Patents

Literature

40results about How to "Reduce handling work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

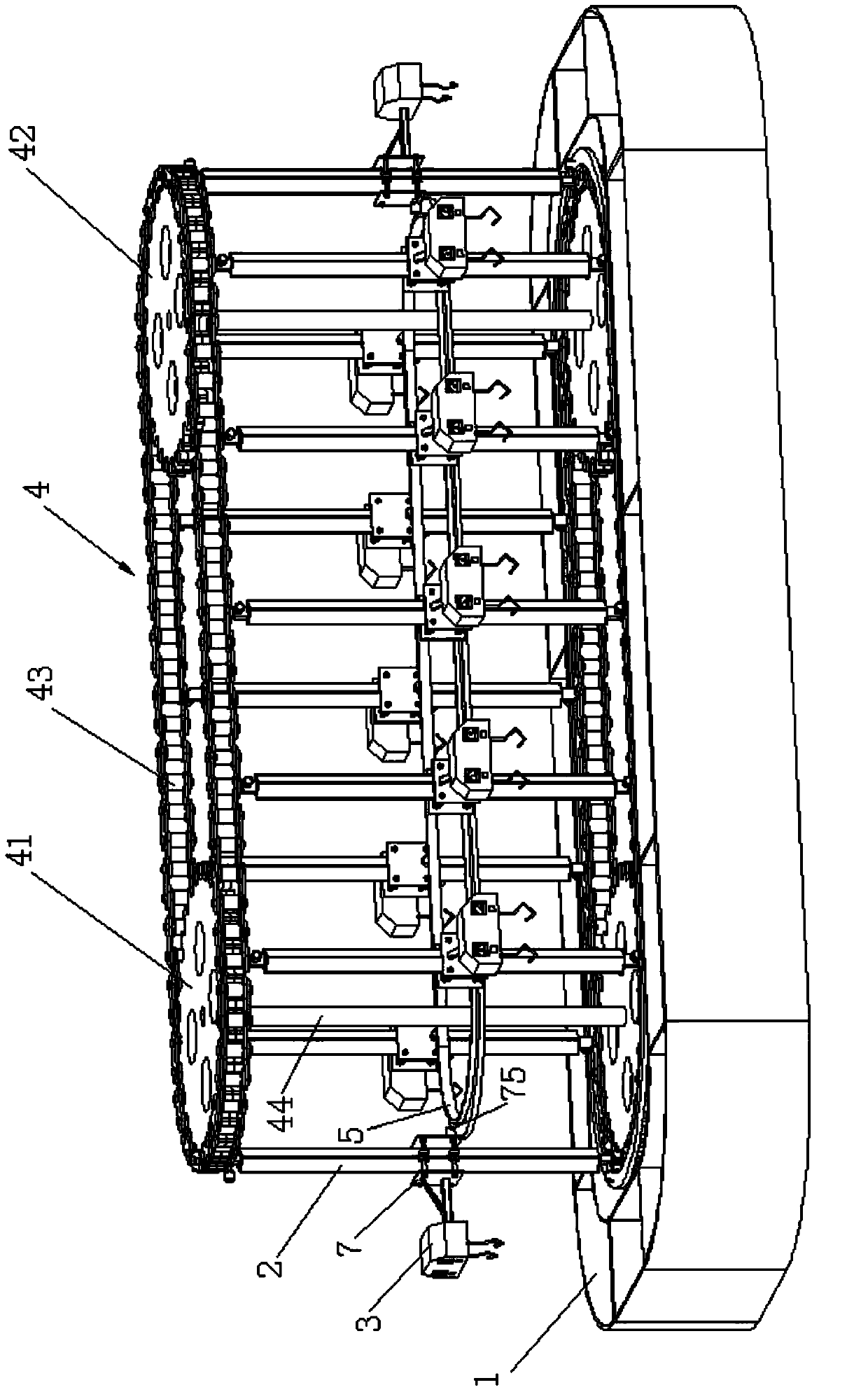

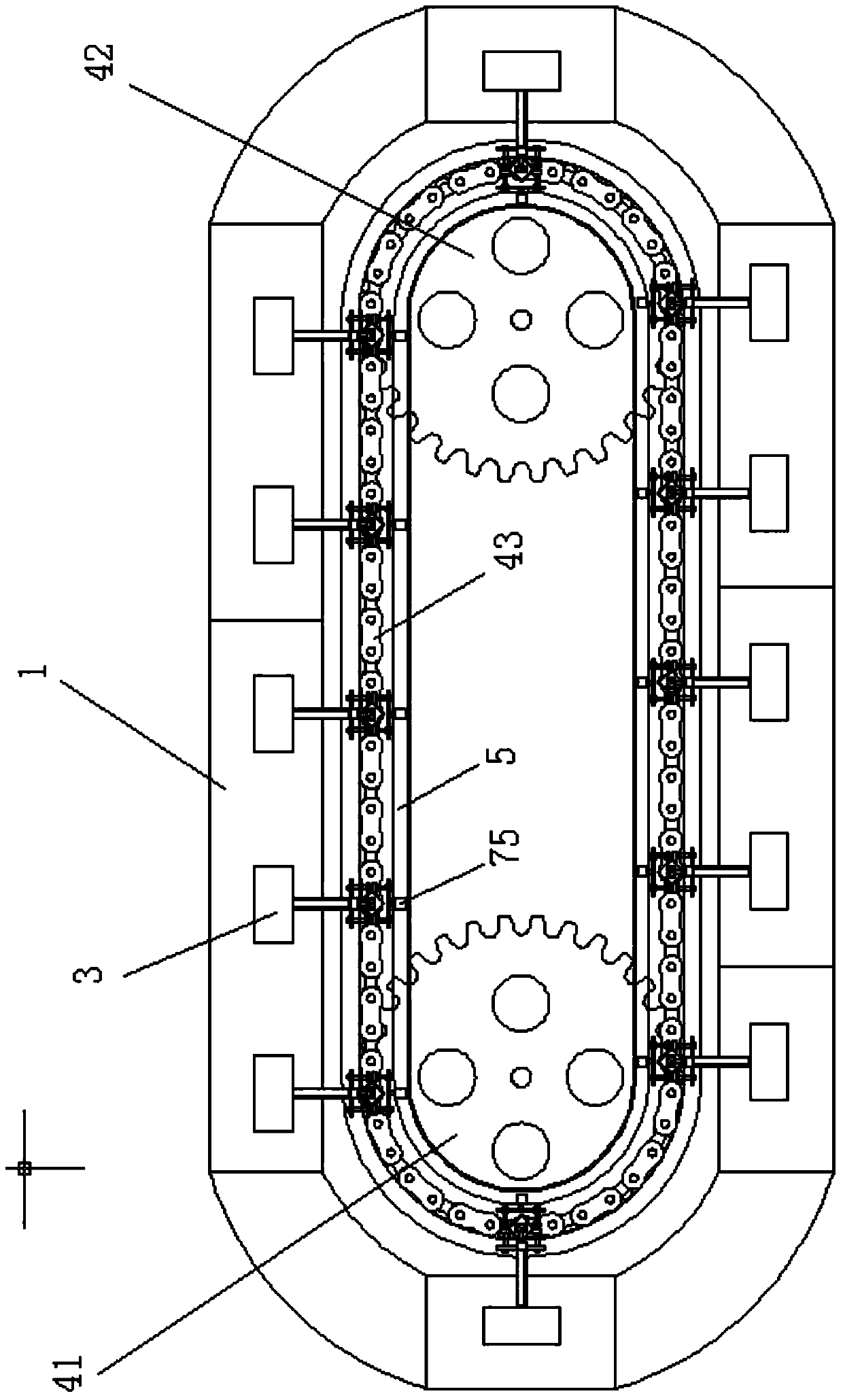

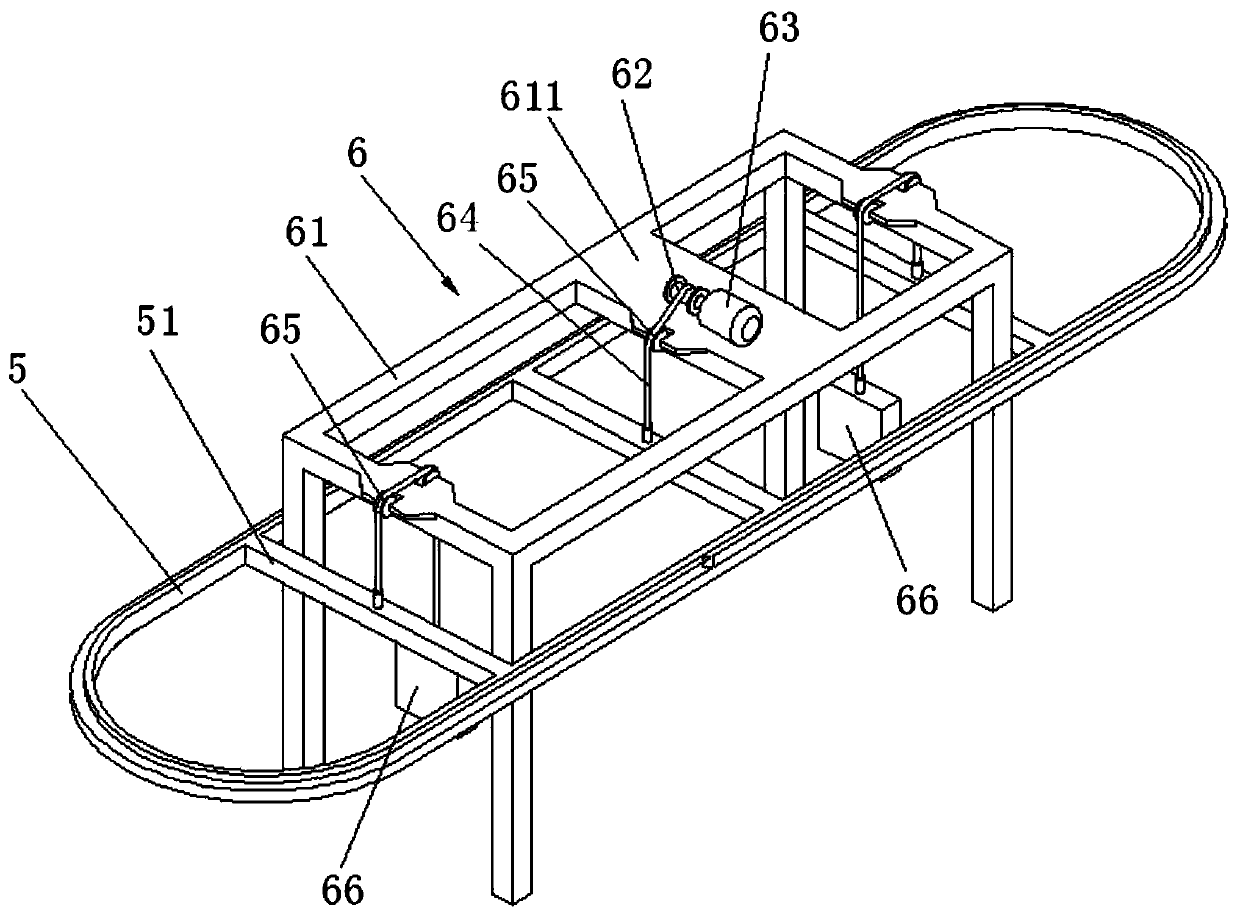

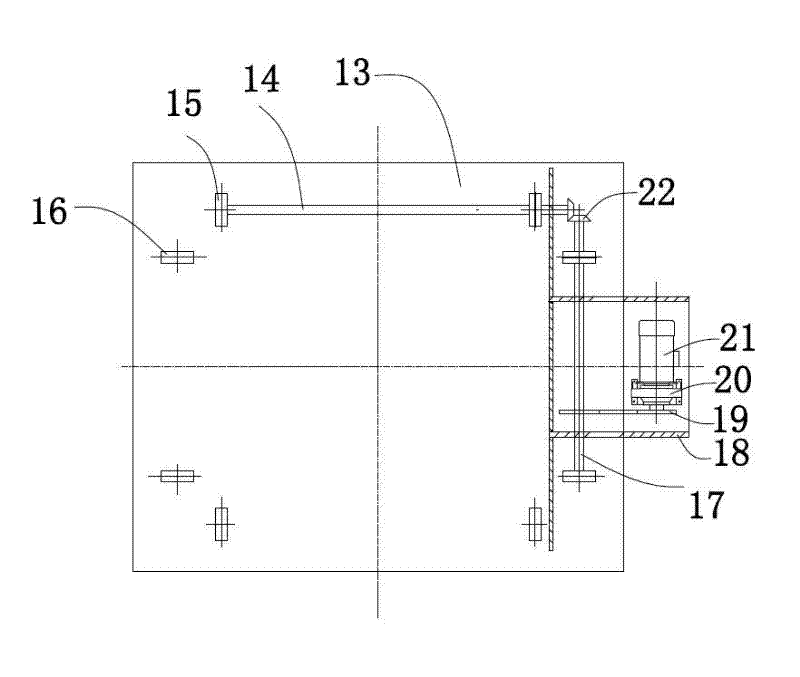

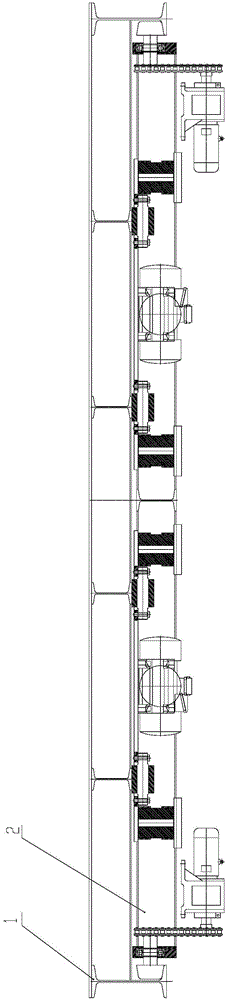

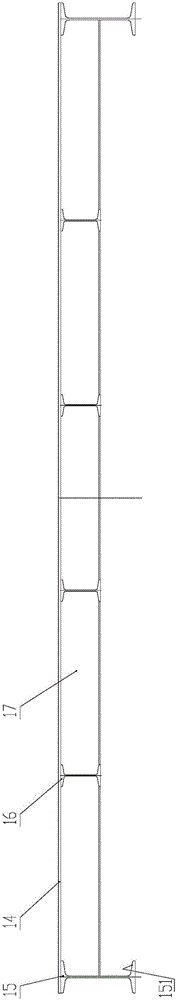

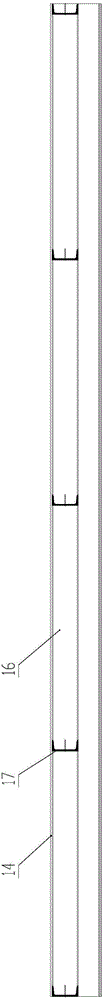

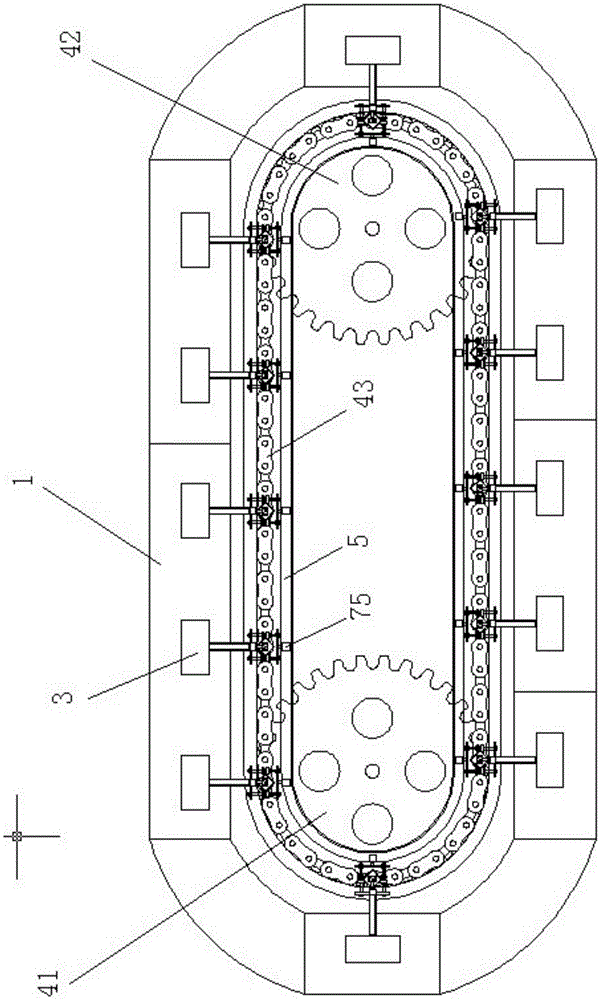

Automatic electroplating equipment for zipper head

ActiveCN103469270AImprove the quality of electroplatingImprove plating qualityCellsSlide fastenersControl systemEngineering

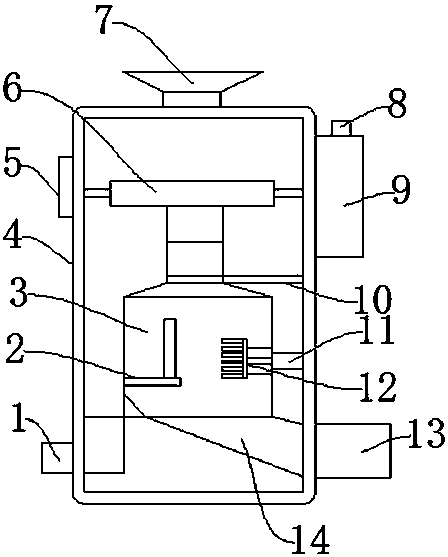

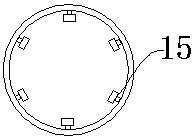

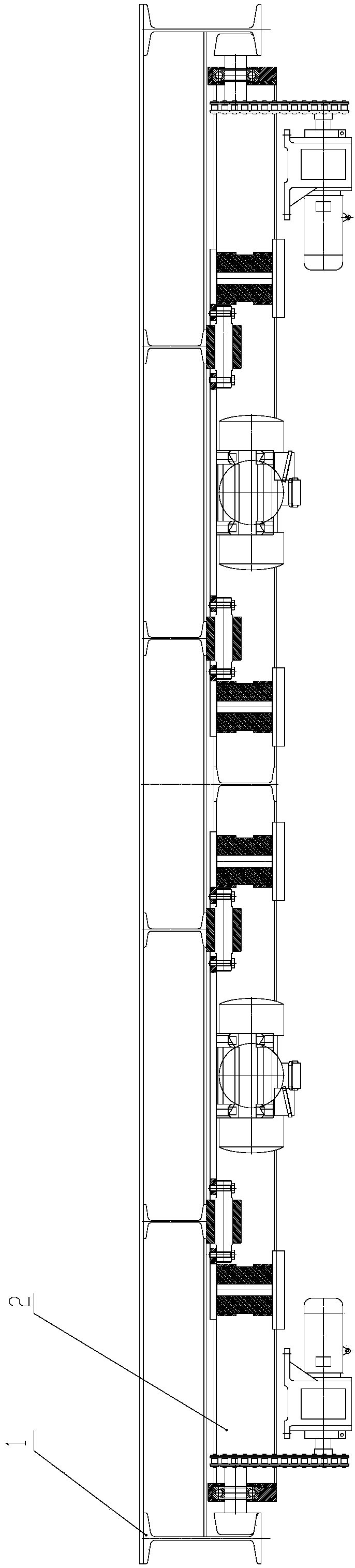

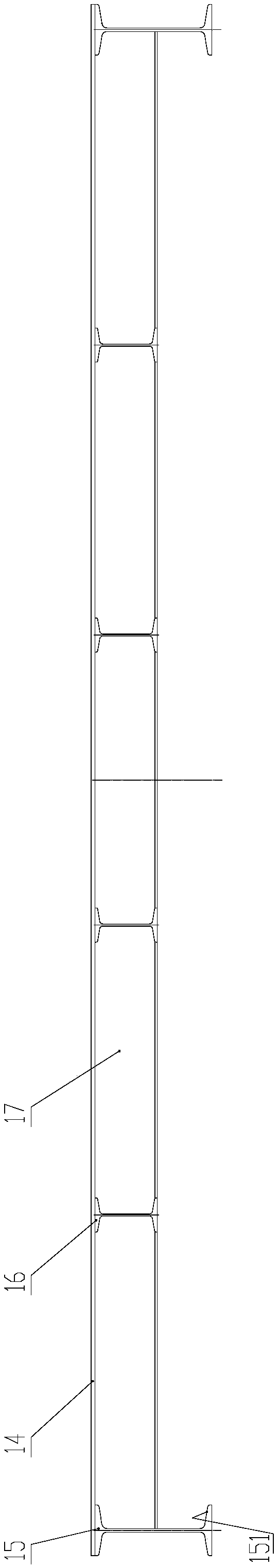

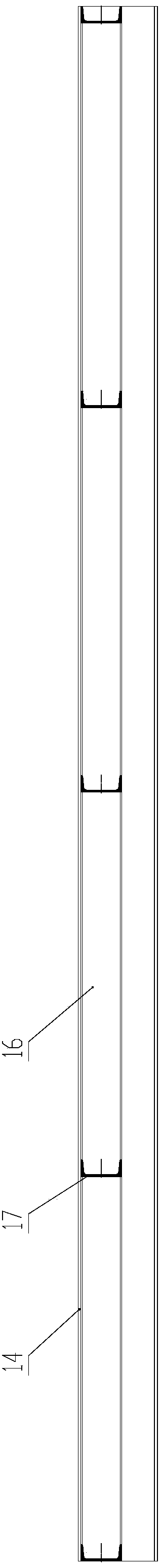

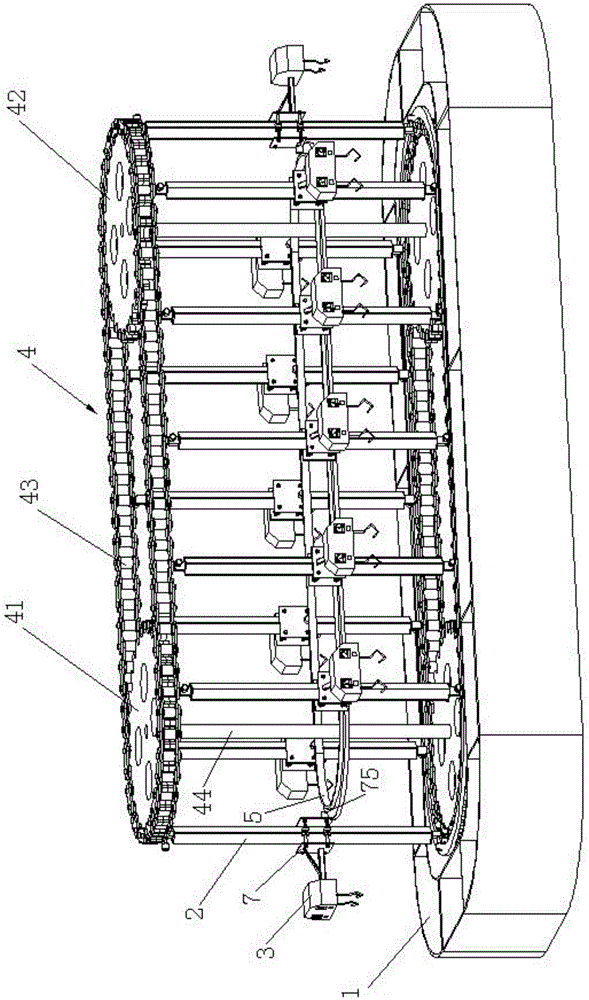

The invention provides automatic electroplating equipment of a zipper head. The equipment consists of electroplating grooves which are formed by a pre-electroplating treatment groove, an electroplating treatment groove and a post-electroplating treatment groove and are connected head-to-tail to form a closed ring, wherein an anode generator is installed on a vertical guide rail which is connected with a chain of a traveling device, the anode generator is further provided with an idler wheel which is placed on a horizontal circular track, and the circular track driven by a lifting device can ascend and descend. Under the effects of a control system, the traveling device and the lifting device, the anode generator intermittently travels on the circular track and circulates according to a sequence of ascending, traveling, descending and stopping. According to the invention, the zipper head is continuously electroplated through the automatic equipment, so that the electroplating production efficiency is greatly improved. Times of the steps are controlled through intelligent programs, so that the electroplating quality is high and the electroplating quality of the zipper head is enhanced. Meanwhile, the labor intensity of the workers is further reduced, and the field environment is improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

