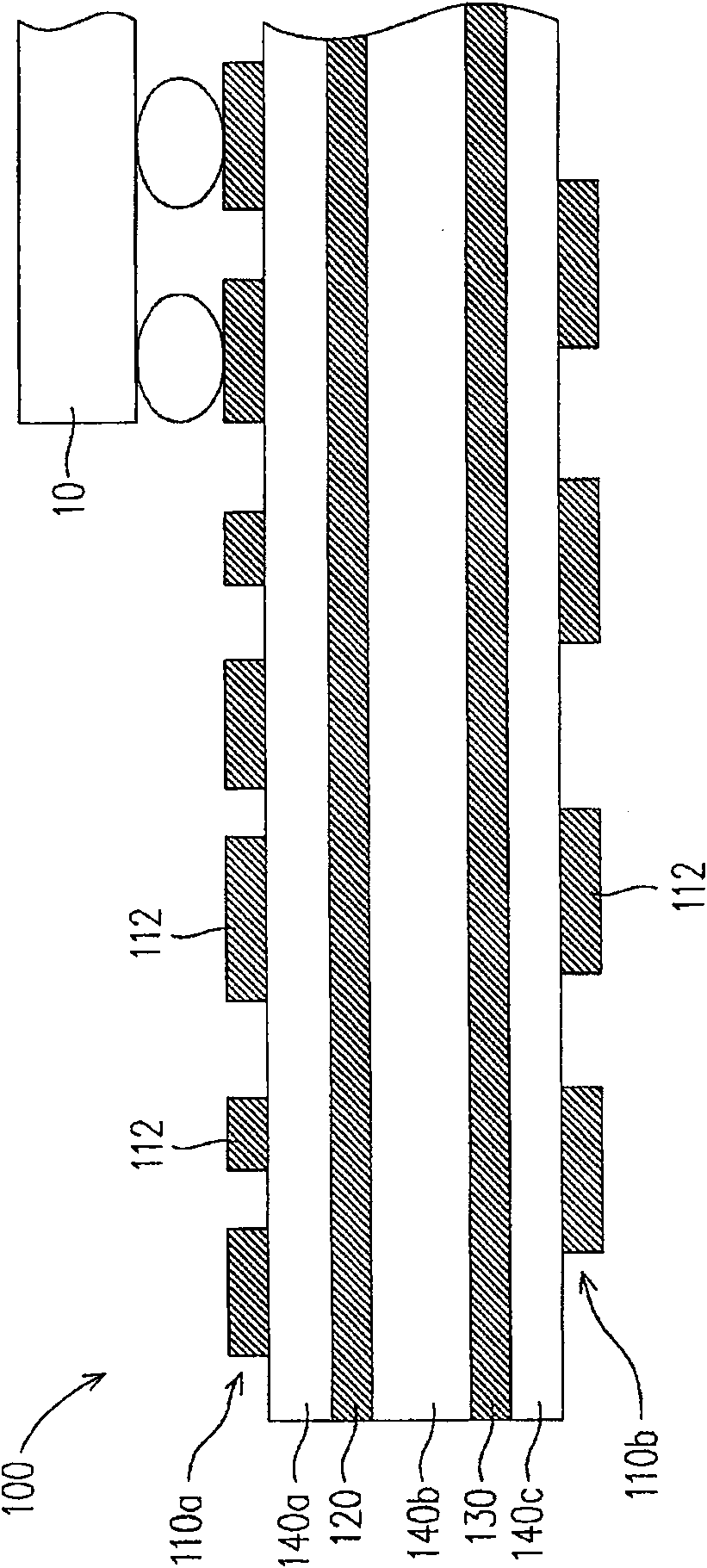

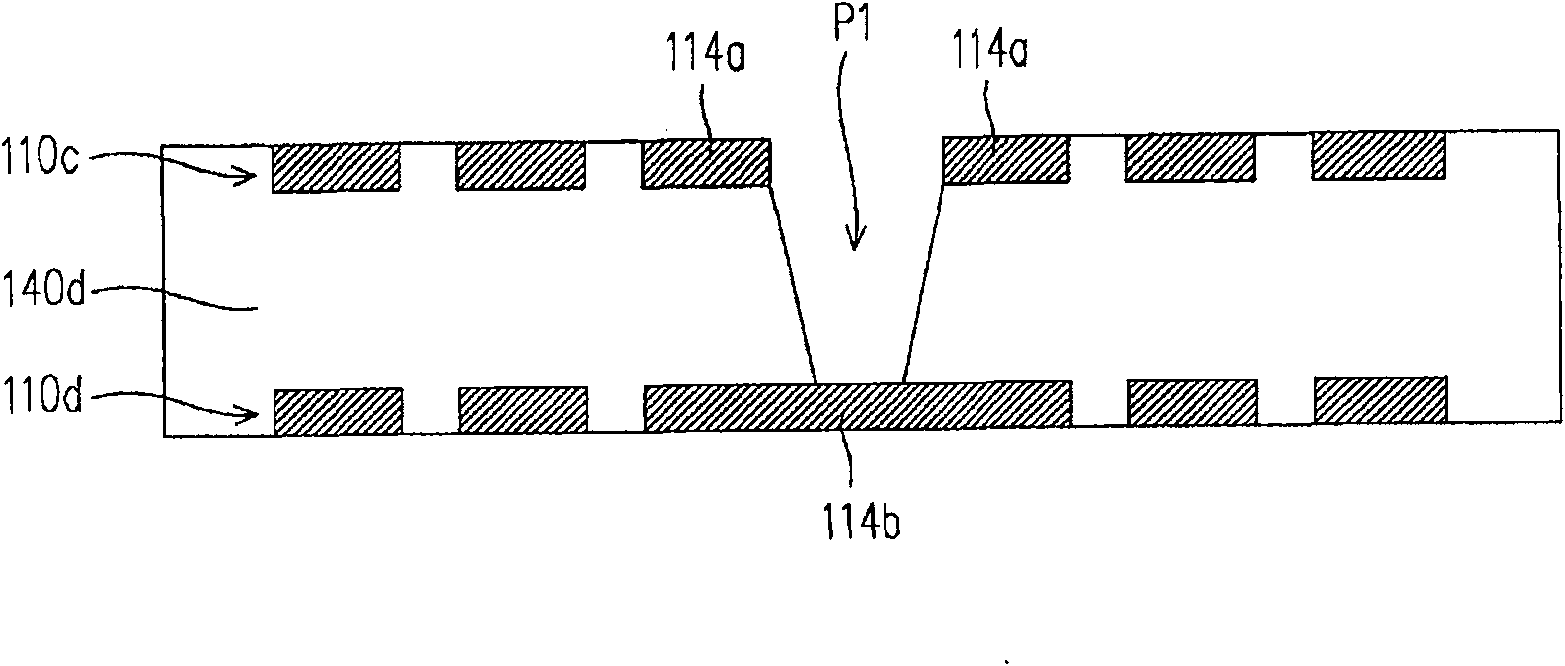

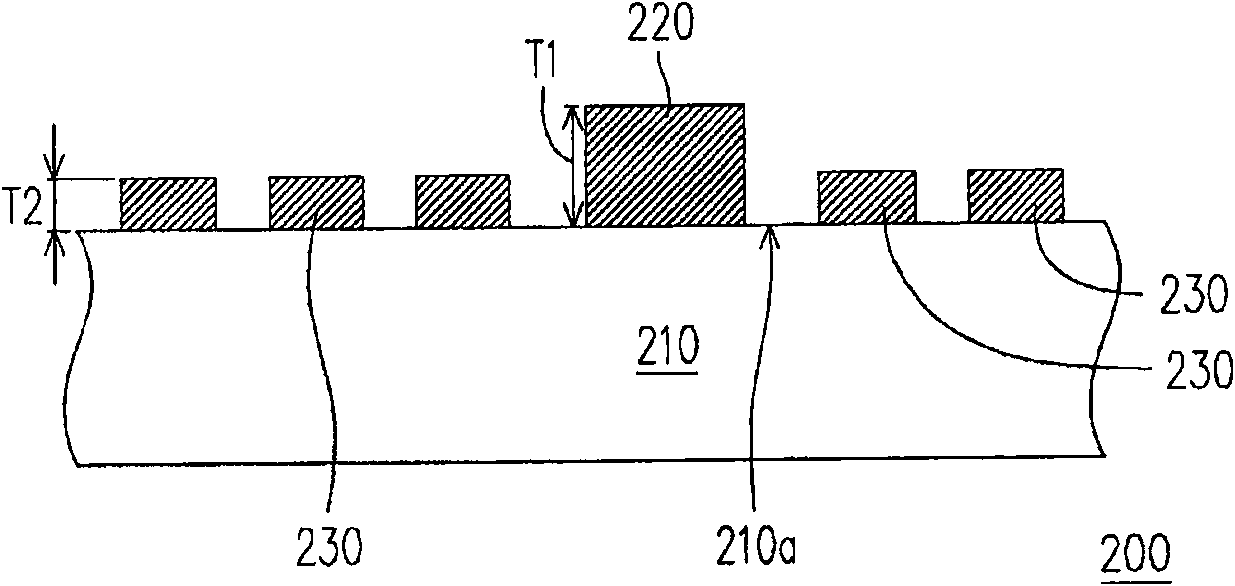

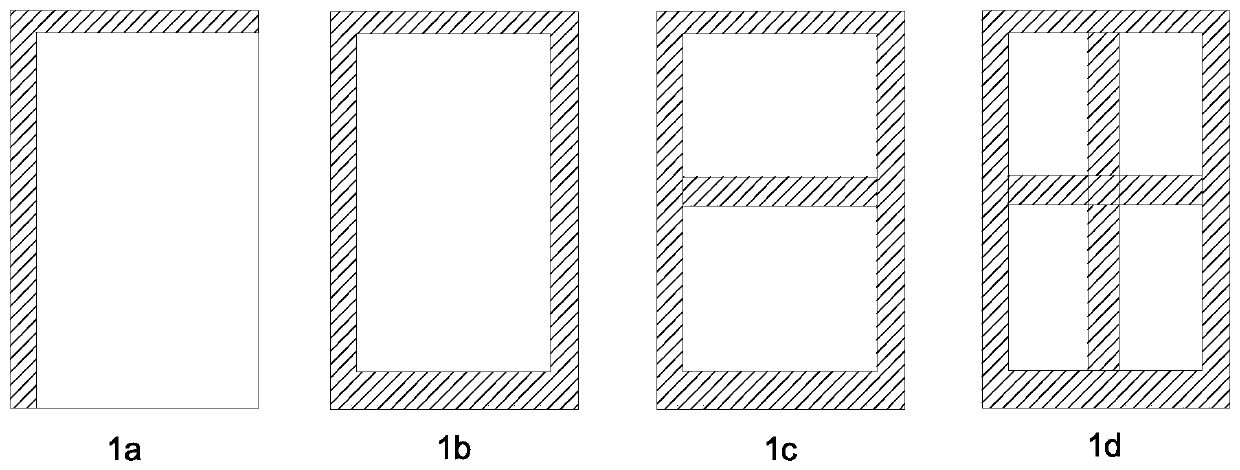

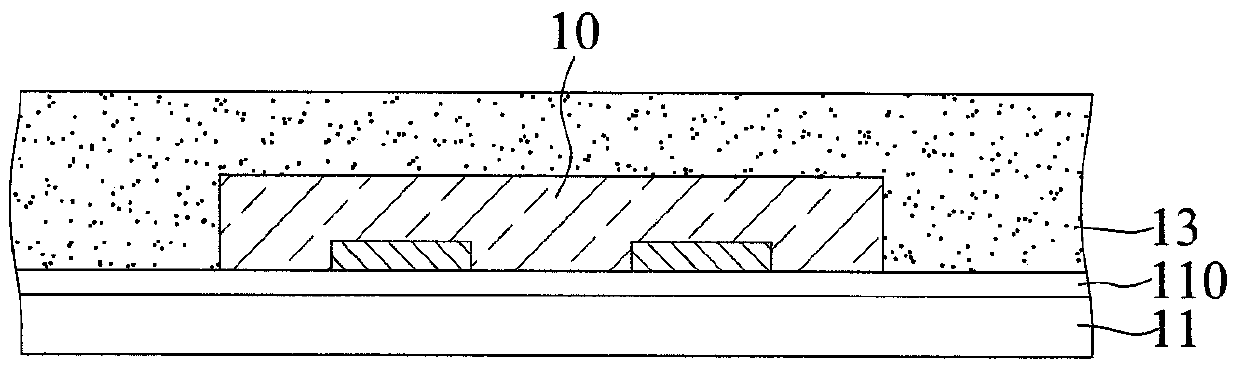

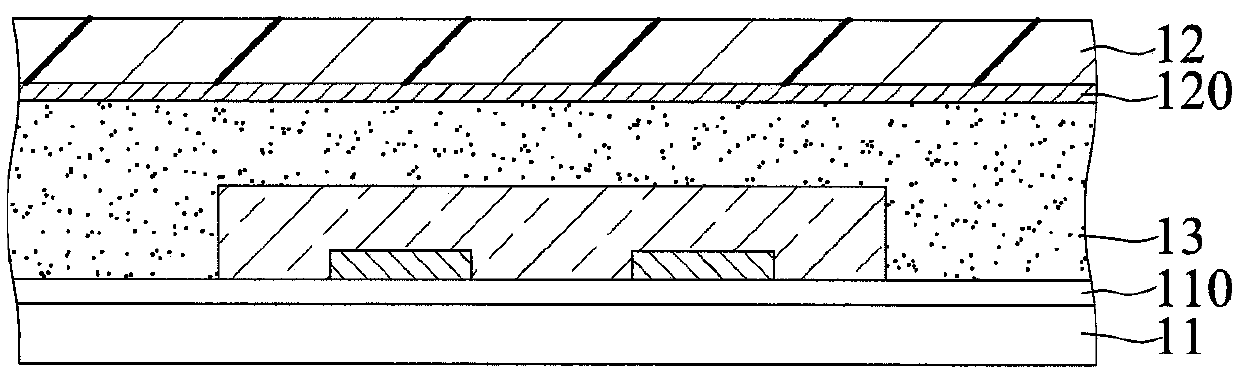

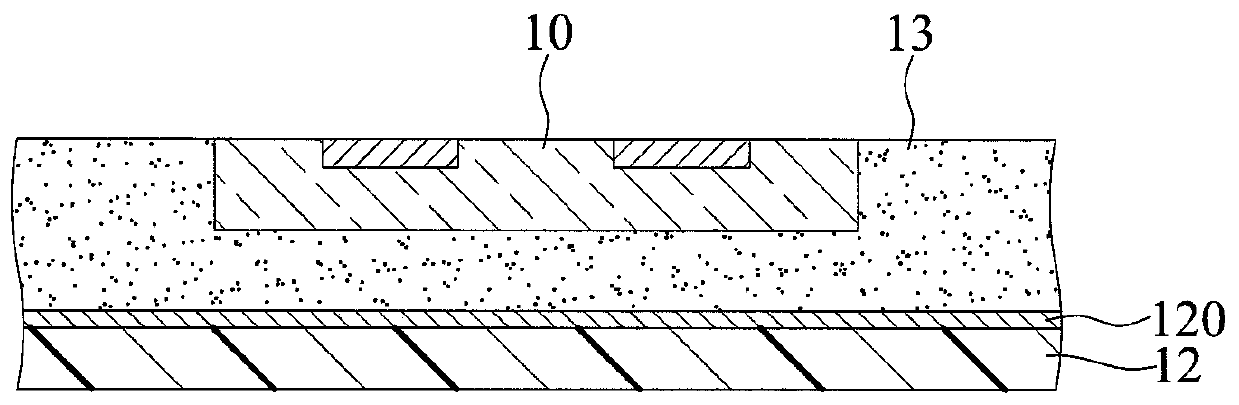

Stereo graphic pattern structure of circuit board and technique thereof

ActiveCN101316475AImprove reliabilityImprove cooling effectPrinted circuit manufactureMetallic pattern materialsEngineeringDielectric layer

The invention discloses a tree-dimensional pattern structure of a circuit board and a circuit technology thereof. The three-dimensional pattern structure of the circuit board comprises a dielectric layer, at least one first three-dimensional pattern and at least one second three-dimensional pattern. The first three-dimensional pattern and the second three-dimensional pattern are configured at a same surface of the dielectric layer. The thickness of the first three-dimensional pattern is larger than the thickness of the second three-dimensional pattern. Due to that the heat-dissipation capacity of the first three-dimensional pattern increases with the increase of the thickness, the first three-dimensional pattern with relatively good heat-dissipation capacity can be used for enhancing the whole heat-dissipation capacity of the circuit board.

