A preheating device and preheating method for TBM tool holder welding

A technology of preheating device and knife holder, applied in induction heating devices, welding equipment, auxiliary devices, etc., can solve the problems of high heat loss, difficult temperature and heating uniformity to meet process requirements, noise and air pollution, etc., so as to improve welding performance. Quality and pass rate, ensure electromagnetic conversion efficiency, save the effect of handling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

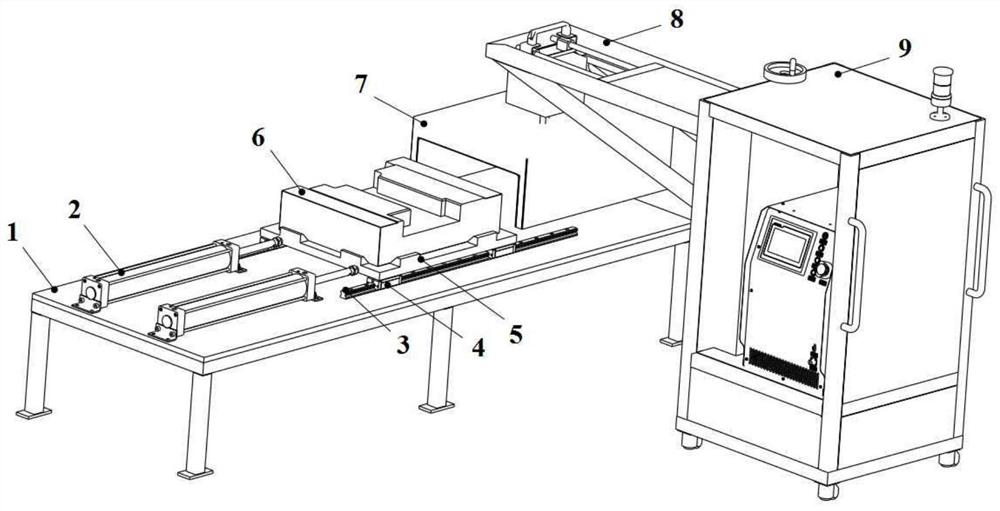

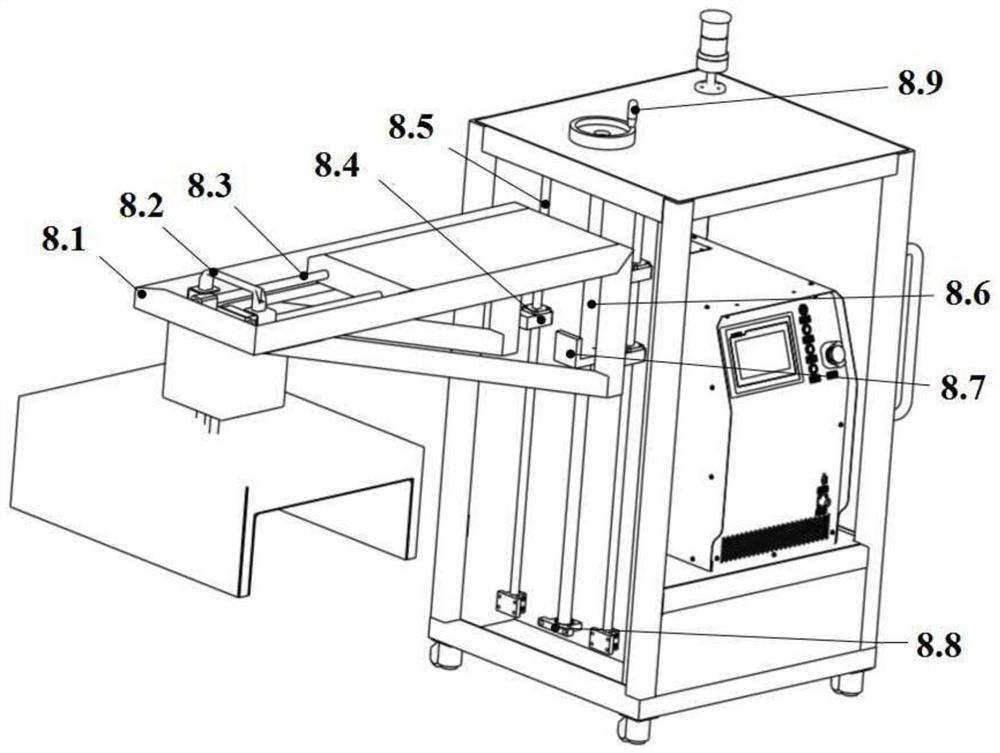

[0034] see Figure 1-2 , a preheating device for TBM tool holder welding, including a working platform 1, a feeding assembly, a cantilever adjustment mechanism 8 and a control cabinet 9, the feeding assembly is arranged on the working platform 1, and the workpiece 6 is realized by the feeding assembly. switch between the welding position and the preheating position; one end of the cantilever adjustment mechanism 8 is movably provided with an induction heating coil 7 for preheating the workpiece 6, and the other end of the cantilever adjustment mechanism 8 is movably arranged on the control cabinet 9; The bottom surface of the control cabinet 9 is provided with a moving assembly to realize the mobile control cabinet 9.

[0035] The moving components are casters, and the casters are arranged on the bottom surface of the control cabinet to realize the movement of the control cabinet; the upper part of the control cabinet 9 is provided with a buzzer. The casters are purchased par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com