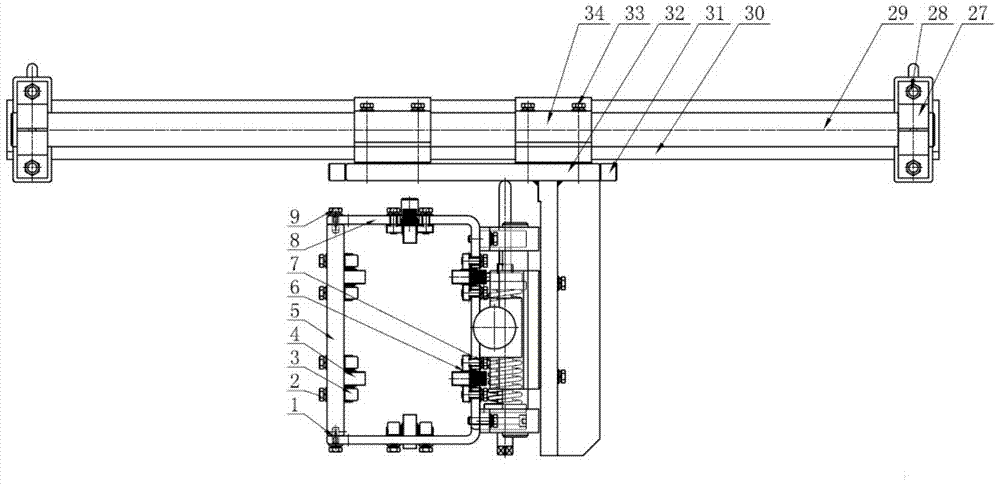

Multiple-mould changing system in triangular arrangement

The invention relates to a multiple-mould changing system in triangular arrangement, which utilizes a single press assorted with multiple moulds, is capable of realizing quick changing of the moulds and reasonable in arrangement, and overcomes defects of large space occupation and long changing time in the prior art adopting the mode that one workstation corresponds to one mould. A stamping mould device comprises a worktable and the moulds fixed on the worktable. A changing mechanism comprises a stamping station and storage stations which are arranged on two sides of the stamping station and in triangular arrangement respectively, the storage stations are connected with the stamping station through running rails, a preparation station communicated with the stamping station is arranged in the middle of each triangular arrangement, and the worktable is arranged on the running rails. Since the stamping station is combined with the preparation stations and multiple storage stations can be arranged on the periphery of one stamping station, floor area is small and space utilization rate is high. Multiple workpieces can be stamped at the same station so that procedures are reduced, workpiece machining efficiency is increased and workload in carrying the workpieces among the stations is decreased.

Owner:ZHEJIANG JINGANG AUTOMOBILE +1

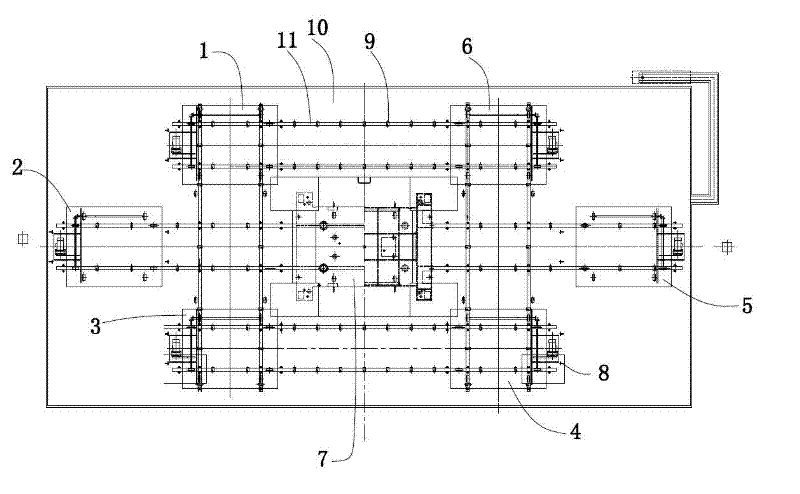

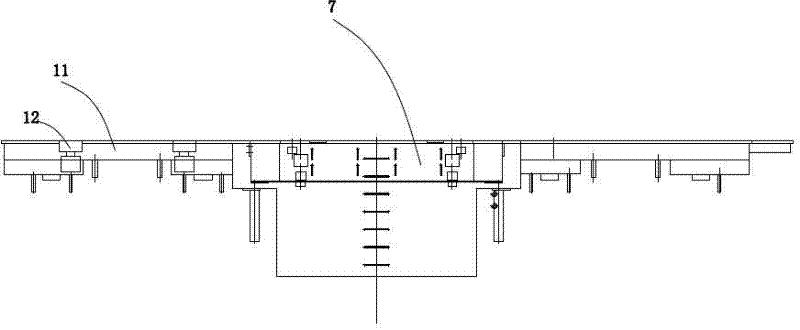

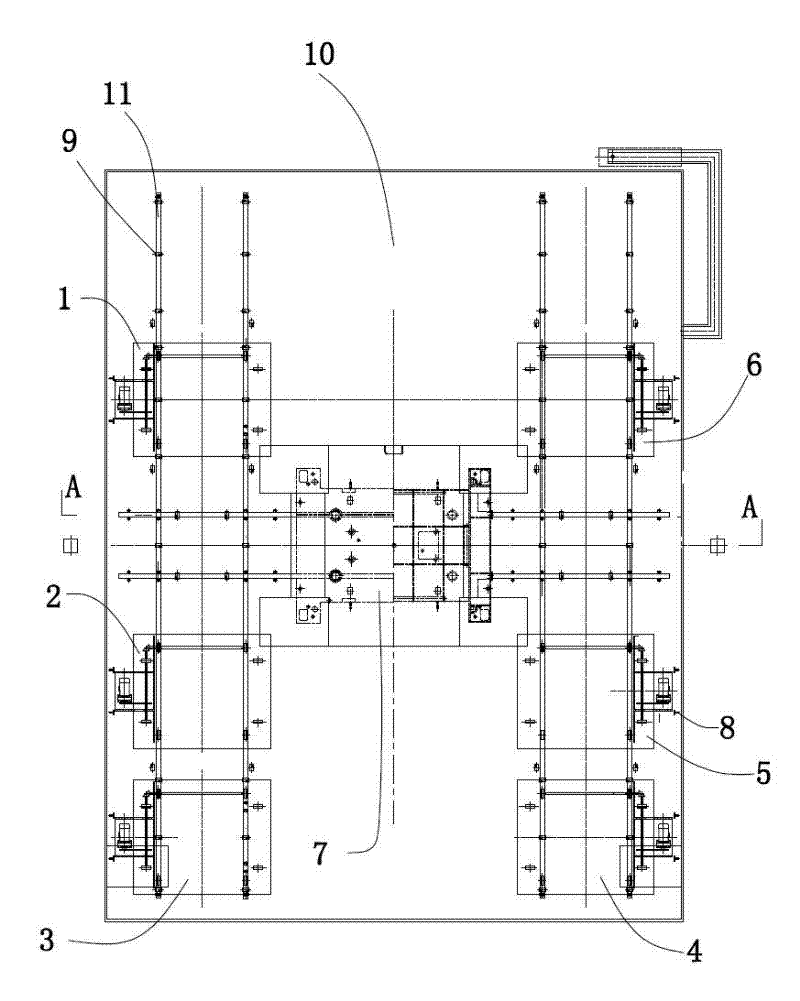

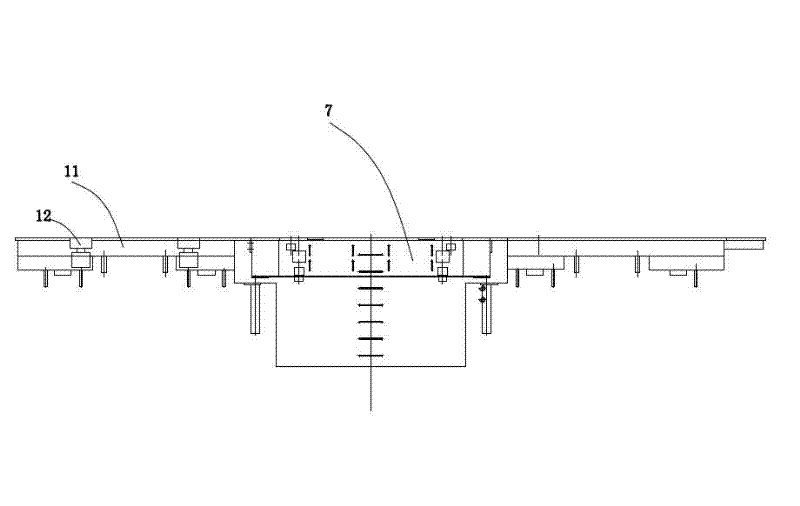

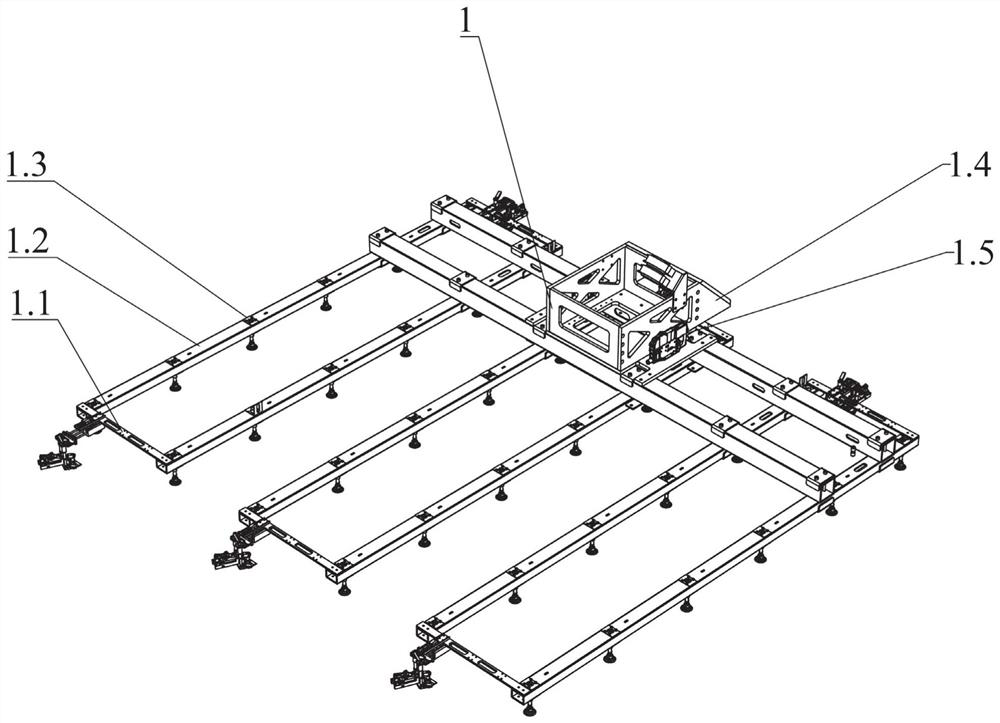

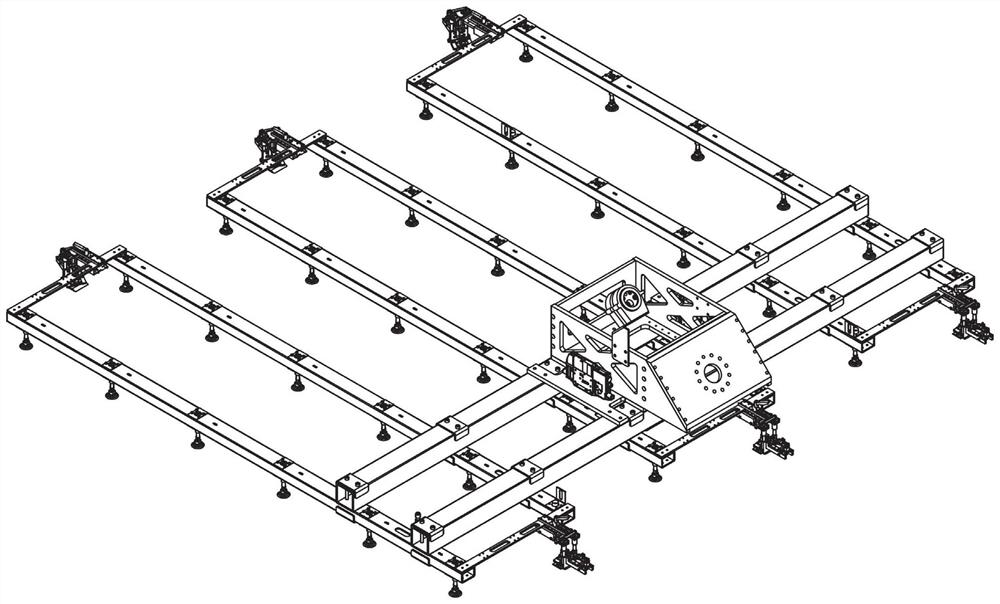

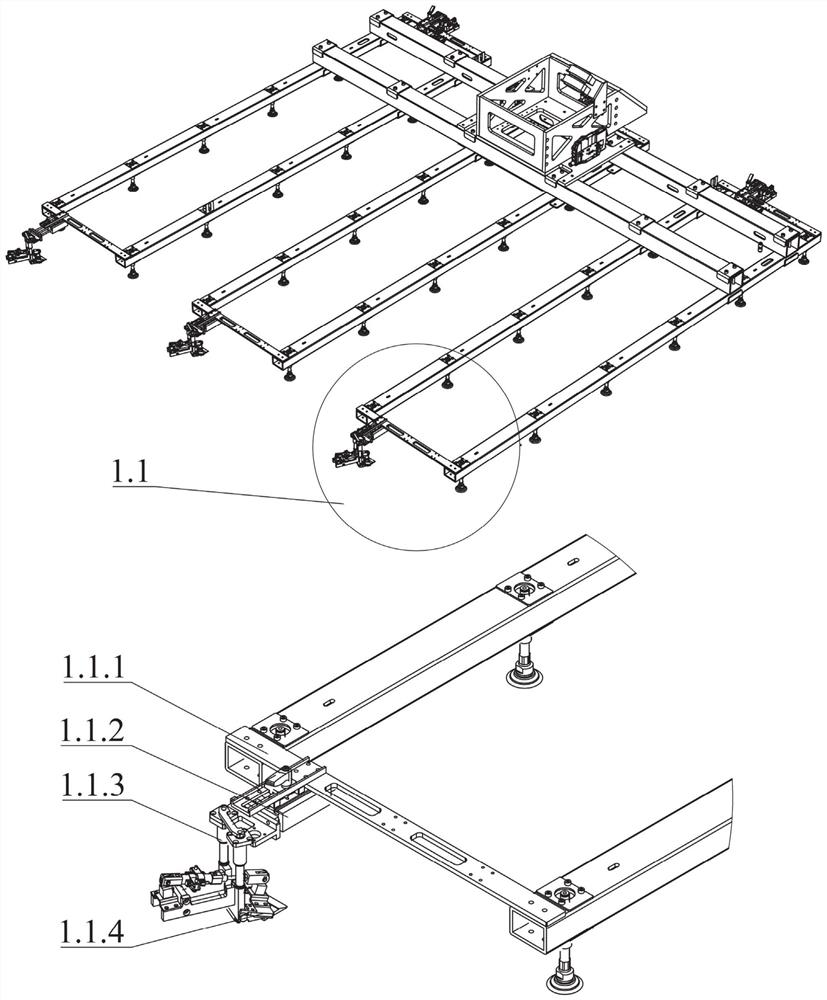

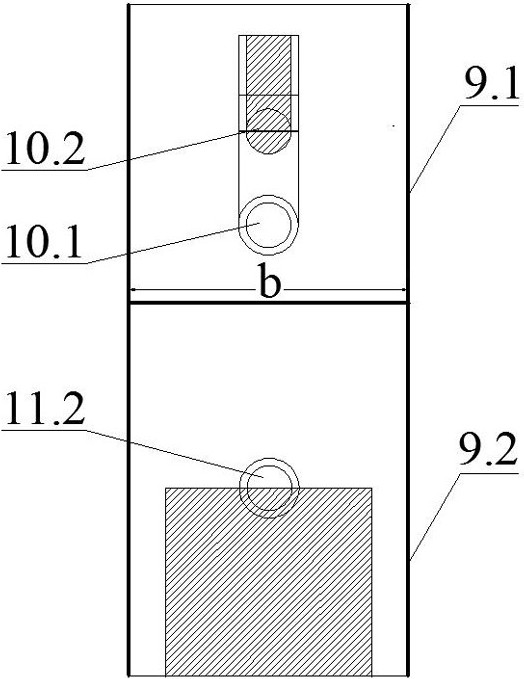

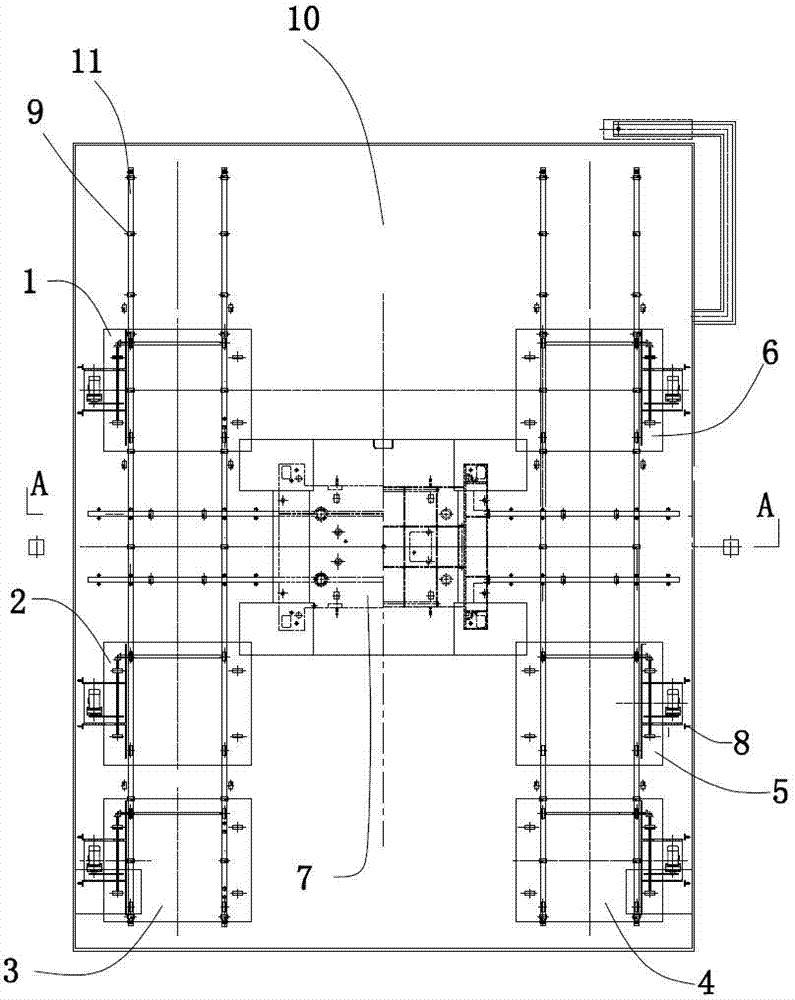

Multiple-mould changing system in parallel arrangement

ActiveCN102527835AImprove processing efficiencyReduce handling workShaping toolsMoulding deviceEngineering

The invention relates to a multiple-mould changing system in parallel arrangement, which utilizes a single press assorted with multiple moulds, is capable of realizing quick changing of the moulds and reasonable in arrangement, and overcomes defects of large space occupation and long changing time in the prior art adopting the mode that one workstation corresponds to one mould. A stamping mould device comprises a worktable and the moulds fixed on the worktable. A changing mechanism comprises a stamping station and storage stations which are arranged on two sides of the stamping station parallelly, the storage stations are connected with the stamping station through running rails, a preparation station communicated with the stamping station is arranged on each running rail on the same line, and the worktable is arranged on the running rails. The stamping station is combined with the preparation stations, and multiple storage stations can be arranged on the periphery of one stamping station, so that floor area is small and space utilization rate is high. Multiple workpieces can be stamped at the same station so that procedures are reduced, workpiece machining efficiency is increased and workload in carrying the workpieces among the stations is decreased.