Owner:UNIMICRON TECH CORP

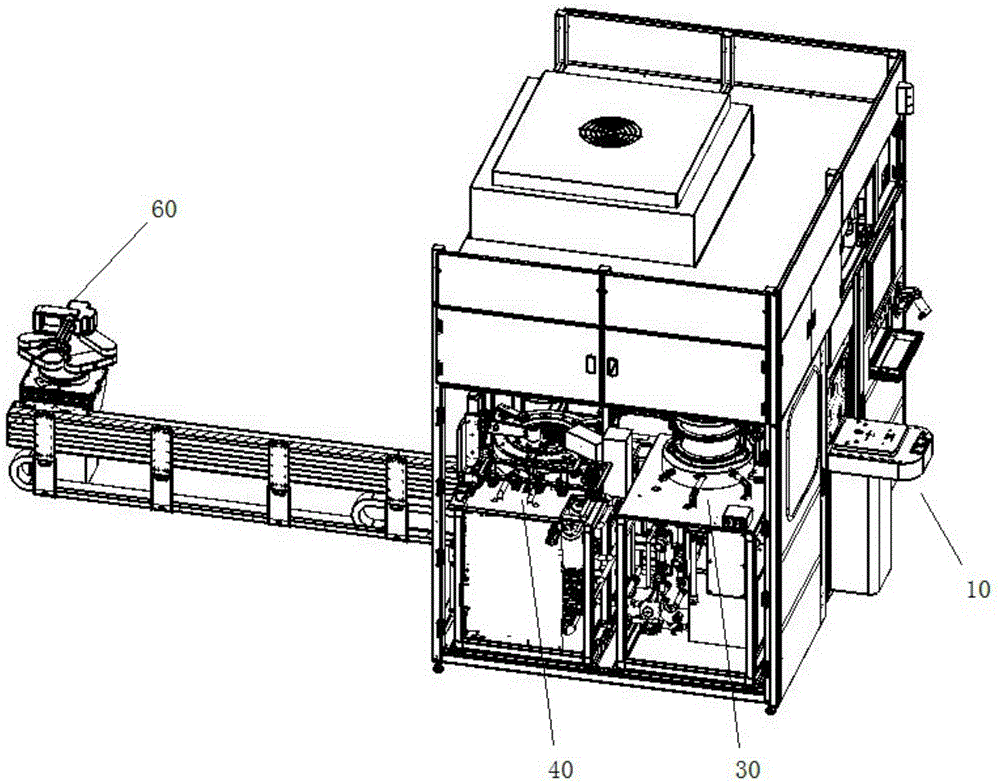

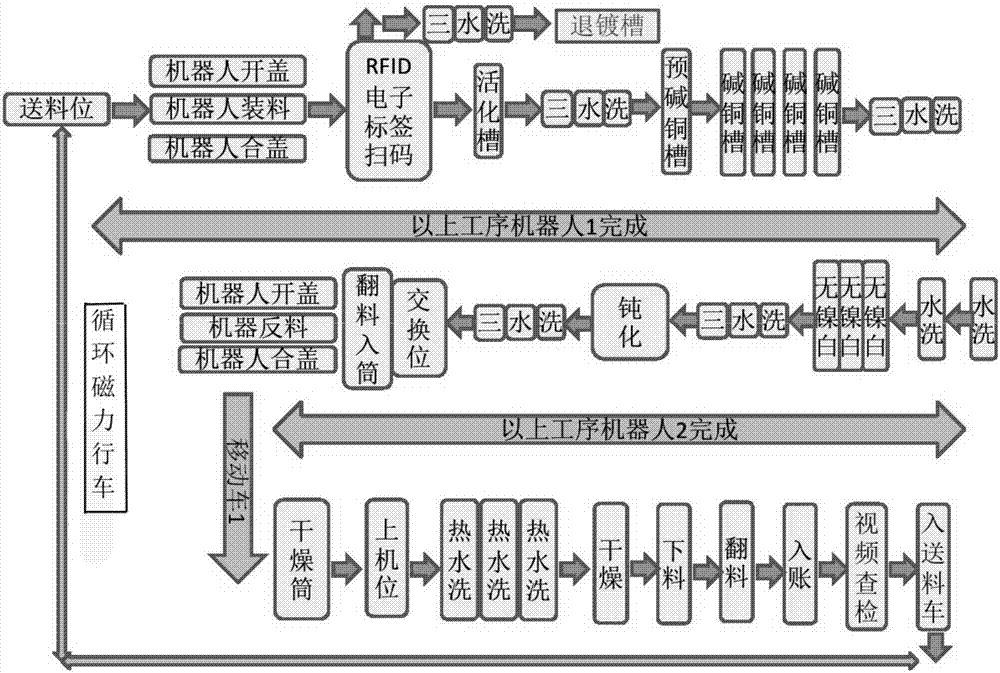

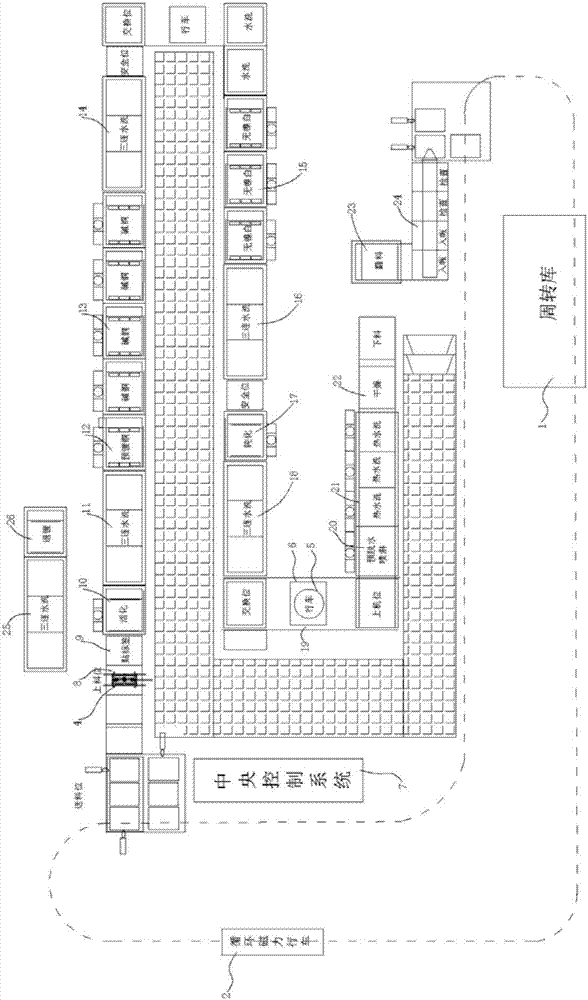

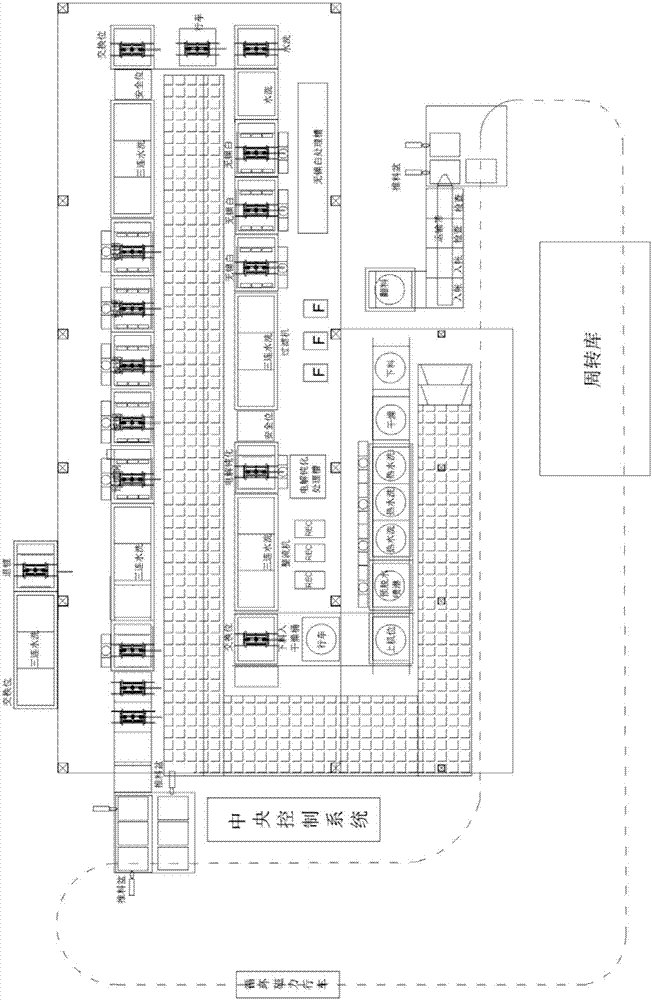

Full-automatic intelligent environment-friendly production system for surface treatment

ActiveCN107541767AEfficiently monitor emissionsEfficiently supervise workshop production work and monitor emissionsCellsWaste water treatment from metallurgical processIntelligent environmentStorage garage

The invention relates to a full-automatic intelligent environment-friendly production system for surface treatment. The full-automatic intelligent environment-friendly production system comprises a transfer warehouse, a circulating magnetic force travelling vehicle, a material box, a manipulator, a roller, a drying cylinder, a moving vehicle, a surface treatment electroplating production line, a drying clean production line, a pure water treatment system and a central control system. The circulating magnetic force travelling vehicle circularly moves among the transfer warehouse, surface treatment electroplating production line and the drying clean production line, pre-electroplated products are taken out from the transfer warehouse to be placed into the material box, the circulating magnetic force travelling vehicle drives the material box to move to a feeding position, and the central control system controls all devices to synergistically work. The circulating magnetic force travelling vehicle carries the primary products and electroplated products, and the manipulator clamps the products for feeding and discharging on the surface treatment electroplating production line and the drying clean production line to complete corresponding machining. The clean production requirement is met, the automation degree is high, machining is accurate, the product quality is improved, on-siteoperation does not need a great number of people, the labor intensity is small, the production speed is high, and the cost is reduced.

