Circulating water pump motor carrying device

A circulating water pump and handling device technology, which is applied in the field of circulating water pump motor handling devices, can solve the problems of difficulty in ensuring the personal safety of workers, impractical weight of circulating water pump motors, and heavy motor weight, so as to prevent overload operation, facilitate movement, The effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

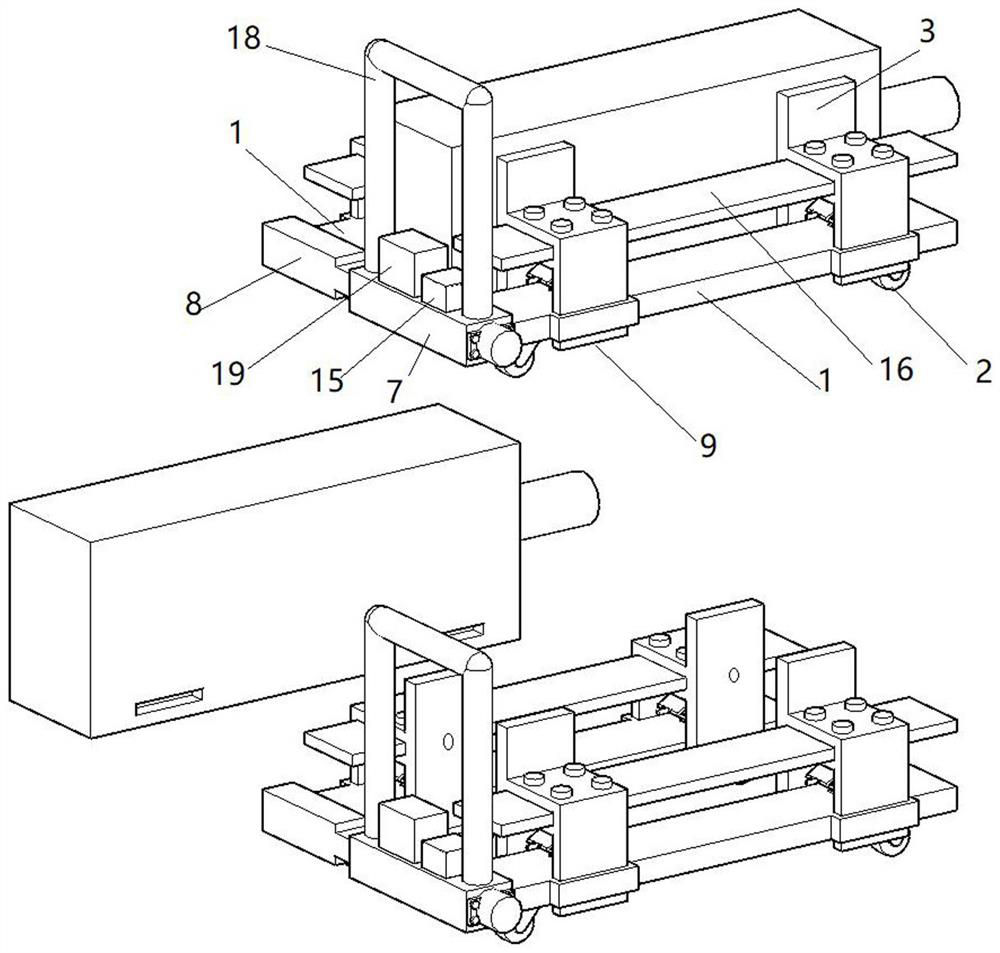

[0025] Such as Figure 1-2 Shown is the first embodiment of the present invention, a circulating water pump motor handling device, including two rectangular parallelepiped symmetrically arranged plate-shaped mounting brackets 1, such as figure 2 As shown, one end of one of the mounting frames 1 is vertically welded to the containing tube 7, and one end of the other mounting frame 1 is vertically welded to the insertion rod 8 that matches the containing tube 7. The mounting frame 1 is provided with a device that drives the two mounting frames 1 to approach or move away from each other. Drive assembly one, drive assembly one includes motor one 5, motor one 5 is installed on one end of housing tube 7, the output shaft of motor one 5 is statically connected to screw rod 6, and screw rod 6 is threaded on the insertion rod 8, at this time forward or reverse Run the motor one 5, and the insertion rod 8 stretches out or enters the containing pipe 7, so that the two mounting frames 1 ...

