A semiconductor diode electroplating processing system

A technology of electroplating treatment and diodes, which is applied in the direction of semiconductor devices, circuits, electrolytic components, etc., can solve the problems of affecting the efficiency and quality of electroplating, inability to electroplating, bubble treatment, etc., to improve the efficiency and quality of electroplating, improve efficiency and quality, Increase the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

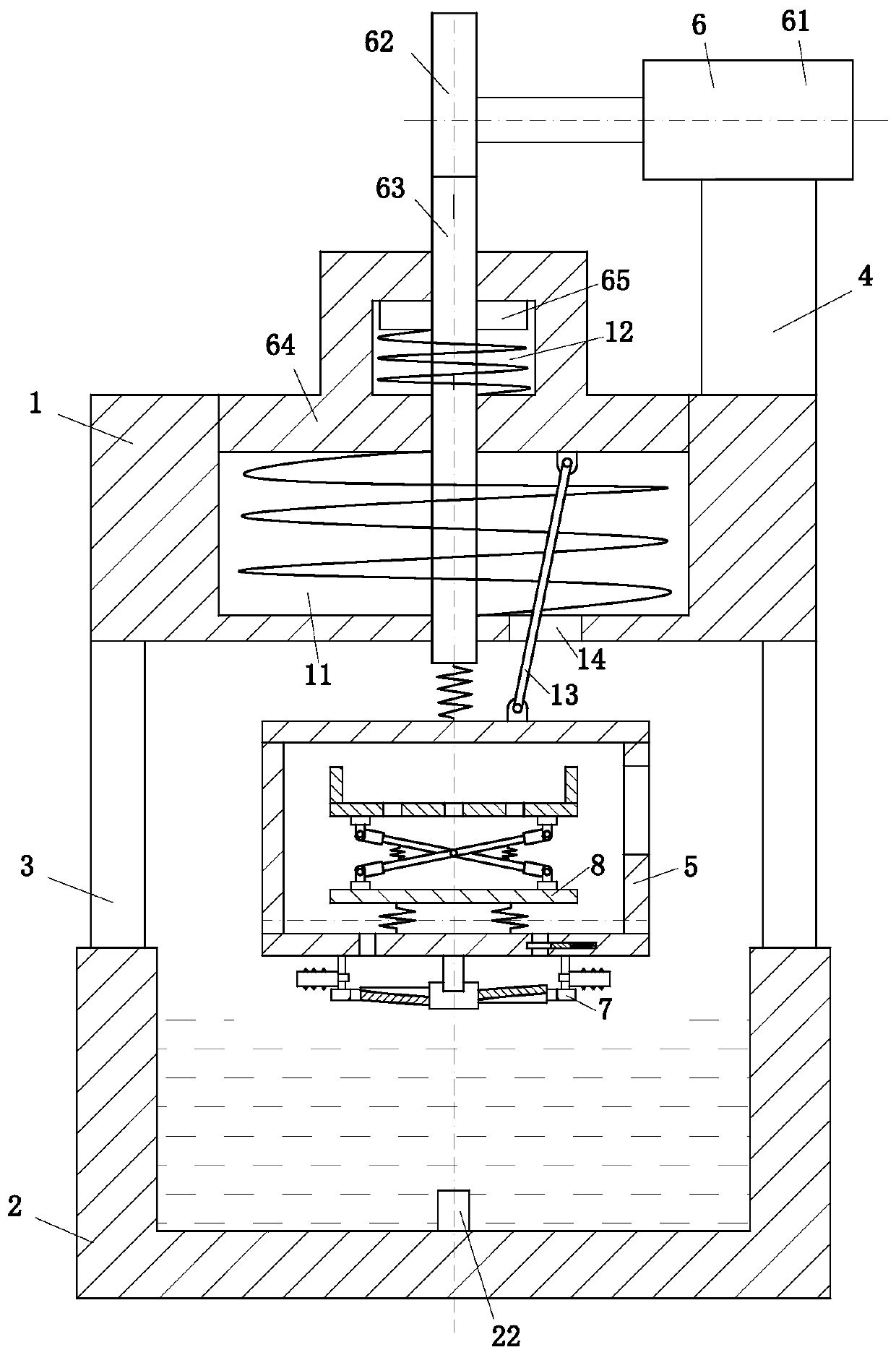

