PCB copper electroplating groove

A technology of electroplating copper and tank body, which is applied in the direction of electrical components, electrolytic process, electrolytic components, etc., can solve the problems that cannot meet the quality and safety requirements of PCB, shorten the periodical maintenance time, and reduce the pollution of copper tank liquid, etc., to achieve Prevent pollution, improve the quality of electroplating, and reduce the effect of copper slag and impurities in copper tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

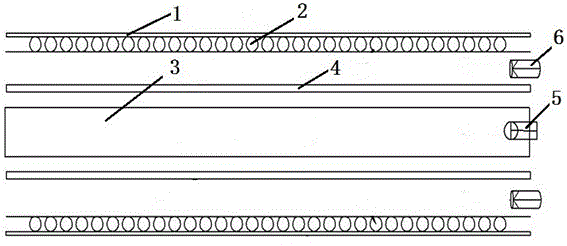

[0023] Such as figure 1 , 2 , 3, a copper electroplating tank for PCB, including a tank body 1, two anodes 2 arranged on both sides of the tank body and a floating board frame 3 arranged in the middle of the tank body for placing PCB boards, below the floating board frame One end of the tank body is provided with a water inlet 5, and a filter screen installation slot 4 is provided between the floating plate frame and the two anodes close to the floating plate frame, and a filter screen is installed on the filter screen installation slot, and the filter screen passes through the fixed base frame and the The plugging of the filter screen installation groove is installed in the tank body, and one end of the tank body between the filter screen and the two anodes is provided with a water outlet 6 for an external filter. In the utility model, a filter screen is arranged in the tank body, combined with the water inlet and the outlet of the external filter, the tank liquid flows betw...

Embodiment 2

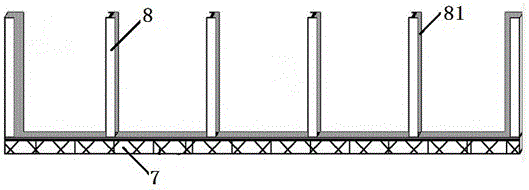

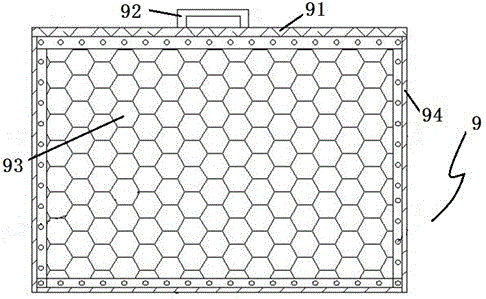

[0029] The PCB electroplating copper tank of this embodiment is the same as most of them, the difference is that the filter screen of this embodiment is provided with seven clamping columns 8 vertically arranged on the fixed base frame and six clamping columns installed between the clamping columns. filter sheet 9. And the length of the filter screen is 6000mm, and the filter screen is provided with six equidistant and side-by-side clamping columns, the distance between adjacent clamping columns is 1000mm, and the length of the clamping columns is preferably 900mm. The width of the groove on the card post should be 50mm. In addition, in this embodiment, the filter cloth is polypropylene filter cloth.

[0030] After the PCB electroplating copper tank of this embodiment is applied to the PCB electroplating process, it can also effectively improve the filtration efficiency, and use the copper particles produced by the anode to isolate them from the cathode, which helps to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com