Tool for vertically hoisting and mounting pipeline and hoisting method of the tool

A hoisting method and tool technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of difficult manufacturing and processing, complicated hoisting tools, inconvenient hoisting, etc., and achieve low installation difficulty, increased hoisting weight, and less labor consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

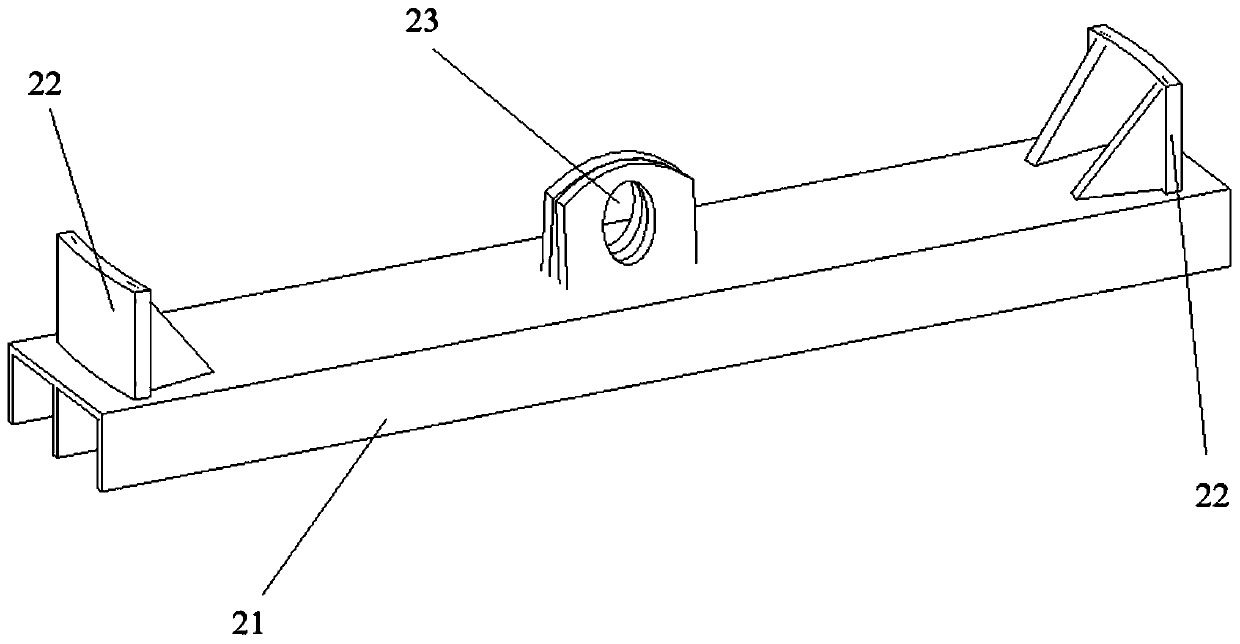

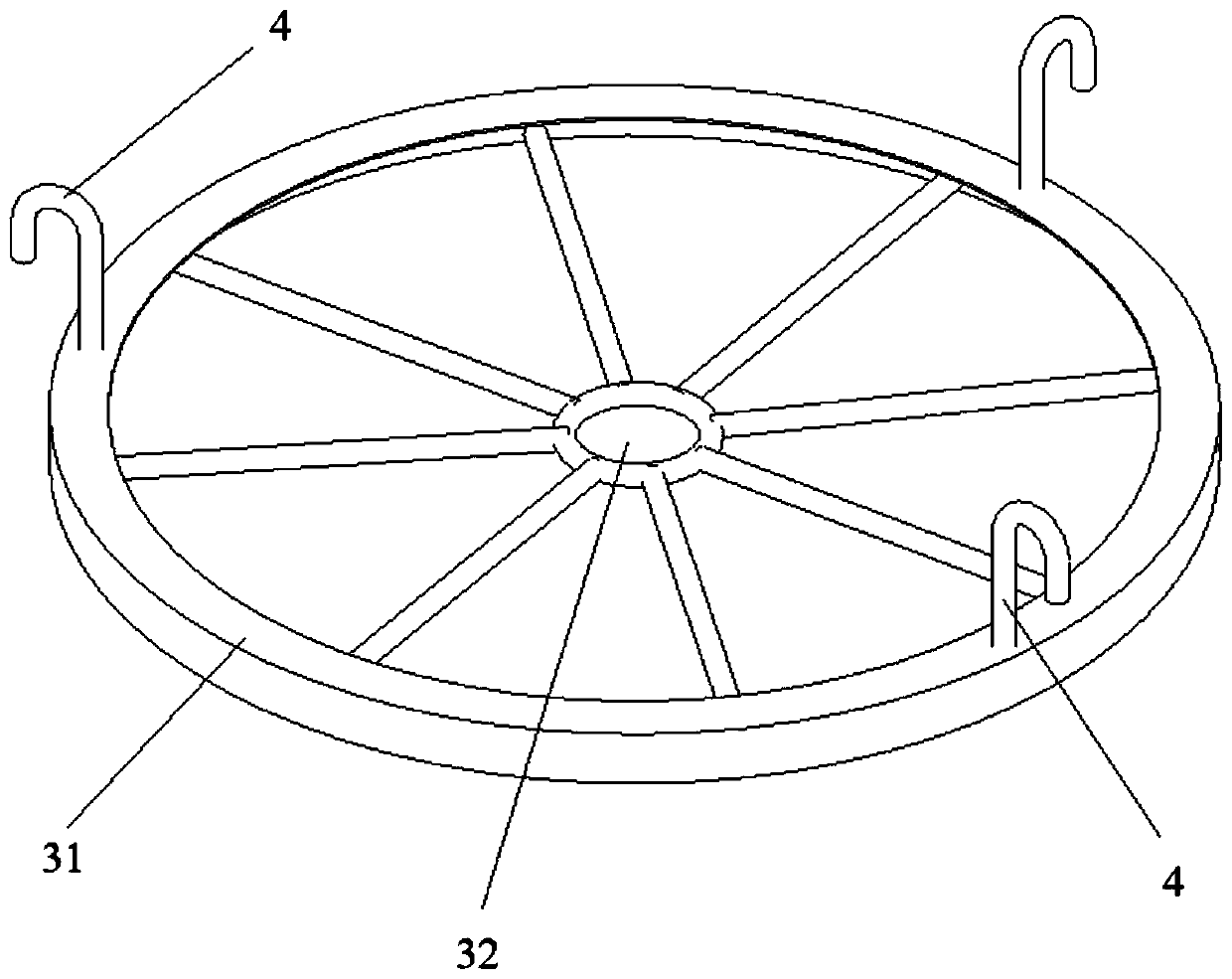

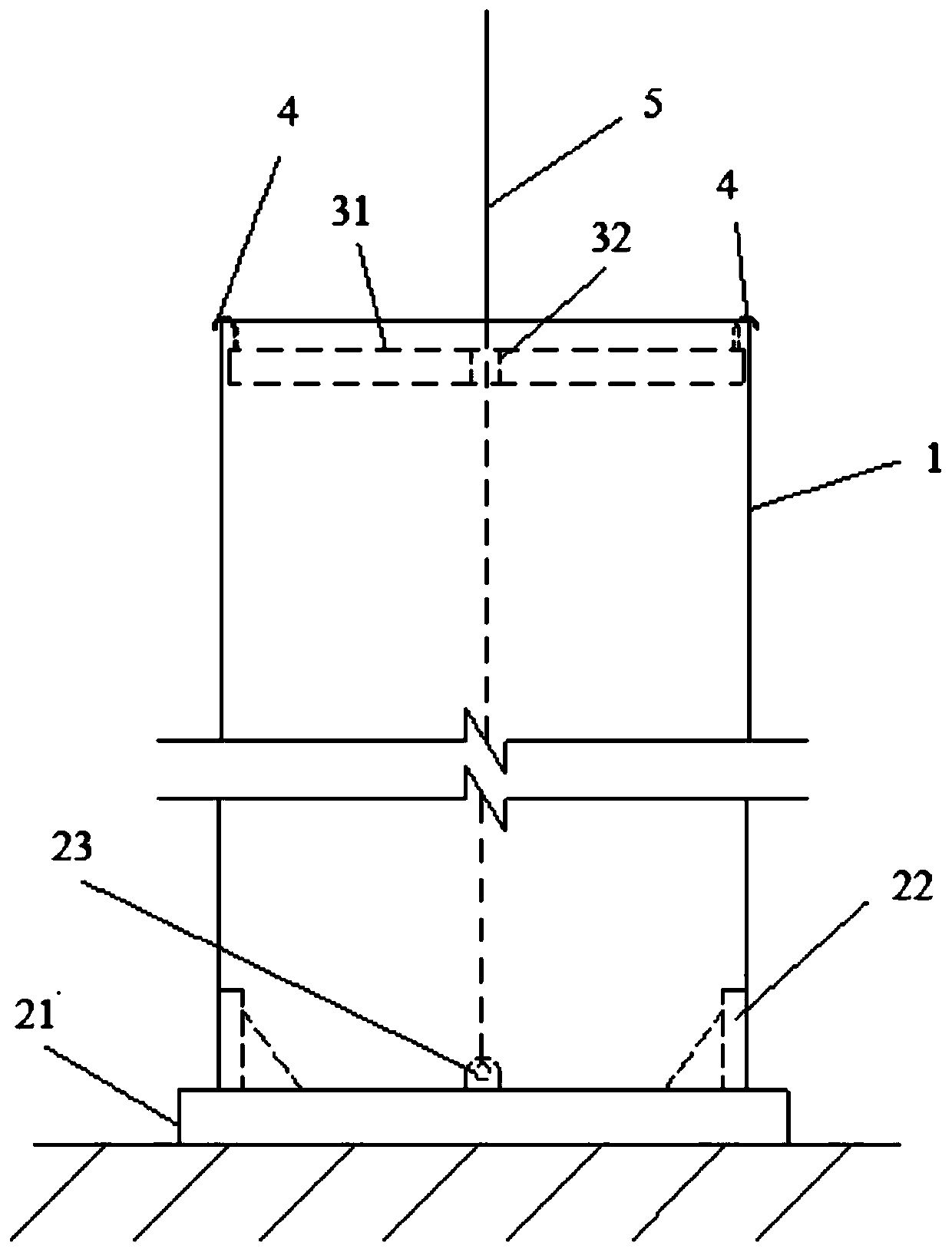

[0039] A tool for vertically lifting and installing pipelines according to the present invention includes a base and a stopper, the base includes a bottom plate 21, and the bottom plate 21 is provided with at least two seat plates 22, the seat plates 22 The outer wall is adapted to the inner diameter of the pipe joint 1, and the middle part of the bottom plate 21 is also provided with a hoisting hole 23. The limiting body includes a frame body 31 and a through hole 32 arranged in the middle part of the frame body 31. The limiting body The shape and size of the body are adapted to the shape and size of the pipe joint 1 .

[0040] Specifically, as in this embodiment, such as figure 1 As shown, the bottom plate 21 is a shaped steel bar, and the two ends of the shaped steel bar are respectively provided with a seat plate 22, and the distance between the two seat plates 22 is determined according to the diameter of the pipe. 21 is welded to the seat plate 22, the seat plate 22 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com