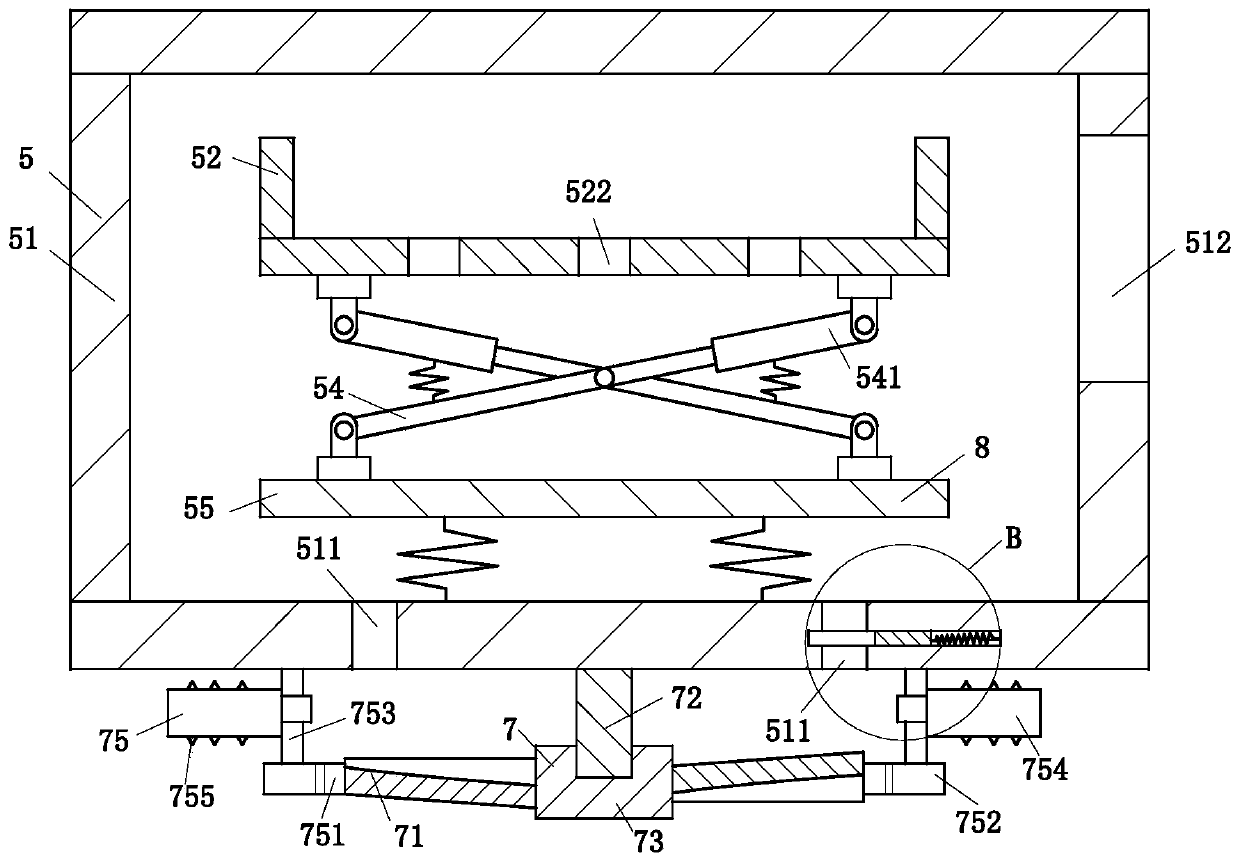

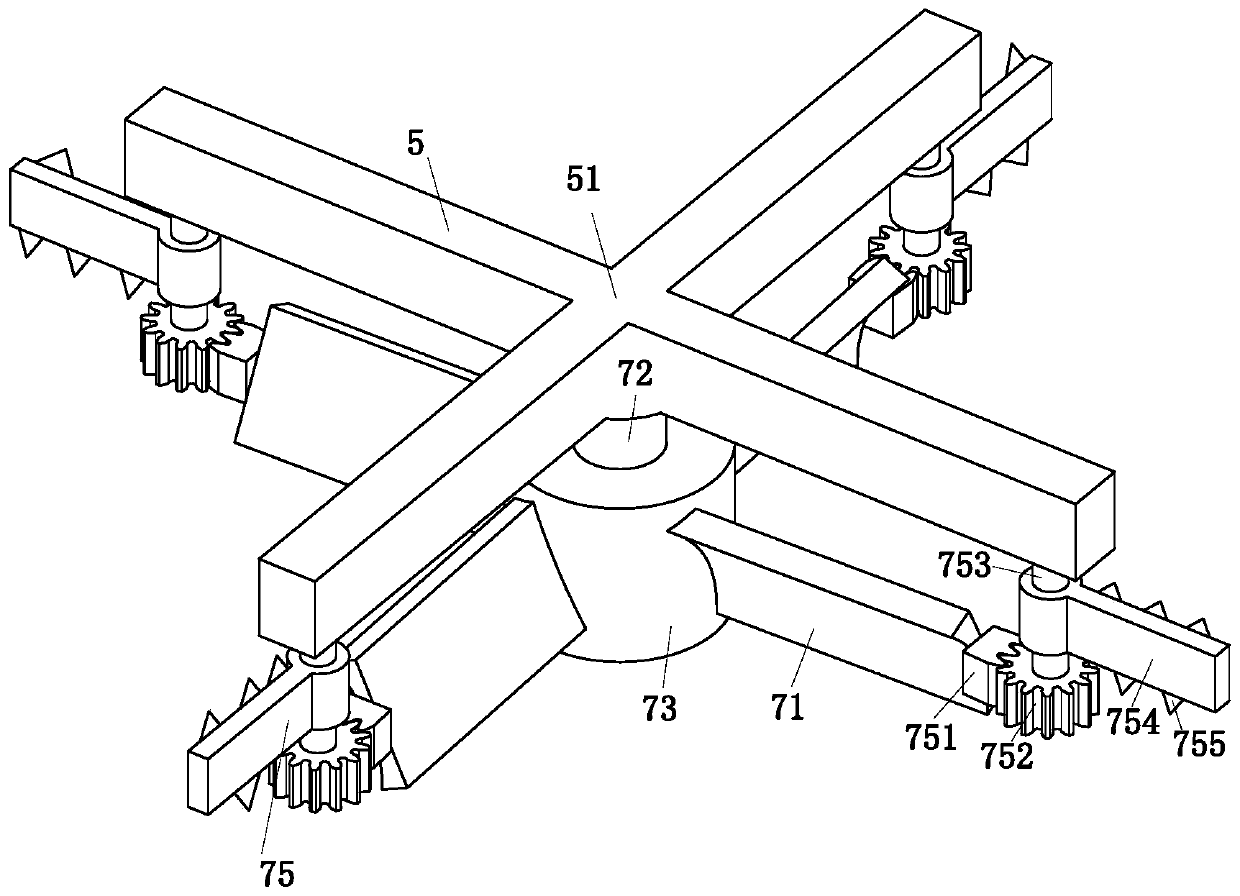

[0026] As an embodiment of the present invention, the electroplating box 5 is provided with a swing module 8 inside, and the electroplating box 5 includes a box body 51, a support plate 52, a vibrating frame 54 and a No. 4 plate 55; the top of the box body 51 The No. 3 spring is fixedly connected with the No. 1 sliding telescopic rod 63, and the bottom of the box body 51 is provided with two No. 1 liquid inlets 511, and the side wall of the box body 51 is provided with an opening and closing door 512; the No. 4 plate 55 passes through The No. 4 spring is fixedly installed at the bottom of the casing 51; the vibrating frame 54 is made up of two No. 1 telescopic rods 541; One end of the No. 1 telescopic rod 541 is hinged at the top of No. 4 plate 55, and the other end of the No. 1 telescopic rod 541 is hinged at the bottom of the support plate 52; the bottom of the support plate 52 is provided with a No. 2 liquid inlet 522, and the support The plate 52 is used to store semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com