Embodiment approach

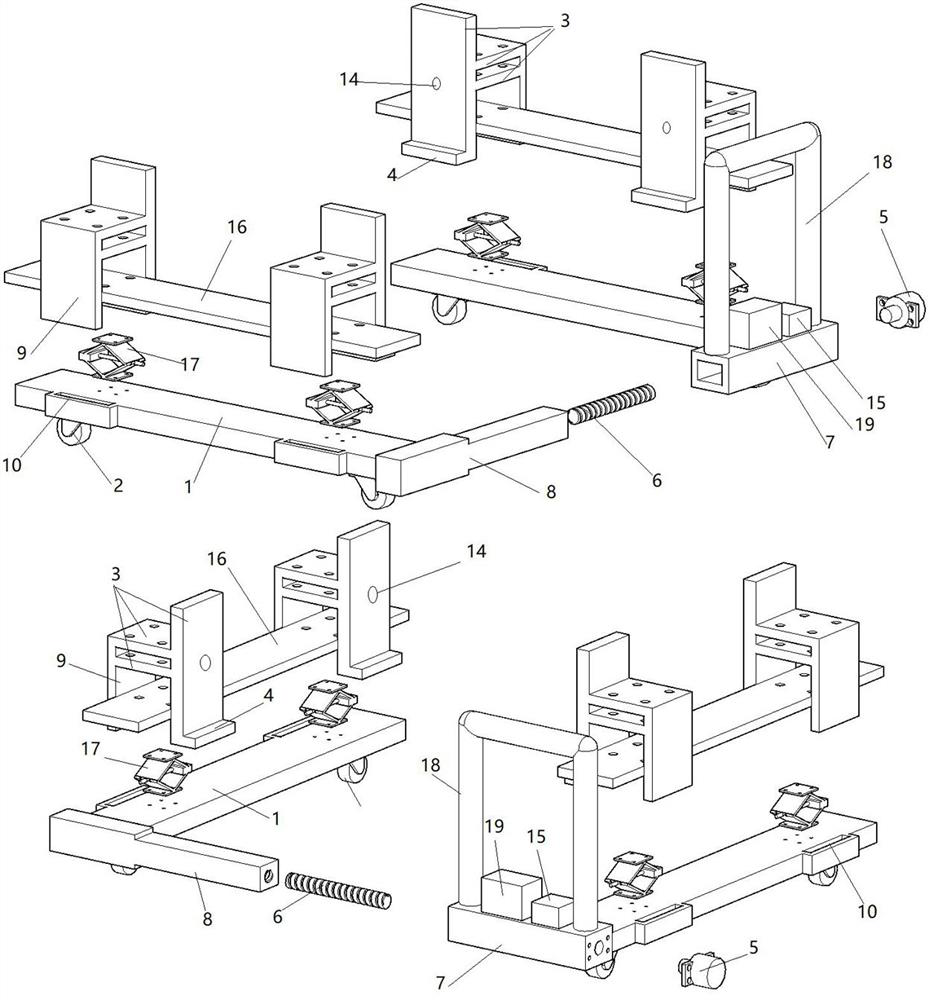

[0030] Such as Figure 3-4 Shown is the second embodiment of the present invention. The difference between this embodiment and the first embodiment is that the installation frame 1 is provided with a driving assembly three for changing the forward direction of the universal wheel 2 and a locking assembly for locking the forward direction of the universal wheel 2 .