Owner:ZHEJIANG JINGANG AUTOMOBILE +1

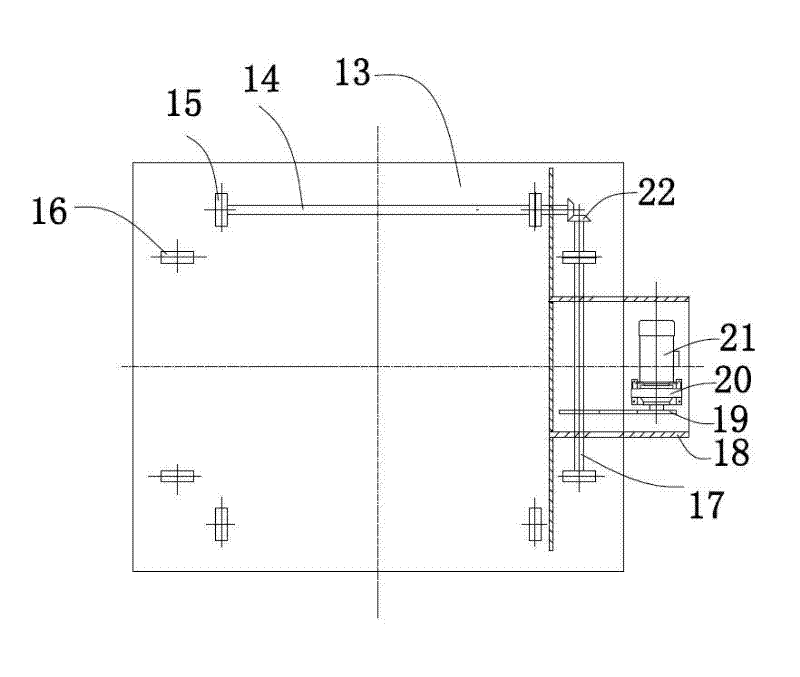

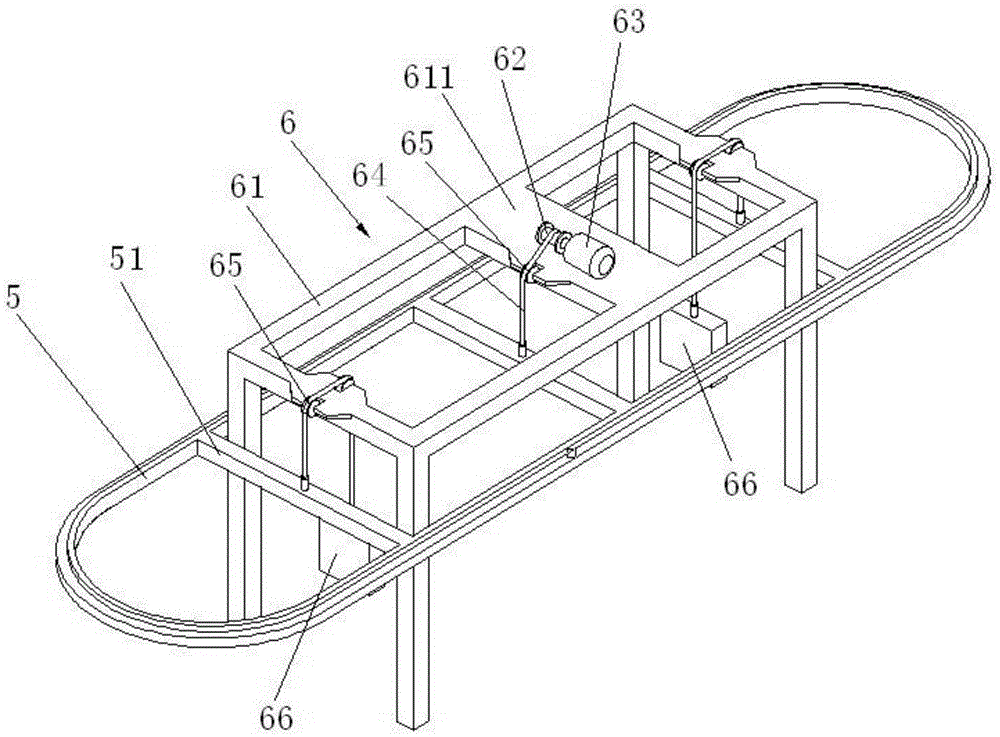

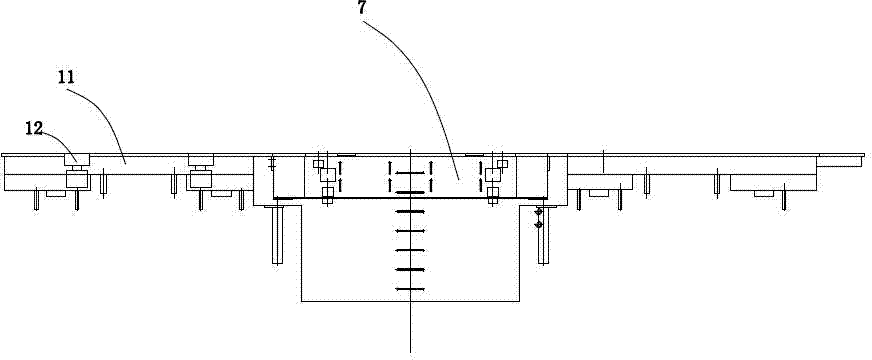

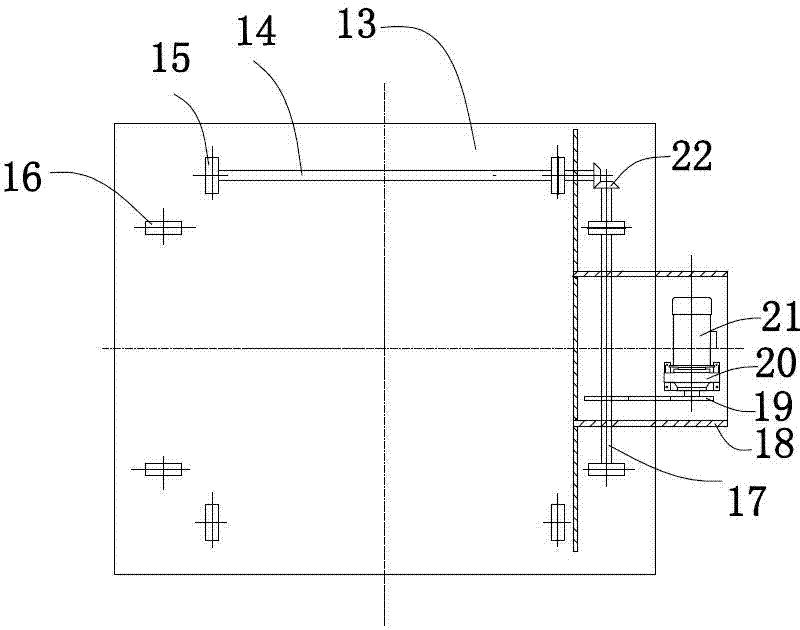

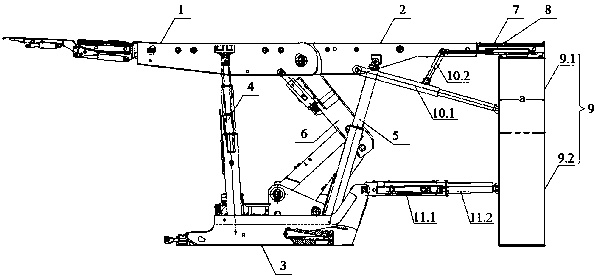

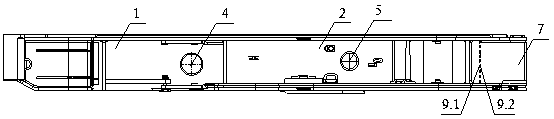

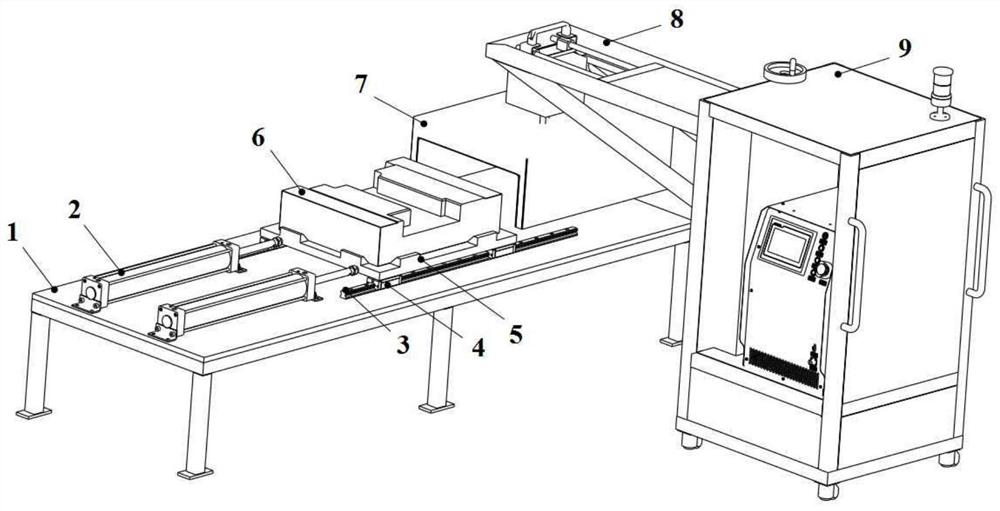

PC prefabricated component forming equipment

ActiveCN106217589AReduce handling workEasy to carry outCeramic shaping apparatusEngineeringProduction quality

The invention provides PC prefabricated component forming equipment. The PC prefabricated component forming equipment comprises two parts of a mold table and a vibration platform, and is characterized in that the mold table is a fixed platform; a guide rail is arranged on the fixed platform; the vibration platform is a mobile vibration platform; a vibration mechanism and a walk driving mechanism are arranged on the mobile vibration platform; the walk driving mechanism is positioned on the guide rail, so that the mobile vibration platform is movably arranged on the fixed platform along the guide rail corresponding to the fixed platform. The PC prefabricated component forming equipment adopts a working mode of fixed mold table and automatic moving vibration platform, improves the working efficiency, reduces the cost, improves the prefabricated component production quality, and reduces the working intensity of operators.

Owner:ANHUI XINGHUA FORKELEVATOR

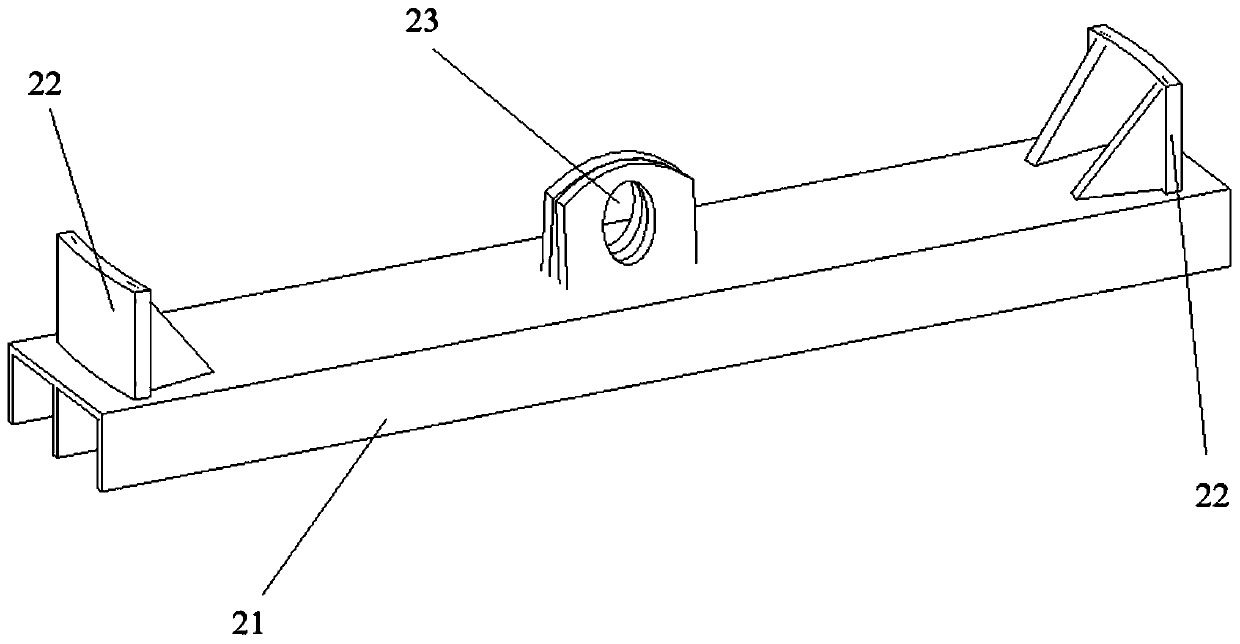

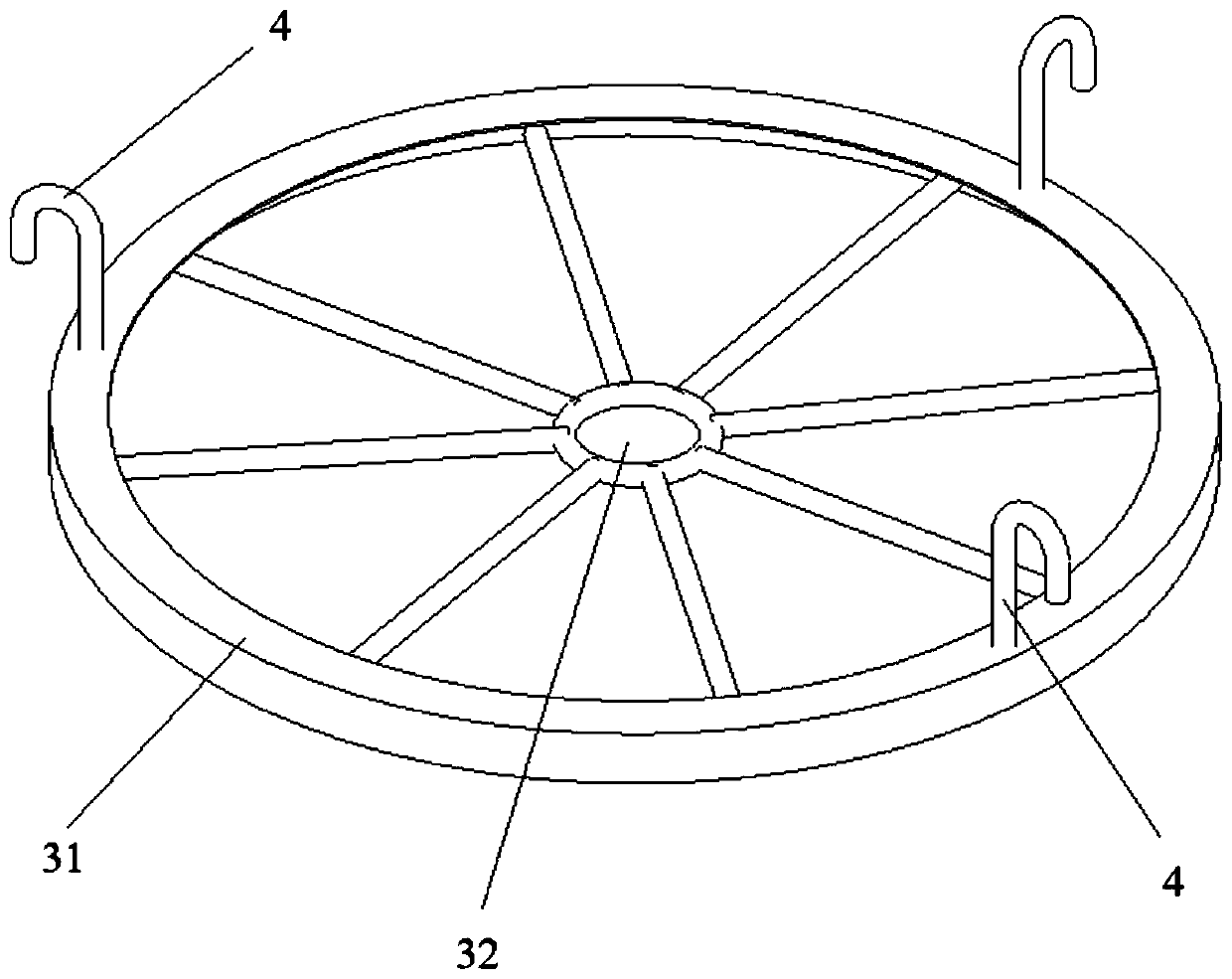

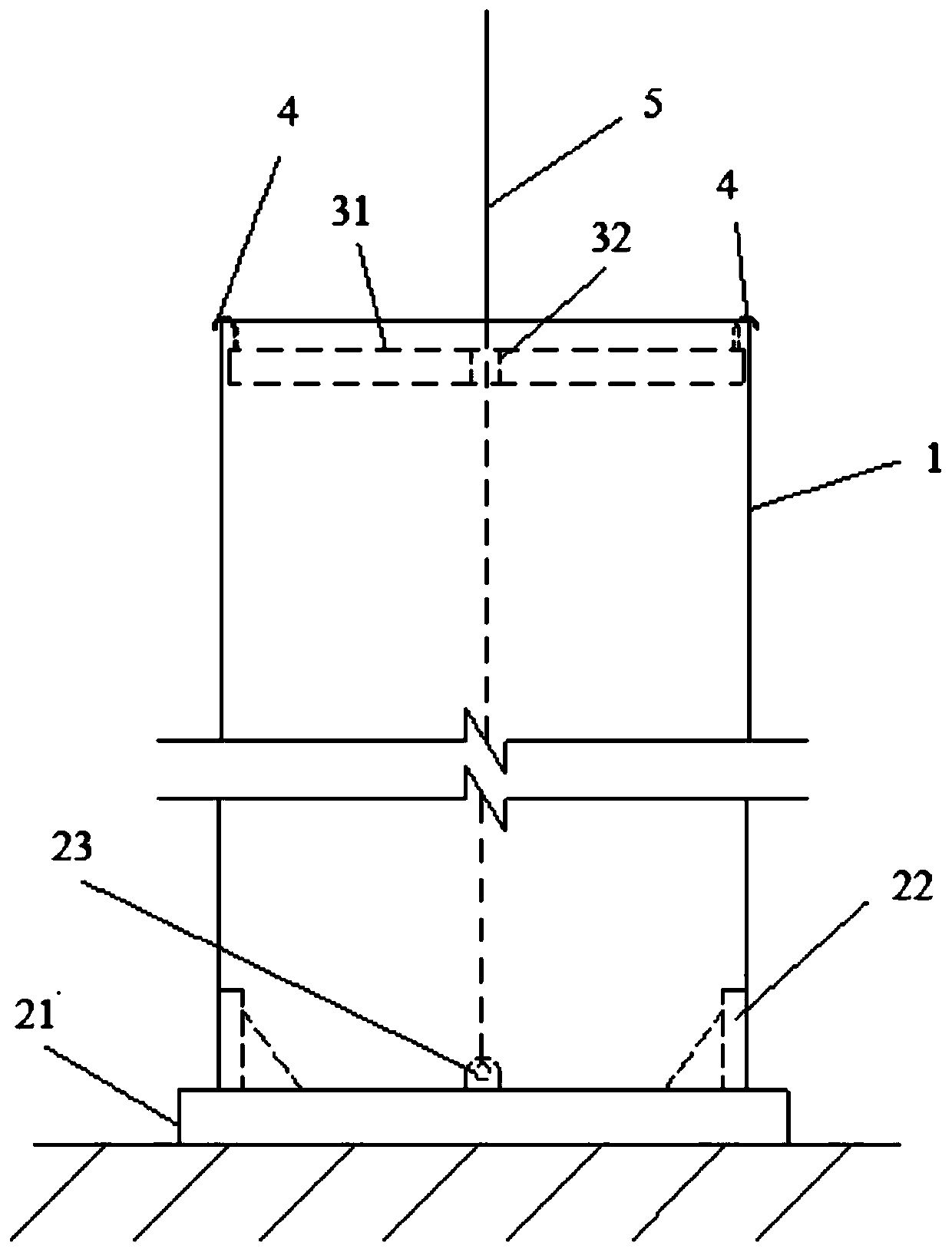

Tool for vertically hoisting and mounting pipeline and hoisting method of the tool

InactiveCN111362118AReduce difficultyReduce installation difficultyLoad-engaging elementsStructural engineeringPipe

The invention discloses a tool for vertically hoisting and mounting a pipeline and hoisting method of the tool. The tool comprises a base and a limiting body, wherein the base is used for being connected with the bottom of a pipe joint, and the limiting body is used for being connected with the top of the pipe joint; the base comprises a bottom plate, at least two seat plates are arranged on the bottom plate, the outer wall of the seat plates is matched with the inner diameter of the pipe joint, and a hoisting hole is further formed in the middle part of the bottom plate; and the limiting bodycomprises a frame body and a through hole formed in the middle part of the frame body, and the shape and the size of the limiting body are matched with the shape and the size of the pipe joint. The tool is simple in structure, low in cost, easy and convenient to manufacture and light in weight, so that the hoisting weight cannot be obviously increased; and meanwhile, the stability and perpendicularity of pipeline hoisting can be effectively guaranteed through limitation of the two ends, and the mounting efficiency is high, so that the construction period is effectively shortened, and the toolcan be suitable for hoisting operation of pipelines large in pipe diameter, long in length and heavy in weight.

