Wafer processing unit

A technology for processing devices and wafers, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as low placement accuracy, inability to guarantee wafer stability, and wafer damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

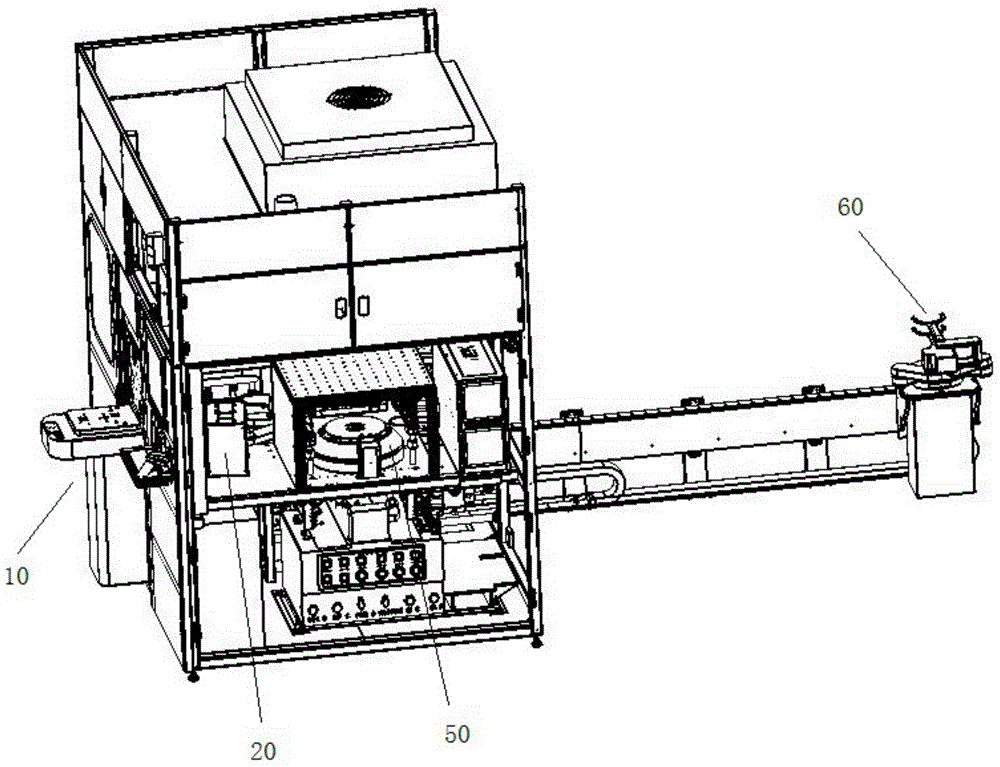

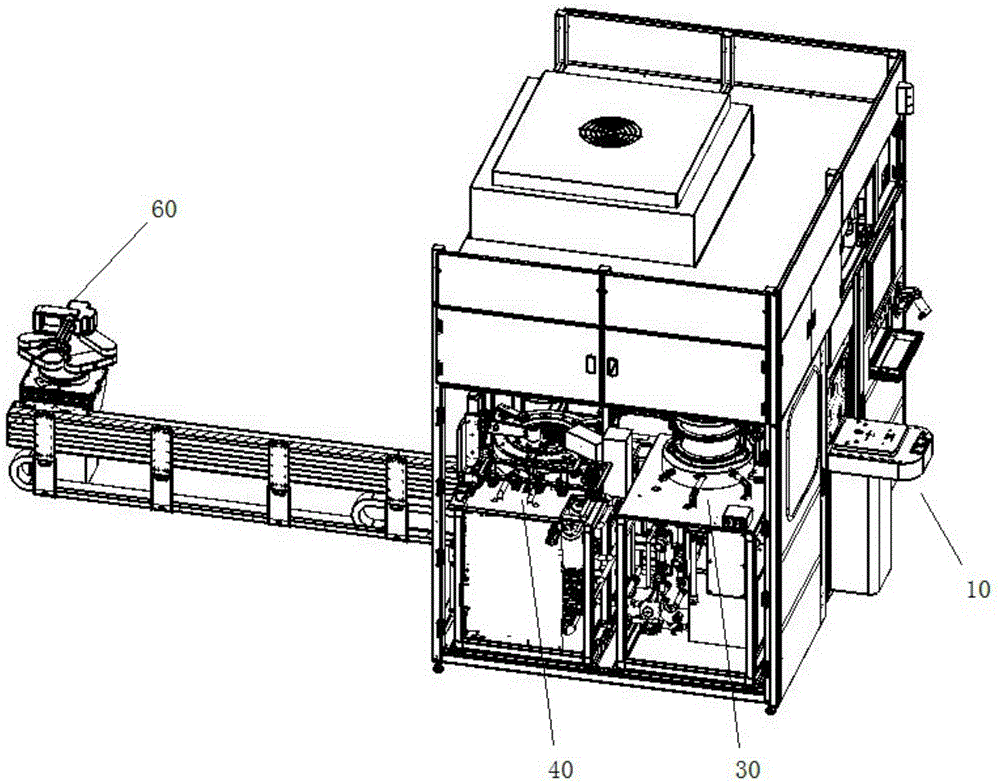

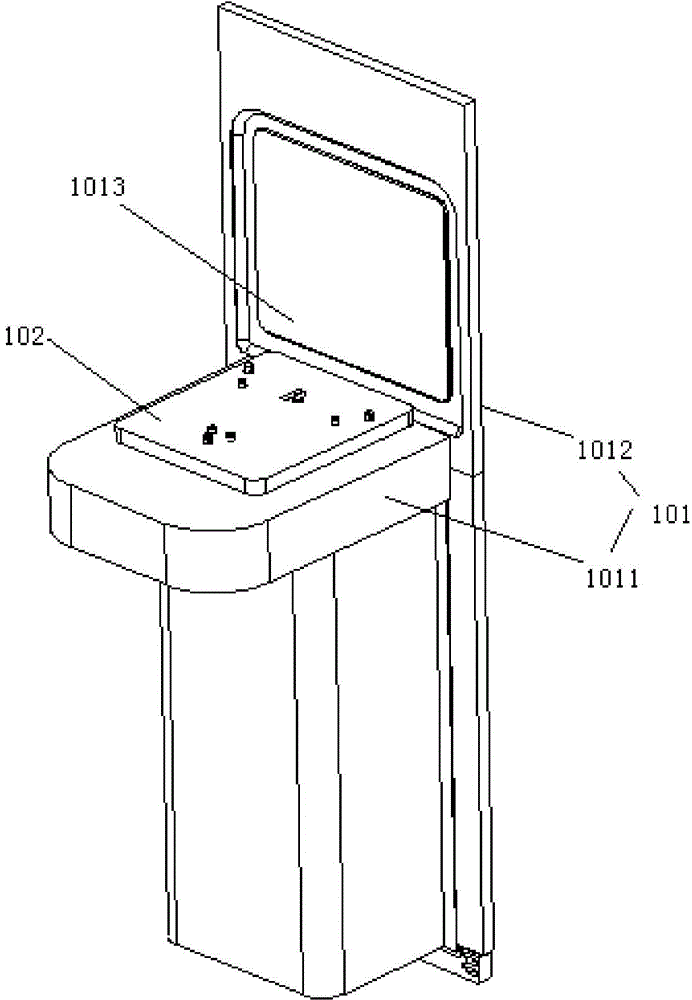

[0156] Such as figure 1 with 2 As shown, the wafer processing device includes a wafer storage box cover opening device 10 , a wafer position calibration device 20 , a wafer pre-plating processing device 30 , a wafer plating device 40 , a wafer cleaning device 50 , and a manipulator 60 . The manipulator 60 is used to transport the wafer 01 from the above-mentioned one device to the other device. The structure of manipulator 60 is prior art. The manipulator takes out the wafer from the wafer storage box, sends the wafer to the wafer electroplating pretreatment device for protection treatment, and then takes it out and sends it to the wafer electroplating device for electroplating treatment. After the electroplating is completed, the wafer is taken out by the robot and sent to the cleaning device for cleaning. After the cleaning is completed, the manipulator places the wafer on the wafer position calibration device for calibration. After the wafer position is appropriate, the ...

Embodiment 2

[0249] Different from Embodiment 1, the transmitter and receiver of the photoelectric sensor in this embodiment are located on the same side of the wafer. When the receiver can receive the beam emitted by the transmitter, it means that the beam is reflected by the wafer. When the receiver cannot receive the light beam emitted by the transmitter, it means that the light beam passes through the second through hole 011 , and the wafer 01 is located at a designated position on the support column 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com