Glass carrying gripper device with lining paper

A gripper device and handling device technology, which is applied in the field of machinery and automation, material handling and palletizing, can solve the problems of poor paper laying flatness, large space occupied by equipment, and difficult to separate glass, etc., so as to reduce production rhythm and improve Productivity and the effect of reducing the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

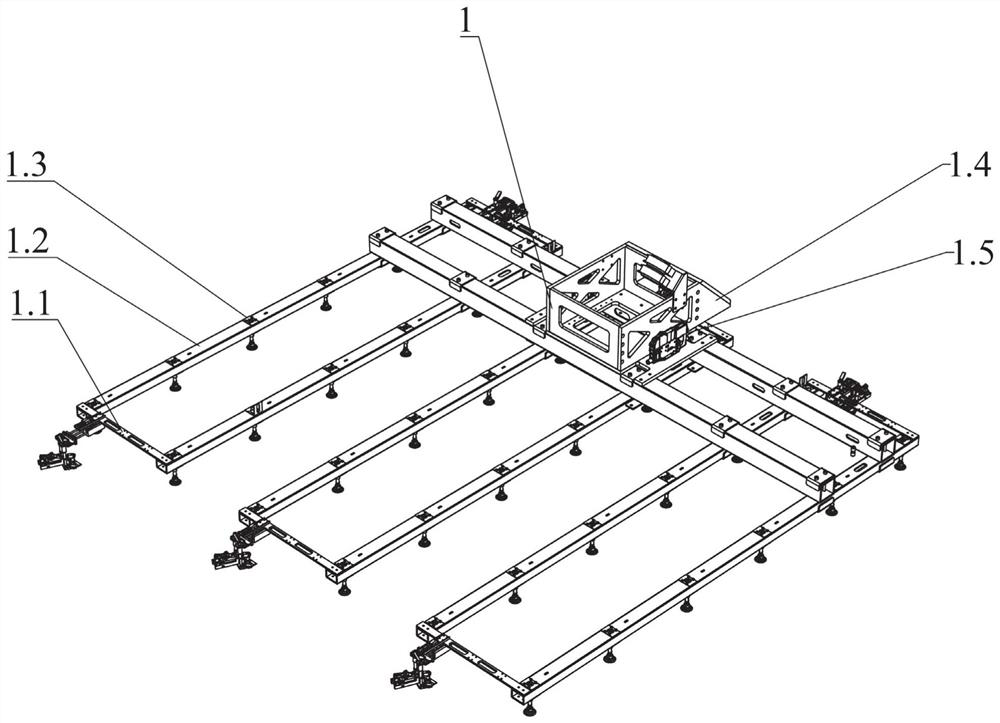

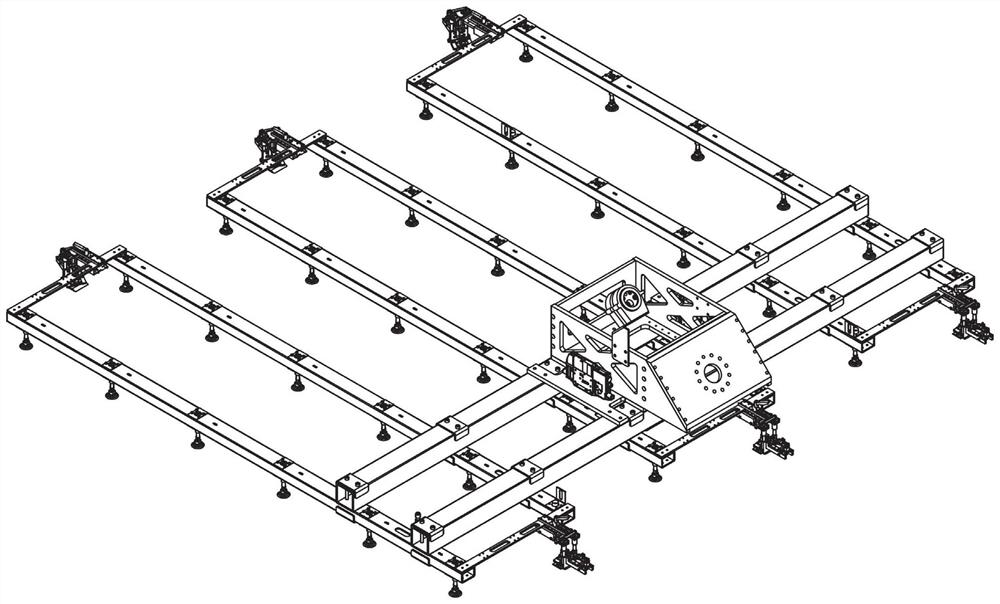

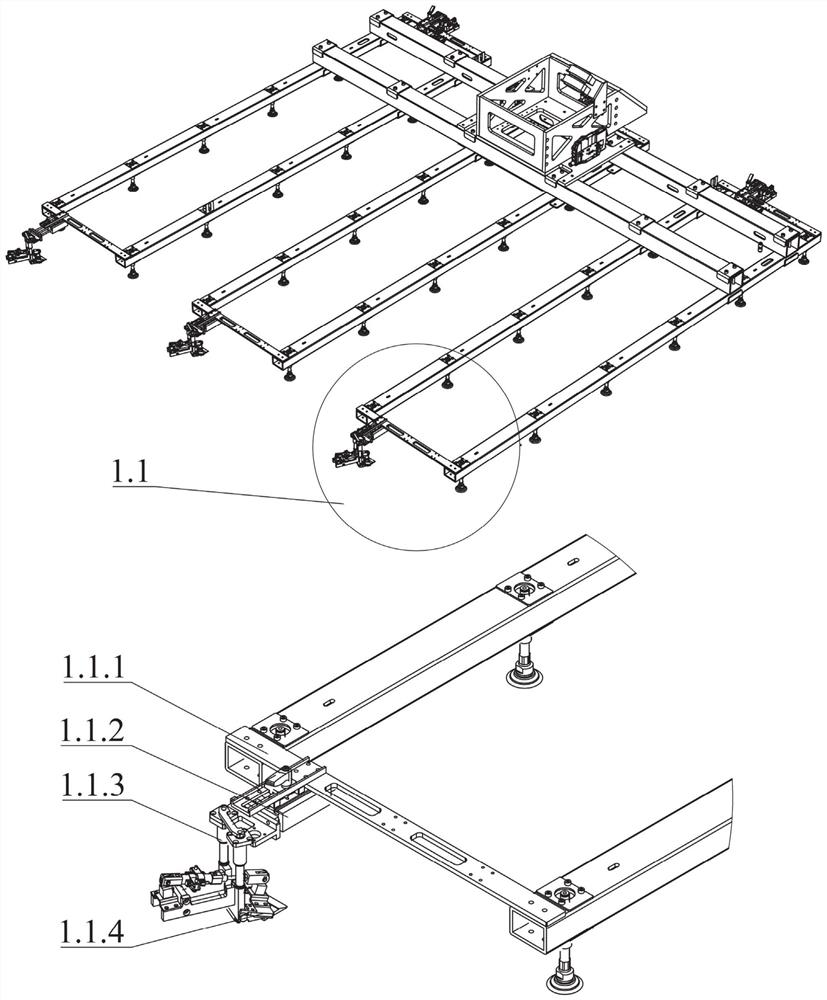

[0033] The glass handling gripper device with backing paper of the present invention includes a backing paper handling device 1.1, a support frame 1.2, a suction cup assembly 1.3, a robot flange 1.4 and a vacuum system 1.5, and the support frame 1.2 is based on different specifications The glass is arranged with a suction cup assembly 1.3, and the backing paper handling device 1.1 is used as an auxiliary tool for the gripper. The robot flange 1.4 is a connecting piece between the robot body and the glass handling gripper with backing paper. The vacuum system 1.5 Installed in the chamber of the robot flange 1.4.

[0034] As a preferred embodiment of the present invention, the liner paper handling device 1.1 includes a fixed support beam assembly 1.1.1, a thin cylinder 1.1.2, a linear bearing assembly 1.1.3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com