Owner:DONGGUAN CRAY AUTOMATION TECH

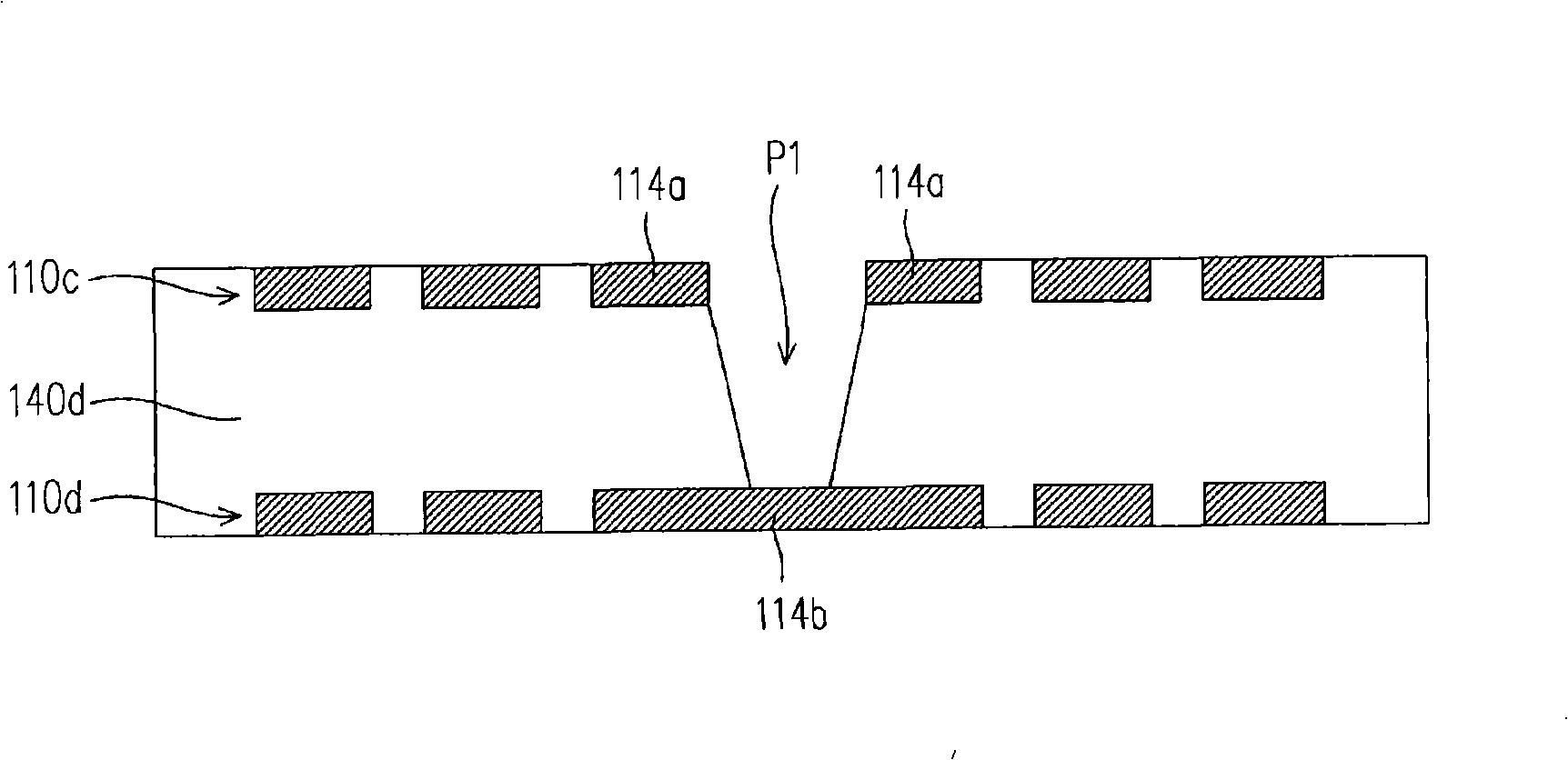

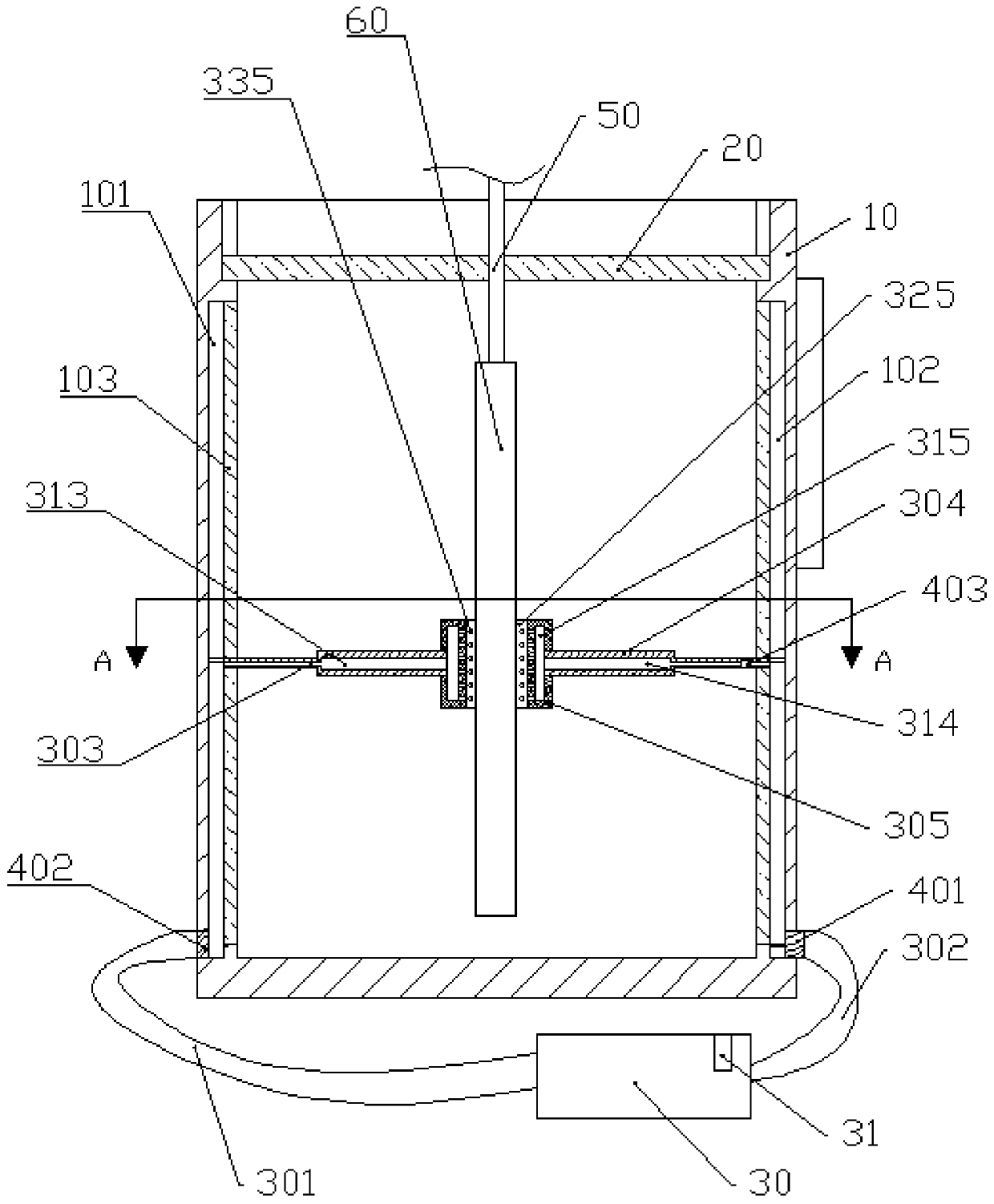

Electroplating system and electroplating method

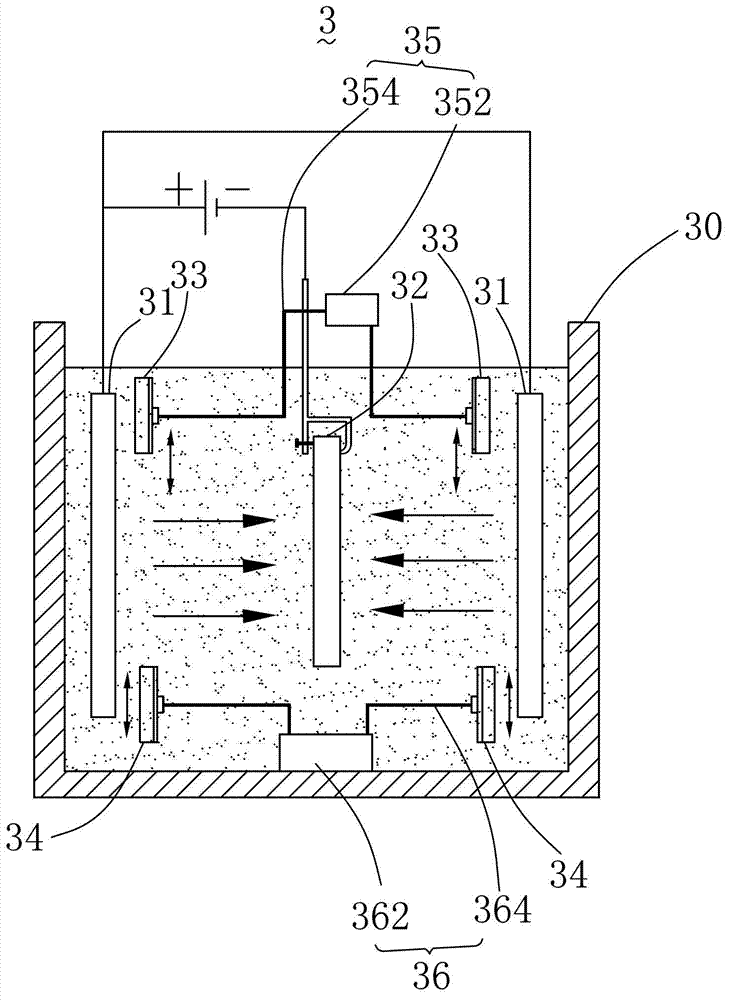

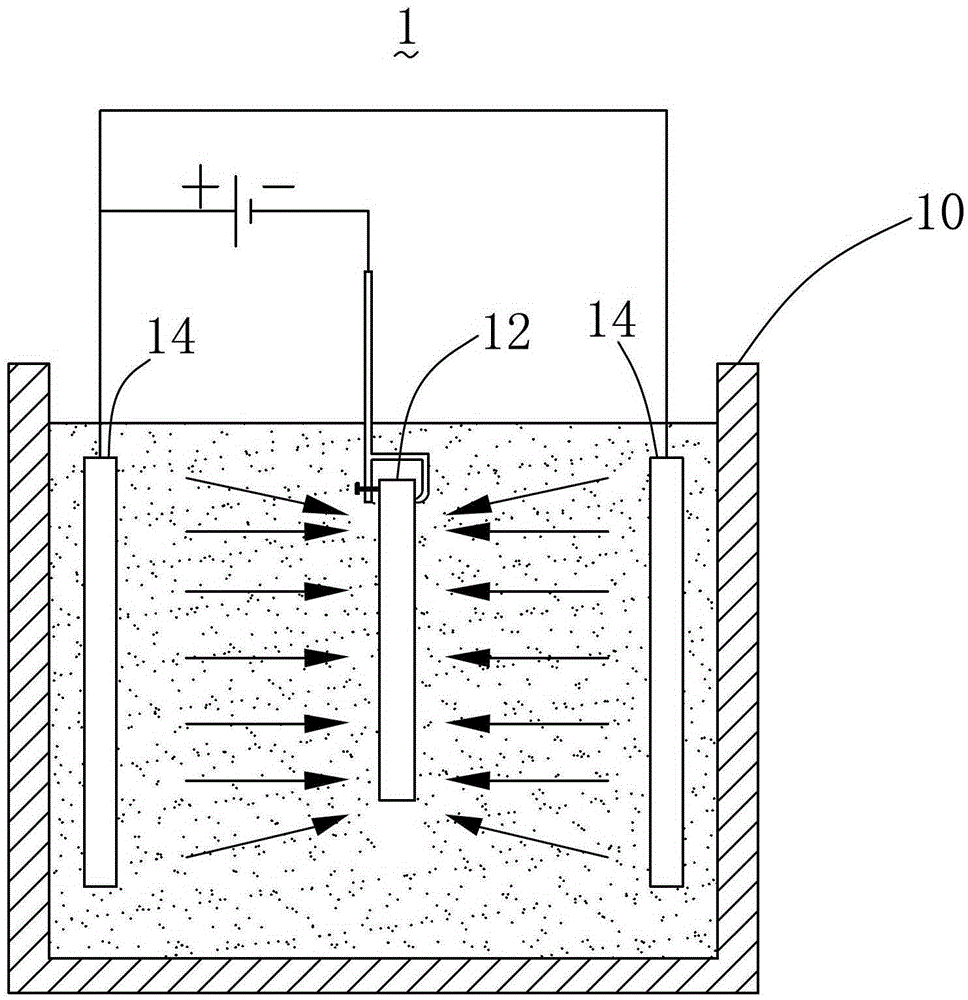

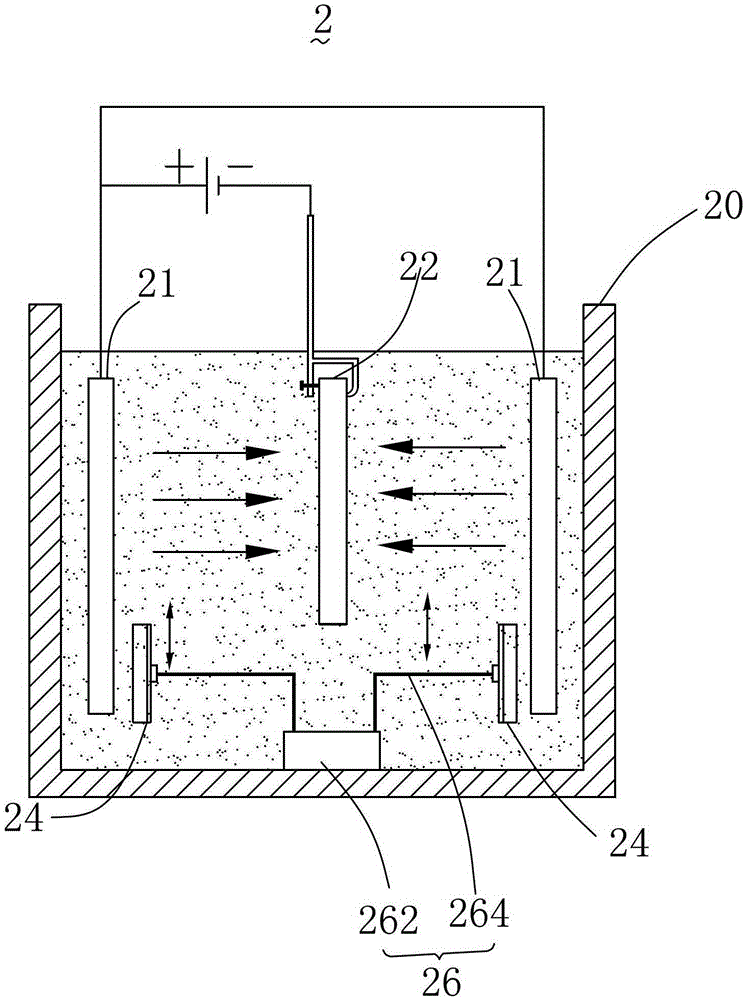

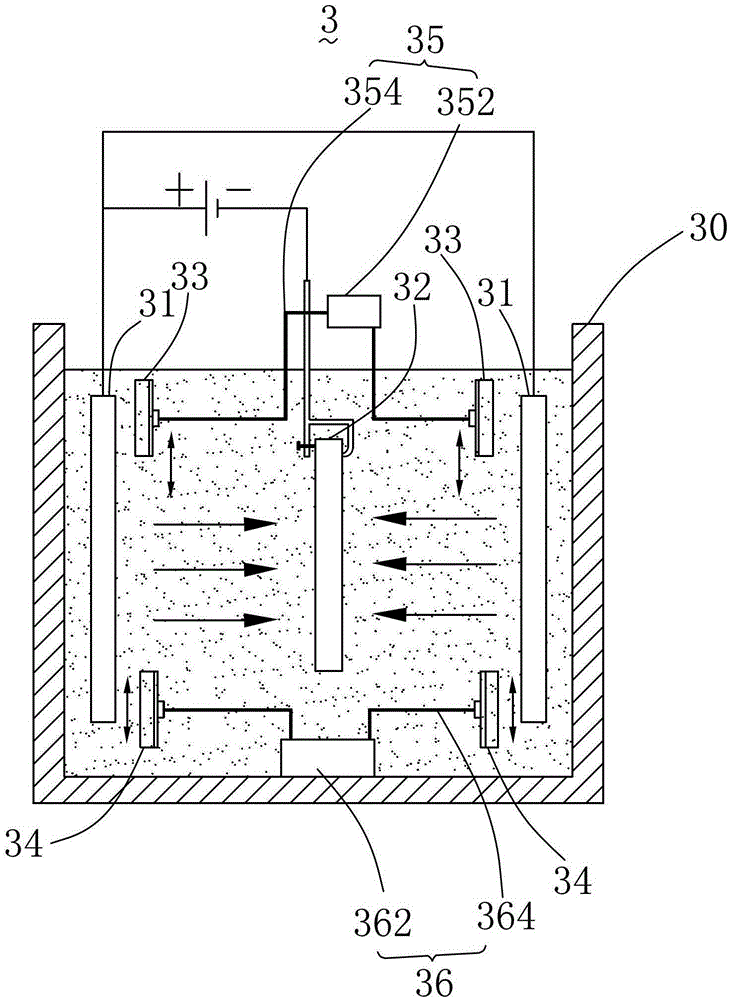

InactiveCN102605397AUniform density distributionImprove the quality of electroplatingCurrent insulating devicesPrinted circuit manufactureDensity distributionEngineering

The invention discloses an electroplating system which comprises an electroplating bath, a power supply device, an anode bar, an electroplating anode, a cathode bar, a hanging rack, an auxiliary cathode bar and an auxiliary cathode shield, wherein the anode bar, the cathode bar and the auxiliary cathode bar are connected to the power supply device; the electroplating anode is fixed on the anode bar; the hanging rack is fixed on the cathode bar, and provided with a plurality of conductive pinch points for fixing a circuit board; the auxiliary cathode shield is fixed on the auxiliary cathode bar, opposite to the hanging rack, and arranged between the hanging rack and the electroplating anode; the auxiliary cathode shield comprises a shield body which is dead against the circuit board; the shield body comprises a peripheral area and a central area; the plurality of conductive pinch points are opposite to the peripheral area; the peripheral area is provided with a first through hole, and the central area is provided with a second through hole; and the first and second through holes are used for controlling the density distribution of metal ions precipitated from the electroplating anode after passing through the auxiliary cathode shield. The invention also provides an electroplating method using the electroplating system above.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

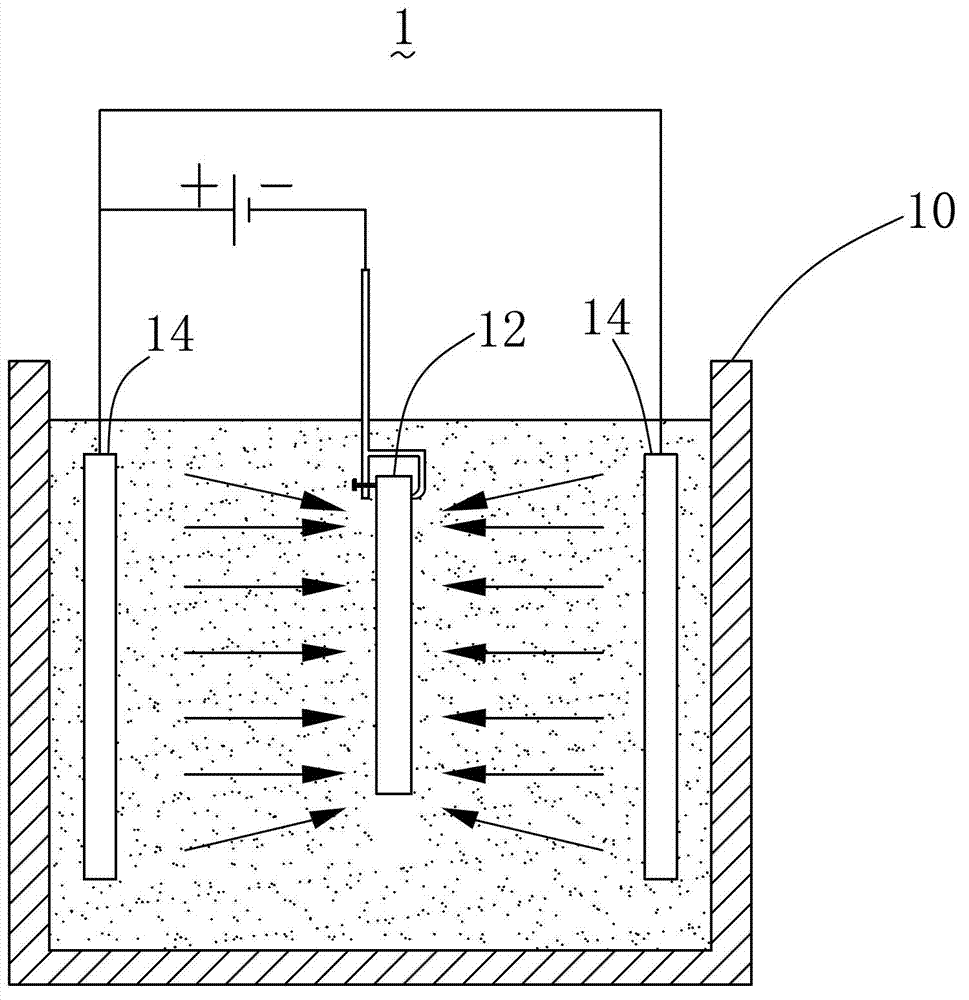

Electroplating method

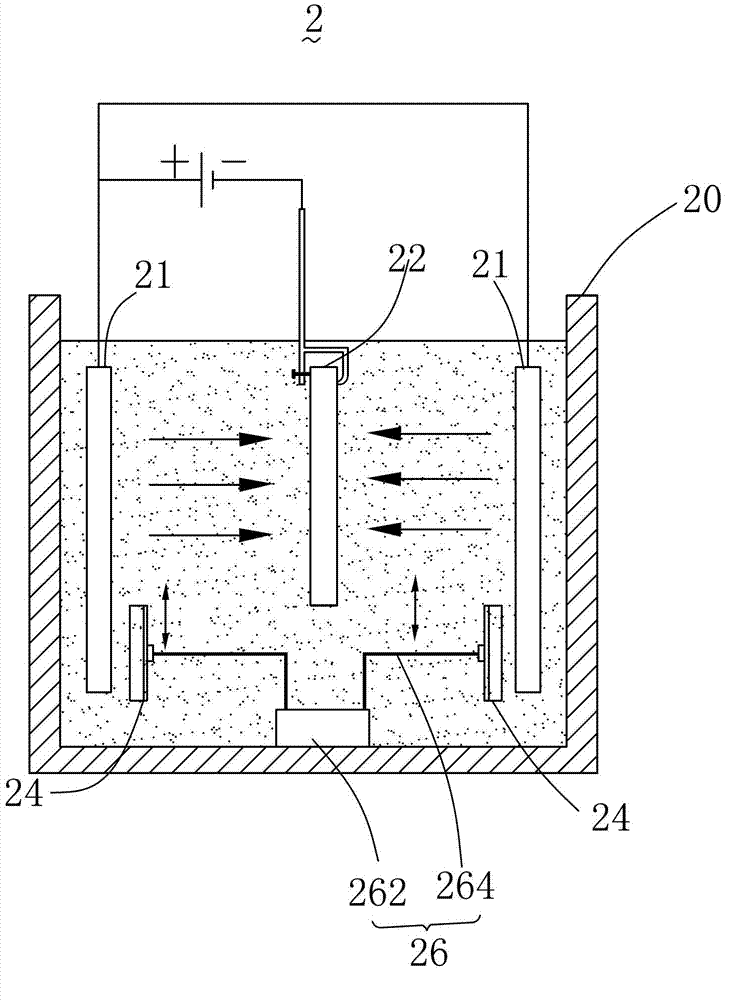

ActiveCN102828211AFlexible adjustment of the directly facing areaImprove the quality of electroplatingCellsElectroplatingCathode

The invention provides an electroplating method, which comprises the following steps: a pair of anodes and an electroplated part are placed in a plating bath with a plating solution, the pair of anodes are respectively arranged at the left side and the right side of the electroplated part and enable electrically connected to the anode of the power supply respectively, the electroplated part enables electrically connected to the cathode of power supply for being as the cathode; a pair of first baffle plates are arranged between the pair of anodes and closed to one end of the electroplated part; according to the requirements of an electroplate area of the electroplated part, the first baffle plates are controlled to cover a part of area of the electroplated part; power supply is switched on, and the electroplated part is electroplated. The electroplating method is characterized in that the first baffle plates are arranged between the pair of anodes, the area of the electroplated part directly opposite to the anode can be adjusted in a flexible way, thereby uniform electroplating of part of the electroplated part can be selectively completed, and the uniform electroplating of the integral electroplated part can be completed, the electroplate quality is enhanced, the application scope is wide, and the practicality is obviously increased.

Owner:东莞市五株电子科技有限公司

Stereo graphic pattern structure of circuit board and technique thereof

ActiveCN100581314CImprove reliabilityImprove cooling effectPrinted circuit manufactureMetallic pattern materialsDielectric layerElectrical and Electronics engineering

The invention discloses a tree-dimensional pattern structure of a circuit board and a circuit technology thereof. The three-dimensional pattern structure of the circuit board comprises a dielectric layer, at least one first three-dimensional pattern and at least one second three-dimensional pattern. The first three-dimensional pattern and the second three-dimensional pattern are configured at a same surface of the dielectric layer. The thickness of the first three-dimensional pattern is larger than the thickness of the second three-dimensional pattern. Due to that the heat-dissipation capacity of the first three-dimensional pattern increases with the increase of the thickness, the first three-dimensional pattern with relatively good heat-dissipation capacity can be used for enhancing the whole heat-dissipation capacity of the circuit board.

