PC prefabricated component forming equipment

A technology for forming equipment and prefabricated components, applied in the field of construction machinery, can solve the problems of insufficient pulp, insufficient pulping, uneven vibration, etc., and achieve the effects of improving work efficiency, reducing handling work, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

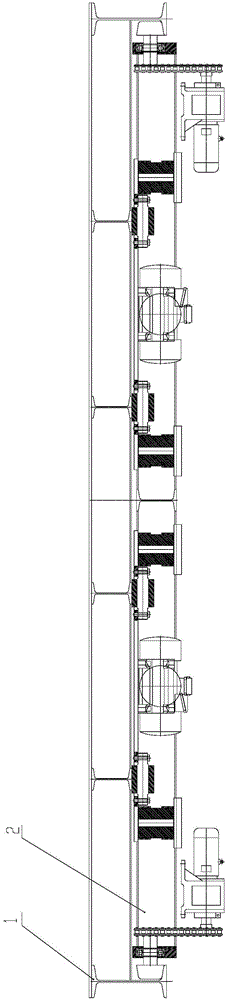

[0040] Such as figure 1 As shown, the PC prefabricated component molding equipment provided by the present invention includes two parts: a mold table 1 and a mobile vibration platform 2, wherein the mold table 1 is a fixed platform on which guide rails are arranged, and the vibration platform 2 is a mobile vibration platform The mobile vibration platform is provided with a walking drive mechanism, and the walking drive mechanism is placed on the guide rail, so that the mobile vibration platform is movably arranged on the fixed platform relative to the fixed platform along the guide rail.

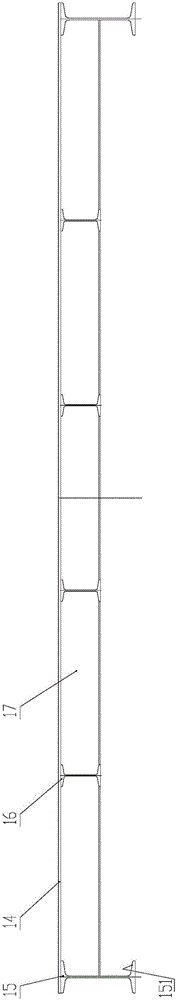

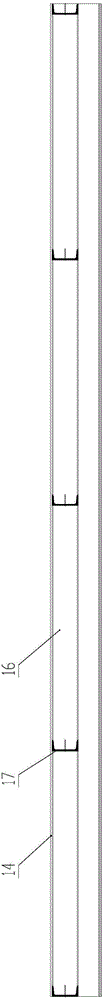

[0041] Such as figure 2 , image 3 and Figure 4 As shown, the fixed platform as the mold table includes the fixed mold platform main beam 15, the fixed mold platform secondary beam 16, the fixed mold platform crossbeam 17 and the fixed mold platform bottom plate 14, and the fixed mold platform bottom plate 14 is fixedly connected with the crossbeam 17 and the secondary beam 16, two I-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com