High-precision material color-sorting device

A color sorting device and high-precision technology, applied in sorting and other directions, can solve problems such as material loss, unsuitable sieve plate cleaning, complex material positioning and extraction structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0047] In the following description, use of suffixes such as 'module', 'part' or 'unit' for denoting elements is only for facilitating description of the present invention and has no specific meaning by itself. Therefore, 'module', 'part' or 'unit' may be used in combination.

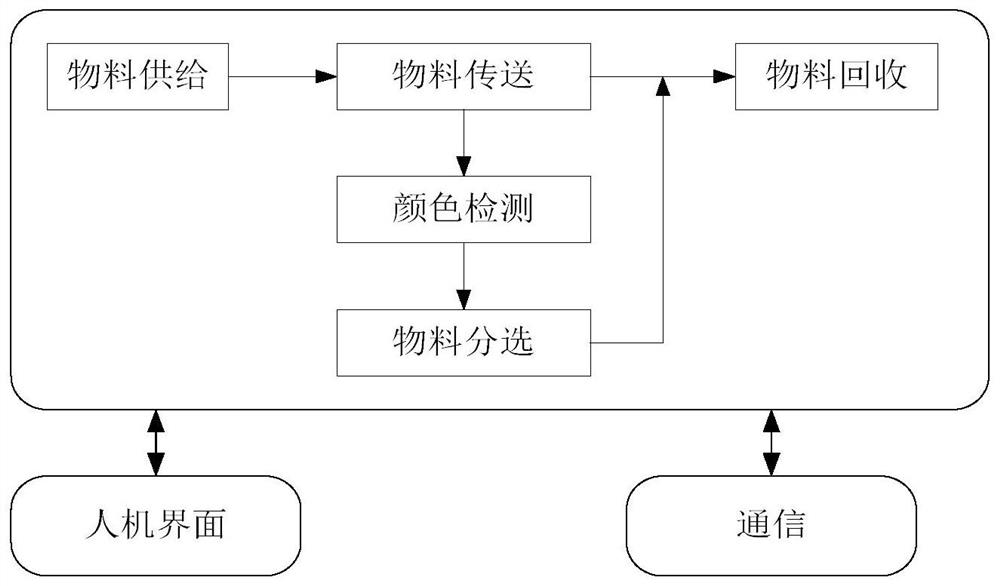

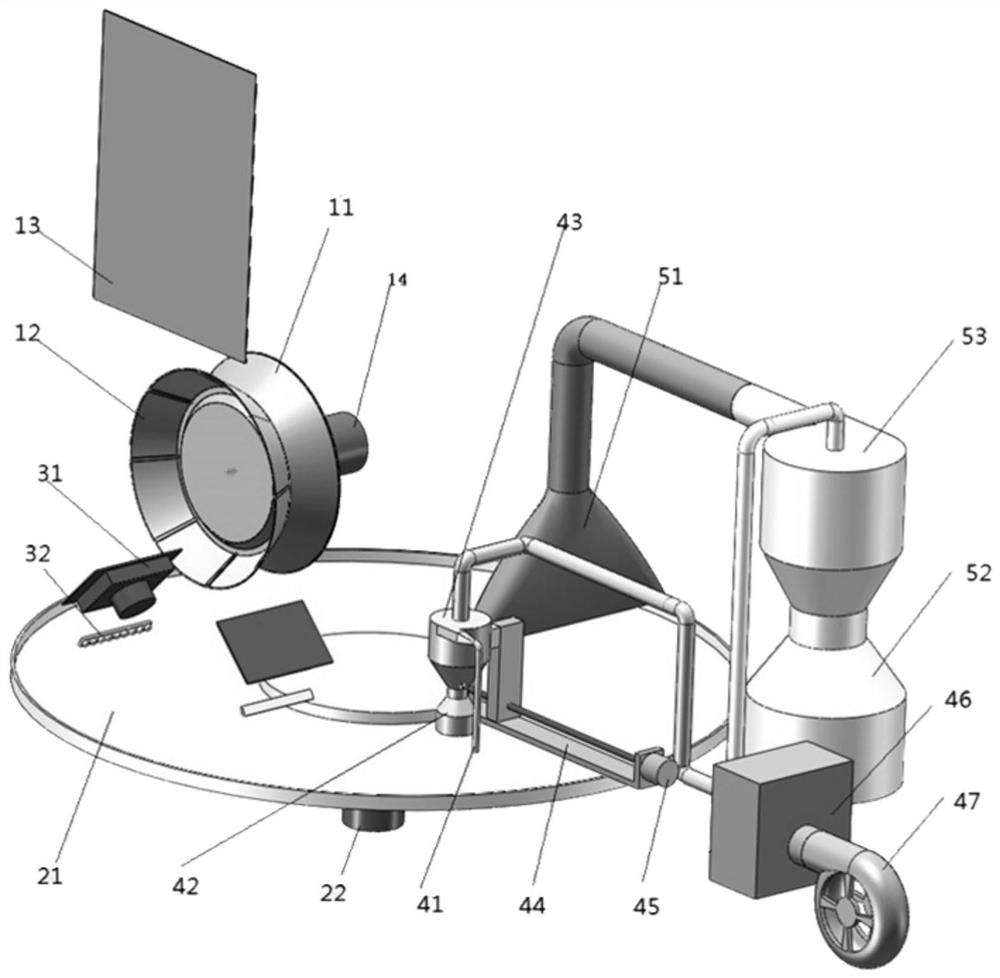

[0048] The embodiment of the present invention provides a high-precision material color sorting device, such as figure 1As shown, the material color sorting device is mainly composed of the following modules: material supply, material transmission, color detection, different-color material sorting, material recovery, man-machine interface and communication modules. Among them, in order to improve the subsequent dispersion effect in the embodiment of the present invention, the material supply module pre-disperses the material, which is benefici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com