Owner:UNIMICRON TECH CORP

Pneumatic copper ball addition apparatus

The invention relates to a pneumatic copper ball addition apparatus, which uses the thrust effect of the air pressure conveys the copper ball from a work walkway to every titanium basket used for placing the copper ball, the work of adding the copper ball is completely conveyed to the work walkway to finish without normal operation of electroplate equipment, the copper ball can be added in safe, reliable, easy and rapid mode during the normal operation process of the electroplate equipment, thereby the production time is saved, the production power is enhanced, the resource waste is reduced, the electroplate quality is enhanced, the manual work is reduced, and the labor intensity is reduced.

Owner:竞铭机械(深圳)有限公司

Pattern electroplating method with pattern electroplating accompanying plating plate reusable

ActiveCN110602893AAchieve reuseReduce manufacturing costConductive material chemical/electrolytical removalConductive pattern reinforcementEngineeringTime of use

The invention relates to the technical field of printed circuit boards, in particular to a pattern electroplating method with a pattern electroplating accompanying plating plate reusable. When a VCP is used to carry out pattern electroplating processing on a production board, a pattern electroplating accompanying plating plate which makes an accompanying plating pattern and electroplates a nickelgold layer on the accompanying plating pattern as an etching protection layer is used for accompanying plating, the pattern electroplating accompanying plating plate is used to pass through an alkaline etching line when the production board in each line completes electroplating processing, a copper layer formed on the surface of the pattern electroplating accompanying plating plate in the patternelectroplating processing process is removed through etching processing, the pattern electroplating accompanying plating plate restores the state before the use and can be used again in pattern electroplating processing, reuse of the pattern electroplating accompanying plating plate is realized, the problems that the appearance of the existing pattern electroplating accompanying plating plate becomes poor and the existing pattern electroplating accompanying plating plate becomes heavier and thicker along with increase of the number of times of use, and consequently the pattern electroplating accompanying plating plate falls off, a clamp is damaged, and a copper cylinder is polluted in the pattern electroplating process are completely solved, the production cost can be reduced, and the production efficiency can be improved.

Owner:珠海崇达电路技术有限公司 +1

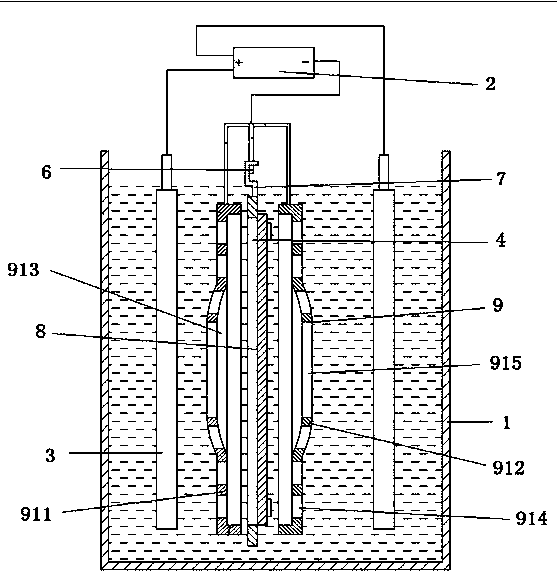

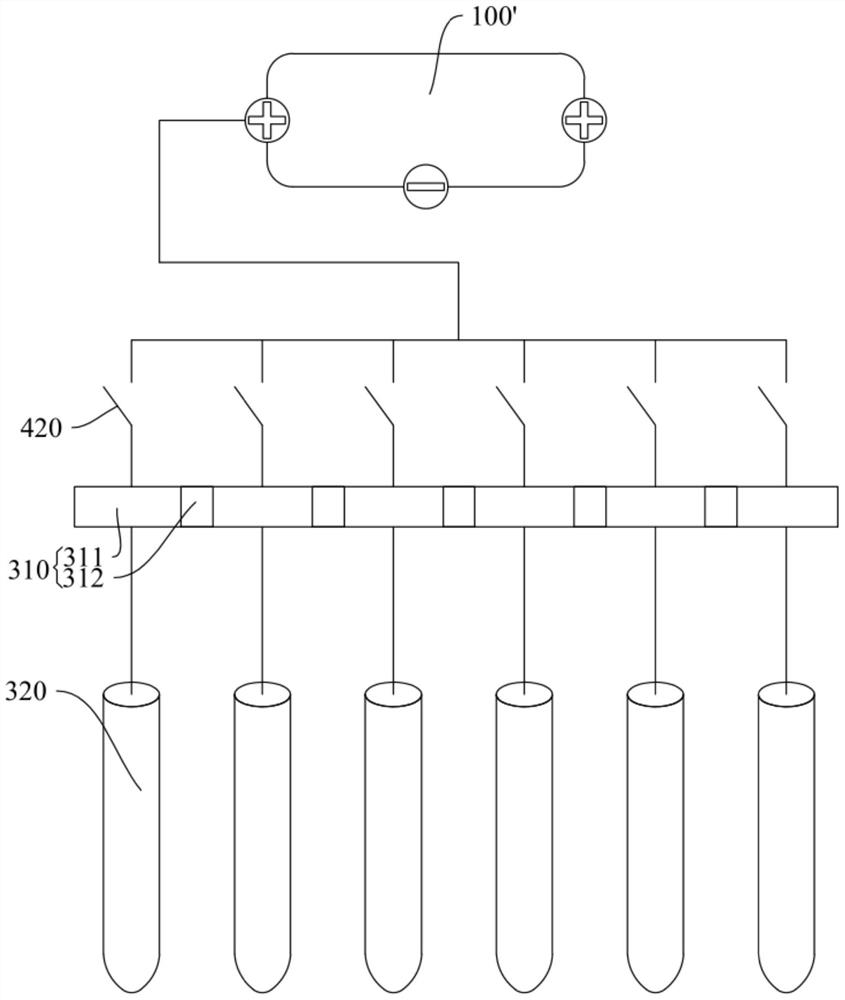

A semiconductor diode electroplating processing system

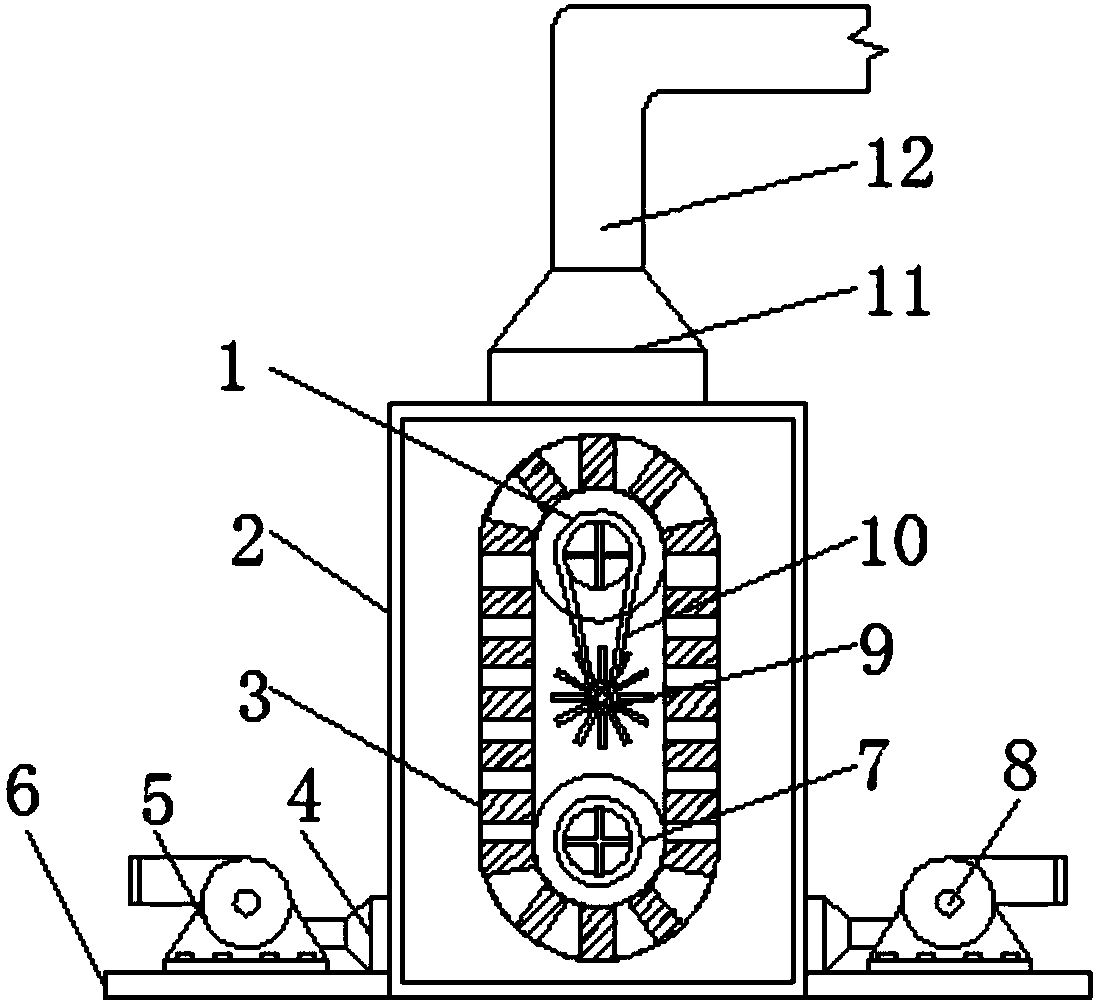

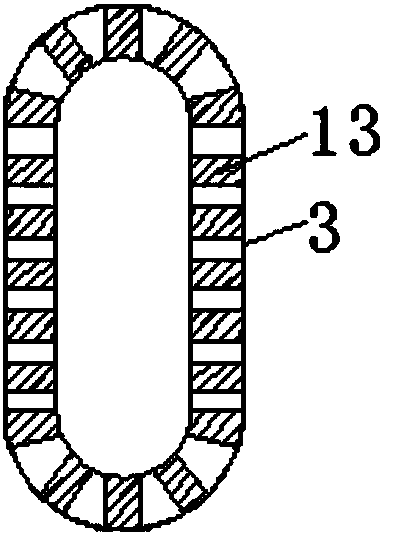

ActiveCN108796592BImprove plating efficiencyImprove the quality of electroplatingCellsSemiconductor devicesEngineeringCam

The invention belongs to the technical field of semiconductor diode production, and particularly relates to a semiconductor diode electroplating treatment system. The semiconductor diode electroplating treatment system comprises a top plate, an electroplating bath, a supporting column, an electroplating tank, a drive module and a stirring module; the drive module comprises a first motor, a first cam, a first sliding telescopic rod, a first sliding block, and a second sliding block, through cooperation of the first cam, the first sliding block and the first sliding telescopic rod, the electroplating tank swings while descending, electroplating liquid makes sufficient contact with the semiconductor diode, a third sliding block plugs a first liquid inlet in the right side, the electroplatingliquid enters from the first liquid inlet in the left side of a bottom plate of a tank body and impacts a fourth plate, a supporting disc on the fourth plate shakes, the electroplating liquid enters the electroplating tank, through vibration of a vibration frame, the semiconductor diode vibrates, the contact area between the electroplating liquid and the semiconductor diode can be increased, and the electroplating efficiency and the quality of the semiconductor diode are improved.

Owner:吉林瑞能半导体有限公司

Split type electric-heating water tap

InactiveCN102563204AAvoid storageImprove the quality of electroplatingValve members for heating/coolingValve housingsElectricityWater discharge

The invention discloses a split type electric-heating water tap. The split type electric-heating water tap comprises a water discharging pipeline and a body, wherein the water discharging pipeline and the body are communicated, and a valve core is arranged at the communicating position; and a water dividing bin, which is detachably connected with the body and is internally provided with electric heating pieces, is arranged below the body. The split type electric-heating water tap has the advantages that the body and the water dividing bin part are designed as two independent parts; and due to the split type structure, only independent electroplating needs to be carried out on the body, so that the electroplating solution is prevented from being stored in the water dividing bin in the electroplating link, and the whole electroplating quality is improved. The split type electric-heating water tap can be used as an electric-heating water tap.

Owner:GUANGZHOU SEAGULL KITCHEN & BATH PROD

Electroplating equipment and electroplating method

InactiveCN107761158AUniform density distributionImprove uniformityElectrodesDensity distributionEngineering

The invention relates to electroplating equipment. The electroplating equipment comprises an electroplating tank, a power supply device, an anode bar, an electroplating anode, a cathode bar and a hanging frame, wherein one end of the cathode bar and one end of the anode bar are respectively connected with the anode and the cathode of the power supply device, the cathode bar and the anode bar are oppositely arranged at the two sides of the hanging frame, the hanging frame is provided with multiple conductive pinch points, the electroplating equipment also comprises an auxiliary cathode bar andan auxiliary cathode cover, the auxiliary cathode bar is connected with the cathode of the power supply device, and the auxiliary cathode cover is fixedly connected with the auxiliary cathode rod. Compared with the prior art, the electroplating equipment and the electroplating method in the technical scheme have the advantages that the auxiliary cathode cover can be utilized for controlling the quantity of metal ions passing through a first through hole and a second through hole, so that the density distribution of the metal ions after passing through the auxiliary cathode cover is more uniform, and the thickness uniformity of a metal layer deposited on a circuit board is improved, so that the electroplating quality of the circuit board is improved.

