Pattern electroplating method with pattern electroplating accompanying plating plate reusable

A technology of pattern electroplating and accompany plating, which is used in the reinforcement of conductive patterns, removal of conductive materials by chemical/electrolytic methods, electrical components, etc. The effect of improving electroplating quality and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

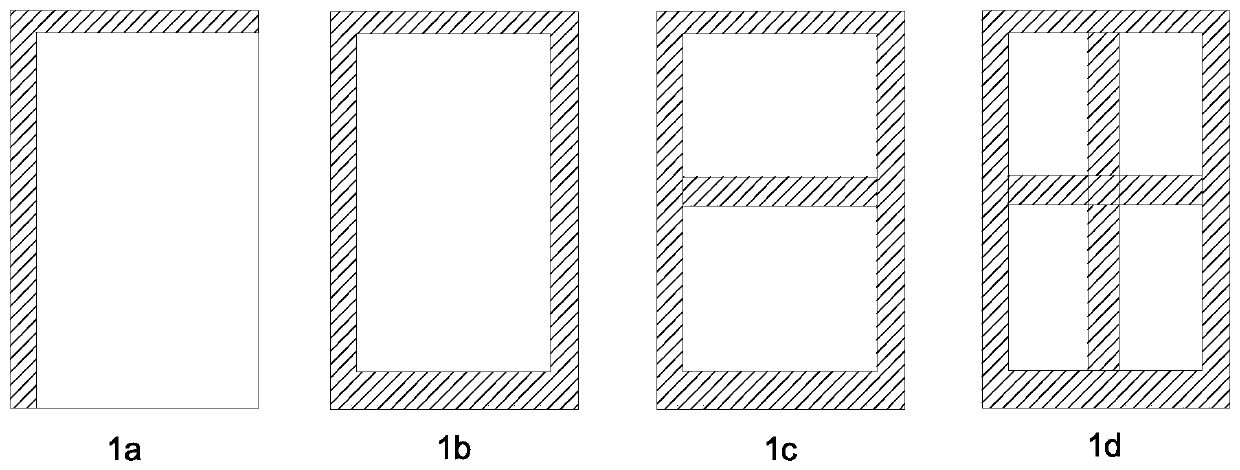

[0028] The present embodiment provides a pattern electroplating method that can be reused for a pattern electroplating accompanying plate, including making a pattern electroplating accompanying plate with a pattern for accompanying plating and being made with a nickel-gold protective layer on the pattern for accompanying plating. The pattern electroplating accompanying plate is etched so that the pattern electroplating accompanying plate can be repeatedly used in pattern electroplating. The specific pattern electroplating method comprises the following steps:

[0029] (1) Select a double-sided copper-clad laminate with a copper layer thickness of H OZ, and cut the double-sided copper-clad laminate according to the size of the production board to obtain a substrate. The height of the substrate is equivalent to the height of the production board, and the height difference is controlled within the range of ±3cm.

[0030] The substrate is coated / filmed, exposed, developed, and et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com