Owner:CHENGDU NO 4 CONSTR ENG

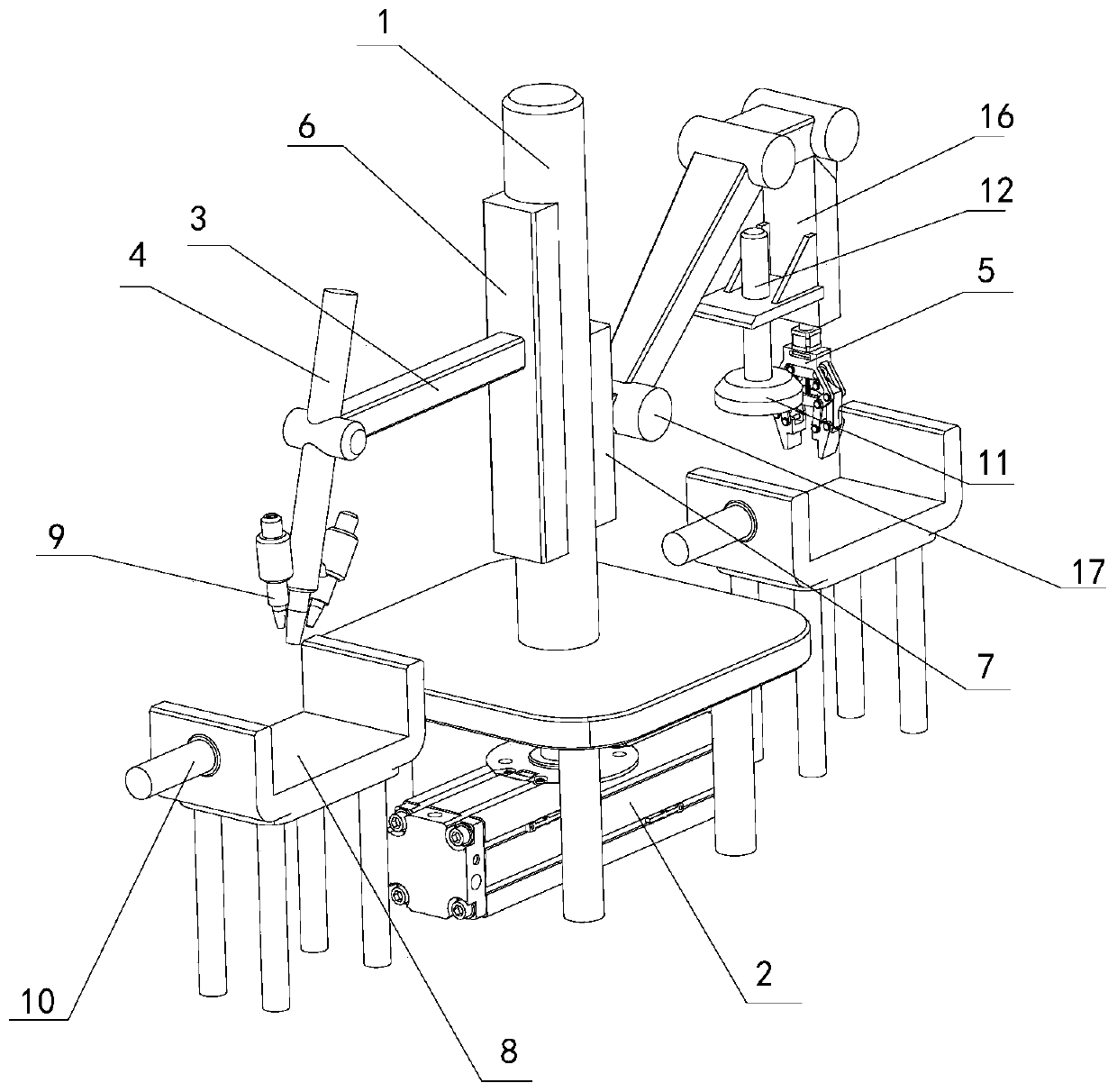

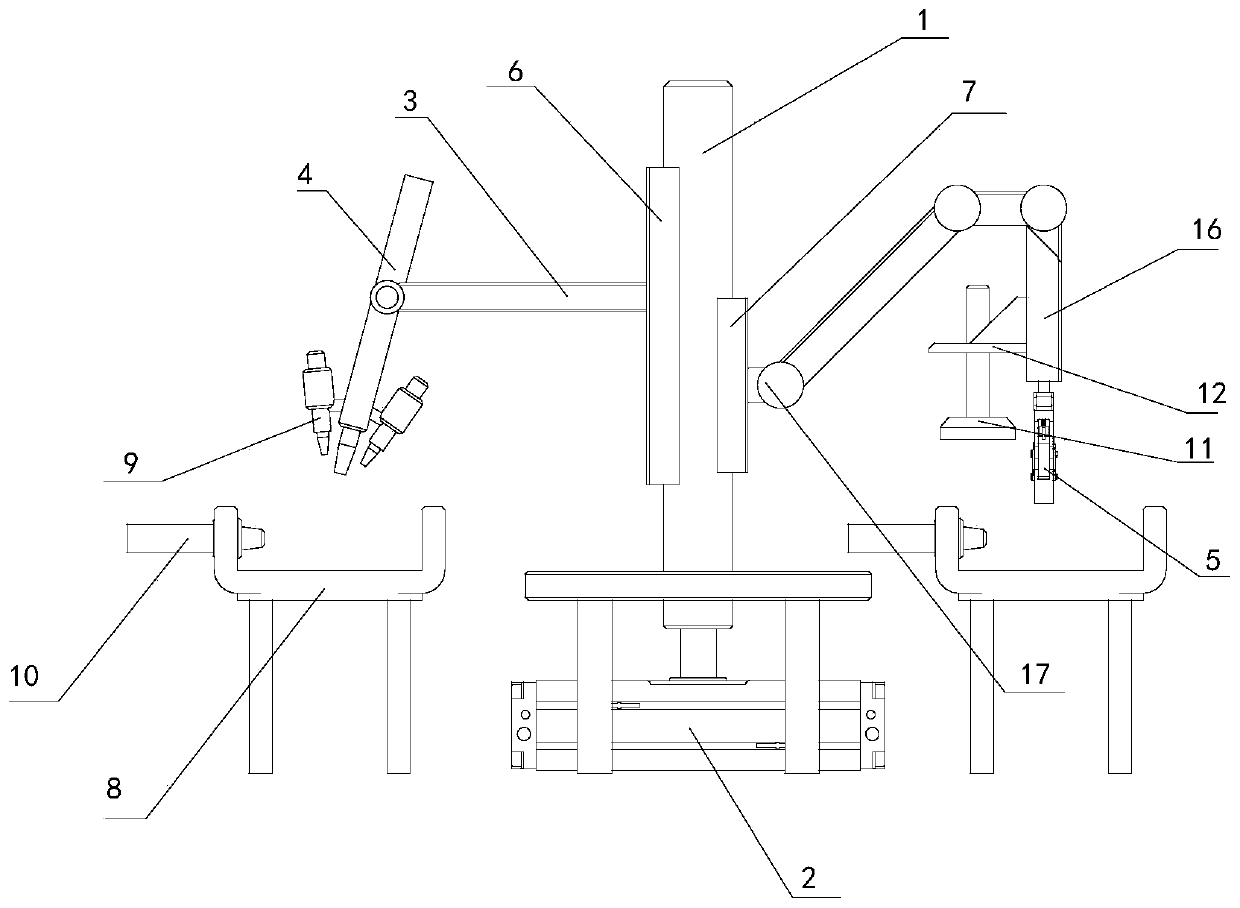

Automatic welding device

ActiveCN111390460AReduce handling workImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWorkbench

The invention discloses an automatic welding device, and belongs to the welding field. The automatic welding device comprises a machine base, a central shaft, a first drive mechanism, a support frame,a welding gun, a mechanical arm, a mechanical hand, a first sliding rail, a second sliding rail, and a workbench, wherein the central shaft is arranged vertically on the machine base; the first drivemechanism is used for driving the central shaft to rotate; the support frame is arranged vertically on the central shaft; the welding gun is articulated on the support frame and is driven to rotate by a second drive mechanism; the mechanical arm is articulated on the central shaft; the mechanical hand is arranged on the mechanical arm, and is used for clamping a workpiece to be clamped; the firstsliding rail and the second sliding rail are fixedly arranged on the central shaft; the support frame is in slip connection with the central shaft through the first sliding rail; the mechanical arm is in slip connection with the central shaft through the second sliding rail; and the workbench is arranged on the machine base and is used for placing the workpiece. Compared with the prior art, the automatic welding device has higher working efficiency.

Owner:深圳市德洋实验设备有限公司

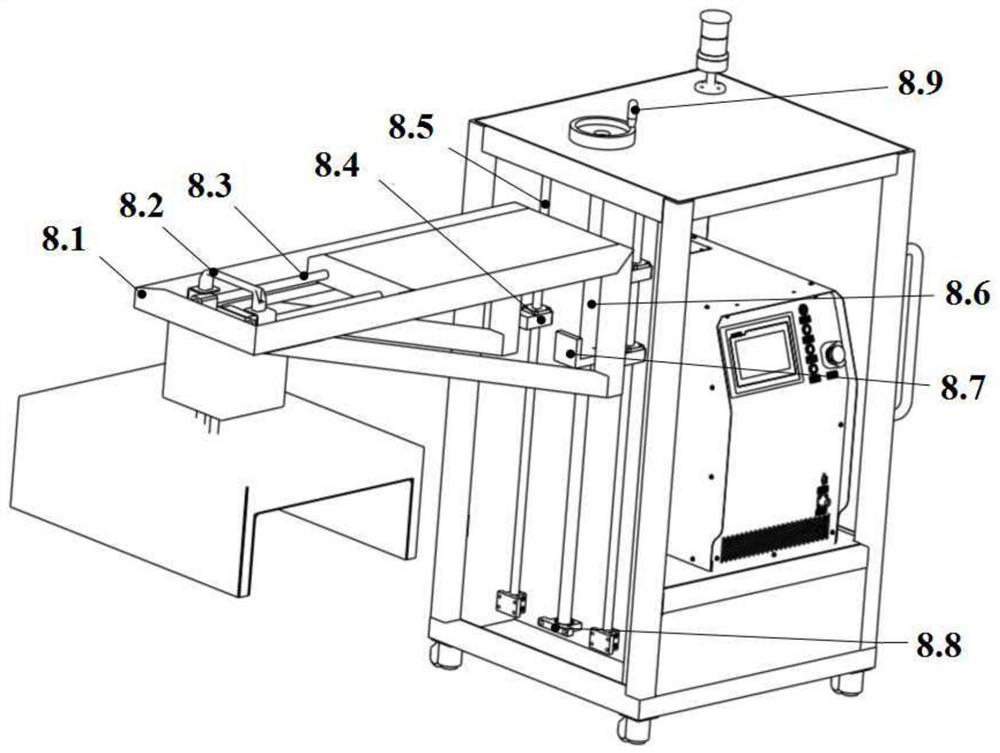

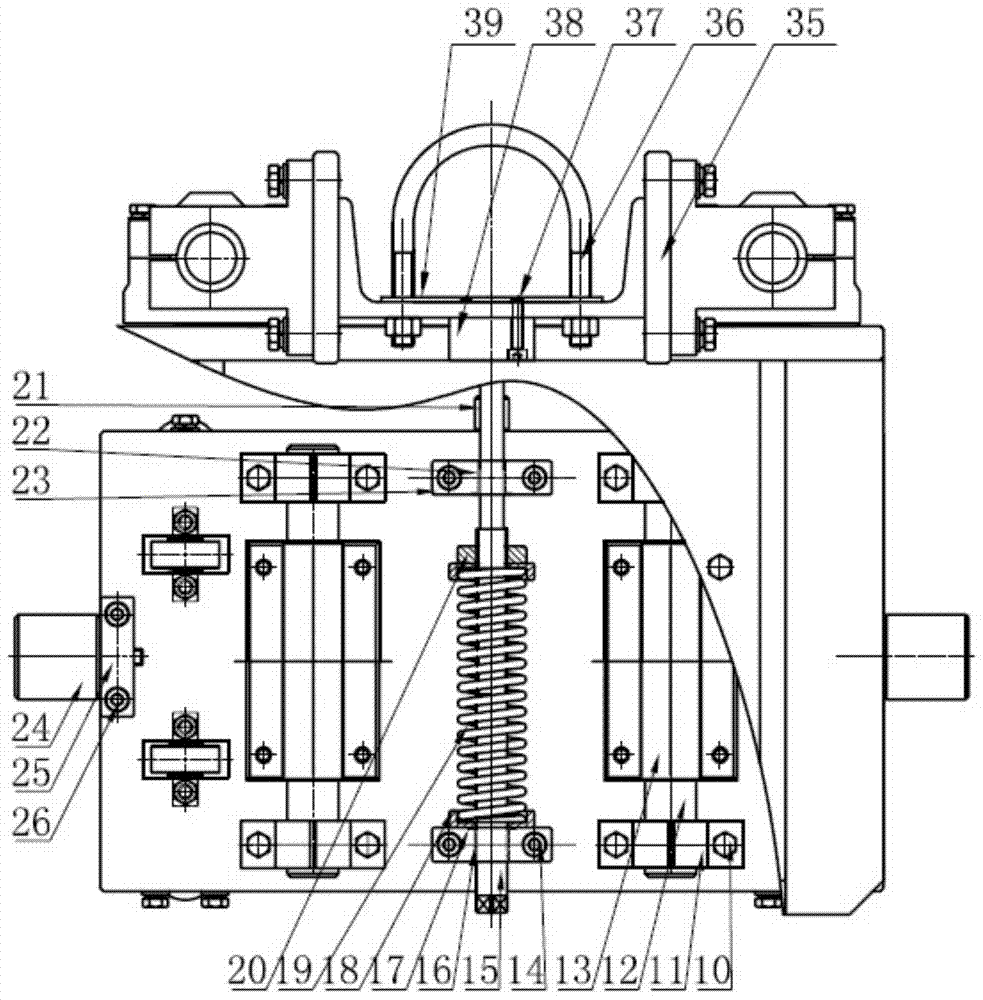

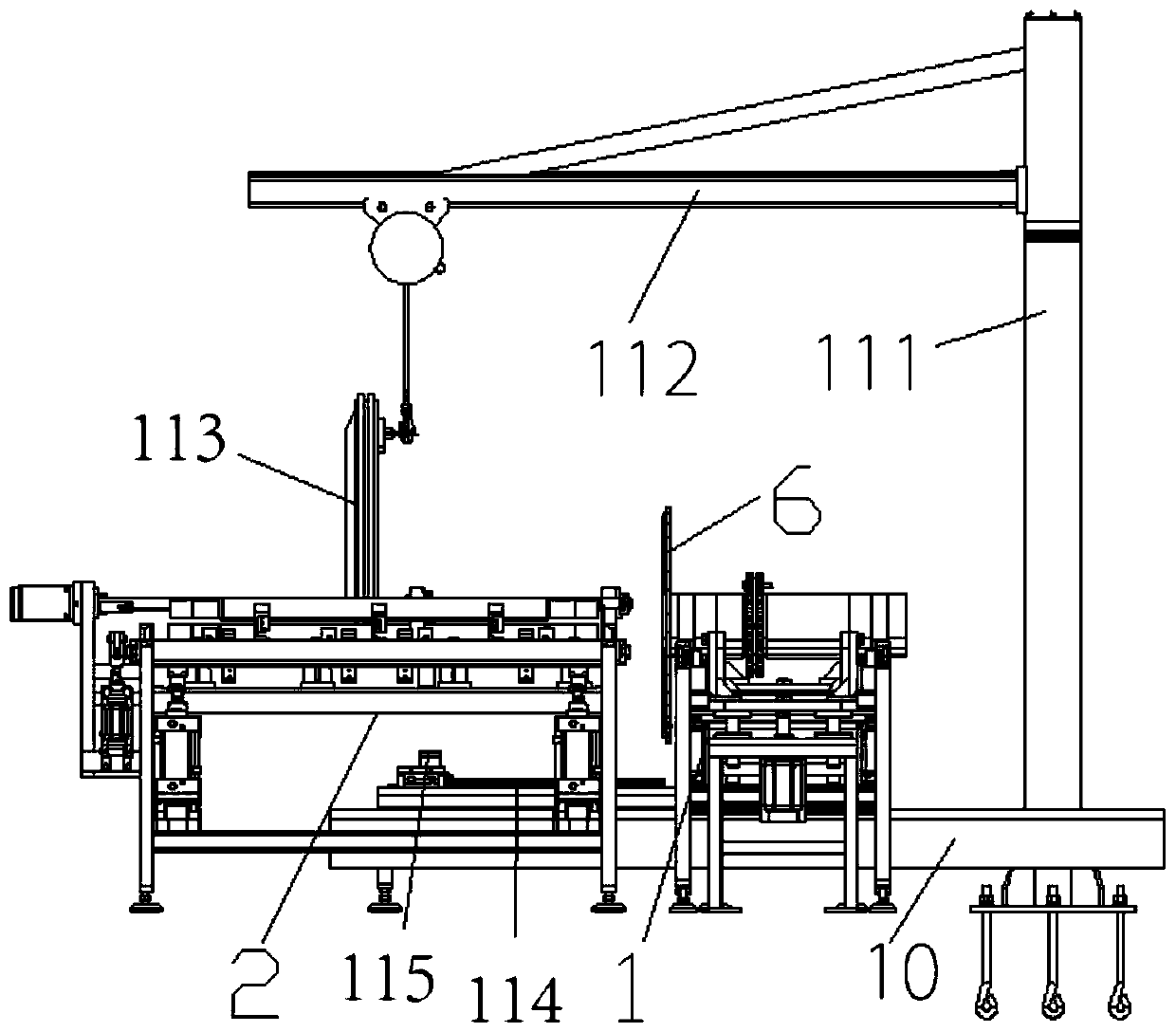

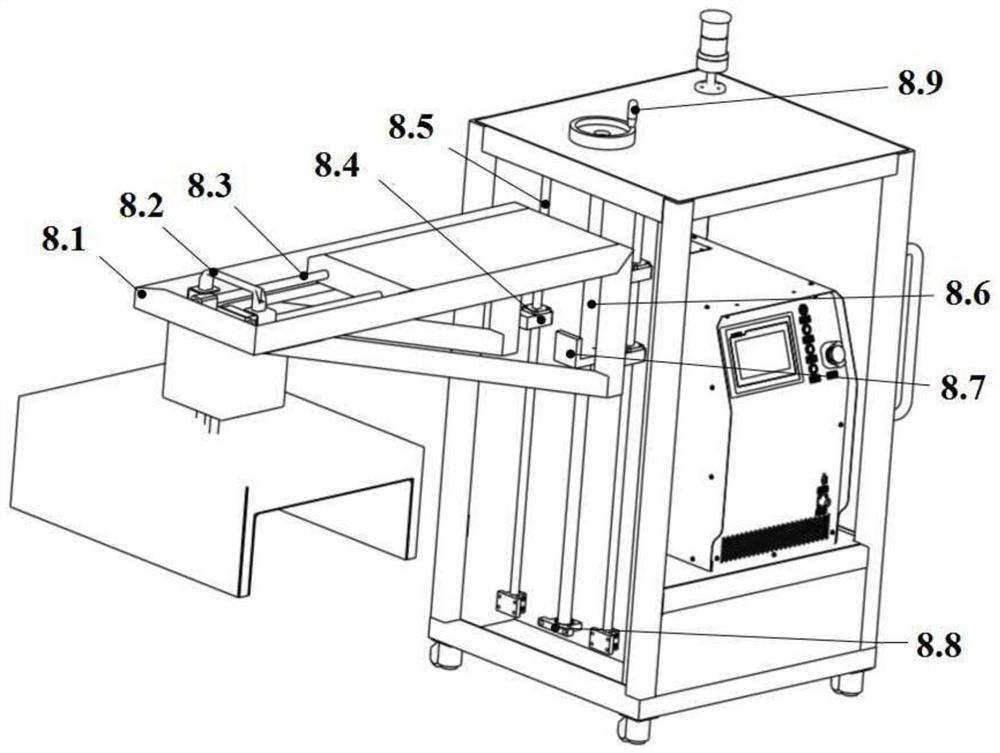

Preheating device and preheating method for TBM tool apron welding

ActiveCN111770598AEffective connectionIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMovement control

The invention provides a preheating device for TBM tool apron welding. The device comprises a working platform, a feeding assembly, a cantilever adjusting mechanism and a control cabinet, the feedingassembly is arranged on the working platform, and the switching of a workpiece between a welding position and a preheating position is achieved through the feeding assembly; one end of the cantileveradjusting mechanism is movably provided with an induction heating coil used for preheating the workpiece, and the other end of the cantilever adjusting mechanism is movably arranged on the control cabinet. A moving assembly is arranged on the bottom surface of the control cabinet to move the control cabinet. According to the preheating device, the effective connection of preheating, welding and post-heating procedures is guaranteed, the carrying work of workpiece at the high temperature is omitted, and the production efficiency and the welding quality of a TBM tool apron are improved. The invention further provides a method for preheating by using the preheating device, and the labor intensity of personnel can be effectively reduced.

