Stereo graphic pattern structure of circuit board and technique thereof

A patterning, circuit board technology, applied in printed circuits, printed circuit manufacturing, printed circuit components, etc., to achieve the effect of improving reliability, improving electroplating quality, and improving heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

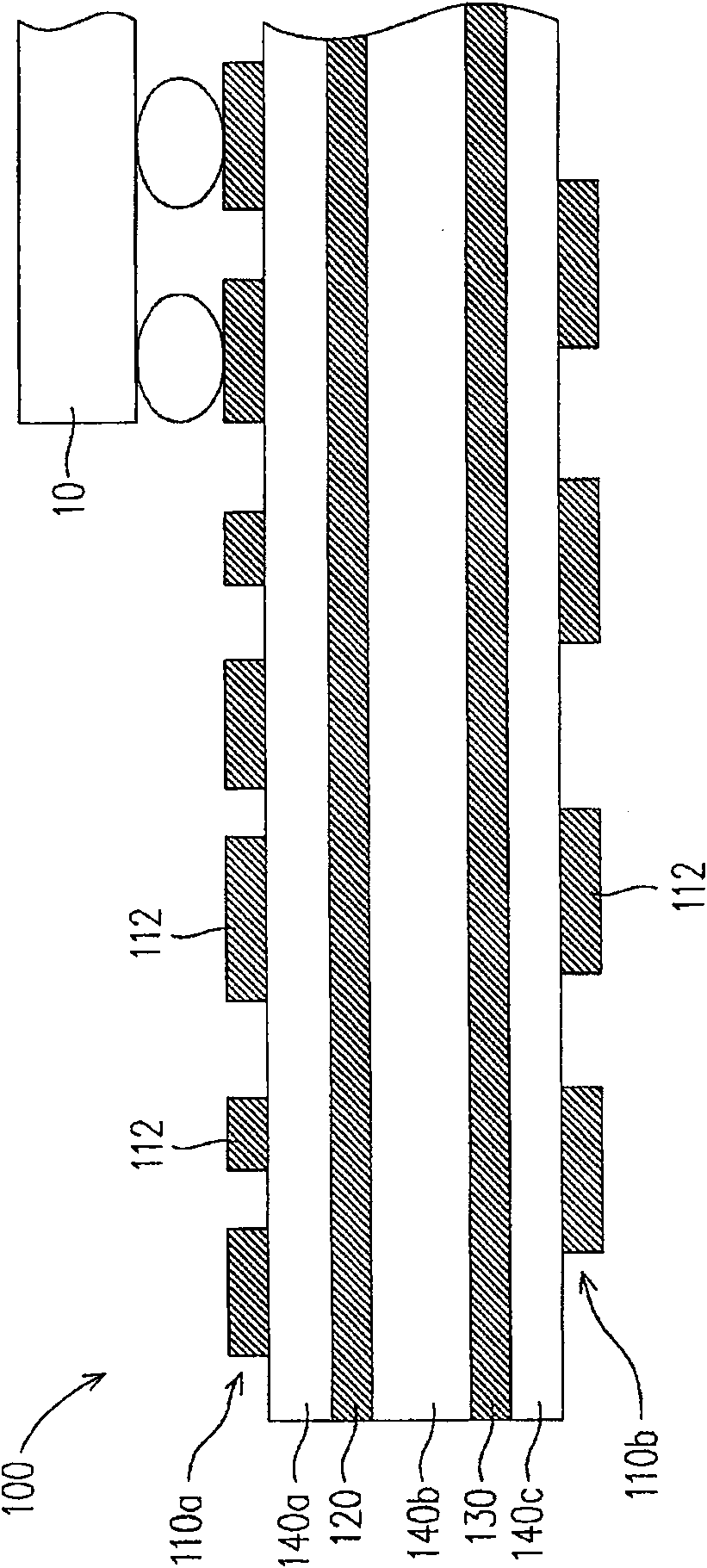

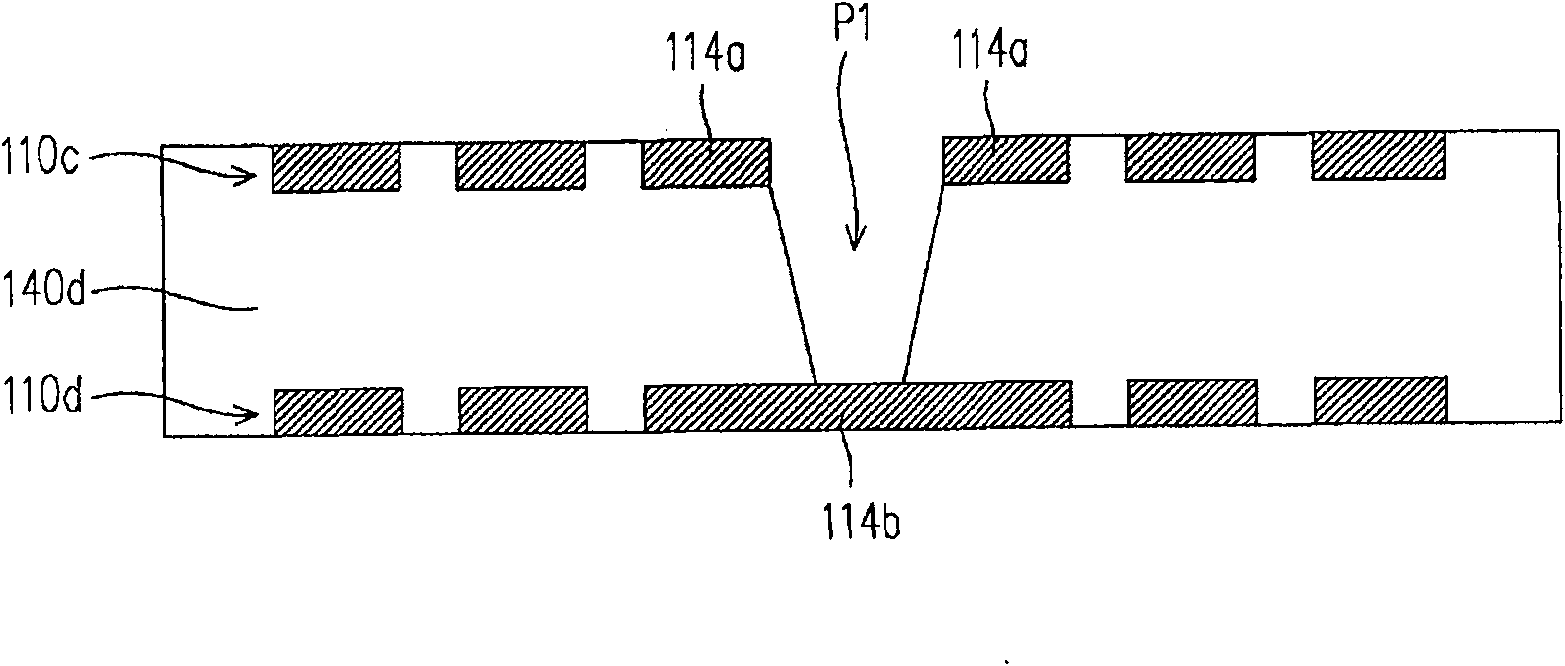

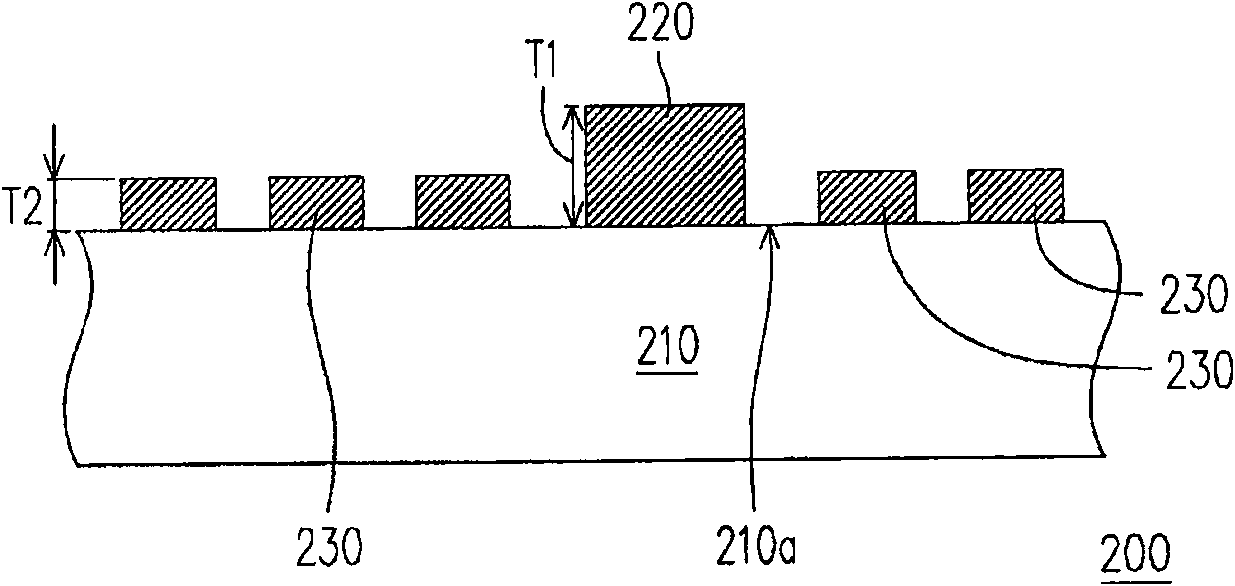

[0042] Figure 2A is a schematic cross-sectional view of a three-dimensional patterned structure of a circuit board according to an embodiment of the present invention, and Figure 2B is a schematic cross-sectional view of a three-dimensional patterned structure of a circuit board according to another embodiment of the present invention. It should be explained in advance that the circuit board can be a two-layer, four-layer, six-layer, eight-layer or more multi-layer circuit board, and the diagram is only represented by the configuration of the three-dimensional patterned structure. Figure 2A Can be used as the outermost circuit layer of the circuit board, while Figure 2BIt can be used as the circuit structure of any layer in the circuit board. Therefore, the circuit board can choose to complete the three-dimensional patterned structure of the present invention as the outermost circuit layer by layer-building method or lamination method after completing the inner layer cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com