Die for punching holes and forming tear line on paper product

A technology of easy tearing and punching, applied in metal processing and other directions, can solve the problems of low production efficiency, increased labor costs, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now elaborate this technical scheme in conjunction with accompanying drawing:

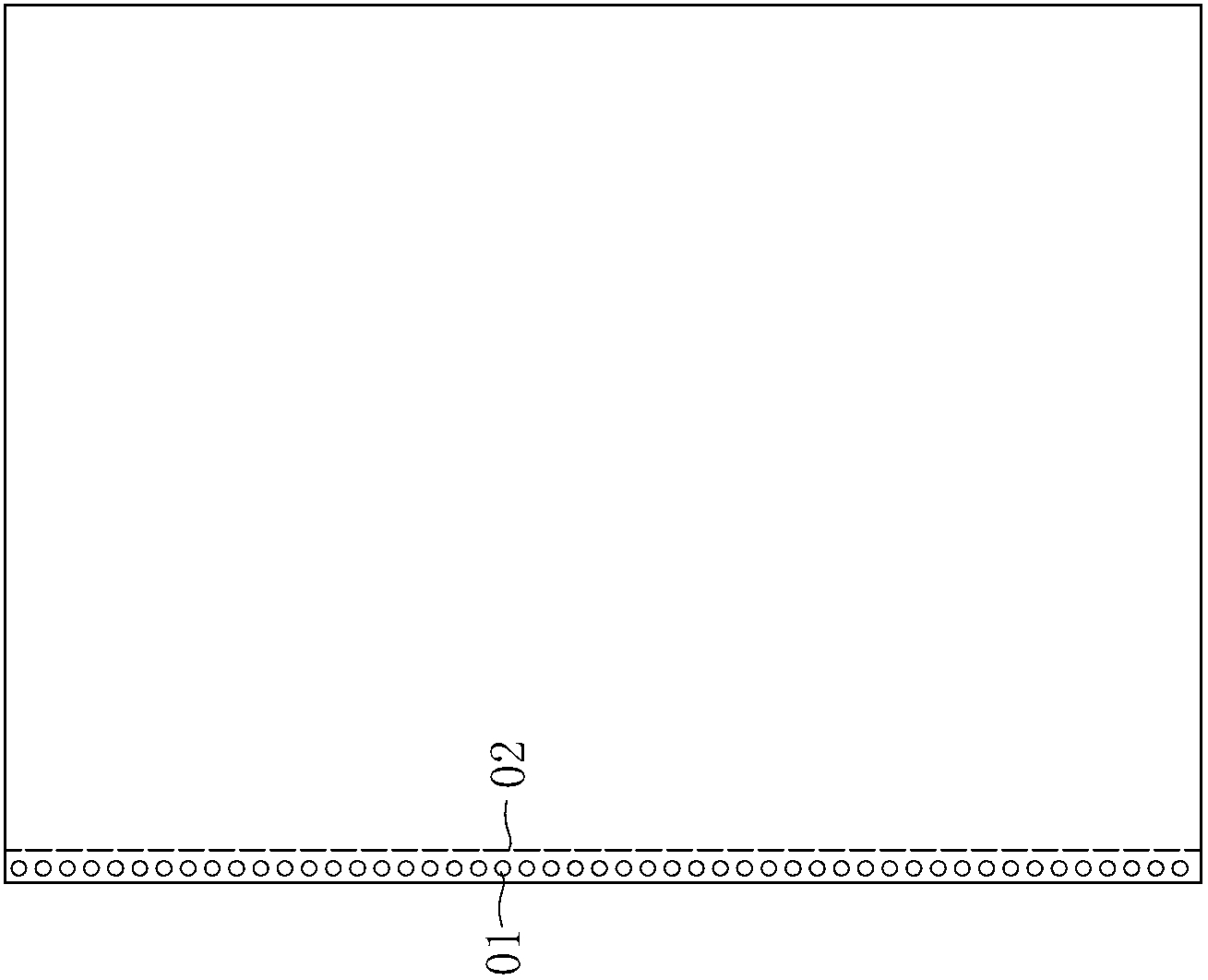

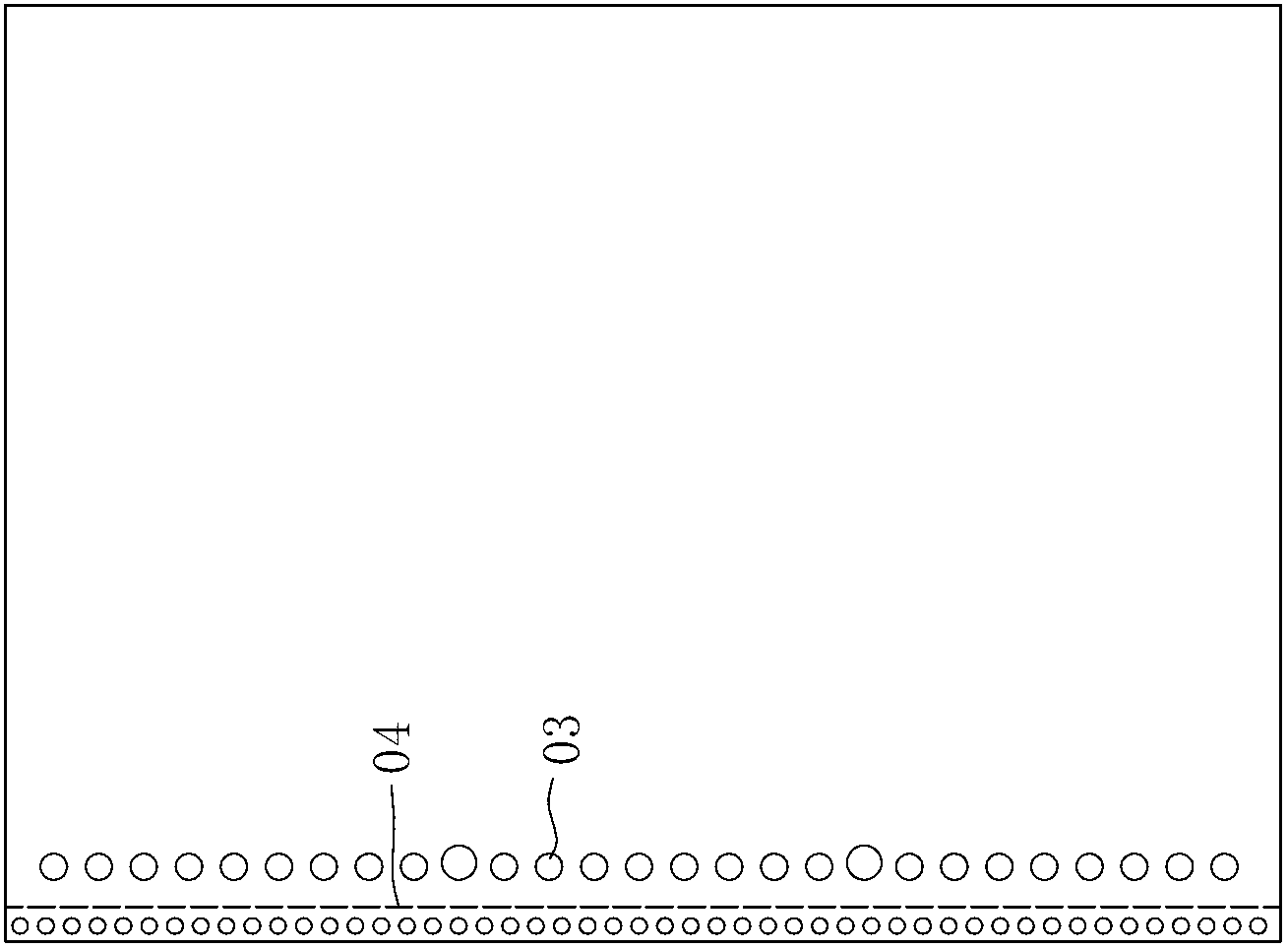

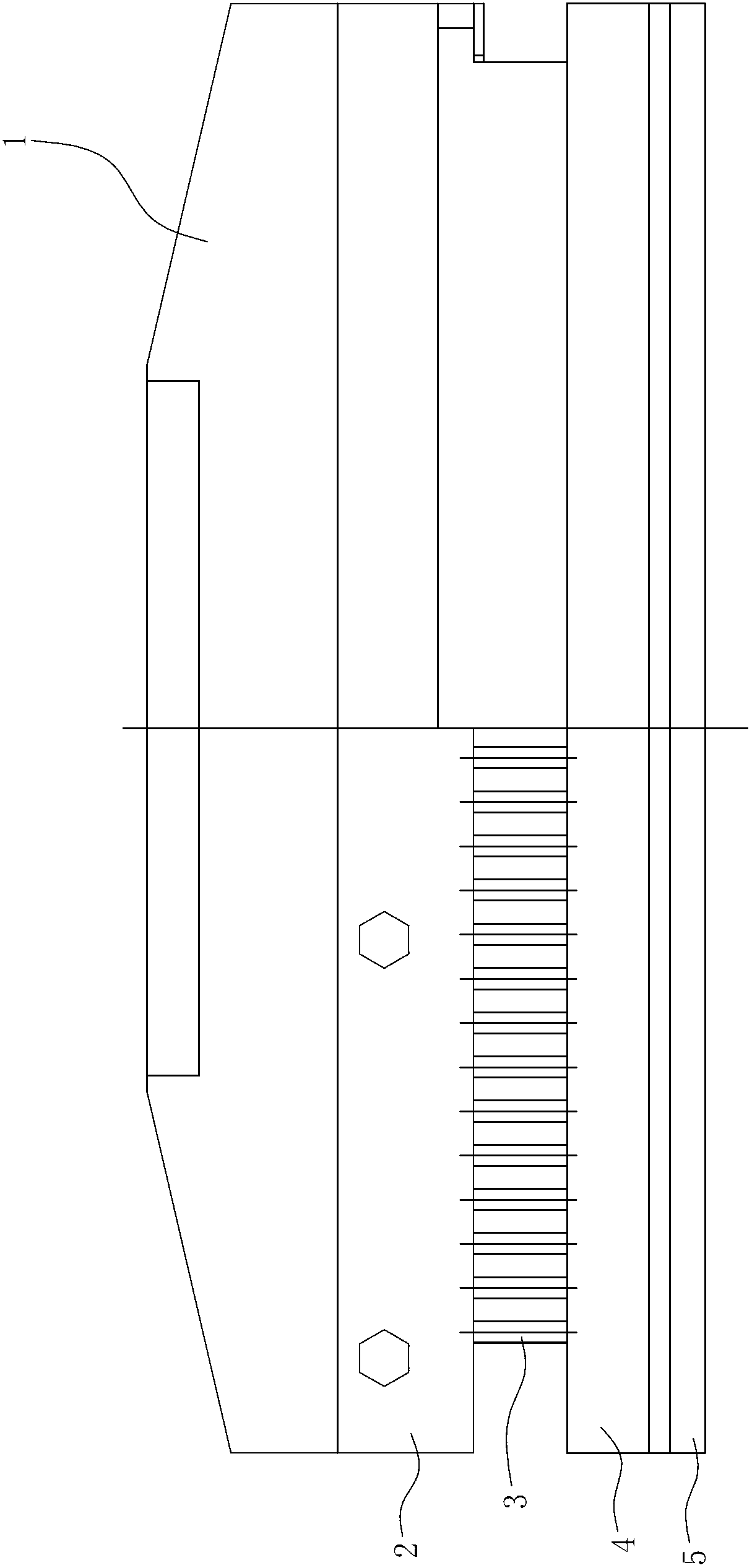

[0014] The easy-to-tear thread mold for paper product punching in this embodiment includes a slider punch 1, a needle hanging plate 2, a punching needle row 3, a guide plate 4 and a bottom plate 5, the guide plate 4 is arranged above the bottom plate 5, and the needle hanging plate 2 is installed At the bottom of the slider punch 1 and above the guide plate 4, the punching needle row 3 is installed on the bottom of the needle hanging plate 2, the needle body passes through the guide plate 4, and the bottom plate 5 is provided with a hole for the punching needle row 3 to punch down. There are two groups of die holes 6 and punching needle rows 3, and on the needle hanging plate 2, between the two groups of punching needle rows 3, and along the arrangement direction of the punching needle rows 3, there are punching and easy-to-tear line needle row 7. The surface of the bottom plate 5 and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com