Owner:GUANGDONG CHAMPION ASIA ELECTRONICS CO LTD

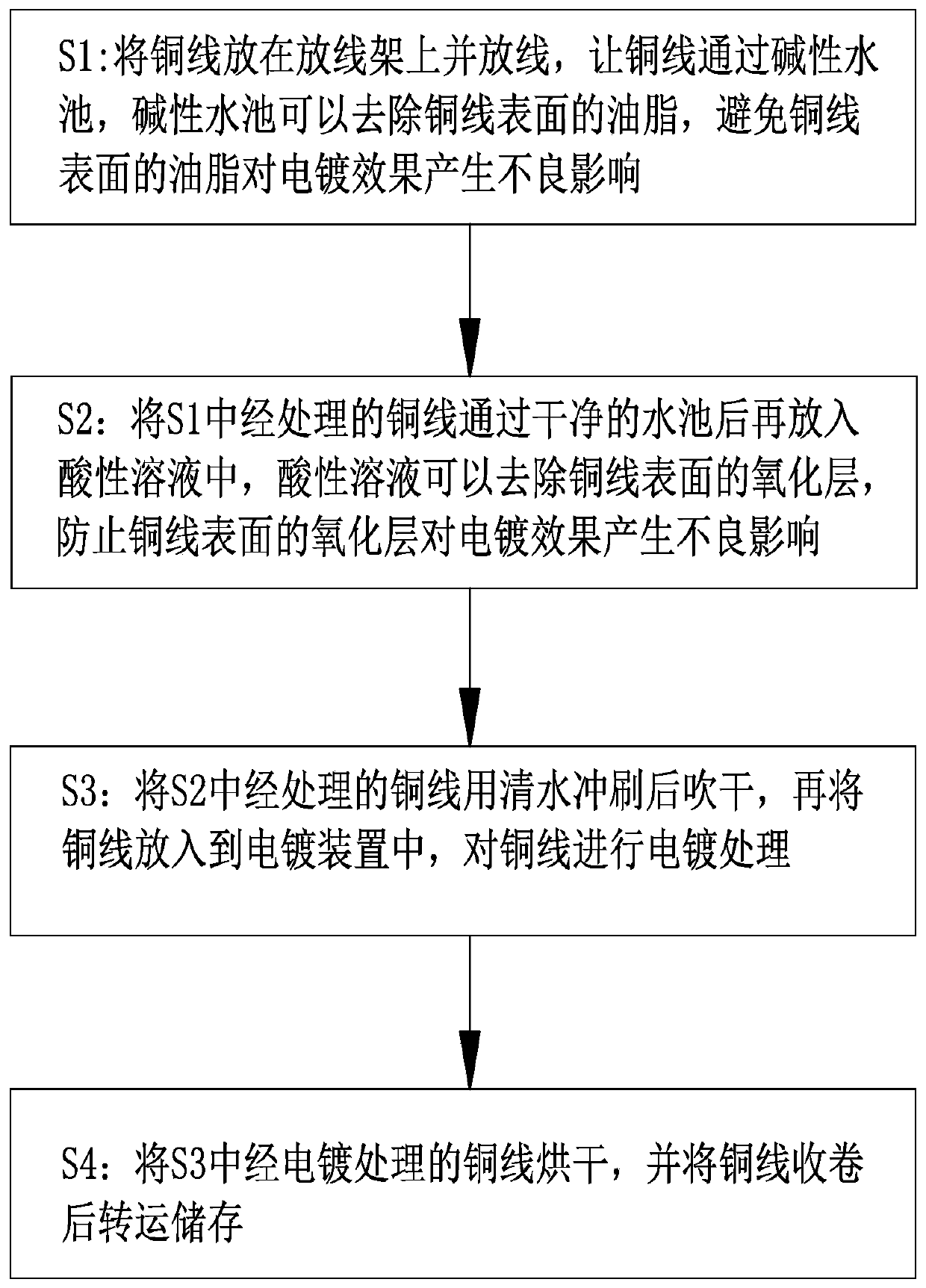

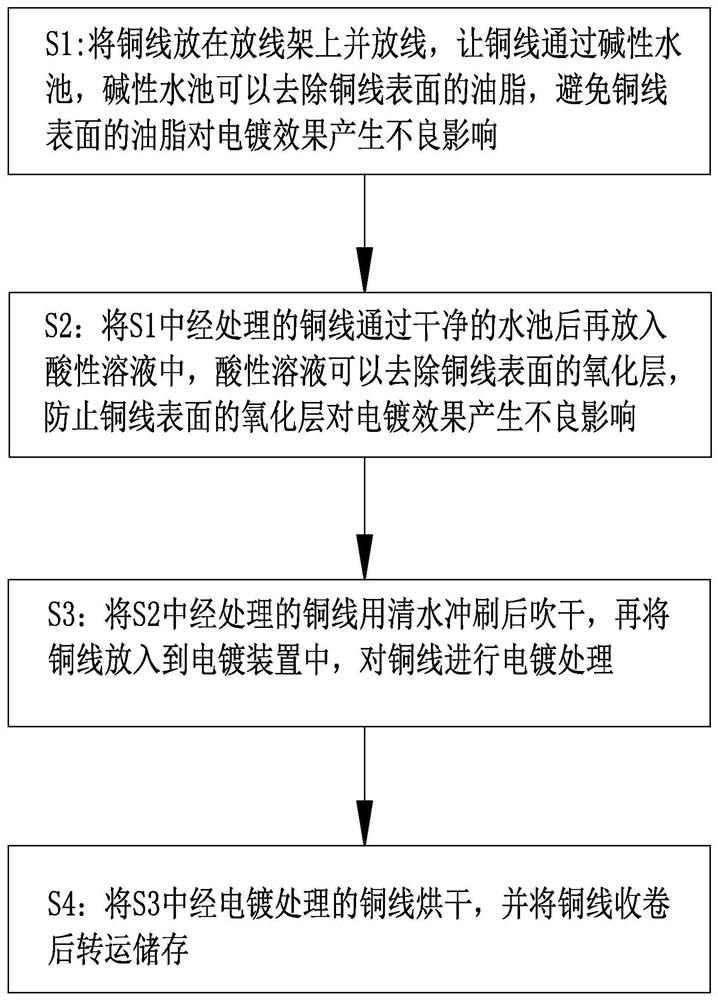

Tinned copper wire electroplating method

The invention belongs to the technical field of electroplating, in particular to a tinned copper wire electroplating method. An electroplating device in the present invention comprises an electroplating bath, the rotating shafts are rotationally mounted at the two sides of the top end of the electroplating bath through the mounting plates, and more than two pulleys are fixed on the surfaces of thetwo rotating shafts at equal intervals. A dryer is fixed to the top end of the electroplating bath, two or more rectangular grooves are formed at the bottom of an inner cavity of the electroplating bath at equal intervals, and the sleeves are slidably connected into the rectangular grooves correspondingly. Two or more rollers are arranged at the two sides of the electroplating bath correspondingly, the roller at one side of the electroplating bath is driven by a motor, and a controller is arranged on the electroplating bath. The electroplating device comprises a push rod motor, a piston and other structures, during the moving process of the piston, the sleeve can be pushed to continuously move, and during the moving process of the sleeve, the electroplating liquid in the electroplating bath is driven to generate surging, so that the impurities in the electroplating bath cannot precipitate, the electroplating liquid is more uniform, and the electroplating effect is improved.

Owner:浙江东翼新材料有限公司

Metal surface treatment electroplating processing method

PendingCN113832515AImprove the quality of electroplatingEfficient removalGrinding machinesCleansing AgentsMachine tool

The invention discloses a metal surface treatment electroplating processing method. The metal surface treatment electroplating processing method comprises the following steps: A, oil removal, cleaning and drying treatment is carried out on the surface of a metal part; and B, cutting and grinding treatment is conducted on the metal part. In the step A, the metal part is put into an oil removal agent for oil removal treatment, then the metal part is put into a cleaning agent for cleaning treatment, finally the metal part is put into a drying box for drying treatment, the drying temperature is 80-100 DEG C, and the drying time is 3-8 minutes; and in the step B, the metal part is cut and ground through a machine tool, and the surface of the metal part is more neat. According to the metal surface treatment electroplating processing method, the surface of the metal part is subjected to oil removal, cleaning and drying treatment firstly, oil stains and other impurities on the surface of the metal part can be effectively removed, the metal part is cut and ground after being dried, and the surface neatness of the metal part can be effectively improved; and meanwhile, the metal part is rinsed after electroplating is completed, and redundant electroplating liquid on the surface of the metal part can be effectively rinsed, so that the electroplating quality of the metal part is effectively improved.

Owner:邦仪精密科技(苏州)有限公司

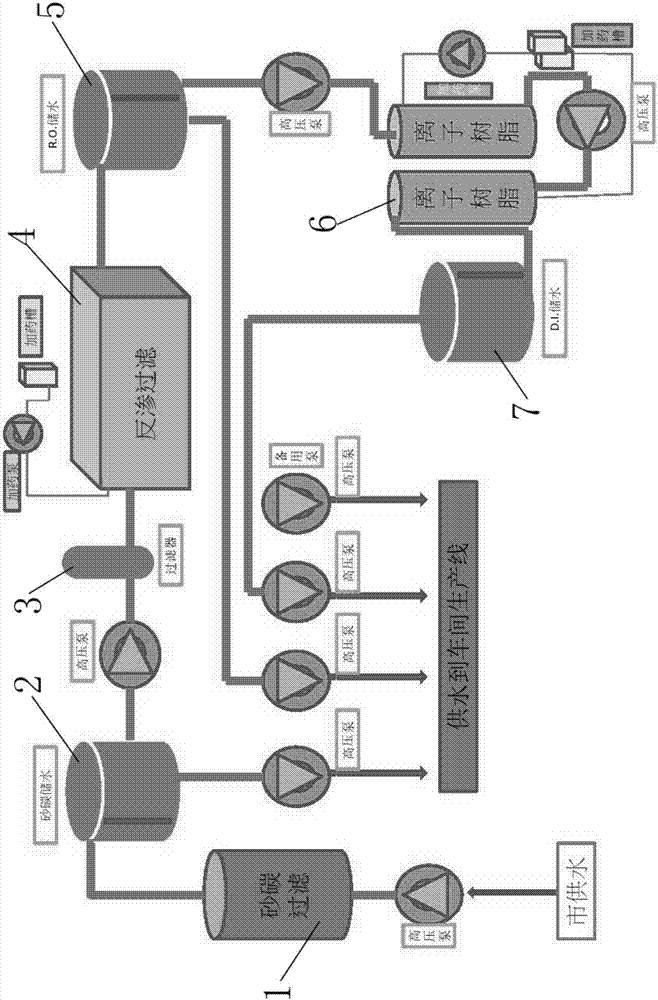

Environment-friendly water treatment system for surface treatment production line

InactiveCN107344776AAvoid wastingReasonable structural designSpecific water treatment objectivesTreatment involving filtrationWater useEnvironmental resistance

The invention relates to an environment-friendly water treatment system for a surface treatment production line. The water treatment system comprises a sand carbon filter device, a first water storage tank, a filter, a reverse osmosis filter device, a second water storage tank, an ion resin filter device, a third water storage tank, a plurality of water pipes and a plurality of high-pressure pumps, wherein municipal water supply source enters the sand carbon filter device for sand carbon filter treatment and then the treated municipal water supply source enters the first water storage tank for storage; the reverse osmosis filter device carries out reverse osmosis filtration on water and then the treated water enters the second water storage tank for storage; and the ion resin filter device carries out adsorption treatment on positive ions and negative ions in water and then the treated water enters the third water storage tank for storage. The water treatment system is reasonable in overall structural design; the municipal water supply source is subjected to filter treatment through the sand carbon filter device, the reverse osmosis filter device and the ion resin filter device separately and the water used when different products are electroplated on 20-100PPM water supply production lines of different qualities, so that the electroplating quality is improved, the water treatment system has energy-saving and environment-friendly effects, the waste of excessive water is avoided, the emission and discharge amount can be reduced and the operating requirements are met.

Owner:DONGGUAN CRAY AUTOMATION TECH

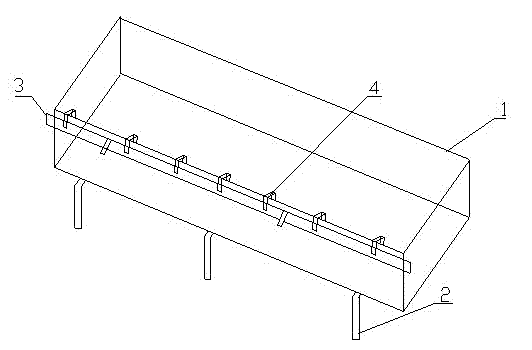

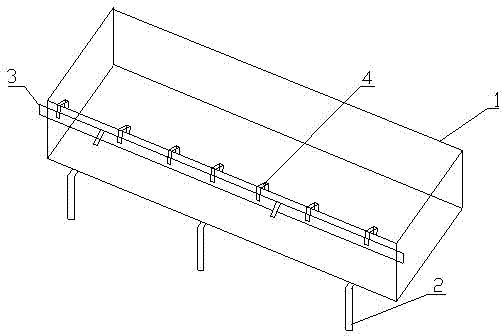

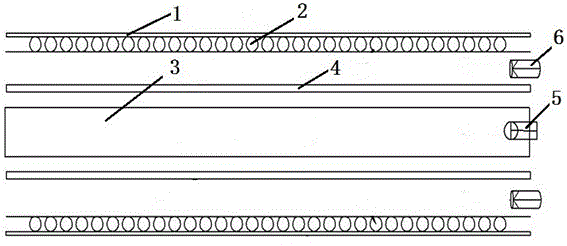

Plating bath

The invention discloses a plating bath. The plating bath which comprises a bath body (1) and a pedestal (2) is characterized in that: a row of electrolytic devices are arranged on the bath body (1); each electrolytic device comprises a transverse copper plate (3) and electrolytic plates (4); the copper plate (3) is fixed on the bath body (1) and is placed on the outer edge of the bath body (1); and each electrolytic plate (4) has a U-shaped appearance, one segment of each electrolytic plate (4) is fixed on the copper plate (3), and the other segment of each electrolytic plate (4) is placed in the electrolytic solution. The plating bath of the invention allows the conductive copper plate to be prevented from the erosion of the plating solution in the plating process, so the conductive stability of the conductive copper plate and the plating quality are improved, and the service life of the conductive copper plate is prolonged.

