Evaluation system and method for elevator brake static braking performance

An elevator brake and evaluation system technology, applied in elevators, transportation and packaging, etc., can solve the problems of not being able to obtain quantitative data of brakes, time-consuming and laborious, and difficult to implement, so as to achieve rapid quantitative and high-precision detection on site and improve inspection and detection. Efficiency, reduce the effect of handling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

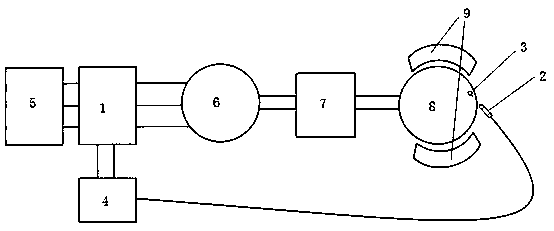

[0028] Example 1: figure 1 For the structural schematic diagram of the evaluation system of the present invention, refer to figure 1 As shown, the elevator brake static braking performance evaluation system of the present invention mainly includes: a variable frequency drive device, a reflective photoelectric switch, a control device and an elevator system.

[0029] The elevator system also includes: a machine room power supply, a car, an elevator motor, a deceleration device, a traction wheel and a brake, wherein the machine room power supply is connected with the variable frequency drive device for power supply; one end of the elevator motor is connected to The variable frequency drive device is connected, the other end of the elevator motor is connected to the traction sheave through the deceleration device, and the brake is used to brake the traction sheave. Preferably, the brake is preferably brake pads. It can be understood that the braking principle of the elevator sy...

Embodiment 2

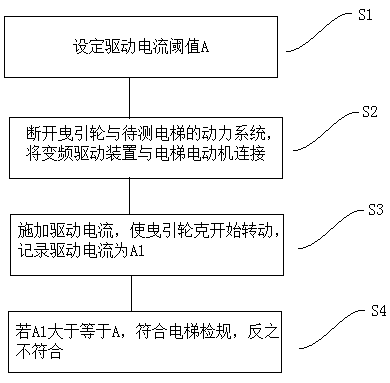

[0031] Example 2: figure 2 For the flow chart of the evaluation method of the present invention, refer to figure 2 As shown, the evaluation method of the elevator brake static braking performance evaluation system of the present invention mainly includes the following steps:

[0032] S1: set the drive current threshold A that the variable frequency drive device makes the traction wheel overcome the braking force of the brake and just start to rotate;

[0033] S2: For an elevator to be tested (the elevator is required to be the same model as the sample elevator, with the same rated load, balance factor, and the same type of traction machine and brake), disconnect the elevator motor from the power system of the elevator to be tested, Connect the variable frequency drive device to the traction sheave of the elevator to be tested through the elevator motor and deceleration device;

[0034] S3: Control the variable frequency driving device to apply driving current to make the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com