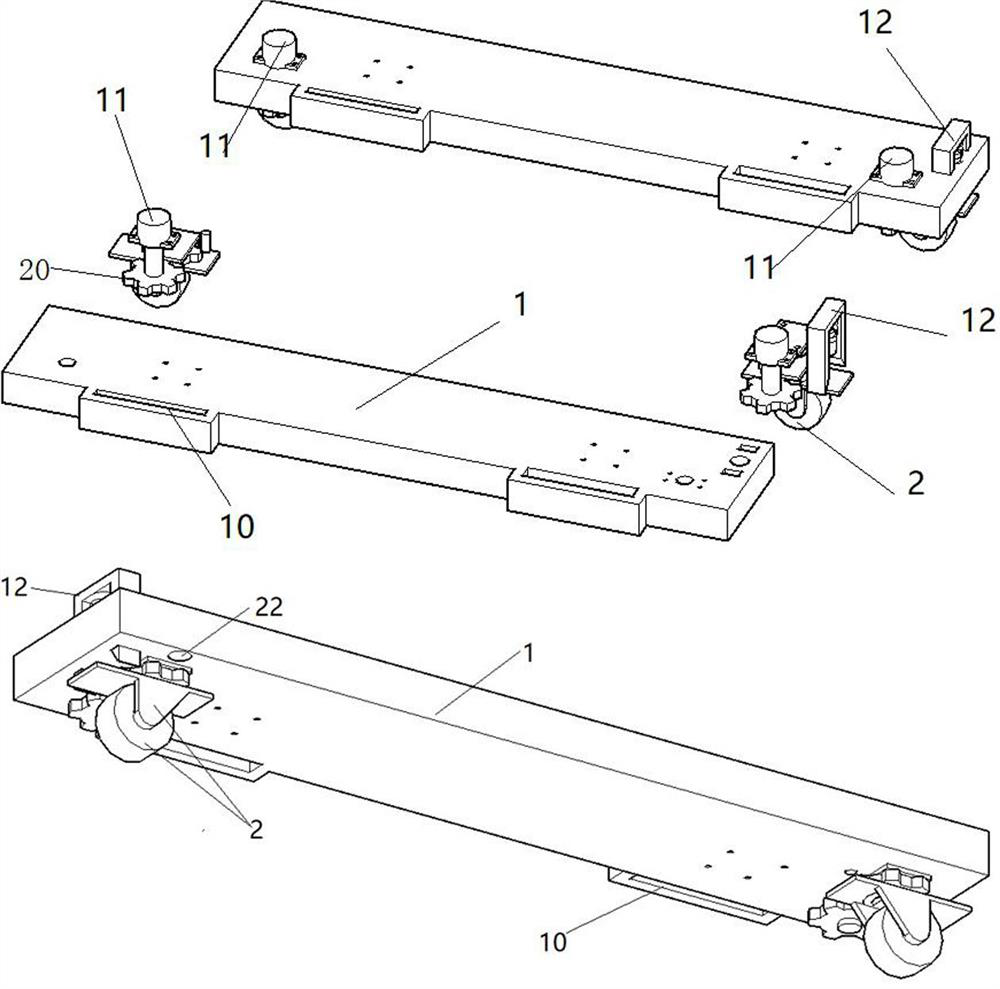

[0031] The drive assembly three includes the motor two 11, the motor two 11 is fixedly installed on the mounting frame 1 by bolts, the mounting frame 1 is processed with a round hole through which the output shaft of the power supply motor two 11 passes, and the output shaft of the motor two 11 is welded on the gear one 20, fixed welding gear 2 21 on the universal wheel 2, gear 1 20 and gear 2 21 interlock each other, start the motor 2 11 at this time, the output shaft of the motor 2 11 rotates synchronously with the universal wheel 2, and drives the two gears close to the handle 18 No braking device is added on t...

Embodiment 3

[0037] Such as Figure 5 Shown is the third embodiment of the present invention. The difference between this embodiment and the first embodiment is that a plurality of universal balls 25 are installed on the side wall of the cleaning hole 10, and the spherical surface of the universal balls 25 is in contact with the extension rod 9, reducing the The frictional force between the extension rod 9 and the removal hole 10 reduces the load of the jack 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com