Plating bath

A technology for electroplating tanks and tank bodies, applied in the direction of plating tanks, etc., can solve problems such as poor electroplating quality, poor electrical conductivity, and contamination of electroplating solution, and achieve the effects of improving electroplating quality, preventing corrosion, and prolonging life

Inactive Publication Date: 2012-03-28

JIANGYIN CHANGLE NEW TECH POWER SUPPLY

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, in the electroplating process of Dumet wire, copper plates are generally used as electroplating conductors. This use has the following disadvantages. , the acid gas in the tank is easy to oxidize the copper plate and cause the pollution of the electroplating solution. Because of the pollution of the electroplating solution, it needs to be cleaned immediately after not using it once. This is quite troublesome and time-consuming.

During cleaning, because the copper plate has been attached with various liquid medicines, the cleaned water also quickly becomes sour, resulting in uneven copper plates due to continuous erosion, resulting in poor electrical conductivity, and because conductive copper plates are extremely important in the electroplating process The instability will cause poor plating quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0011] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

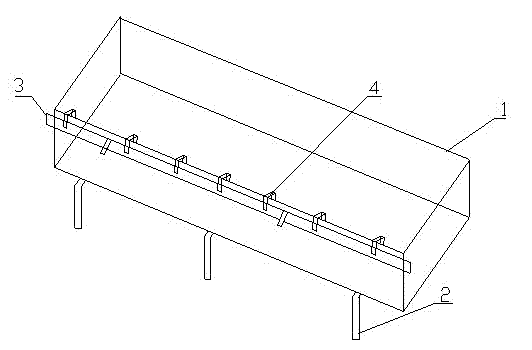

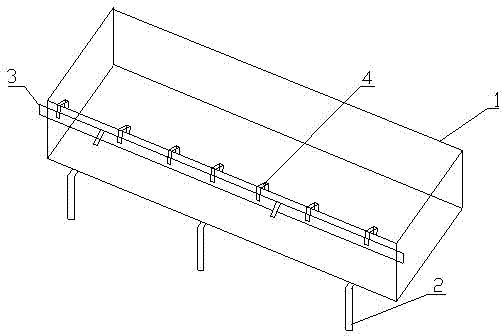

The invention discloses a plating bath. The plating bath which comprises a bath body (1) and a pedestal (2) is characterized in that: a row of electrolytic devices are arranged on the bath body (1); each electrolytic device comprises a transverse copper plate (3) and electrolytic plates (4); the copper plate (3) is fixed on the bath body (1) and is placed on the outer edge of the bath body (1); and each electrolytic plate (4) has a U-shaped appearance, one segment of each electrolytic plate (4) is fixed on the copper plate (3), and the other segment of each electrolytic plate (4) is placed in the electrolytic solution. The plating bath of the invention allows the conductive copper plate to be prevented from the erosion of the plating solution in the plating process, so the conductive stability of the conductive copper plate and the plating quality are improved, and the service life of the conductive copper plate is prolonged.

Description

technical field [0001] The invention relates to the tank field, in particular to an electroplating tank. Background technique [0002] At present, in the electroplating process of Dumet silk, copper plates are generally used as electroplating conductors. This use has the following disadvantages. Because the copper plates are used in the spot plating tank for a long time, the acid gas in the tank is easy to oxidize the copper plates and cause the electroplating solution to oxidize. Pollution, due to the pollution of the electroplating solution, it needs to be cleaned immediately after not being used once, which is quite troublesome and time-consuming. During cleaning, because the copper plate has been attached with various liquid medicines, the cleaned water also quickly becomes acidic, resulting in uneven copper plates due to continuous erosion, resulting in poor electrical conductivity, and because conductive copper plates are extremely important in the electroplating proc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25D17/02

Inventor 李生虎

Owner JIANGYIN CHANGLE NEW TECH POWER SUPPLY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com