Owner:CHINA RAILWAY CONSTR HEAVY IND

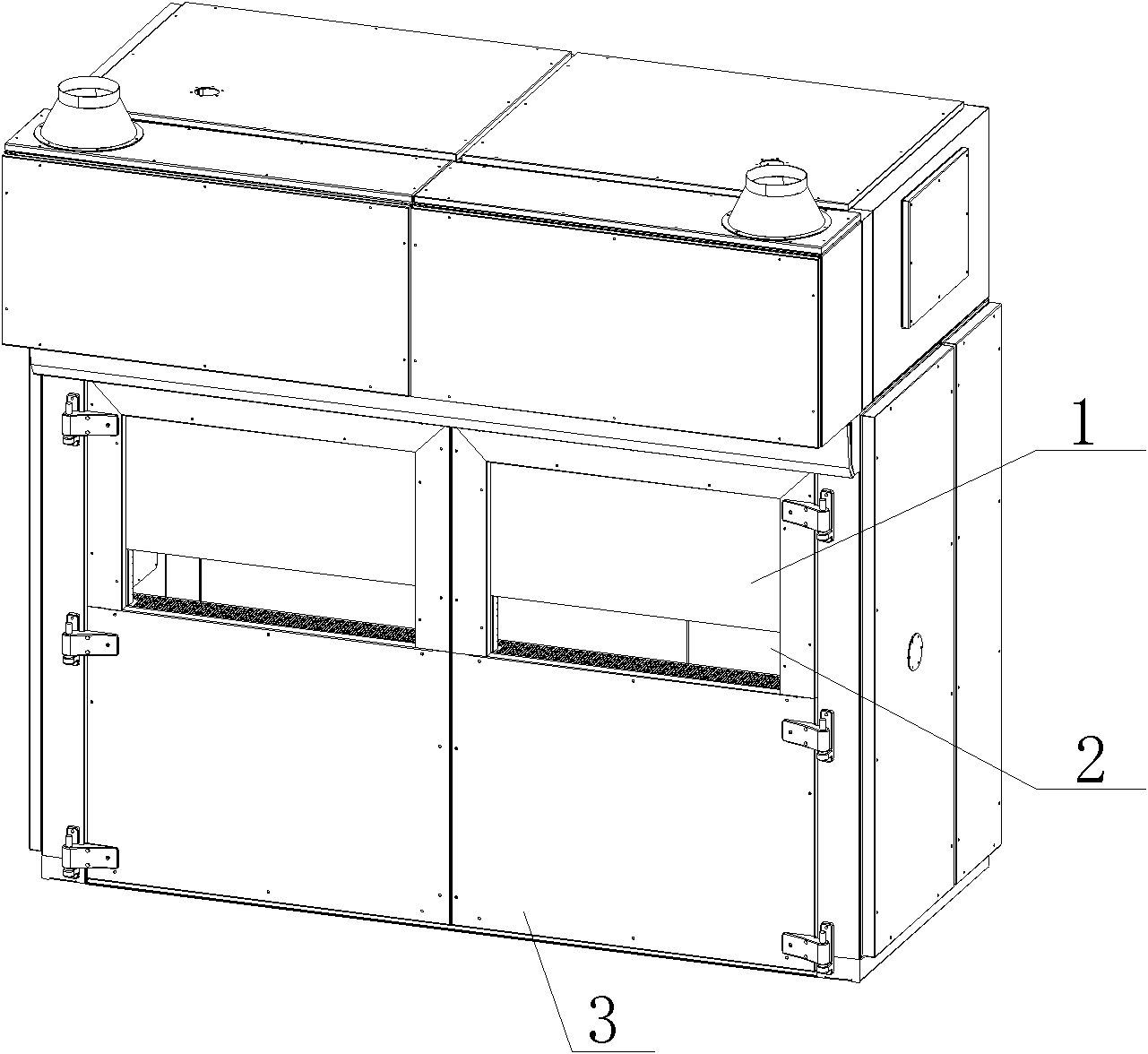

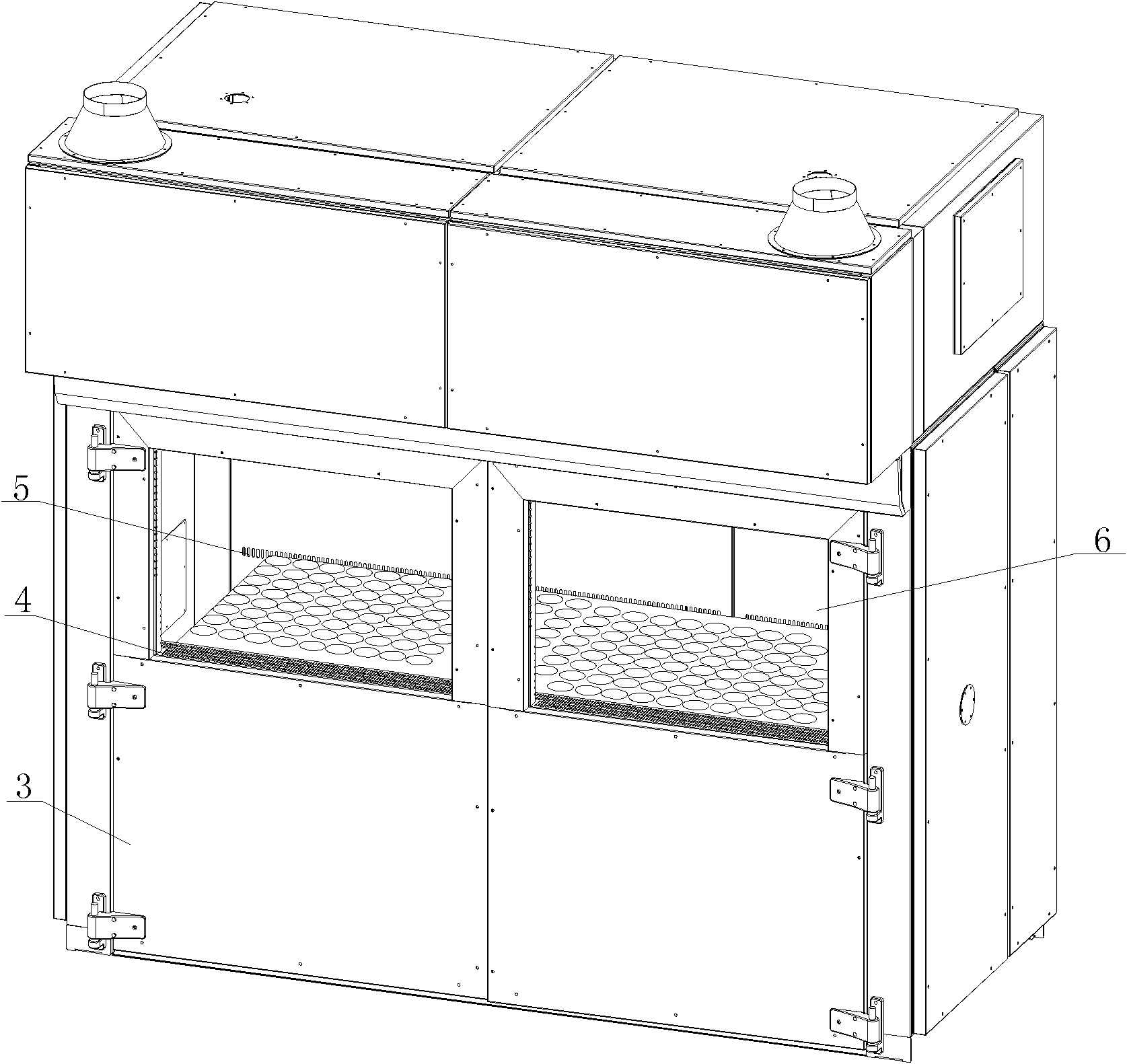

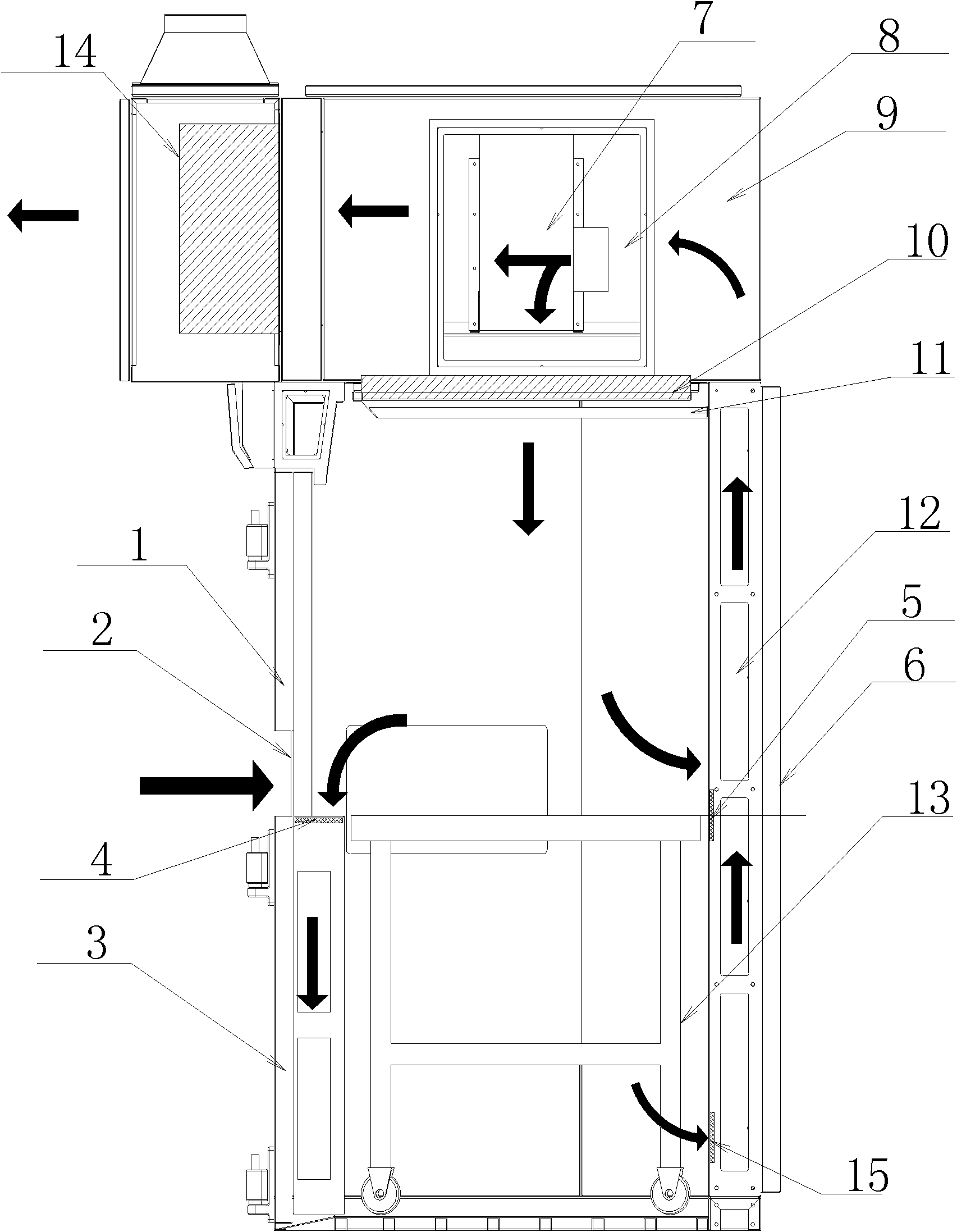

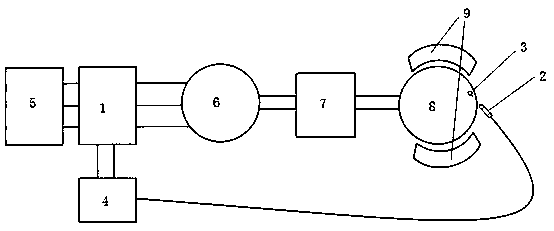

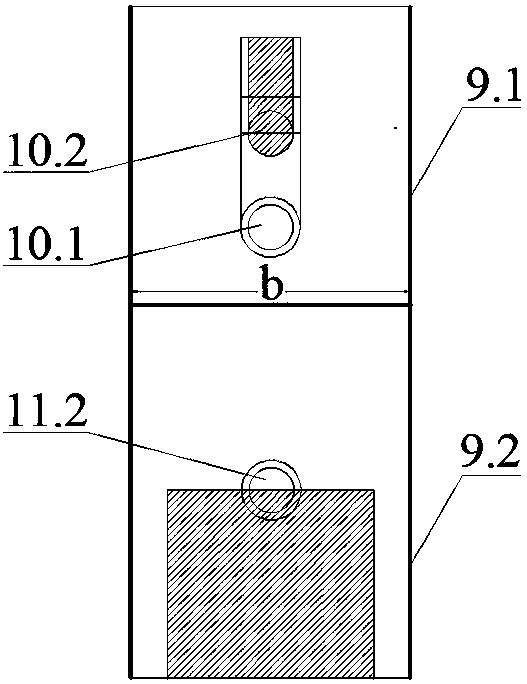

Combined type biologic safety operating chamber

The invention relates to a cleaning device used for a laboratory, and in particular relates to a combined type biologic safety operating chamber. The operating chamber comprises an upper sealing box and a working area, wherein the upper sealing box is positioned above the working area; walls are respectively arranged at the rear side, left side and right side of the working area; the upper sealing box is formed by combining and hermetically connecting metal shells; a door is arranged in front of the working area; the door comprises an operating window and a door body; the walls and the door body are formed by combining and fixedly connecting hollow modules; each hollow module comprises an inner plate and an outer plate; the inner plate and the outer plate are fixedly connected; a hollow cavity is formed between the inner plate and the outer plate; an air port is arranged on the side edge of each hollow module; the hollow cavities between adjacent hollow modules are communicated with each other through the air ports; the hollow cavities are negative pressure cavities; the working area is encircled by the negative pressure cavities; and an operating table type trolley is arranged in the working area. The combined type biologic safety operating chamber can supply a local clean environment to a large-scale experimental device. The combined type biologic safety operating chamber has convenience in mounting, can be mounted on site, and is convenient for an experimenter to perform an experiment.

Owner:青岛柏镁仪器有限公司

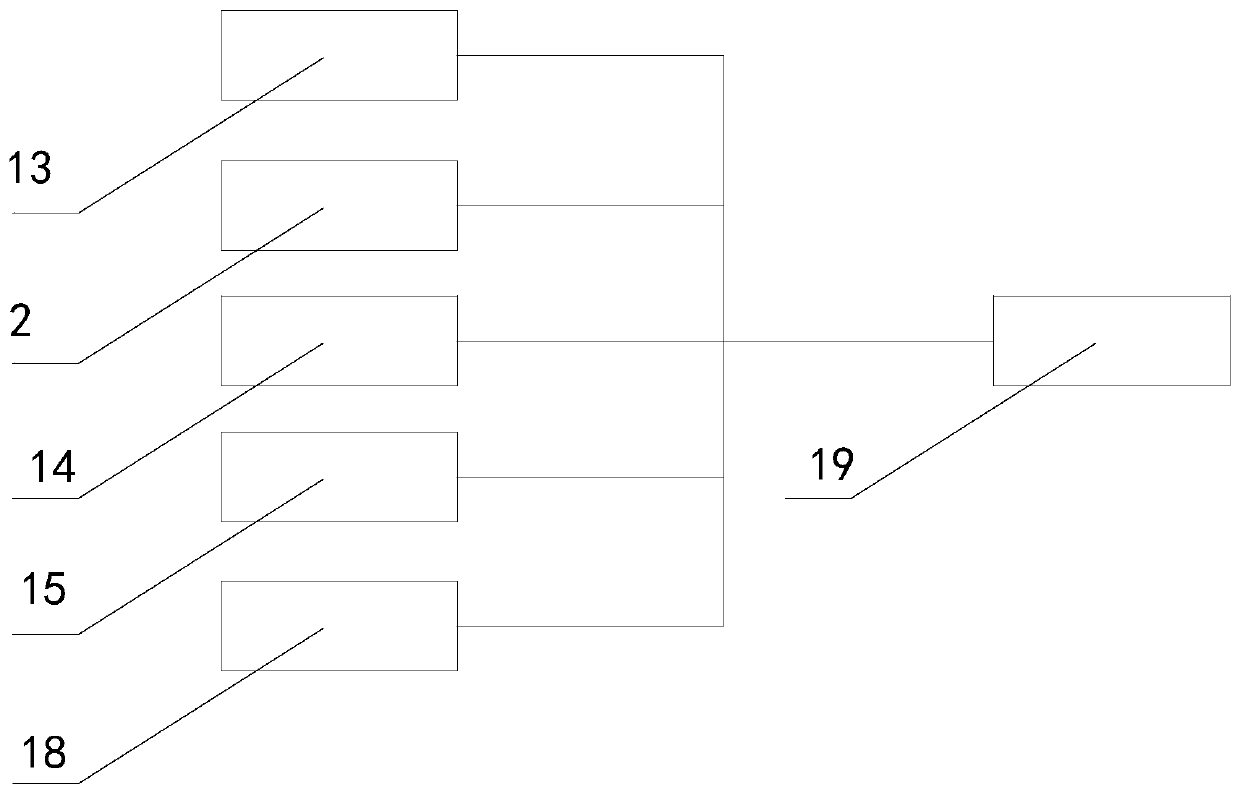

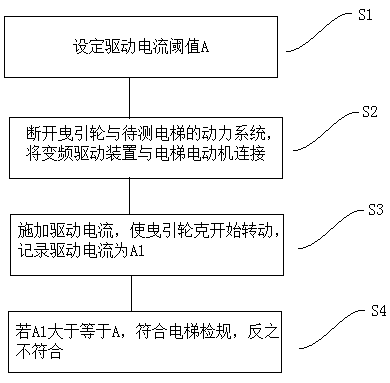

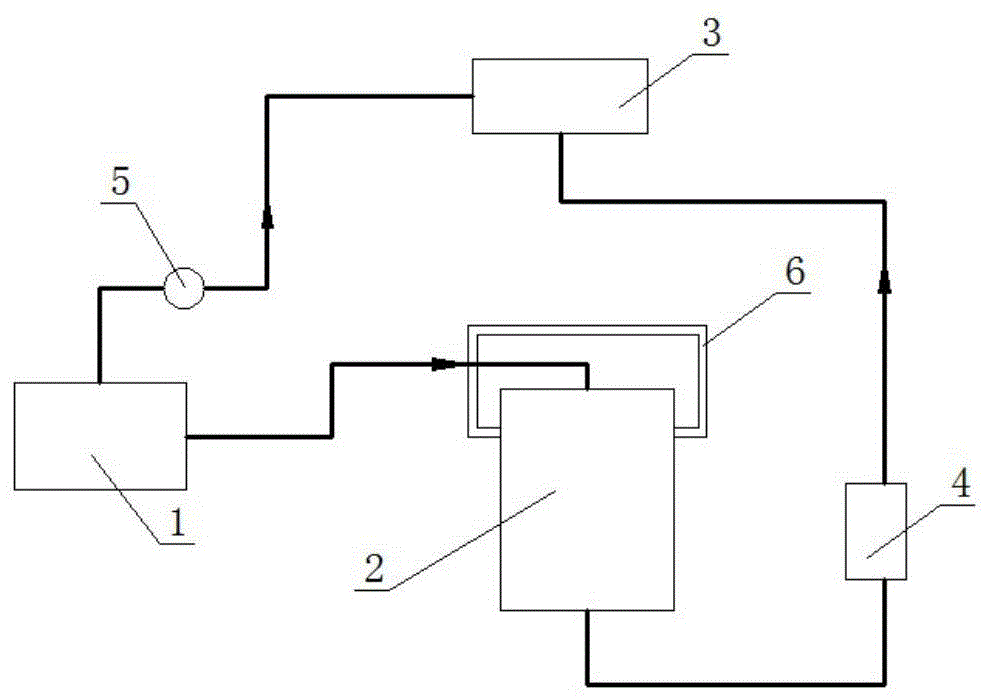

Evaluation system and method for elevator brake static braking performance

ActiveCN111056397AJudging the braking performanceReduce handling workElevatorsSustainable buildingsDriving currentElevator system

The invention relates to an evaluation system and method for elevator brake static braking performance. The evaluation system includes a variable frequency drive device, a reflective photoelectric switch and a control device, wherein the variable frequency drive device is connected to the control device and an elevator system for applying a driving current to control a traction sheave of the elevator system to apply driving torque to a brake of the elevator system; and the reflective photoelectric switch is connected to a reflector arranged on the traction sheave and the control device for detecting rotation of the traction sheave. The system only needs to carry the weight once to complete detection of braking force of multiple elevators with the same type, greatly reduces transportation work before detection, saves time and effort, realizes rapid quantitative high-precision detection on site, improves efficiency of inspection and detection, and solves industry difficult problems in the field.

Owner:GUANGDONG INSPECTION & RES INST OF SPECIAL EQUIP ZHUHAI INSPECTION INST

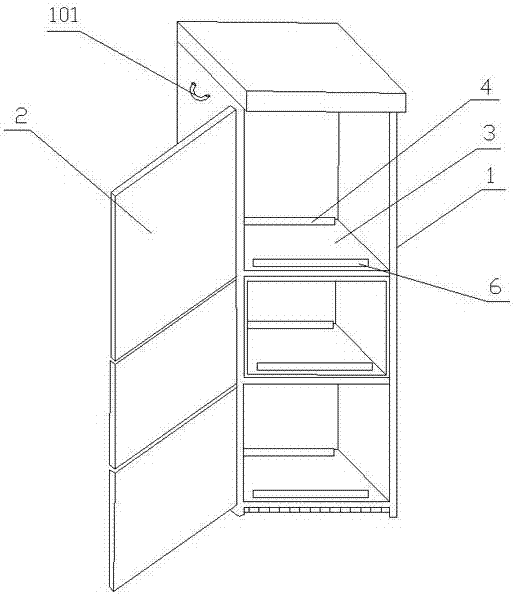

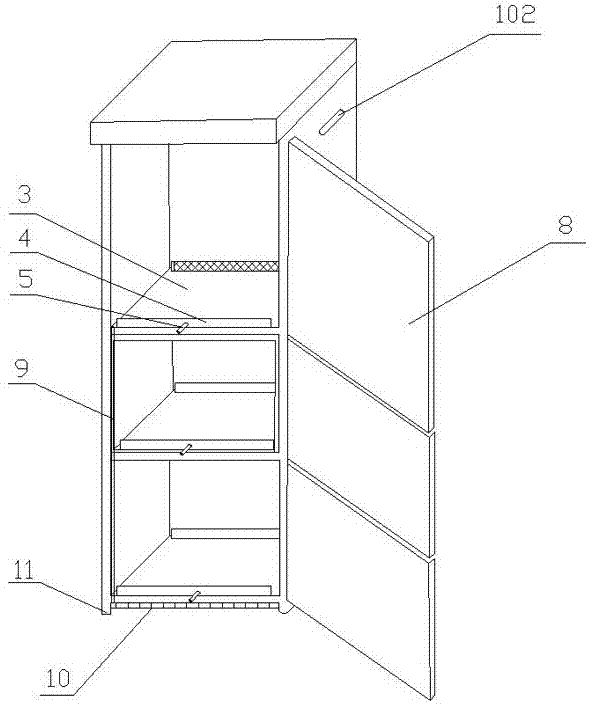

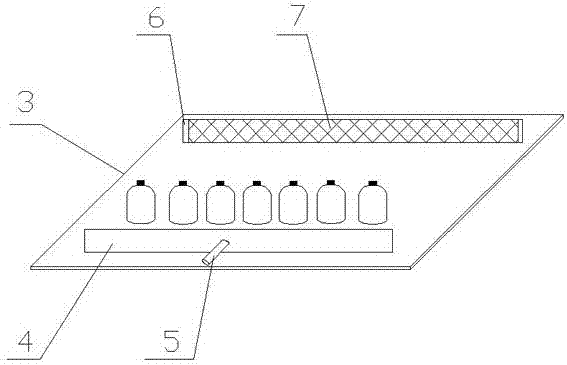

Medical refrigerator capable of avoiding storing confusion of reagents or drugs

PendingCN107883639AAvoid expirationEnsure safetyLighting and heating apparatusDomestic refrigeratorsEngineeringBack door

The invention discloses a medical refrigerator capable of avoiding storing confusion of reagents or drugs. The medical refrigerator includes a box body. The two opposite side surfaces of the box bodyare provided with a front door used for taking out the reagents and a back door used for storing the reagents correspondingly. A pushing plate is arranged at the position, close to the back door, of apartition plate. A baffle is arranged at the position, close to the front door, of the partition plate. The pushing plate is provided with a retractable pulling rod. The retractable pulling rod is pushed so as to drive the pushing plate to move forwards, so that the reagents stored on the partition plate are driven to be propelled towards the front door, it can be ensured that the reagents with early date are used in advance, and the fact that the reagents are expired due to storing disorder of the reagents is prevented effectively. When the pushing plate is needed to be pushed forwards, theretractable pulling rod is lengthened, then the pushing plate is pushed towards the direction of the front door, and the reagents can be taken out from the edge of the front door; and hands can be prevented from frequently stretching into the box body by arranging the retractable pulling rod, and pollution to the internal environment of the box body is reduced accordingly.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Automatic cleaning and slicing device for Chinese yam machining

InactiveCN109770386AImprove efficiencyReduce handling workMetal working apparatusFood treatmentHydraulic cylinderEngineering

The invention discloses an automatic cleaning and slicing device for Chinese yam machining. The device comprises a case, a cutting chamber, a high pressure water pump and a cleaning ring. A feeding hopper is arranged at the top of the case, the high pressure water pump is installed above one side of the case, a water inlet pipe is installed above the high pressure water pump, a water outlet pipe is arranged at one side of the case, an automatic controller is installed at one side of the case, the cleaning ring is arranged at the upper portion inside the case, a high pressure nozzle is arrangedinside the cleaning ring, a partition plate is arranged below the cleaning ring, the cutting chamber is arranged below the partition plate, a baffle is installed inside the cutting chamber, and a hydraulic cylinder is installed at one side inside the cutting chamber. The device has the advantages that after high-pressure flushing is performed on Chinese yam, slicing treatment is directly performed, the Chinese yam raw material transporting work is omitted, the Chinese yam efficiency is improved, and the labor intensity of operators is lowered.

