Repeatedly used thermal insulation quilt and its application method

A heat insulation and application method technology, applied in the direction of layered products, etc., can solve the problems of long installation and disassembly construction period, high construction labor intensity, and non-reusable use, so as to protect workers' health, light weight, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

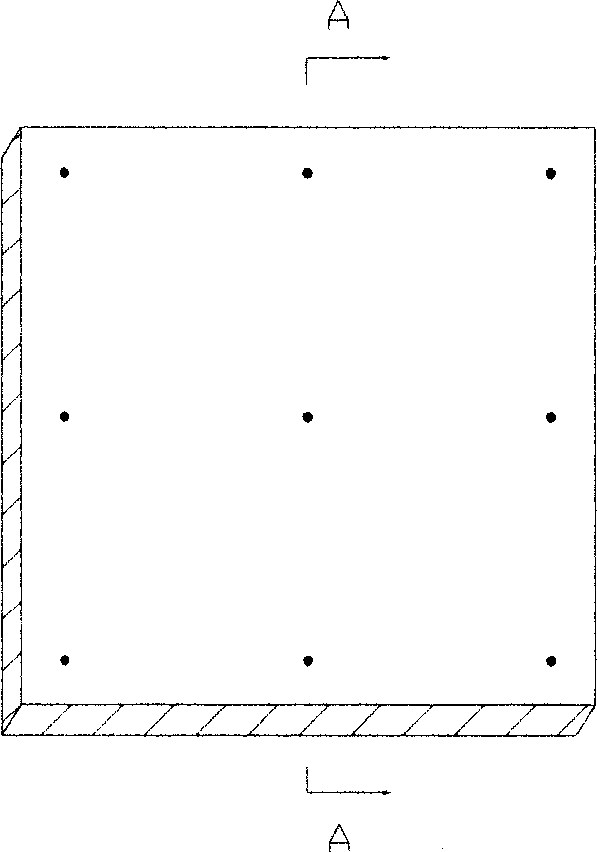

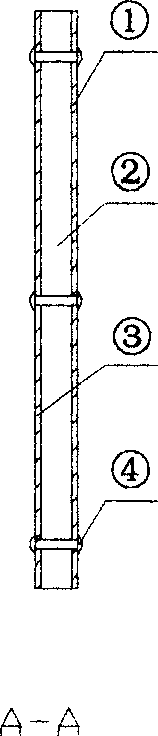

[0034] refer to figure 1 and figure 2 , symbol 1 represents the outer layer, which is glass fiber coated with silicone cloth, symbol 2 represents the thermal insulation layer, which is ceramic (aluminum silicate) fiber blanket, symbol 3 represents the inner layer, which is ceramic (aluminum silicate) fiber coated with vermiculite cloth , Symbol 4 is a metal rivet.

[0035] The thermal insulation layer 2 is covered by the inner layer and the outer layer, and is fixed by metal rivets 4 .

Embodiment 2

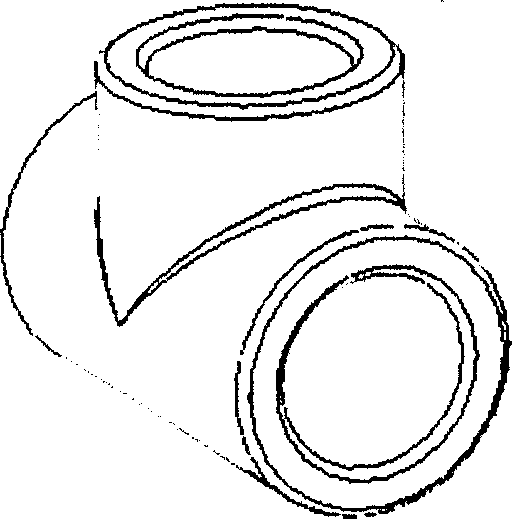

[0037] refer to figure 2 and Figure 4 , are the perspective view and cross-sectional view of the three-way reusable thermal insulation product respectively, wherein the symbol 1 represents the outer layer, which is composed of 0.1-5.0mm PVC-coated or non-PVC-coated glass fiber cloth, and the symbol 2 represents the thermal insulation layer, which consists of 3-300 mm thick glass wool, the symbol 3 represents the inner layer, which is composed of silica gel-coated glass fiber cloth woven with metal wire. The long-term use temperature is 100-600 ° C. The insulation product is glued (water) not shown) connected as a whole.

Embodiment 3

[0039] refer to figure 1 and figure 2 , when a single piece is used, on the left surface of the heat insulation quilt, use rivets to fix the male parts of the three buckles (not shown in the figure), and on the right surface of the heat insulation quilt, use rivets to fix the three buckles The female part of the buckle (not shown in the figure), the distance between the female and male parts of the buckle depends on the size of the workpiece to be covered, and it is better to cover it tightly. If necessary, glue and coating can be used on the joint surface The workpiece is then tied up with rope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com