Owner:JIANGYIN CHANGLE NEW TECH POWER SUPPLY

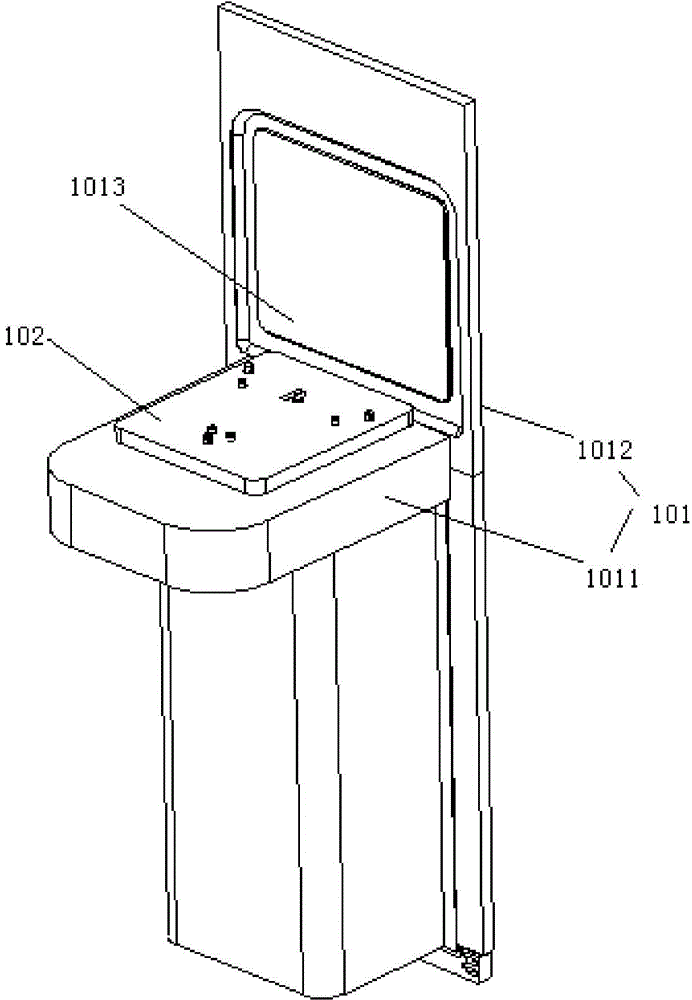

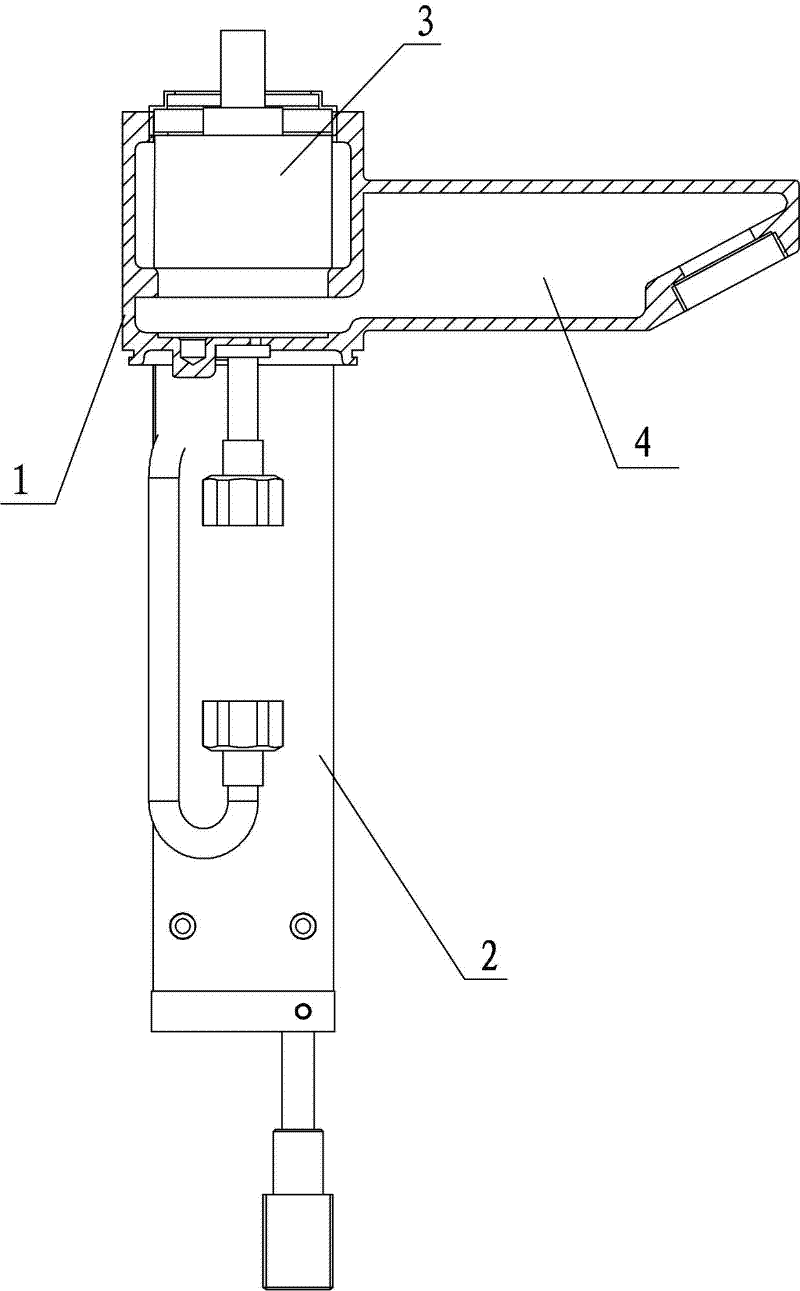

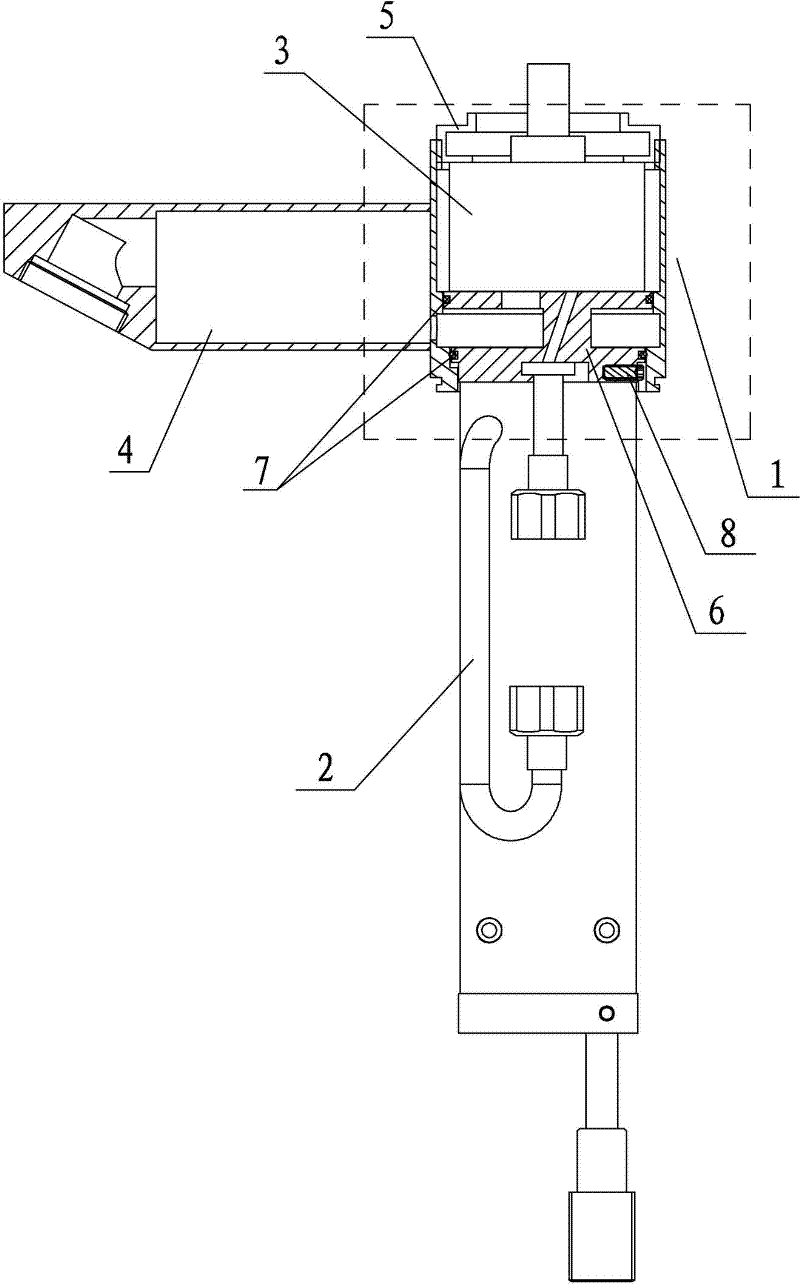

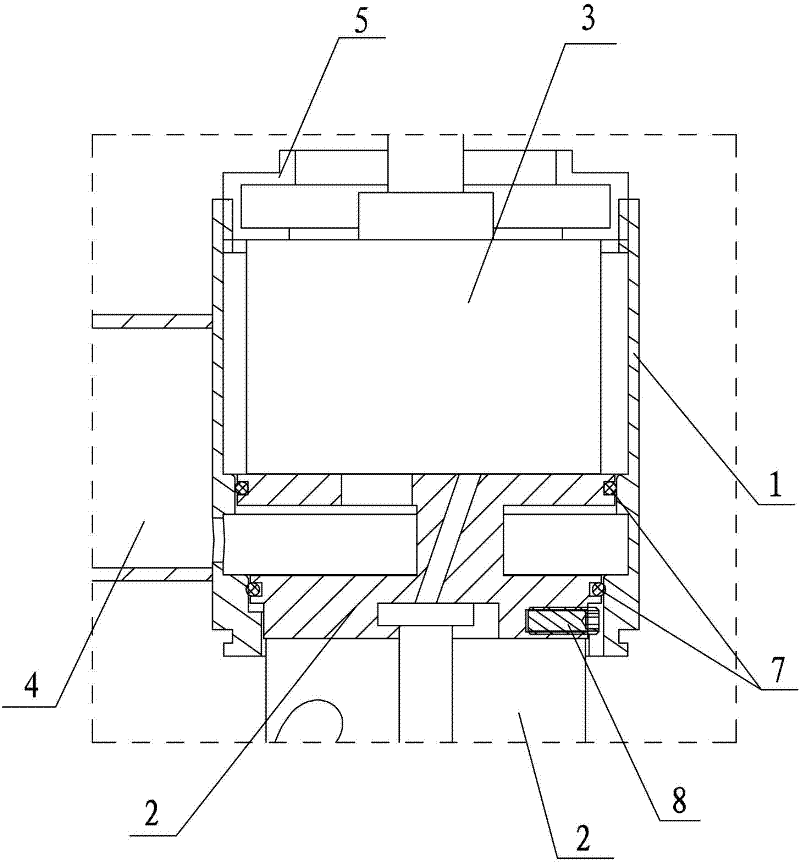

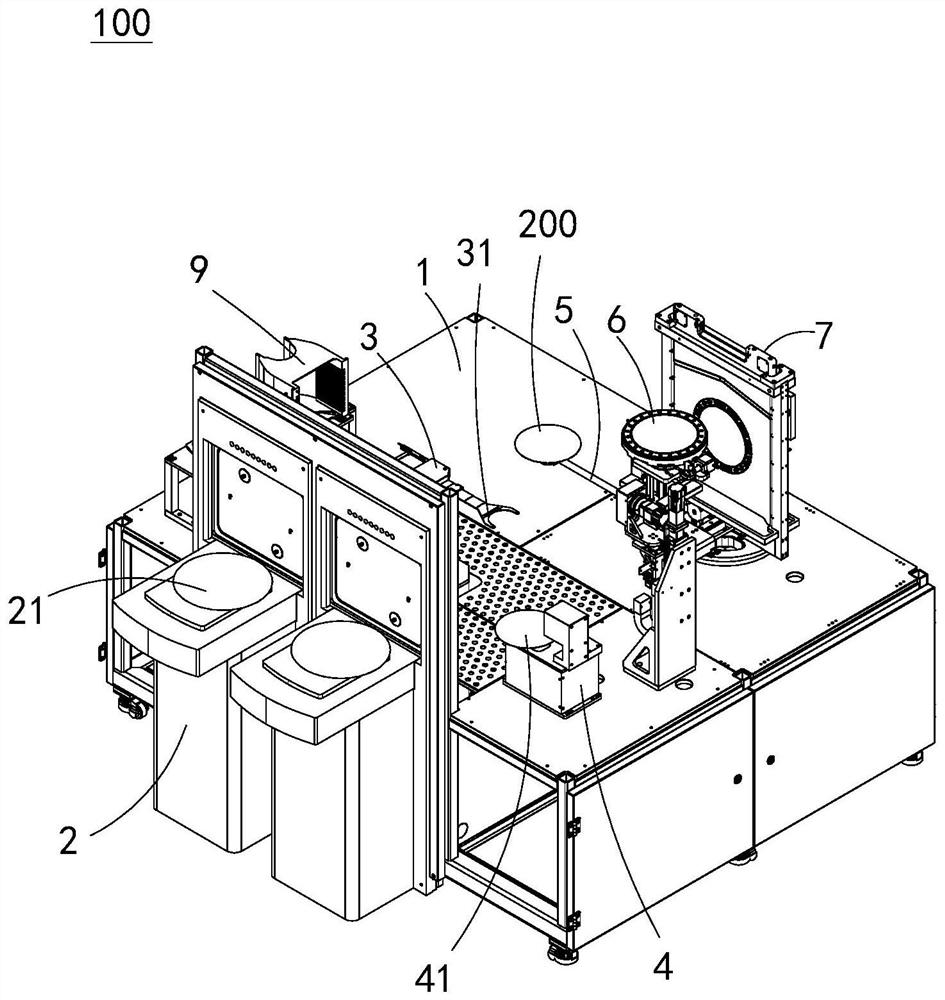

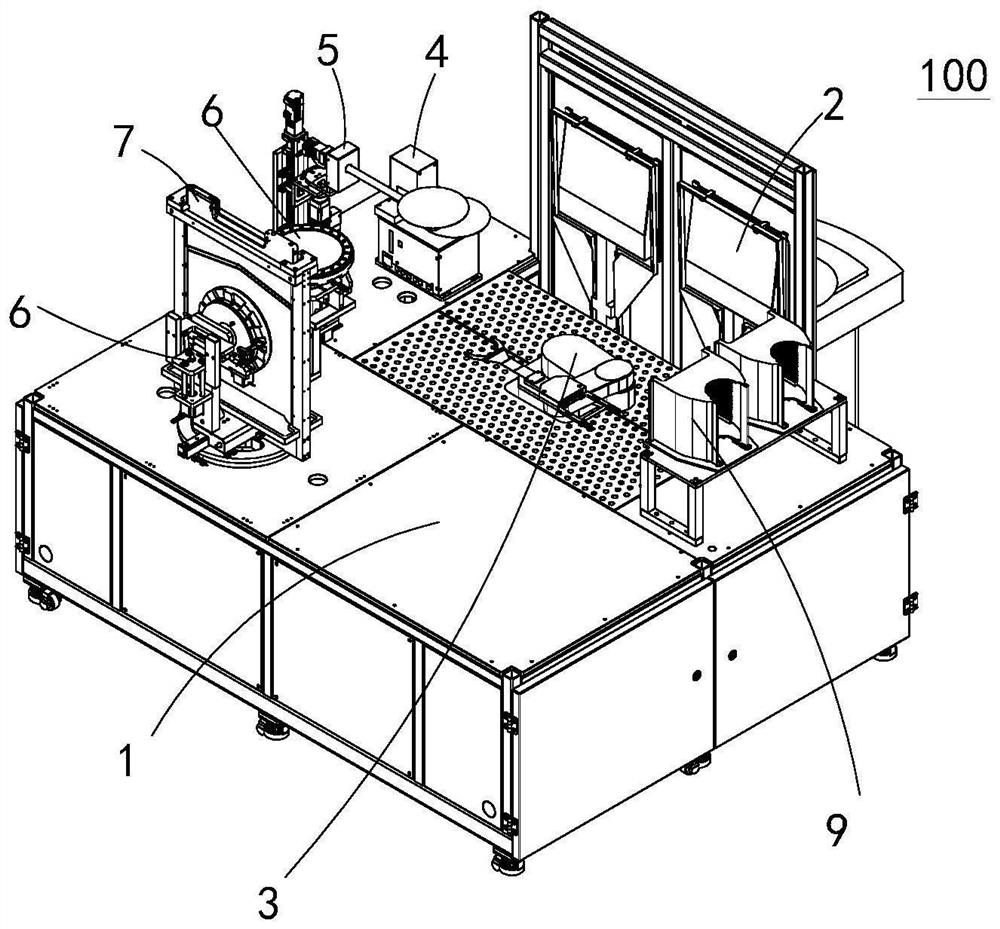

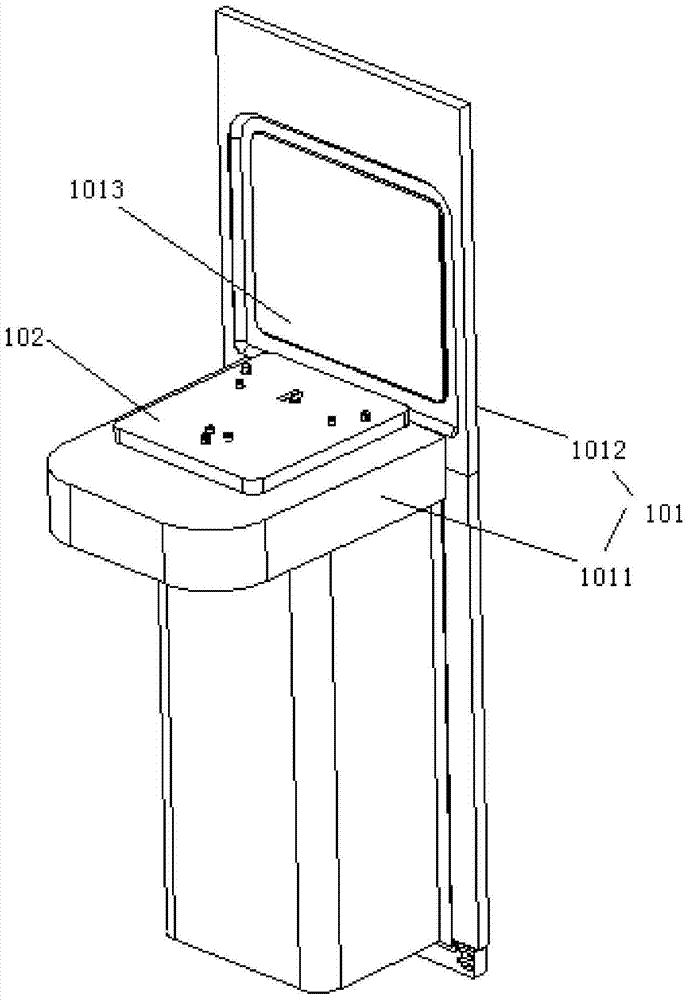

Wafer type product electroplating feeding and discharging equipment

PendingCN113337871AImprove the quality of electroplatingFlipCellsSemiconductor/solid-state device manufacturingRobot handEngineering

The invention discloses wafer type product electroplating feeding and discharging equipment which comprises a workbench, a wafer box loading device, a wafer robot, a wafer calibrator, an overturning manipulator, a mounting and dismounting mechanism, an electroplating hanging tool and a wafer jig. The wafer robot, the wafer calibrator, the overturning manipulator and the mounting and dismounting mechanism are all arranged on the workbench, and the electroplating hanging tool is arranged on the mounting and dismounting mechanism. The wafer box loading device, the wafer calibrator and the overturning manipulator are located in an operation range of a wafer taking arm of the wafer robot. The mounting and dismounting mechanism is located within the operation range of the overturning manipulator, during feeding operation, the wafer products and the wafer jigs are locked and attached to the electroplating hanging tool, and during discharging operation, the wafer products and the wafer jigs are unlocked from the electroplating hanging tool and taken down. Automatic feeding and discharging operation of products can be achieved, equipment operation and control are more flexible, and the efficiency is high.

Owner:厦门柔性电子研究院有限公司 +1

Wafer Handler

ActiveCN104617016BImprove shipping stabilityImprove work efficiencySemiconductor/solid-state device manufacturingEngineeringRejection rate

The invention discloses a wafer processing unit, which is characterized by comprising a wafer electroplating pretreatment device for pre-treating wafers before electroplating, a wafer electroplating device for electroplating the wafers, a wafer cleaning device for cleaning the wafers after electroplating and a manipulator for conveying the wafers from one device to another device. According to the wafer processing unit, the wafer electroplating pretreatment device, the wafer electroplating device and the wafer cleaning device are combined organically; the wafers are conveyed by the manipulator, so that the working efficiency is improved greatly, the manpower is saved, the conveying stability of the wafers is improved, and the damage and rejection rate of the wafers is reduced.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