Owner:成都北辰航易工程设备有限公司

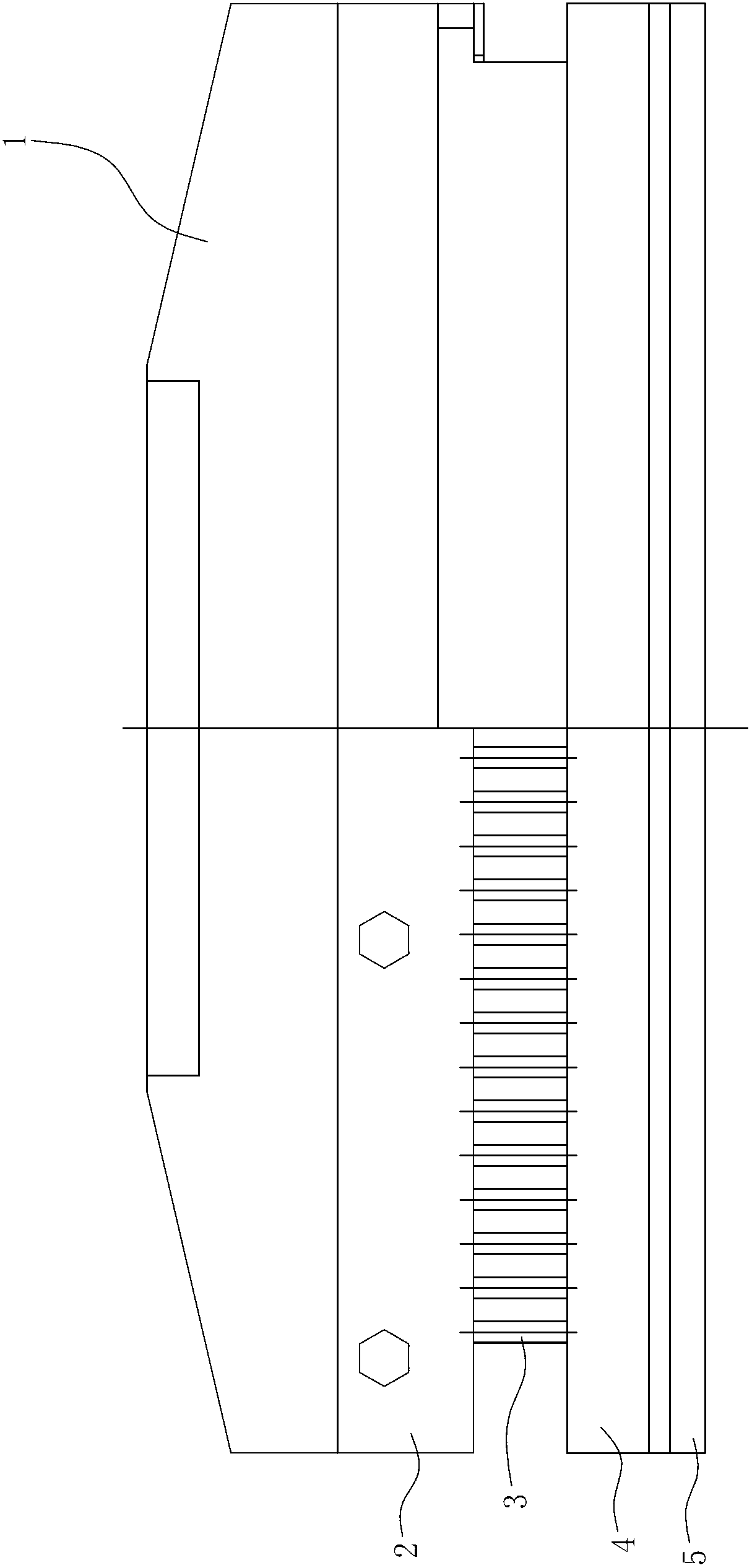

Die for punching holes and forming tear line on paper product

The invention discloses a die for punching holes and forming a tear line on a paper product. The die comprises a slide block punching head, a pin hanging plate, punching pins, a guide plate and a bottom plate, wherein the guide plate is arranged above the bottom plate; the pin hanging plate is arranged at the bottom of the slide block punching head, and is positioned above the guide plate; the punching pins are arranged at the bottom of the pin hanging plate; pin bodies pass through the guide plate; the bottom plate is provided with die holes for downward punching of the punching pins; tear line punching pins are arranged on the pin hanging plate beside the punching pins in the arrangement directions of the punching pins; a soft strip is arranged on the surface of the bottom plate, under the tear line punching pins; and two groups of punching pins are positioned on both sides of the tear line punching pin respectively. After the structure is adopted, punching processing and tear line processing are completed synchronously, i.e. row holes and a tear line can be processed by punching the die downward once, so that a process is simplified, only one piece of equipment is required to be put into production, and the equipment investment is small; and carrying work during production is eliminated, so that the quantity of workers is saved, and the labor cost is reduced.

Owner:陈德来

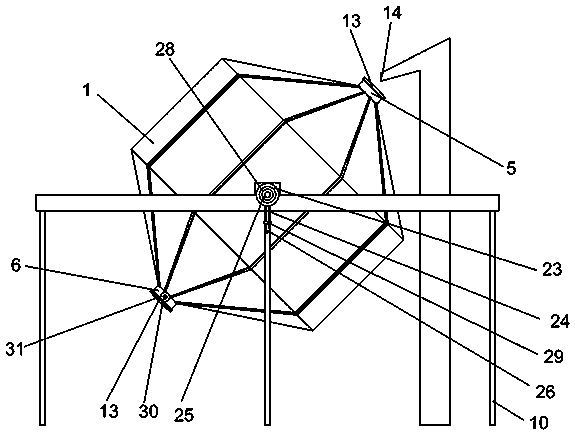

Integrated device and production process for soaking grains, steaming grains and utilizing residual air for making wine

PendingCN111254028AImprove insulation effectImprove pasting effectAlcoholic beverage preparationRotational axisYield (wine)

The invention discloses an integrated device and production process for soaking grains, steaming grains and utilizing residual air for making wine. The integrated device comprises a rotary steamer, wherein the inside of the rotary steamer is provided with a filter plate which divides the inside of the rotary steamer into an independent raw material bin and a water bin; the top of the raw materialbin is provided with a raw material port; the top of the water bin is provided with a water outlet; the rotary steamer is provided with a rotating shaft; two ends of the rotating shaft are respectively provided with L-shaped holes to form a main rotating hollow part and an auxiliary rotating hollow part; the main rotating hollow part and the auxiliary rotating hollow part are both connected with asupporting frame through bearings; a channel inside the main rotating hollow part is connected with the inner wall of the raw material port through a residual gas recovery pipe; a channel inside theauxiliary rotating hollow part is connected with the water bin through a water vapor pipeline; and the main rotating hollow part is connected with a driving component through a transmission component.The device is simple in operation, saves labor, saves time, saves water, saves energy, reduces discharge of grain soaking sewage, increases the wine yield and improves product quality.

Owner:彭州市徐氏酒厂

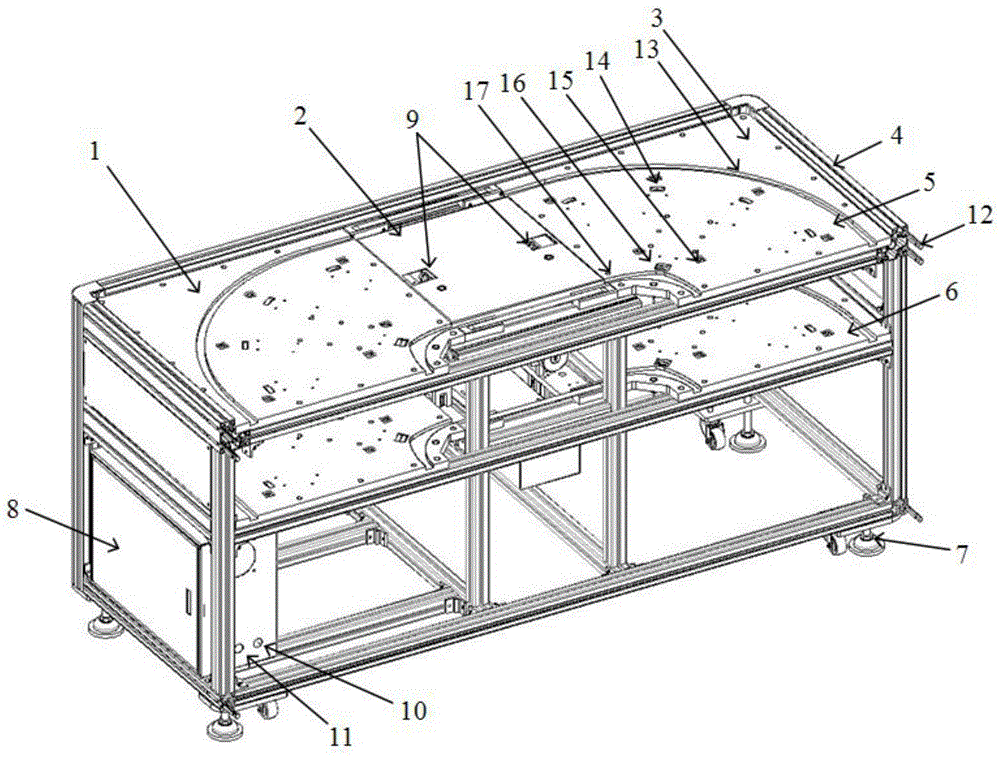

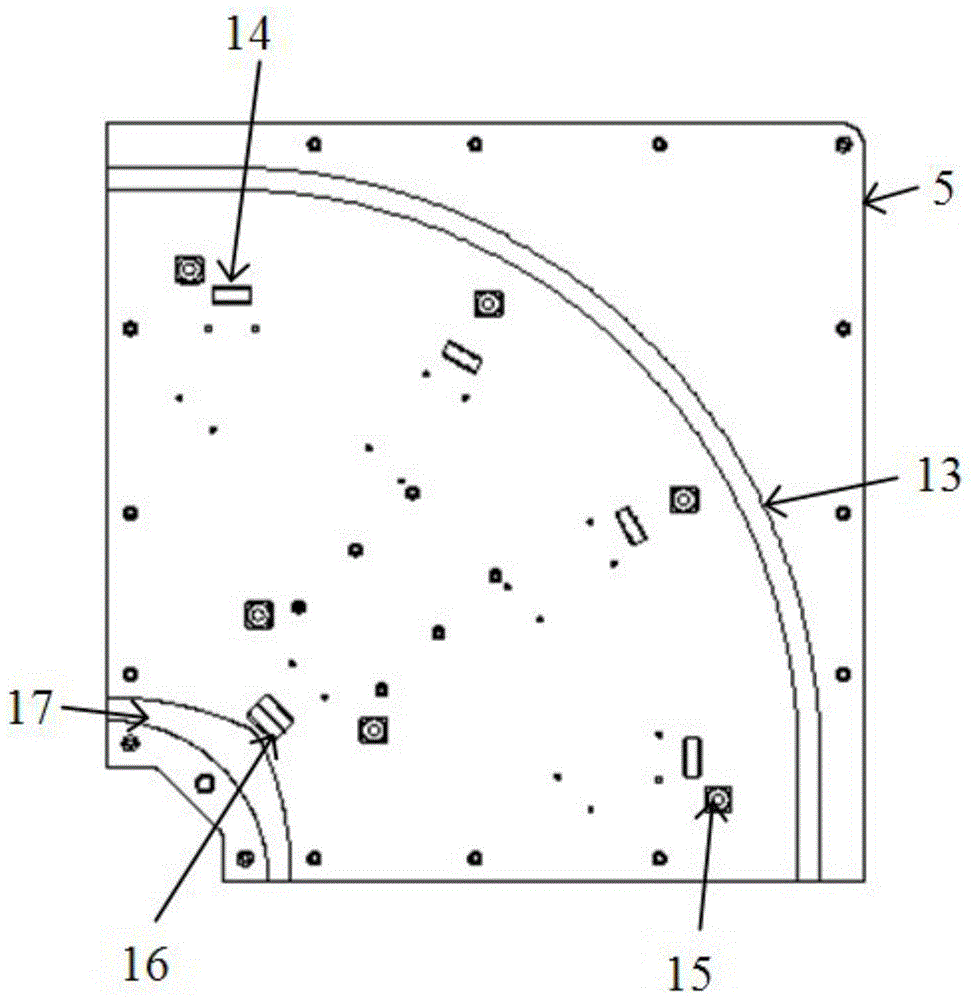

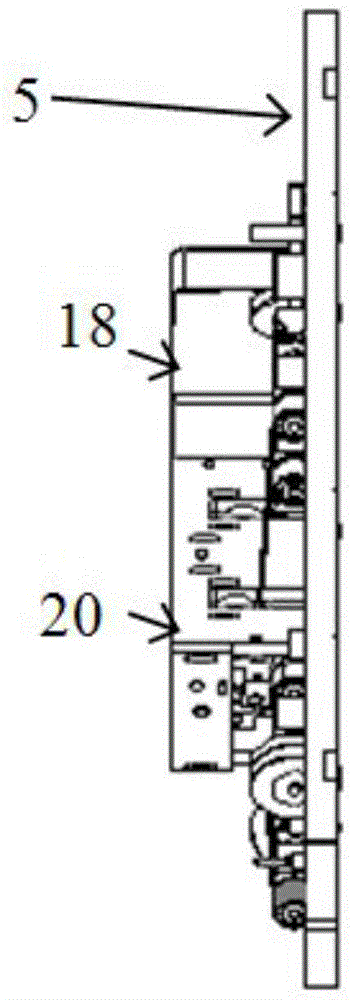

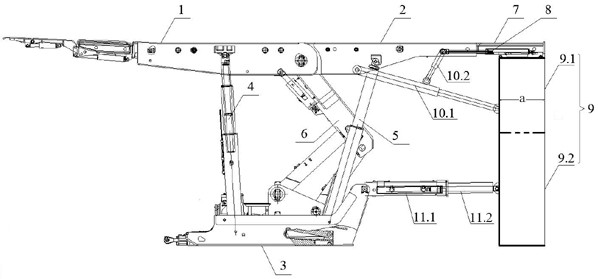

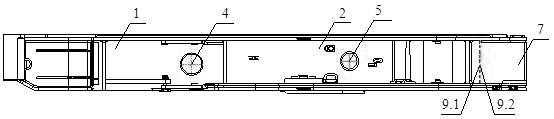

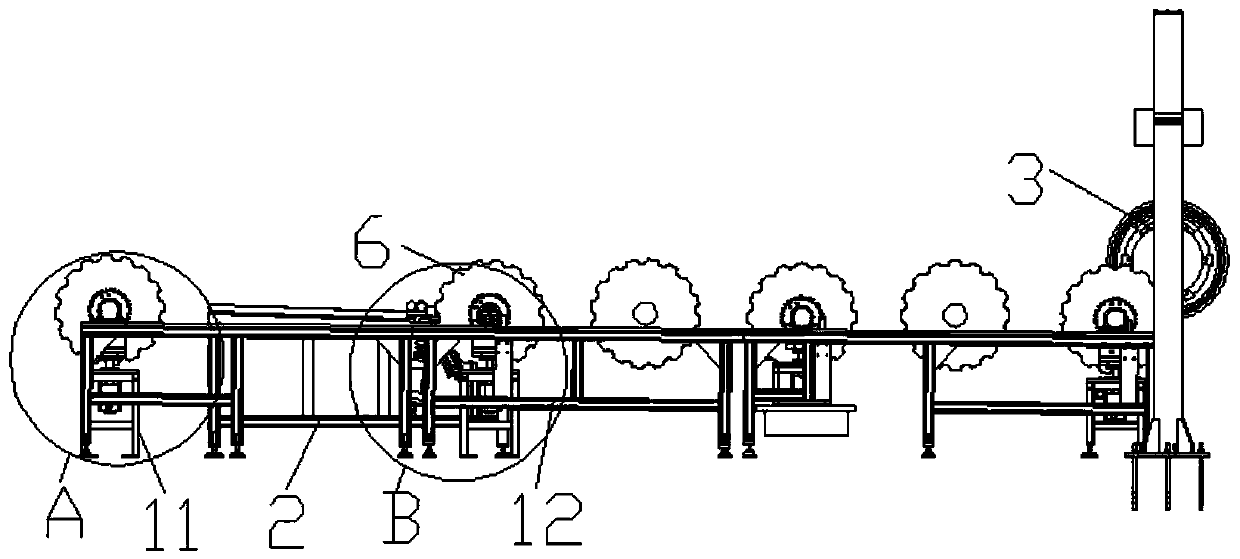

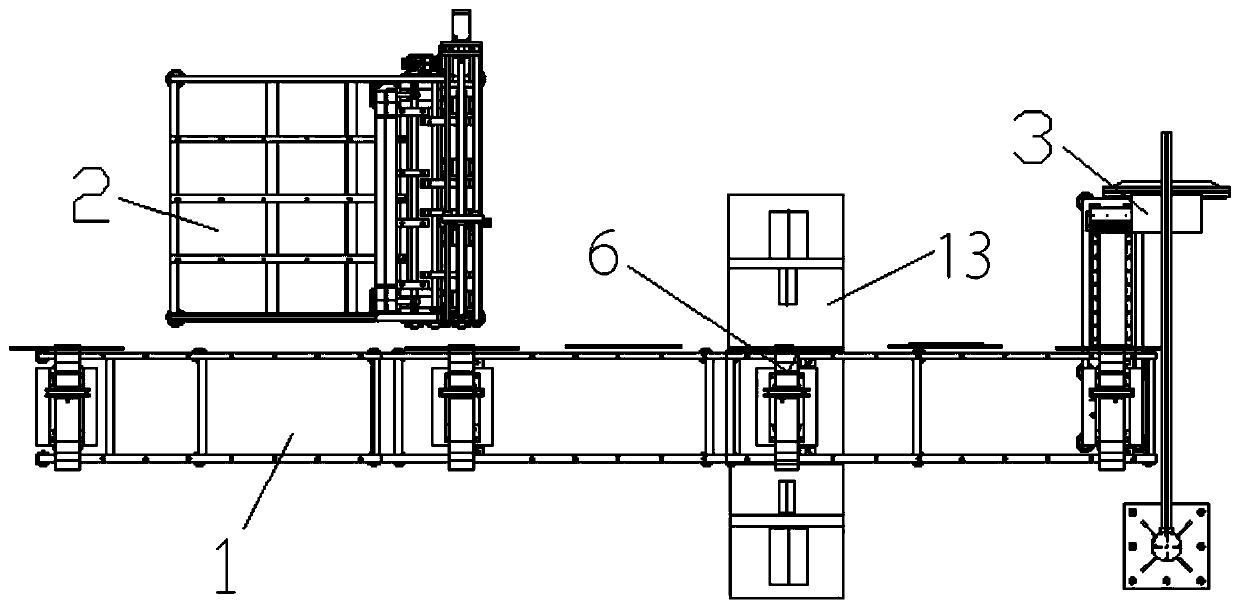

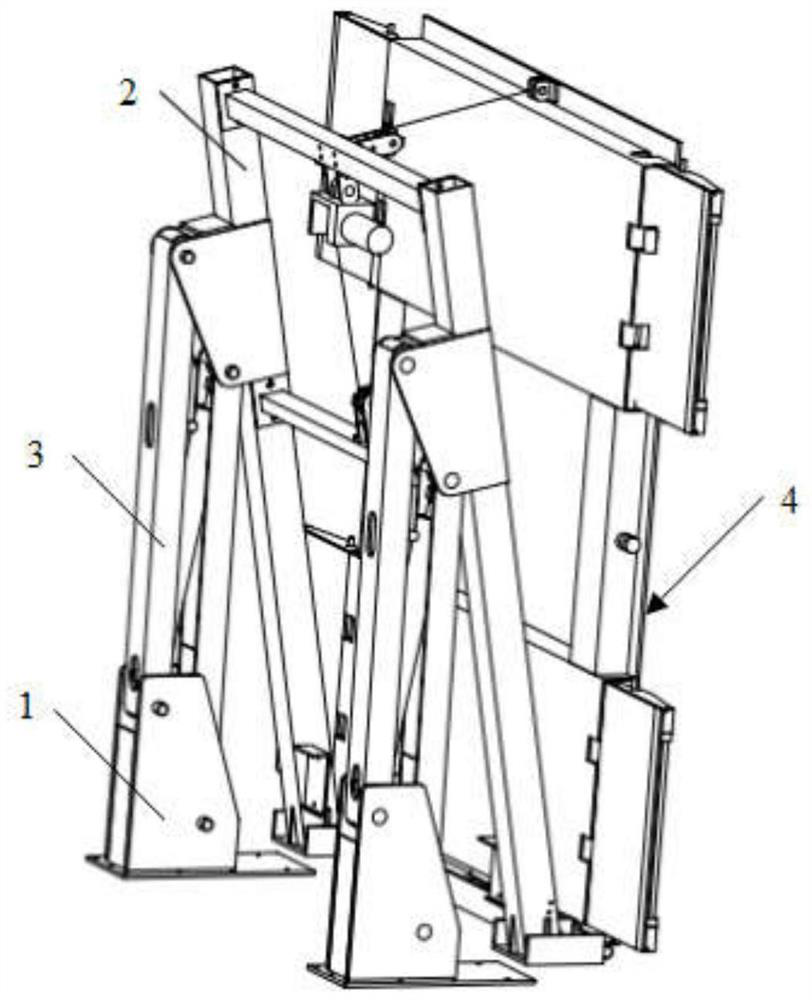

An automatic assembly line corner machine capable of flexible turning and backflow

ActiveCN105059858BReduce handling workIncrease productivityMechanical conveyorsAssembly lineEngineering

The invention discloses an automatic assembly line turning machine capable of achieving flexible turning and backwash. The turning machine is mounted on the turning portion of a U-shaped assembly line, the U-shaped assembly is of a double-layer structure, and the turning machine is composed of two 90-degree turning machine bodies and a linear rail portion. Inner guide grooves and outer guide grooves are formed in the 90-degree turning machine bodies and the linear rail potion, trays are placed on the guide grooves and supported by a belt, a driving rubber wheel and a universal ball, and products are placed on the trays. After the products are produced, the trays drop to the lower layer of the assembly line from a lift at the tail end for backwash, and the trays flowing back are lifted to the upper layer of the assembly line through the lift after reaching the head end. The automatic assembly line turning machine is intelligent, and it is guaranteed that materials such as the products, tray jigs and tools on the assembly line can flexibly turn and achieve transition, and can flow back. The carried empty trays are reduced, so that manpower and material resources are saved. The long and thin assembly line is bent, so that the total length is reduced, the occupied area of the assembly line is reduced, and space is saved.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

