Split type electric-heating water tap

An electric hot water faucet, split-type technology, applied to valve heating/cooling devices, valve details, engine components, etc., can solve problems such as cross-contamination, increase plating time, affect plating quality, etc., to improve plating quality and save costs , the effect of reducing the plating surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

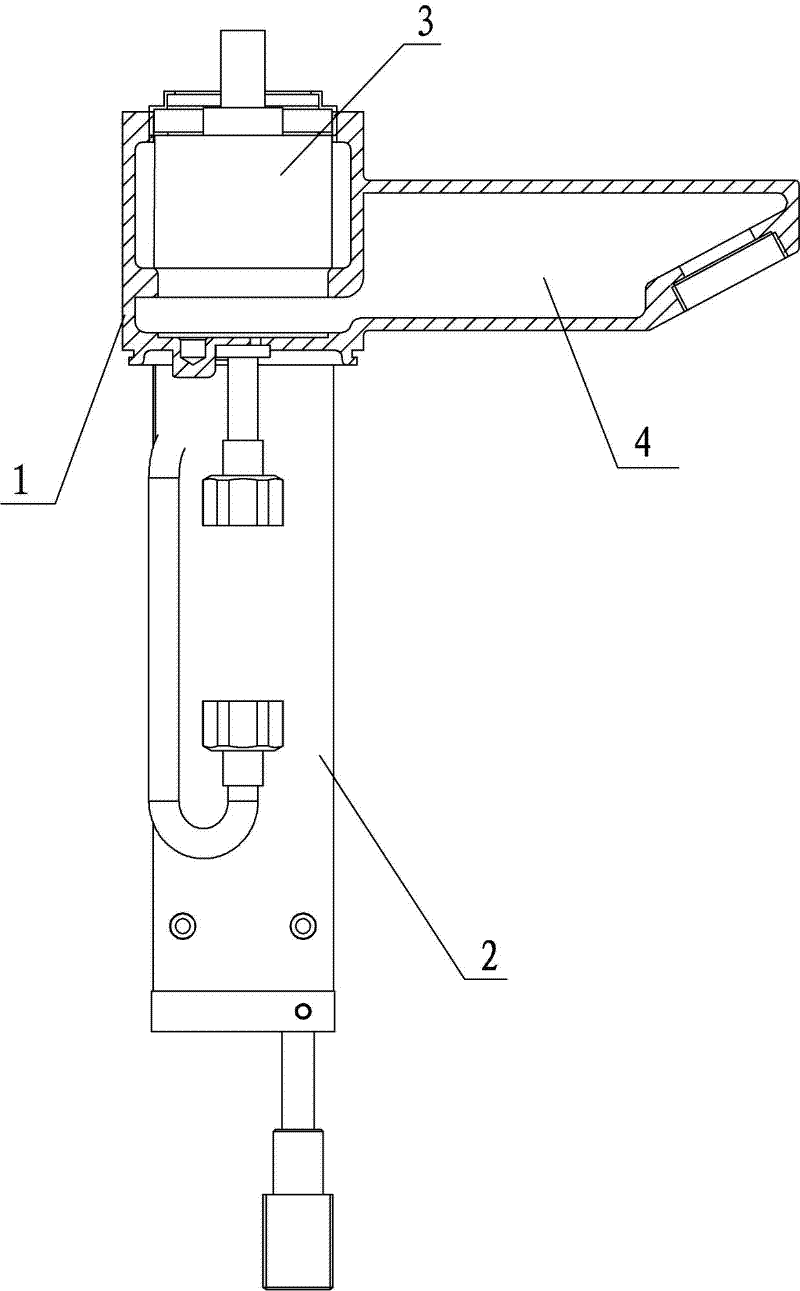

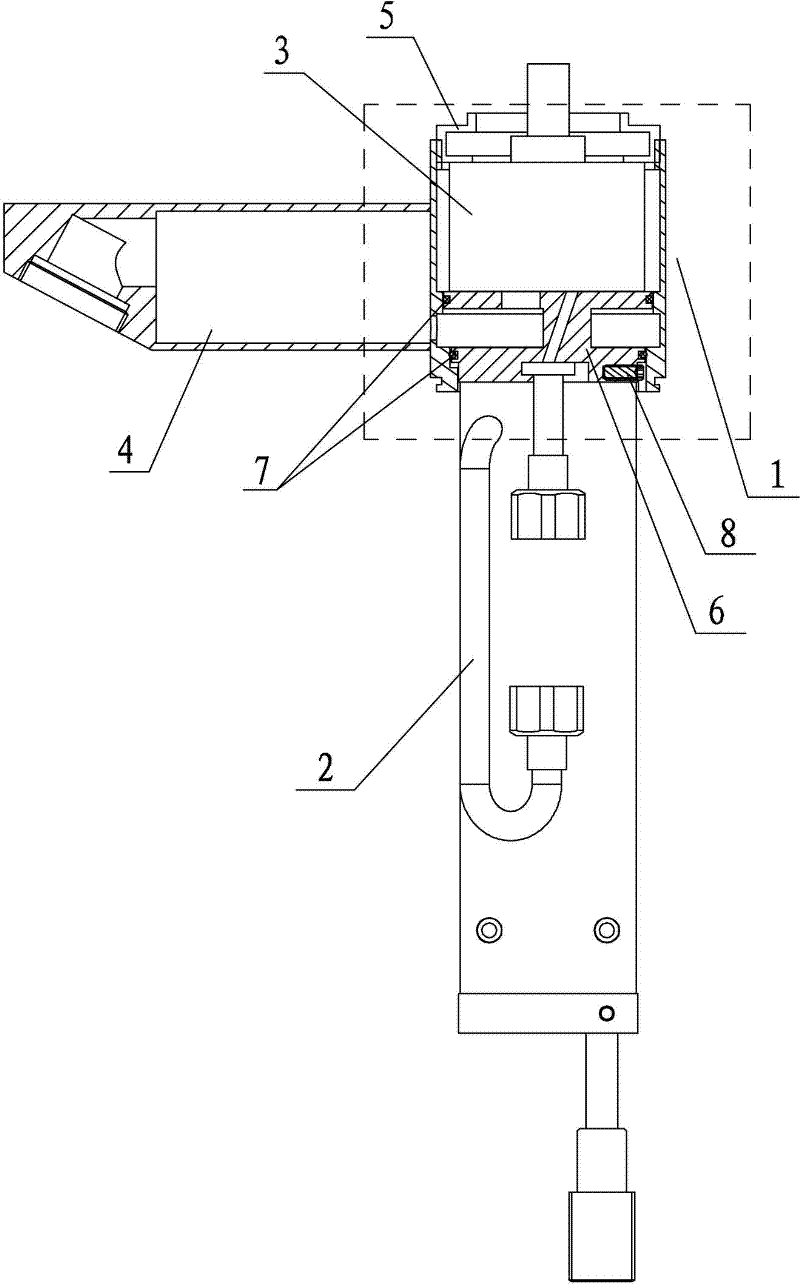

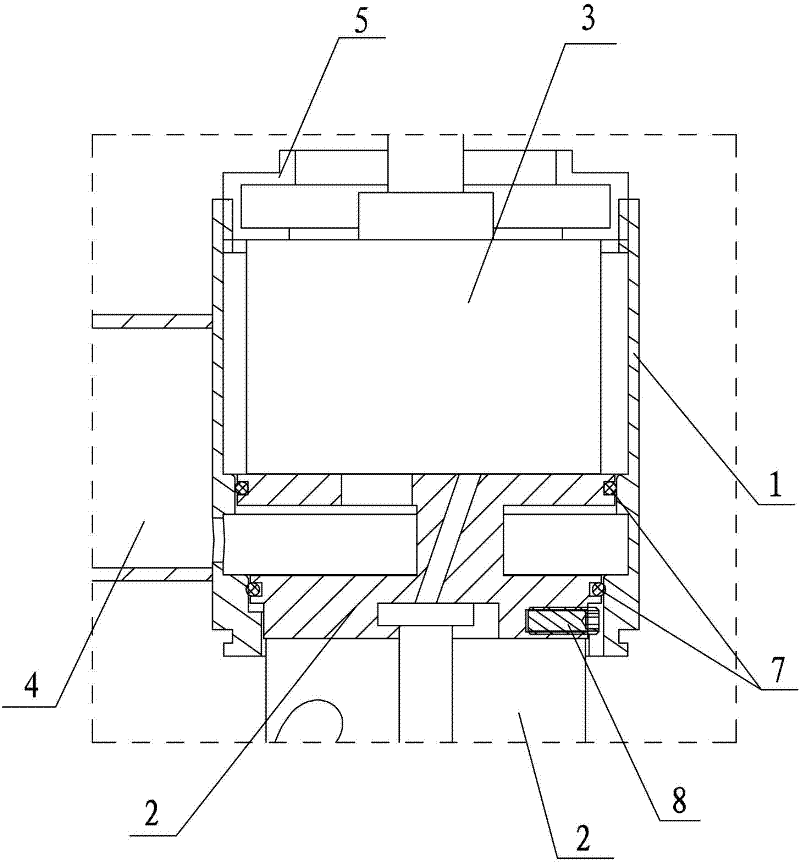

[0018] refer to Figure 2 ~ Figure 3 , a split-type electric hot water faucet, including a water outlet pipe 4 and a body 1, the water outlet pipe 4 communicates with the body 1, a valve core 3 is provided at the communication position, and a detachable connection with the electric heating sheet is provided under the body 1 Dividing tank 2. Certainly, according to the conventional design, the valve core 3 is controlled by a handle arranged outside the body 1 .

[0019] Further as a preferred embodiment, the upper part of the body 1 is provided with an upper cover 5, and the upper cover 5 seals the upper part of the valve core 3 to prevent it from detaching from the main body 1, and the upper end of the water separation chamber 2 is connected with a valve core The base 6, the valve core base 6 is tightly matched with the inner wall of the body 1 and withstands the lower end of the valve core 3. On the lower edge of the body 1, there is a step against the lower end of the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com