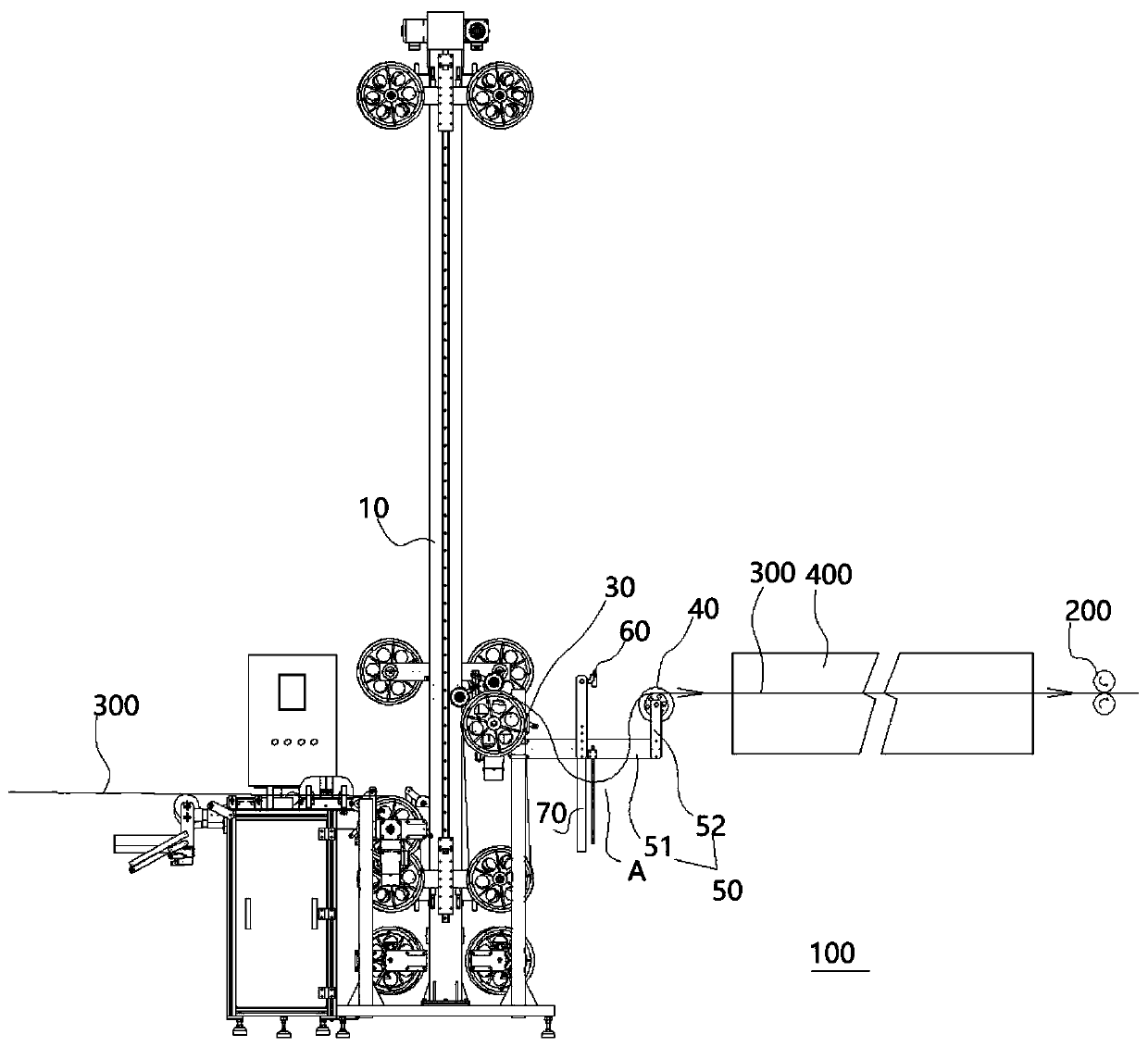

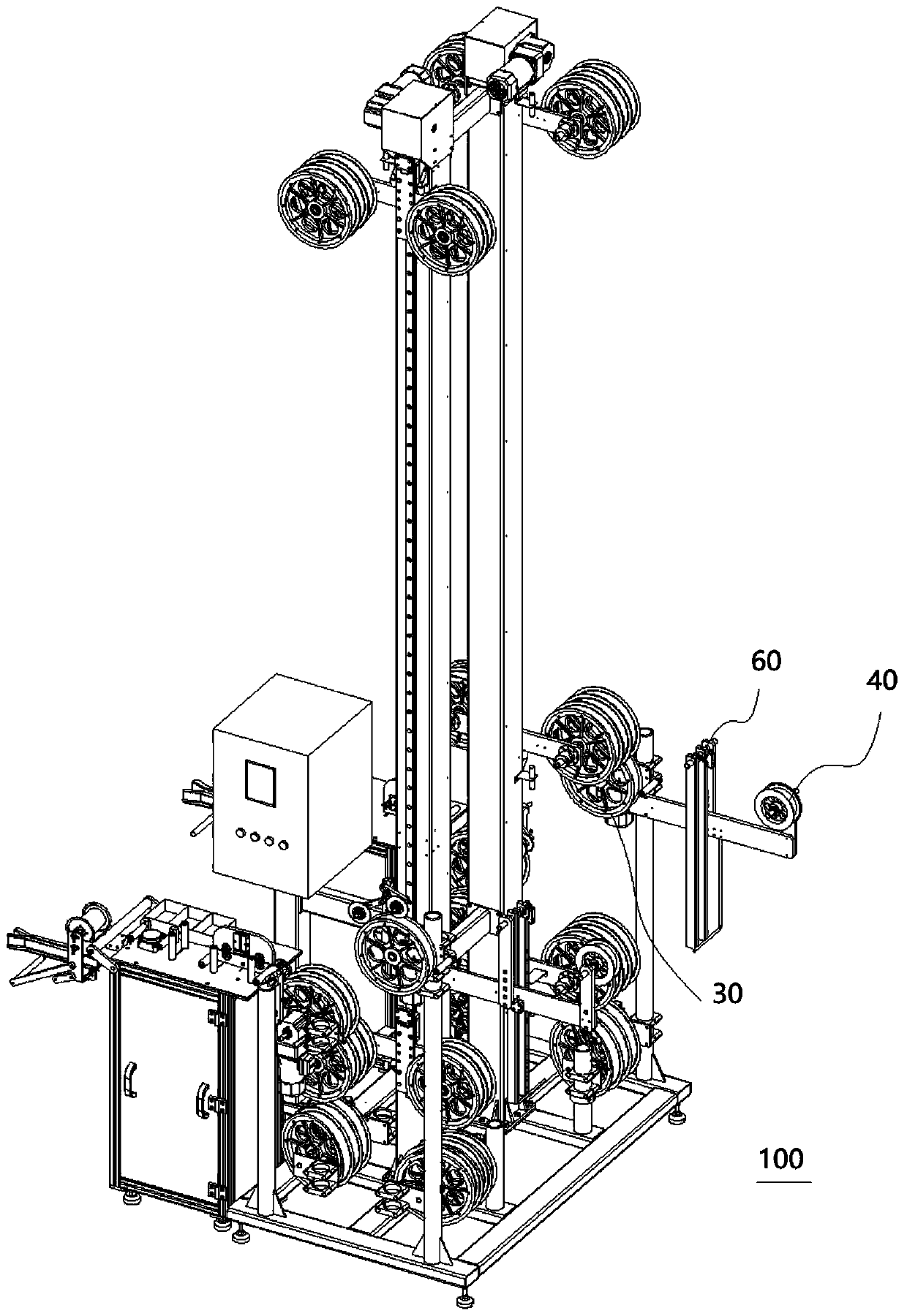

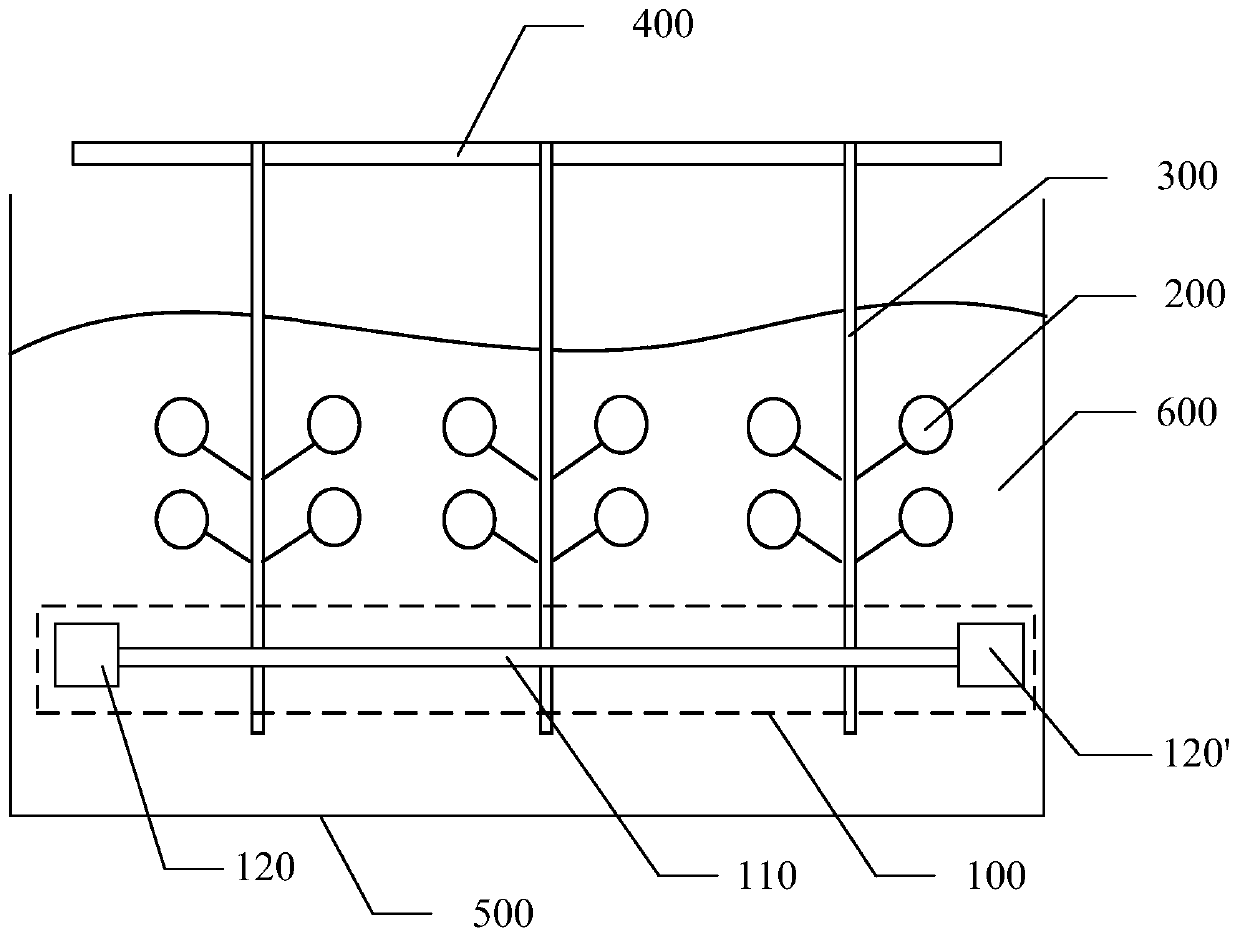

Tension-free buffer device

The invention discloses tension-free buffer device which can be used for being matched with a downstream material belt traction part to convey a material belt into an electroplating tank body betweenthe material belt traction part and the tension-free buffer device. The tension-free buffer device comprises a machine body; an input part, which is arranged in the machine body and used for introducing the material belt into the machine body from the upstream; a discharging wheel which is arranged on the machine body and used for outputting the material belt from the machine body; a guiding part,which is spaced to the discharging wheel to form a tension adjusting area, the linear speed of the guiding part being not larger than that of the material belt traction part, the material belt naturally drooping to enter a tension adjusting area after passing through the discharging wheel, and the guiding part receiving the material belt and conveying the material belt and the material belt traction part into the electroplating bath body in a matched mode; and a driving part which can adjust the linear speed of the discharging wheel according to the drooping shape of the material belt in thetension adjusting area. According to the tension-free buffer device, the material belt can enter the electroplating bath body in a loose state, so that the tension of an electroplating line is reduced, the tension is kept absolutely stable, the electroplating quality is improved, and the production efficiency is improved.

Owner:KUNSHAN YIDING IND TECH CO LTD

Swing device for hanging tool

Owner:SHANDONG TAIKAI HIGH VOLTAGE SWITCH

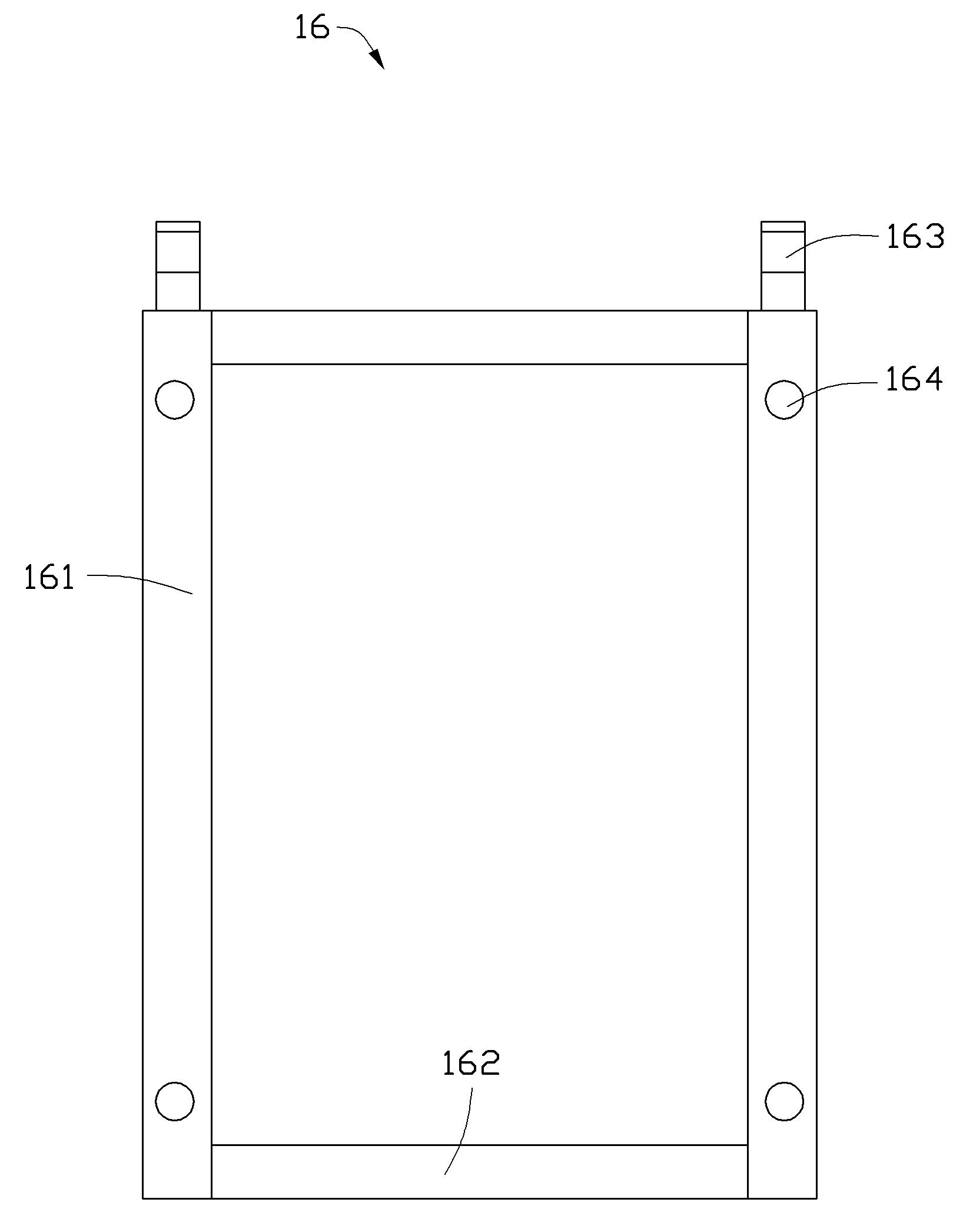

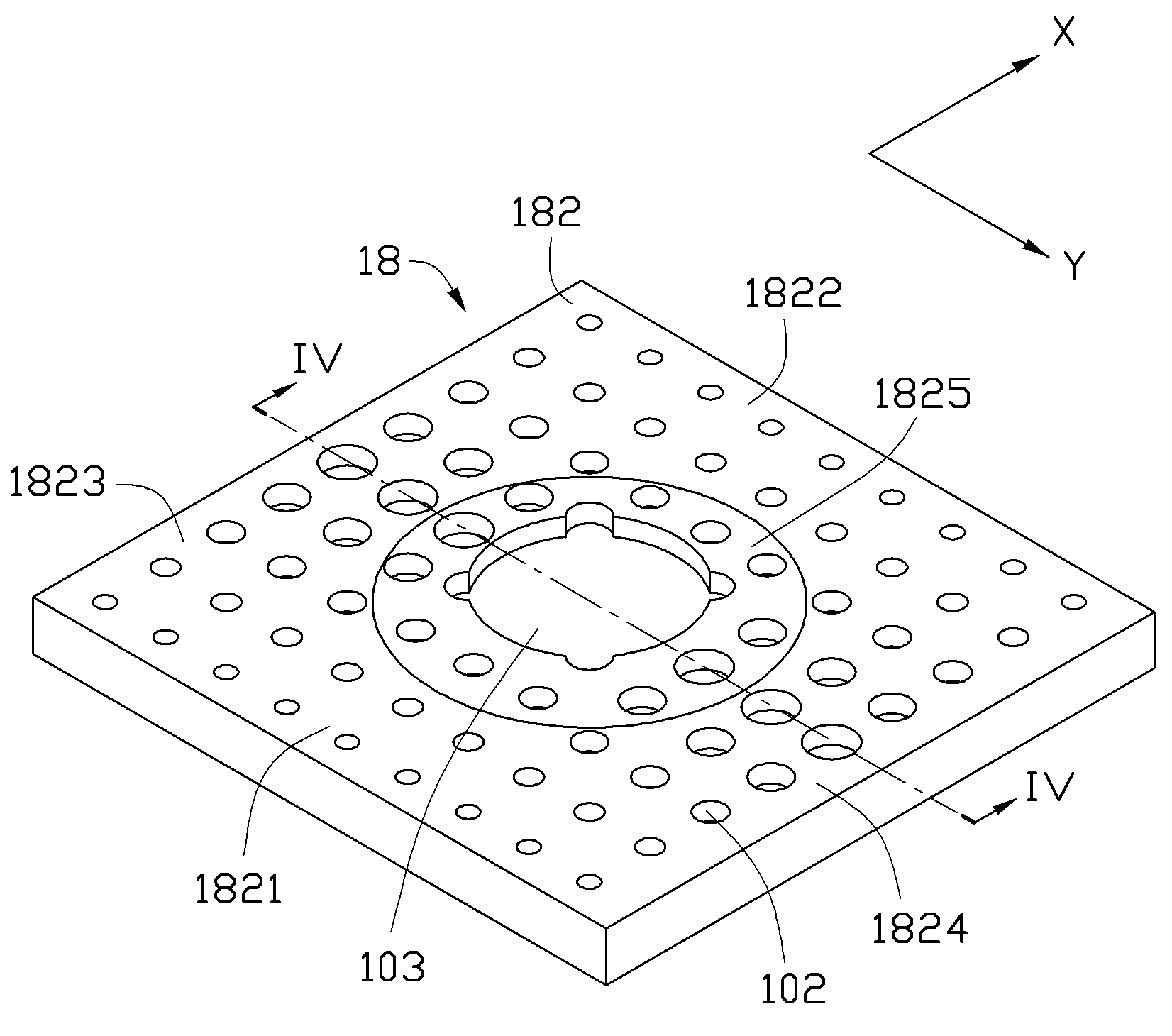

Zipper head automatic anodizing equipment

ActiveCN103469270BImprove the quality of electroplatingImprove plating qualityCellsSlide fastenersControl systemEngineering

The invention provides an automatic anodizing equipment for zipper sliders. The plating tank consisting of a pre-plating treatment tank, a plating treatment tank and a post-plating treatment tank is connected from end to end to form a closed ring. The anode generator is installed on a vertical guide rail. The guide rail is connected with the chain of the walking device, and the anode generator is also provided with rollers, which rest on the horizontal circular track, and the circular track can rise and fall under the drive of the lifting device; in the control system, the walking device and the lifting Under the action of the device, the anode generator walks intermittently on the circular track, and cycles in the order of rising, walking, falling, and staying. The present invention enables the zipper head to be electroplated continuously through automated equipment, which greatly improves the production efficiency of electroplating, and controls the time of each process by an intelligent program. The electroplating quality is high, and the electroplating quality of the zipper head is improved. The labor intensity is reduced, and the on-site environment is improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

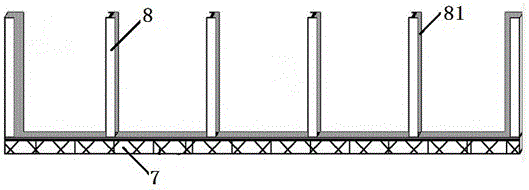

Drying equipment in LED bracket electroplating

InactiveCN107631602AEvenly heatedImprove qualityDrying gas arrangementsDrying machines with progressive movementsEngineeringMechanical engineering

The invention discloses drying equipment in LED bracket electroplating. The drying equipment comprises an automatic drying device body. The bottoms of shells of the two sides of the automatic drying device body are fixedly provided with a first drying fan and a second drying fan in a symmetrical and screwed mode through fixing bottom plates. The first drying fan and the second drying fan communicate with the interior of the automatic drying device body through flow equalizing plates. The vertical centerline of the interior of the automatic drying device body is rotationally connected with a drying transmission chain frame through a top driving wheel. The lower portion of the interior of the drying transmission chain frame is rotationally connected with a bottom driven wheel. According to the drying equipment, firstly, a drying frame is designed to be of a structure of the drying transmission chain frame and can be driven to rotate by the top driving wheel during drying, so that parts on the drying transmission chain frame can be heated evenly, thus the drying equipment in LED bracket electroplating is better in drying quality, and improves the product electroplating quality.