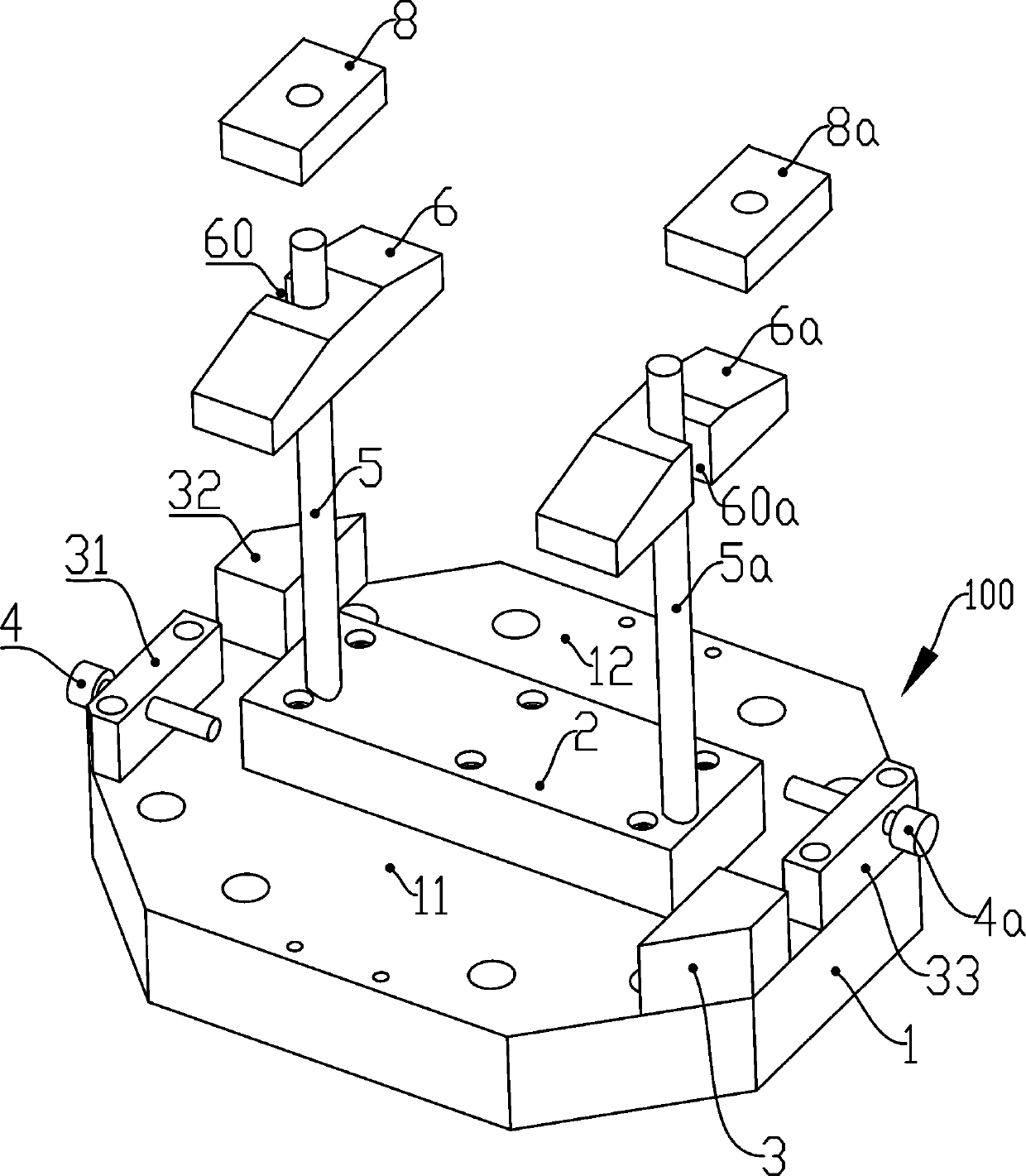

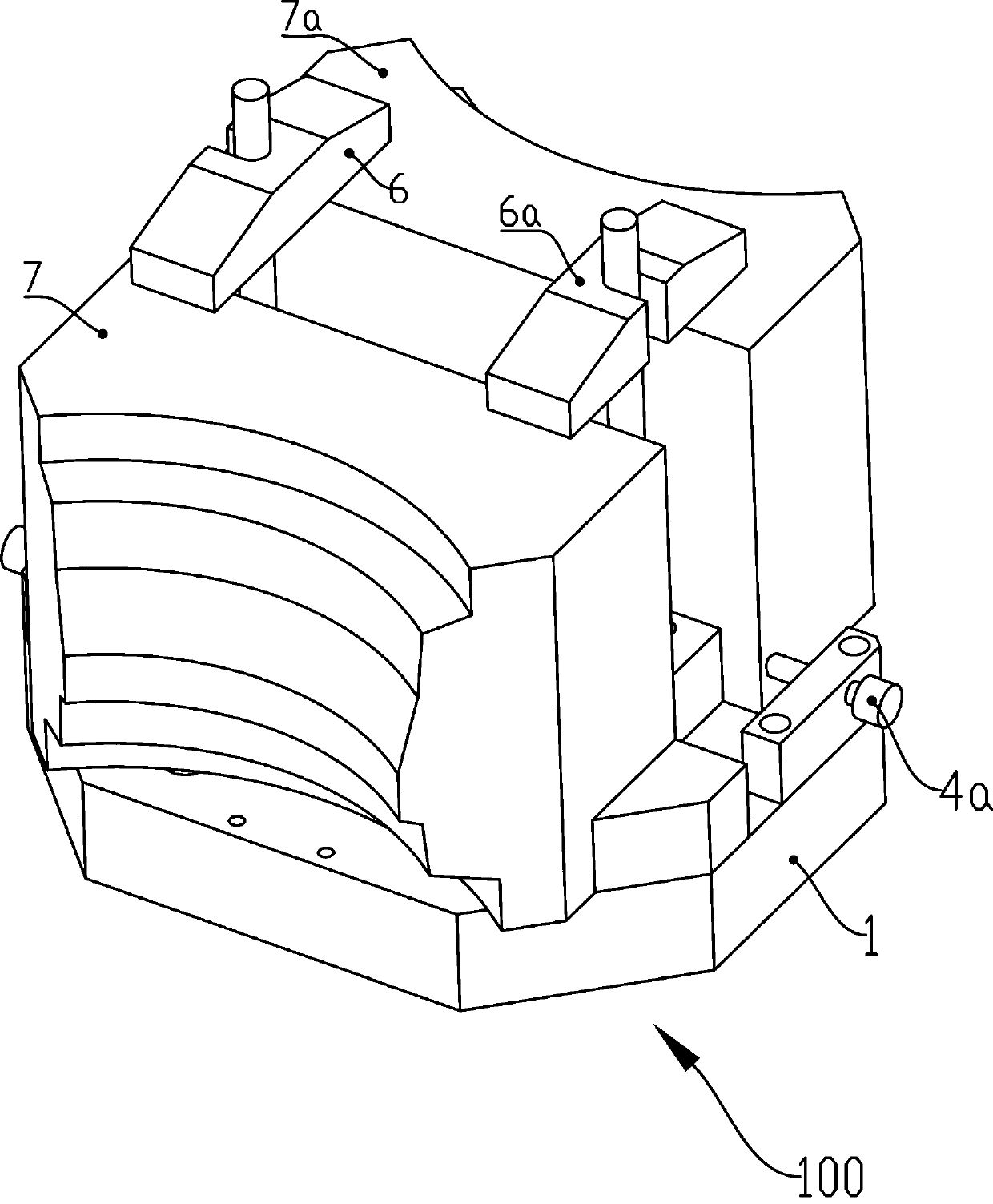

Positioning clamp for clamping hub side modules

PendingCN107855802AReduce handling workEasy to operatePositioning apparatusMetal-working holdersVertical projectionEngineering

The invention relates to a positioning clamp for clamping hub side modules. The positioning clamp for clamping the hub side modules comprises an installing base; the rough center area of the installing base is provided with a middle dividing boss extending transversely; the space on the installing base is divided by the middle dividing boss into two side mold positioning spaces arranged in a front-area divided manner; the left side and the right side of each side mold positioning space are each provided with a side edge boss; one side edge boss is provided with a limiter capable of moving transversely; the middle dividing boss is further provided with a pair of supporting columns arranged in a front-back manner in the transverse direction and a pair of ejecting pressing blocks movably arranged on a supporting column in a penetrating and sleeving manner; part of the vertical projection areas of the front end and the rear end of each ejecting pressing block fall into the side mold positioning spaces arranged in the front-rear divided manner; and nuts rotationally connected with a thread of the supporting column and capable of being ejected and pressed on the ejecting and pressing blocks are further included. In this way, the two hub side modules can be conveniently and fast positioned at the same time, and the machining precision of the hub side modules can also be improved easily.

Owner:FOSHAN NANHAI SUPERBAND MOLD

Glass carrying gripper device with lining paper

PendingCN112744588AReduce processShorten the takt timeCharge manipulationConveyor partsStructural engineeringSlip sheet

The invention relates to a glass carrying gripper device with lining paper. The glass carrying gripper device with the lining paper comprises a lining paper carrying device, a support frame, a suction cup assembly, a robot flange plate and a vacuum system, wherein the support frame is used for arranging the suction cup assembly according to glass with different specifications; the lining paper carrying device is used as an auxiliary tool of a gripper; the robot flange plate is a connecting piece of the robot body and the glass carrying gripper with the lining paper; and the vacuum system is installed in a cavity of the robot flange plate. According to the glass carrying gripper device with the lining paper provided by the invention, the glass is adsorbed by the gripper, and the lining paper on the bottom surface of the glass is clamped at the same time, so that the glass carrying gripper device with the lining paper is used as an integral unit for carrying or stacking work, the procedure of manually laying the lining paper is reduced, the carrying and matching work of different materials by multiple robots is reduced, the production takt of a station is reduced, and the production efficiency is improved.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

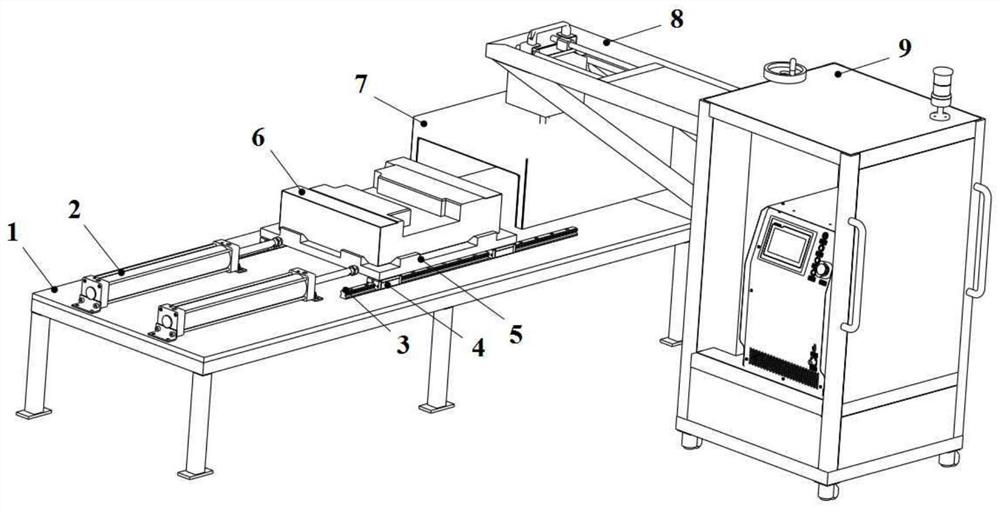

A pc prefabricated component forming equipment

ActiveCN106217589BReduce handling workEasy to carry outCeramic shaping apparatusEngineeringUltimate tensile strength

The invention provides PC prefabricated component forming equipment. The PC prefabricated component forming equipment comprises two parts of a mold table and a vibration platform, and is characterized in that the mold table is a fixed platform; a guide rail is arranged on the fixed platform; the vibration platform is a mobile vibration platform; a vibration mechanism and a walk driving mechanism are arranged on the mobile vibration platform; the walk driving mechanism is positioned on the guide rail, so that the mobile vibration platform is movably arranged on the fixed platform along the guide rail corresponding to the fixed platform. The PC prefabricated component forming equipment adopts a working mode of fixed mold table and automatic moving vibration platform, improves the working efficiency, reduces the cost, improves the prefabricated component production quality, and reduces the working intensity of operators.

Owner:ANHUI XINGHUA FORKELEVATOR

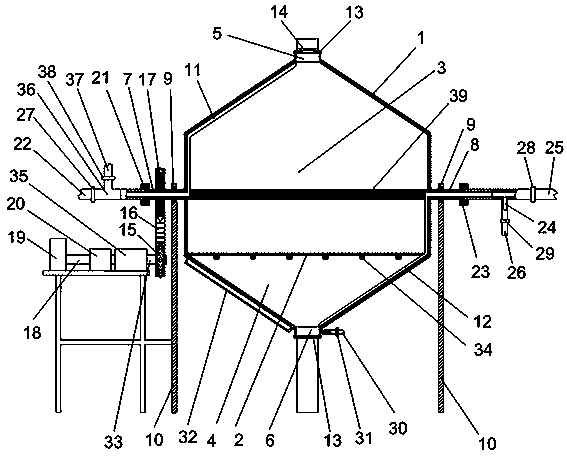

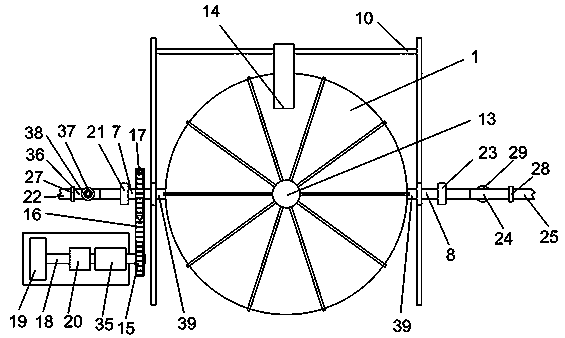

Zipper head automatic anodizing equipment

ActiveCN103469270BImprove the quality of electroplatingImprove plating qualityCellsSlide fastenersControl systemEngineering

The invention provides an automatic anodizing equipment for zipper sliders. The plating tank consisting of a pre-plating treatment tank, a plating treatment tank and a post-plating treatment tank is connected from end to end to form a closed ring. The anode generator is installed on a vertical guide rail. The guide rail is connected with the chain of the walking device, and the anode generator is also provided with rollers, which rest on the horizontal circular track, and the circular track can rise and fall under the drive of the lifting device; in the control system, the walking device and the lifting Under the action of the device, the anode generator walks intermittently on the circular track, and cycles in the order of rising, walking, falling, and staying. The present invention enables the zipper head to be electroplated continuously through automated equipment, which greatly improves the production efficiency of electroplating, and controls the time of each process by an intelligent program. The electroplating quality is high, and the electroplating quality of the zipper head is improved. The labor intensity is reduced, and the on-site environment is improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

Roof block filling hydraulic support and using method thereof

ActiveCN110005460BReduce handling workAchieve demouldingMaterial fill-upMine roof supportsEngineeringIndustrial engineering

Owner:TAIYUAN UNIV OF TECH

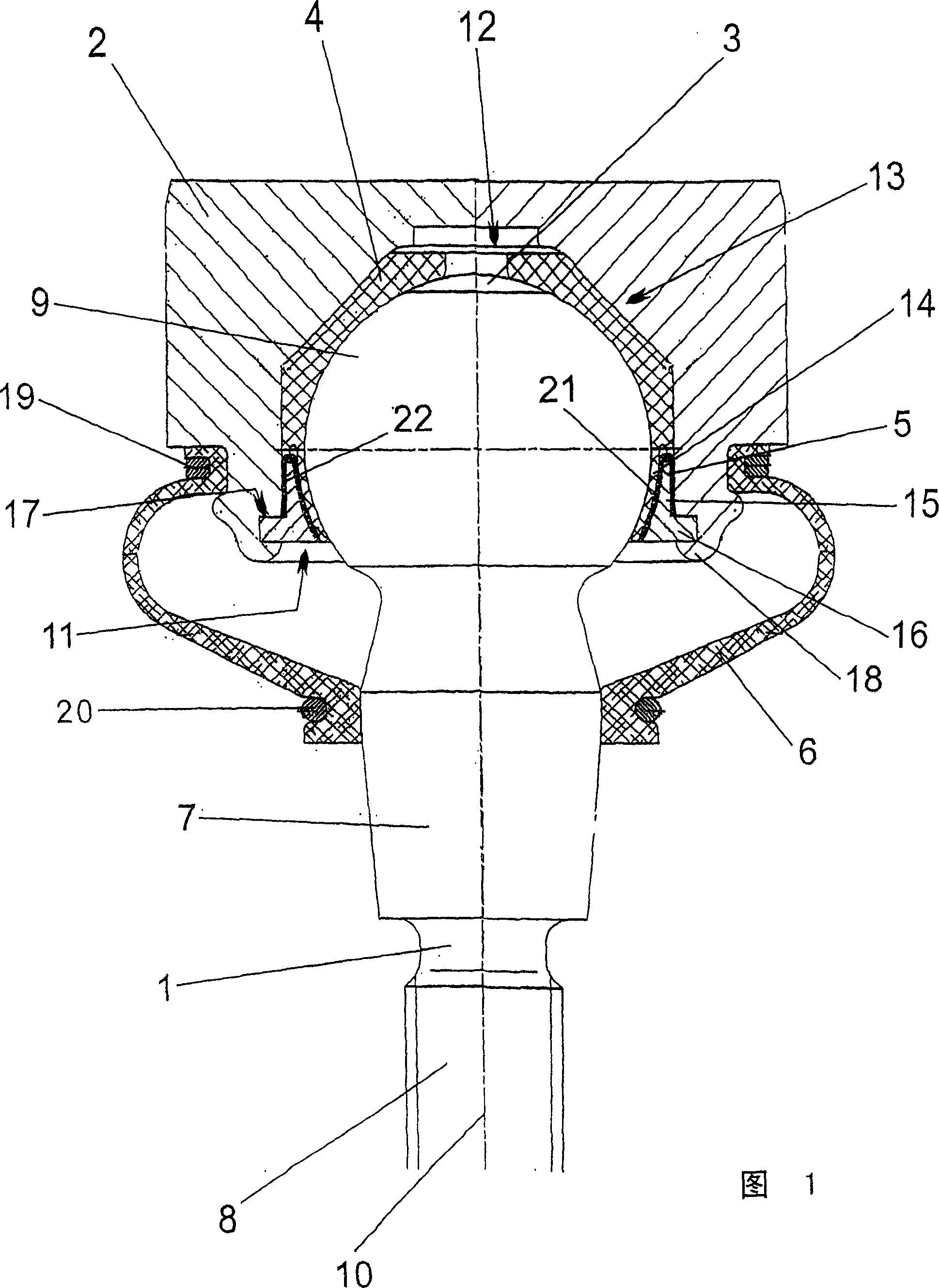

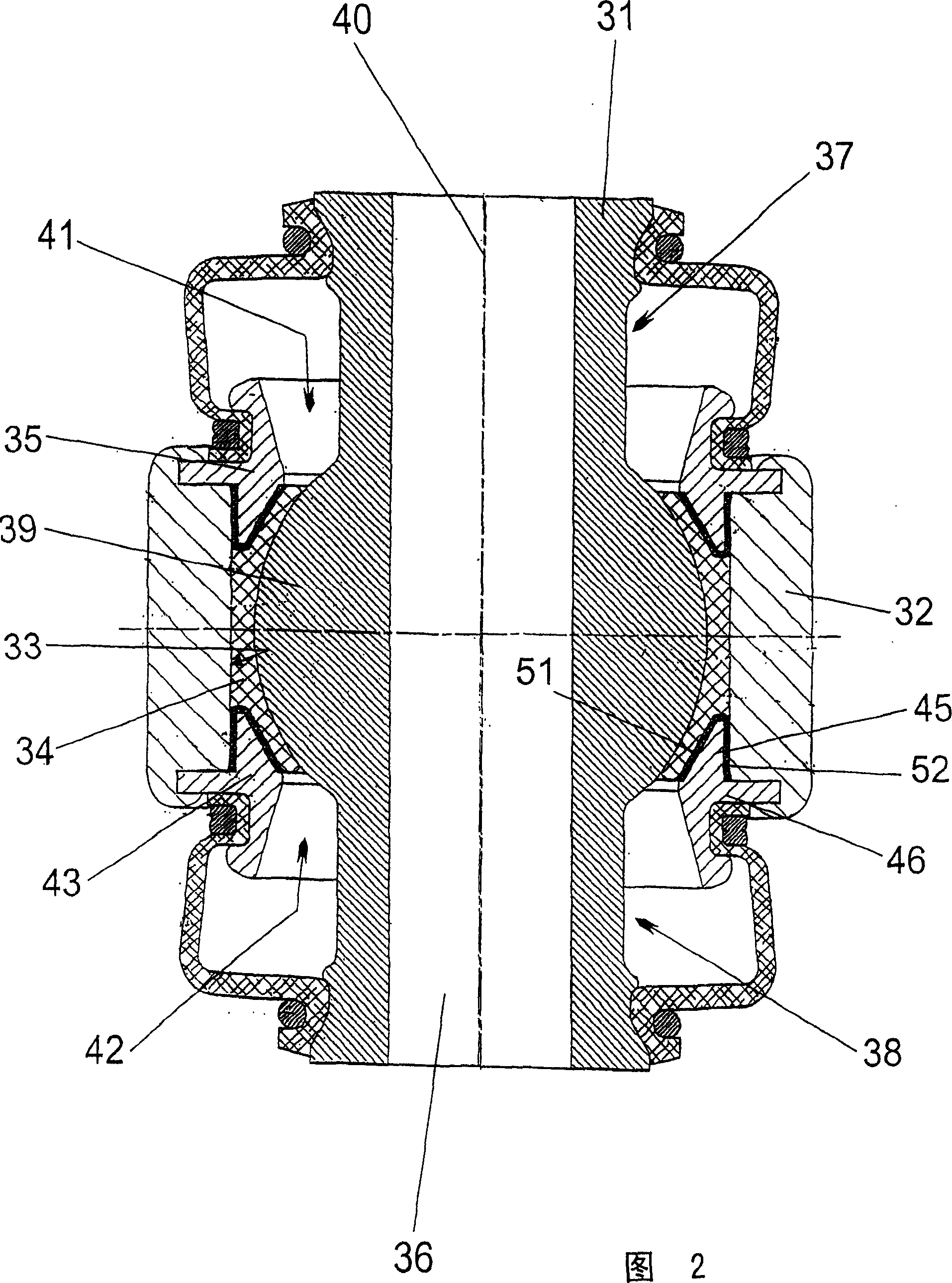

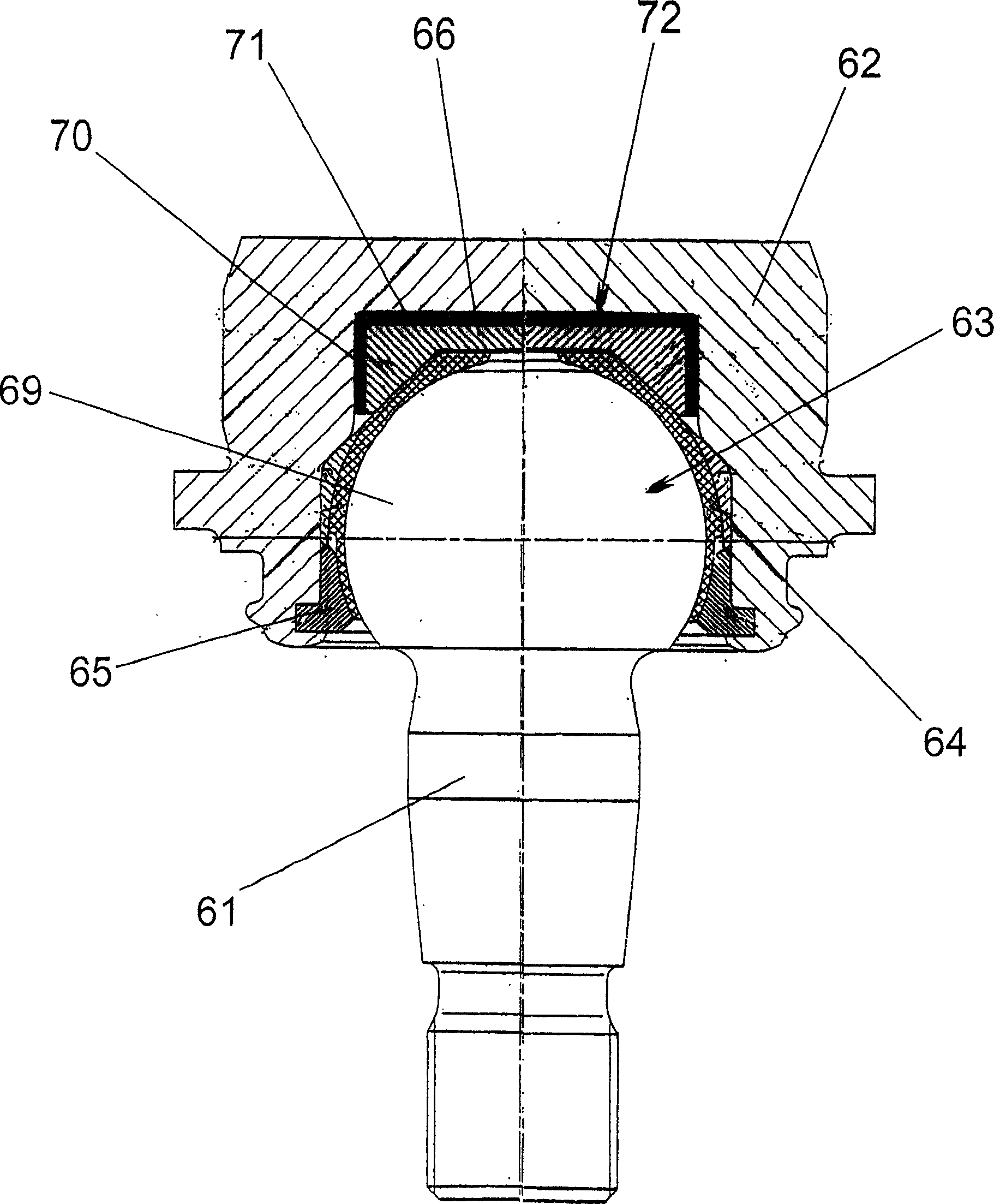

Ball-and-socket joint

InactiveCN1263960CAvoid skewAvoid widening tolerancesPivotal connectionsPivotsSpherical jointBearing surface