Owner:CHENGDU KECHUANGCHENG TECH

Plating method

ActiveCN102828211BFlexible adjustment of the directly facing areaImprove the quality of electroplatingCellsElectroplatingCathode

Owner:东莞市五株电子科技有限公司

A kind of tinned copper wire electroplating method

ActiveCN110528040BNo contactAvoid Plating FailureEdge grinding machinesCellsCopper wireElectric machine

The invention belongs to the technical field of electroplating, specifically a tinned copper wire electroplating method. The electroplating device used in the present invention includes an electroplating pool. Both sides of the top of the electroplating pool are installed with rotating shafts through the rotation of the mounting plate. Two The surface of the rotating shaft is fixed with more than two pulleys at equal distances, the top of the electroplating pool is fixed with a dryer, and the bottom of the inner cavity of the electroplating pool is equidistantly provided with more than two rectangular grooves, each of which is slidably connected with sleeves. Two or more rollers are arranged on both sides of the electroplating pool, and the rollers on one side of the electroplating pool are all driven by a motor, and a controller is provided on the electroplating pool; the electroplating device used in the present invention includes a push The structure of the rod motor and the piston can push the casing to move continuously during the movement of the piston. During the movement of the casing, it drives the electroplating solution in the electroplating pool to oscillate, so that the impurities in the electroplating pool will not precipitate, and also make the The electroplating solution is more uniform, which improves the electroplating effect.

Owner:浙江东翼新材料有限公司

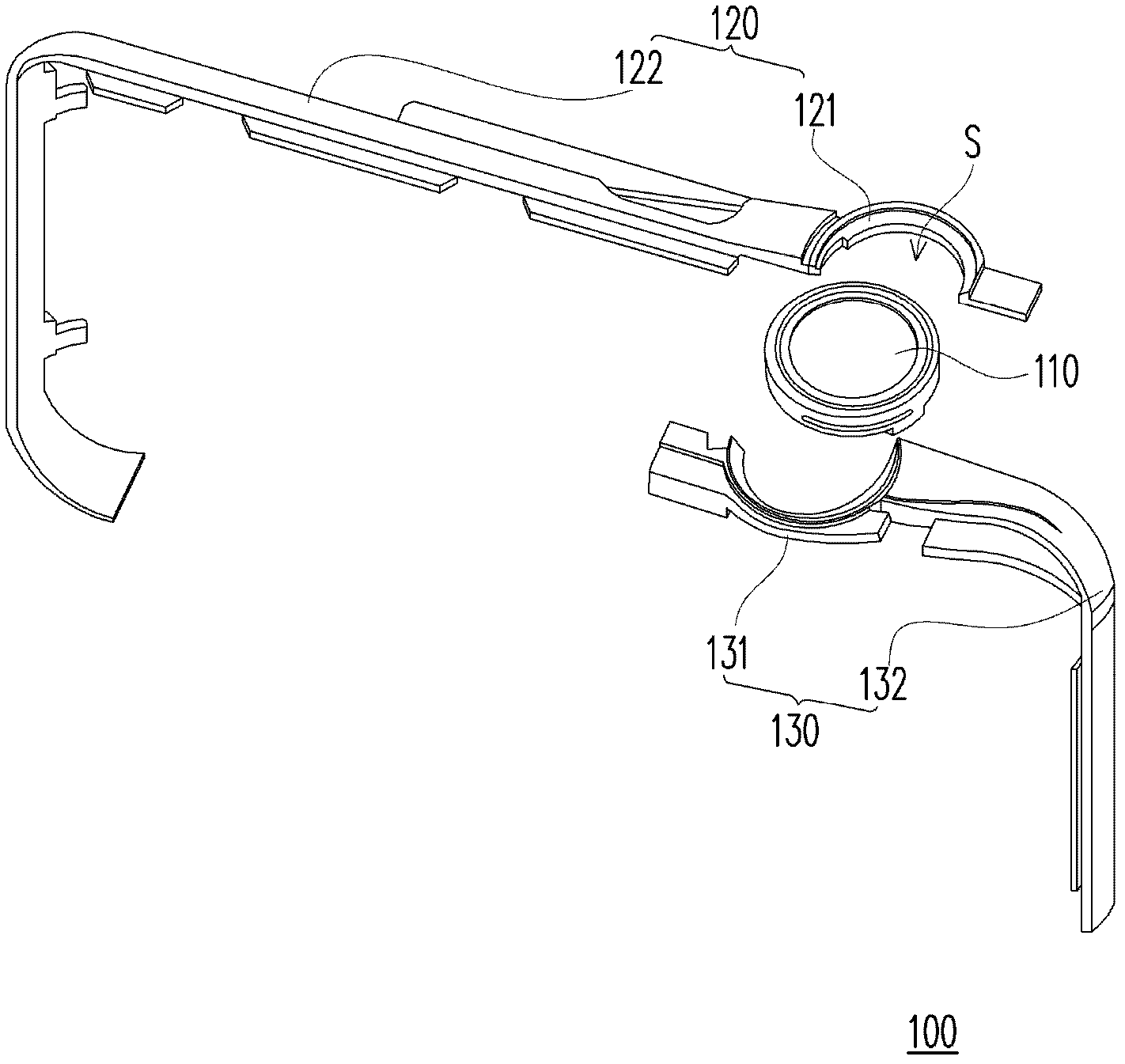

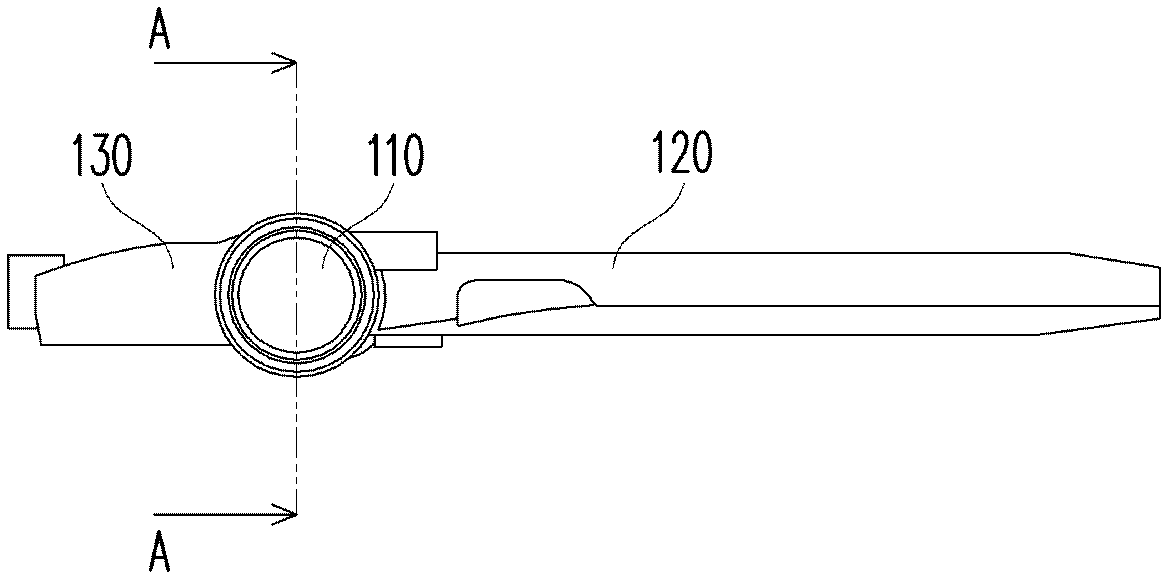

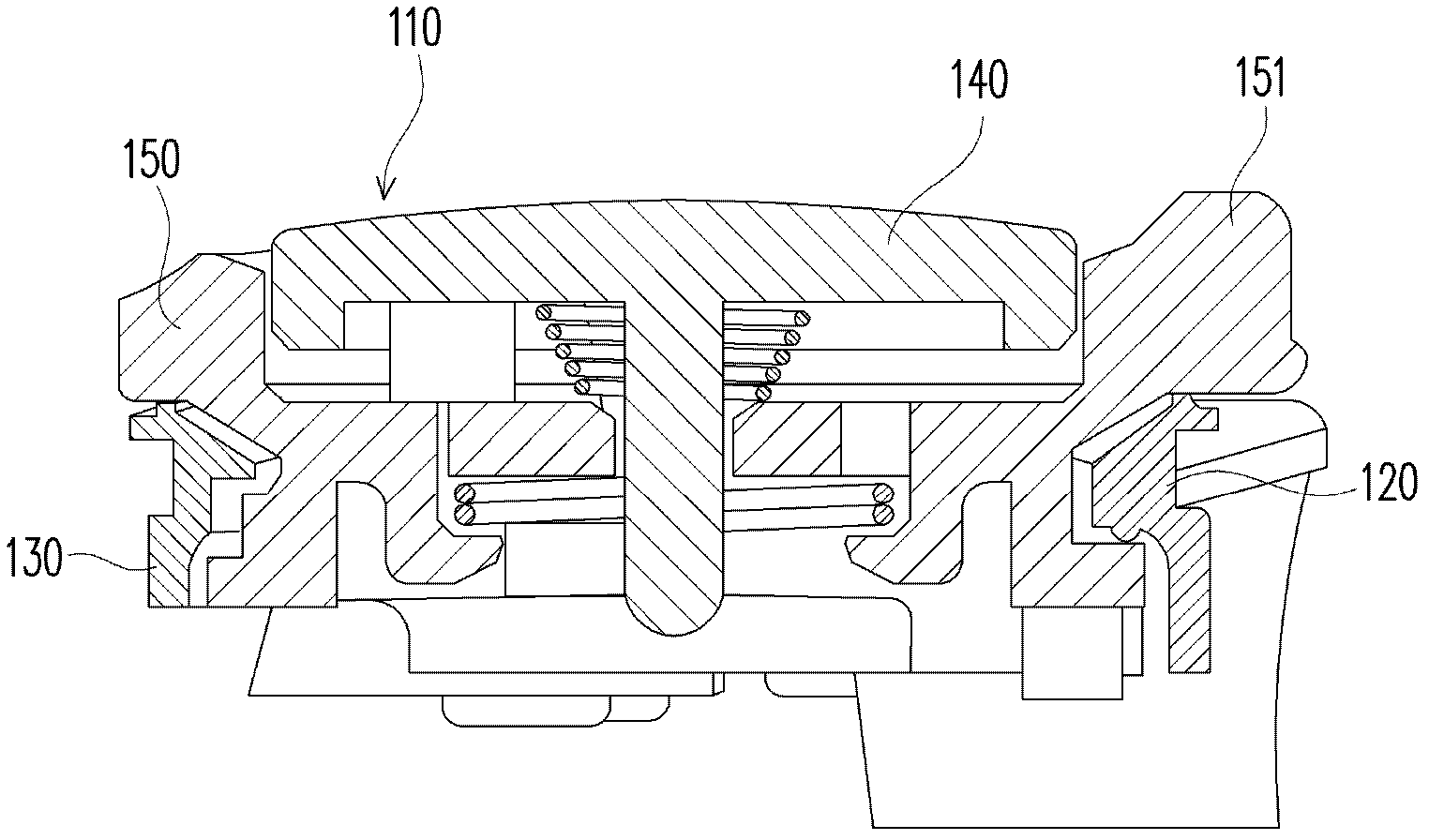

Zooming key structure

InactiveCN102810423BImprove molding qualityImprove the quality of electroplatingElectric switchesEngineeringMechanical engineering

Owner:ALTEK CORP

Vertical Continuous Plating Equipment

ActiveCN112760701BGentle curveReduce usageCellsCurrent conducting devicesElectrical connectionControl cell

The invention relates to the field of circuit board production, and provides a vertical continuous electroplating equipment, which includes a cathode conveyor belt, a clamp, an electroplating tank and an anode on-off assembly. The anode insulation section connected between two adjacent anode conductive sections, each anode conductive section is connected to the positive pole of the rectifier in parallel; the anode on-off assembly includes a first inductor, a first control unit electrically connected to the first inductor, and multiple An anode switch electrically connected to the first control unit, the first control unit is used to calculate the time for the plate to pass through each anode conductive section according to the speed of the plate when the plate passes the first sensor, and to control the anode switch on the plate Closed when passing the anode conductive section, and open when no plate passes the anode conductive section. The vertical continuous electroplating equipment can achieve precise electroplating on the board, basically avoid the use of accompanying plating boards, increase production capacity, reduce costs, improve electroplating quality, and reduce the difference in copper plating thickness of each board.

Owner:KINWONG ELECTRONIC TECH (ZHUHAI) CO LTD

A kind of tin plating leveling method for circuit board

ActiveCN107937972BUniform thicknessImprove immersionCellsPrinted circuit manufactureTin platingEngineering

The invention relates to the field of circuit board machining methods, and particularly discloses a tin plating leveling method for a circuit board. According to the tin plating leveling method for the circuit board, a tin plating device is adopted, a spraying mechanism in the tin plating device can be used for enhancing the liquidity of an electroplating solution in an electroplating box in the tin plating process, and the electroplating solution on the two sides of the circuit board can be exchanged, so that the electroplating solution in the whole electroplating box is uniform and stable and the electroplating efficiency of the circuit board can be effectively improved.

Owner:重庆市志益鑫电子科技有限公司

A kind of reusable electroplating method for accompanying plate

ActiveCN110602891BAchieve reuseReduce manufacturing costPrinted circuit manufactureMetallurgyProtection layer

The invention relates to the technical field of printed circuit boards, in particular to a reusable electroplating method for accompanying plating boards. When the present invention uses VCP to carry out the electroplating process to the production board, use the accompanying plating plate with electroplated nickel-gold layer as the etching protection layer, and make the accompanying plating plate go through alkaline once when the production board of each line completes the electroplating treatment. Etching line, remove the copper layer formed on the surface of the accompanying plated plate during the electroplating process through etching, so that the accompanying plated plate can be restored to the state before use, so that it can be re-used in the electroplating process, realizing the reuse of the accompanying plated plate, completely avoiding It solves the problems that the existing accompanying plated plate will deteriorate in appearance and become heavier and thicker as the number of times of use increases, which will cause the accompanying plated plate to drop, fixture damage, copper cylinder pollution and other problems during the electroplating process, which can reduce production costs and improve production efficiency. 10 The production capacity of 10,000 square meters can save about 15,000 yuan in the production cost of accompanying plated plates.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

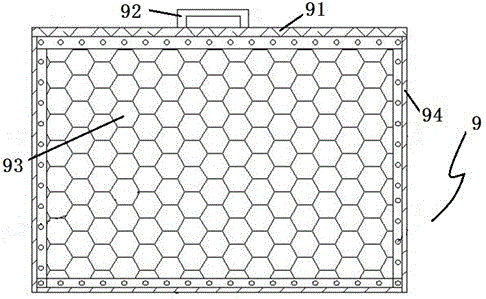

PCB copper electroplating groove

ActiveCN102392281BEffective filteringReduce pollutionCellsPrinted circuit manufactureBiochemical engineeringCopper

The invention relates to a PCB copper electroplating groove, which comprises a groove body, two positive electrodes disposed on two sidewalls of the groove body and a kickboard rack which is arranged in the middle of the groove body and is used for disposing a PCB. One end of the groove body below the kickboard rack is provided with a water inlet. An installation groove for a screen filter is disposed near the kickboard rack between the kickboard rack and the two positive electrodes. The installation groove for the screen filter is provided with the screen filter. One end of the groove body between the screen filter and the two positive electrodes is provided with a water outlet externally connected with a filter. The screen filter concretely contains a fixed pedestal, a plurality of clamp poles vertically arranged on the fixed pedestal and a plurality of filters installed between the clamp poles, wherein the filter comprises a bracing frame, a handle arranged on the top of the bracing frame and filter cloth arranged on the side surface of the bracing frame; strip-shaped grooves are disposed on the side of the clamp poles; strip-shaped bosses are correspondingly arranged on the two sides of the filters; and the filters can be detachably installed on the clamp poles through the joint of the bosses and the grooves. According to the invention, copper ash and impurities in the copper grooves can be effectively minimized and the copper electroplating groove pollution can be prevented.

Owner:南通胜宏科技有限公司

Semiconductor package and manufacturing method thereof

ActiveCN105321894BReduce roughnessImprove the quality of electroplatingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

Owner:SILICONWARE PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com