Owner:ZF LEMFOERDER METALLWAREN AG

Multiple-mould changing system in parallel arrangement

ActiveCN102527835BImprove processing efficiencyReduce handling workShaping toolsEngineeringWorkstation

The invention relates to a multiple-mould changing system in parallel arrangement, which utilizes a single press assorted with multiple moulds, is capable of realizing quick changing of the moulds and reasonable in arrangement, and overcomes defects of large space occupation and long changing time in the prior art adopting the mode that one workstation corresponds to one mould. A stamping mould device comprises a worktable and the moulds fixed on the worktable. A changing mechanism comprises a stamping station and storage stations which are arranged on two sides of the stamping station parallelly, the storage stations are connected with the stamping station through running rails, a preparation station communicated with the stamping station is arranged on each running rail on the same line, and the worktable is arranged on the running rails. The stamping station is combined with the preparation stations, and multiple storage stations can be arranged on the periphery of one stamping station, so that floor area is small and space utilization rate is high. Multiple workpieces can be stamped at the same station so that procedures are reduced, workpiece machining efficiency is increased and workload in carrying the workpieces among the stations is decreased.

Owner:ZHEJIANG JINGANG AUTOMOBILE +1

Paint spraying device

InactiveCN104415893AReduce handling workReduce labor intensityLiquid surface applicatorsLiquid spraying apparatusProcess engineeringAir compressor

The invention relates to a paint spraying device, which comprises an air compressor, a storage tank and a spray head, wherein a lifting ring is arranged on the storage tank, an air outlet of the air compressor is connected with two compressed air delivery pipelines, one compressed air delivery pipeline is connected with an air inlet of the spray head, the other compressed air delivery pipeline is connected with the upper end of the storage tank, the bottom of the storage tank is connected with a feed inlet of the spray head through a conveying pipeline, and a flowmeter is further arranged on the conveying pipeline. The carrying work of a paint tank can be reduced, the labor intensity of operating workers can be reduced, the paint spraying device is suitable for remote or overhead spraying operation, the production efficiency is improved, the flow rate of paint is conveniently controlled, the use is safe and reliable, and the moving is convenient.

Owner:中泰致远(天津)涂料有限公司

A three-axis mobile balance car for manual manifolds of hard pipes

ActiveCN104843445BRealize dockingEasy to assembleMechanical conveyorsSupporting systemMobile vehicle

Owner:BEIJING VP

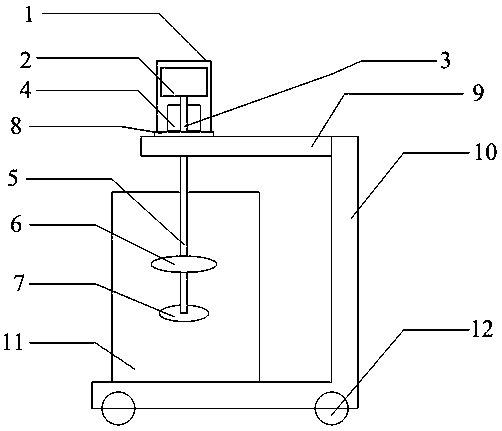

Detachable stirring device

InactiveCN108176289ACrush evenlyFlexible moving processRotary stirring mixersTransportation and packagingBiochemical engineering

The invention discloses a detachable stirring device. The detachable stirring device is characterized in that a stirring motor is arranged in a stirrer shell, the stirring motor is connected with a reducing motor through a connector, the reducing motor is connected with a stirrer main shaft, a large fan blade and a small fan blade are arranged at the other end of the stirrer main shaft, the stirrer shell is arranged on a stirrer pedestal, the stirrer pedestal is connected with a frame crossbeam, the frame crossbeam is connected with a main frame, the main frame is provided with a stirring barrel, and rolling wheels are arranged under the frame. The technical problem to be solved by the invention is to provide the detachable stirring device. The detachable stirring device can drives the stirrer main shaft through the motor, the crushing and the mixing of materials by using the fan blades are used to achieve the uniform stirring purpose; and the stirring device can be dismounted from thestirrer pedestal, so the problem of difficulty in cleaning the blades of traditional stirrers is solved.

Owner:TAIZHOU KELUOMIDE MACHINERY EQUIMENT CO LTD

Shaft automatic driving assembling conveying line

PendingCN110153703AReduce handling workReduce labor intensityAssembly machinesMetal working apparatusSprocketDouble row

The invention discloses a shaft automatic driving assembling conveying line. An unpowered conveying line, a shaft automatic assembling mechanism, a double-row chain wheel hoisting mechanism and an electric system are included; the unpowered conveying line, the shaft automatic assembling mechanism and the double-row chain wheel hoisting mechanism are all connected with the electric system; the shaft automatic assembling mechanism is arranged on one side of the unpowered conveying line; the double-row chain wheel hoisting mechanism is arranged at one end of the acting direction of the unpoweredconveying line; and the position, corresponding to the shaft automatic assembling mechanism, on the unpowered conveying line is provided with a limiting mechanism. A feeding mechanism and a shaft penetrating mechanism can omit the carrying and assembling work by people on a shaft, the labor intensity of people is greatly relieved, double hands can also be liberated in the shaft penetrating processto do other auxiliary work, and the problems that during current shaft assembling, the manual assembling efficiency is low, and precision is poor are solved.

Owner:JIANGSU TONGLI MACHINERY

Roof-contacted building block filling hydraulic bracket and use method thereof

ActiveCN110005460AReduce handling workAchieve demouldingMaterial fill-upMine roof supportsArchitectural engineeringUltimate tensile strength

The invention provides a roof-contacted building block filling hydraulic bracket and a use method thereof, and belongs to the technical field of hydraulic brackets. The roof-contacted building block filling hydraulic bracket comprises a bracket body; the bracket body comprises a front top beam, a rear top beam, a base, a front column, a rear column and a four-connecting rod mechanism, wherein thetwo ends of the front column are separately hinged to the front top beam and the base, the two ends of the rear column are separately hinged to the rear top beam and the base, the four-connecting rodmechanism is arranged between the front column and the rear column, a telescopic beam is arranged at the tail of the rear top beam, a telescopic beam jack in the telescopic beam extends from the telescopic beam and the rear top beam, and a filling pouring mould is arranged below the telescopic beam; and a mould height-adjusting device and a mould pushing device are arranged between the filling pouring mould and the bracket body. A hydraulic bracket building block has short setting time, high strength, good roof-contacted effect and continuous building block, ''separating walls'' do not need tobe arranged artificially, the filling efficiency is high, machine-following operation can be realized, and safe and efficient mining is achieved.

Owner:TAIYUAN UNIV OF TECH

A preheating device and preheating method for TBM tool holder welding

ActiveCN111770598BIncrease productivityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesThermodynamicsProcess engineering

The invention provides a preheating device for TBM tool holder welding, which includes a working platform, a feeding assembly, a cantilever adjustment mechanism and a control cabinet, the feeding assembly is arranged on the working platform, and the workpiece is in the welding position through the feeding assembly and the preheating position; one end of the cantilever adjustment mechanism is movable and provided with an induction heating coil for preheating the workpiece, and the other end of the cantilever adjustment mechanism is movably arranged on the control cabinet; The components realize the mobile control cabinet. The preheating device of the present invention ensures the effective connection of preheating, welding and post-heating processes, saves the work of handling workpieces under high temperature, and improves the production efficiency and welding quality of the TBM tool holder. The present invention also provides a preheating method using the above preheating device, which can effectively reduce the labor intensity of personnel.

Owner:CHINA RAILWAY CONSTR HEAVY IND

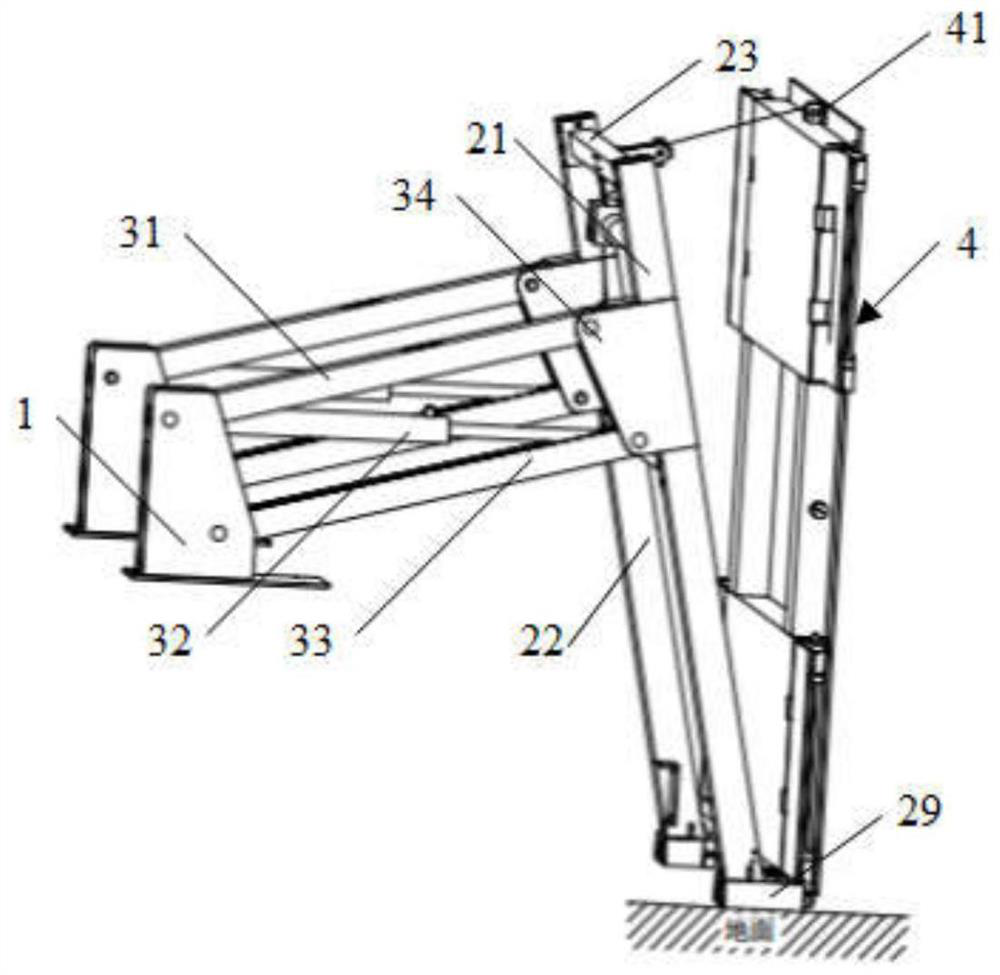

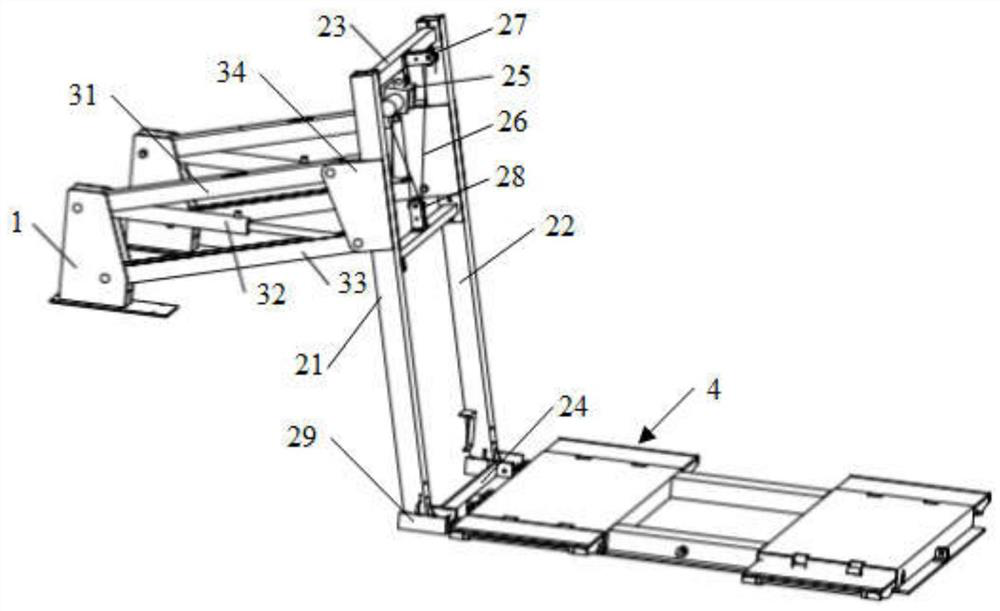

Vehicle-mounted lifting machine

The embodiment of the invention discloses a vehicle-mounted lifting machine. According to the specific implementation mode, the vehicle-mounted lifting machine comprises a base, a supporting assembly, a connecting rod assembly and a lifting machine assembly, the two ends of the connecting rod assembly are connected with the base and the first end of a supporting rod in a pivoted mode respectively, the lifting machine assembly is connected with the second end of the supporting assembly in a pivoted mode, and the base is fixedly arranged on a vehicle; the lifting machine assembly can be vertically overturned relative to the second end of the supporting assembly, so that the lifting machine assembly is folded or unfolded to the supporting assembly; and the connecting assembly can rotate relative to the base, and the supporting assembly and the lifting machine assembly are lifted or put down, so that the vehicle-mounted lifting machine is folded or unfolded. According to the implementation mode, the occupied area of the vehicle-mounted lifting machine can be optimized, the carrying work of the lifting machine is reduced, then the working efficiency is improved, and the workload of workers is reduced.

Owner:北京英之杰天祥汽车技术服务有限公司

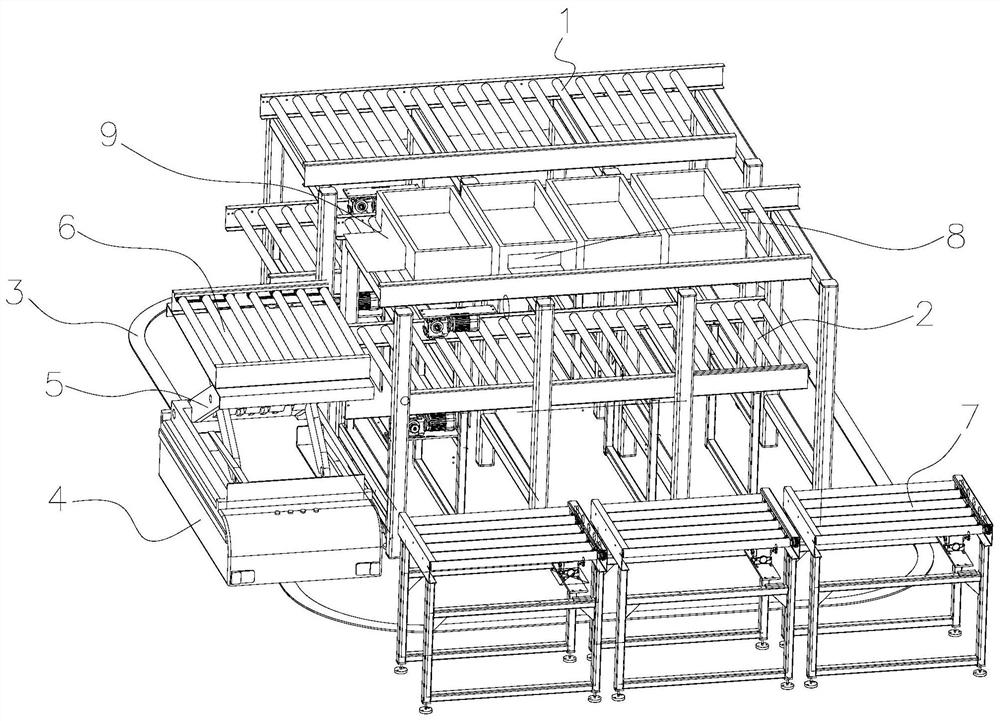

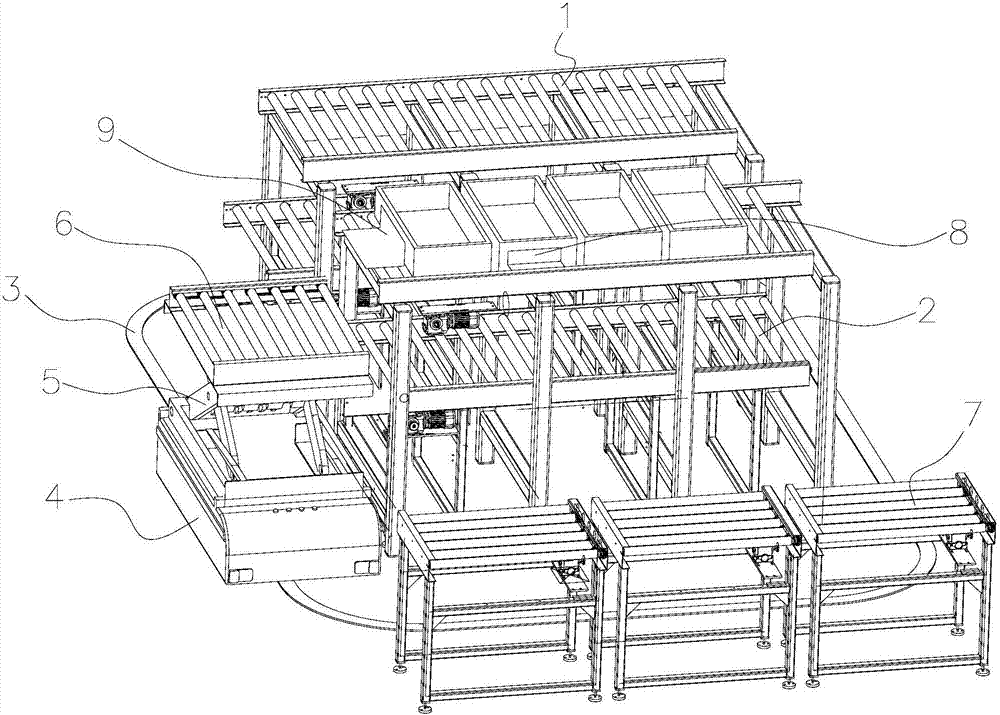

Apparatus for growing seedlings

ActiveCN107278687BLess likely to damage the seedbedReduce handling workCultivating equipmentsEngineeringMechanical engineering

The invention provides a seedling culture device which comprises an upper platform, a lower platform, an upper driving mechanism and a lower driving mechanism. The upper driving mechanism drives the upper platform, so that a seedling bed on the upper platform can horizontally move in the X-axis direction, and the lower driving mechanism drives the lower platform, so that a seedling bed on the lower platform can horizontally move in the X-axis direction. According to the seedling culture device, the seedling beds are cultured on a double-layer stereoscopic warehouse, manual inspection is performed on a material receiving device, automatic carrying is achieved between the double-layer stereoscopic warehouse and the material receiving device, worker carrying is omitted, time and labor are saved, efficiency is high, and the seedling beds cannot be easily damaged.

Owner:ZHEJIANG UNIV

Seedling culture device

The invention provides a seedling culture device which comprises an upper platform, a lower platform, an upper driving mechanism and a lower driving mechanism. The upper driving mechanism drives the upper platform, so that a seedling bed on the upper platform can horizontally move in the X-axis direction, and the lower driving mechanism drives the lower platform, so that a seedling bed on the lower platform can horizontally move in the X-axis direction. According to the seedling culture device, the seedling beds are cultured on a double-layer stereoscopic warehouse, manual inspection is performed on a material receiving device, automatic carrying is achieved between the double-layer stereoscopic warehouse and the material receiving device, worker carrying is omitted, time and labor are saved, efficiency is high, and the seedling beds cannot be easily damaged.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com