Standardized tray circulation management platform based on NB-LOT technology

A technology for managing platforms and pallets, applied in the field of logistics management, can solve the problems of underutilized value of pallets, weakened carrying capacity, and low frequency of use, etc., to facilitate classification and query of transportation locations, reduce logistics costs, and have practical functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

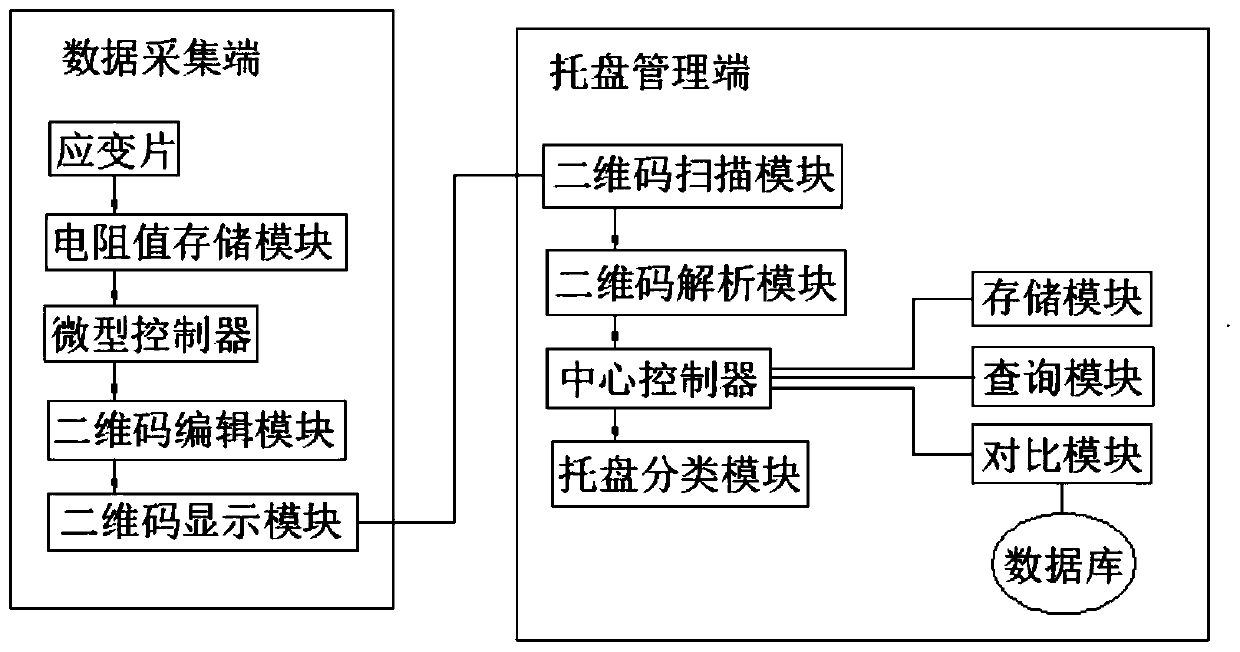

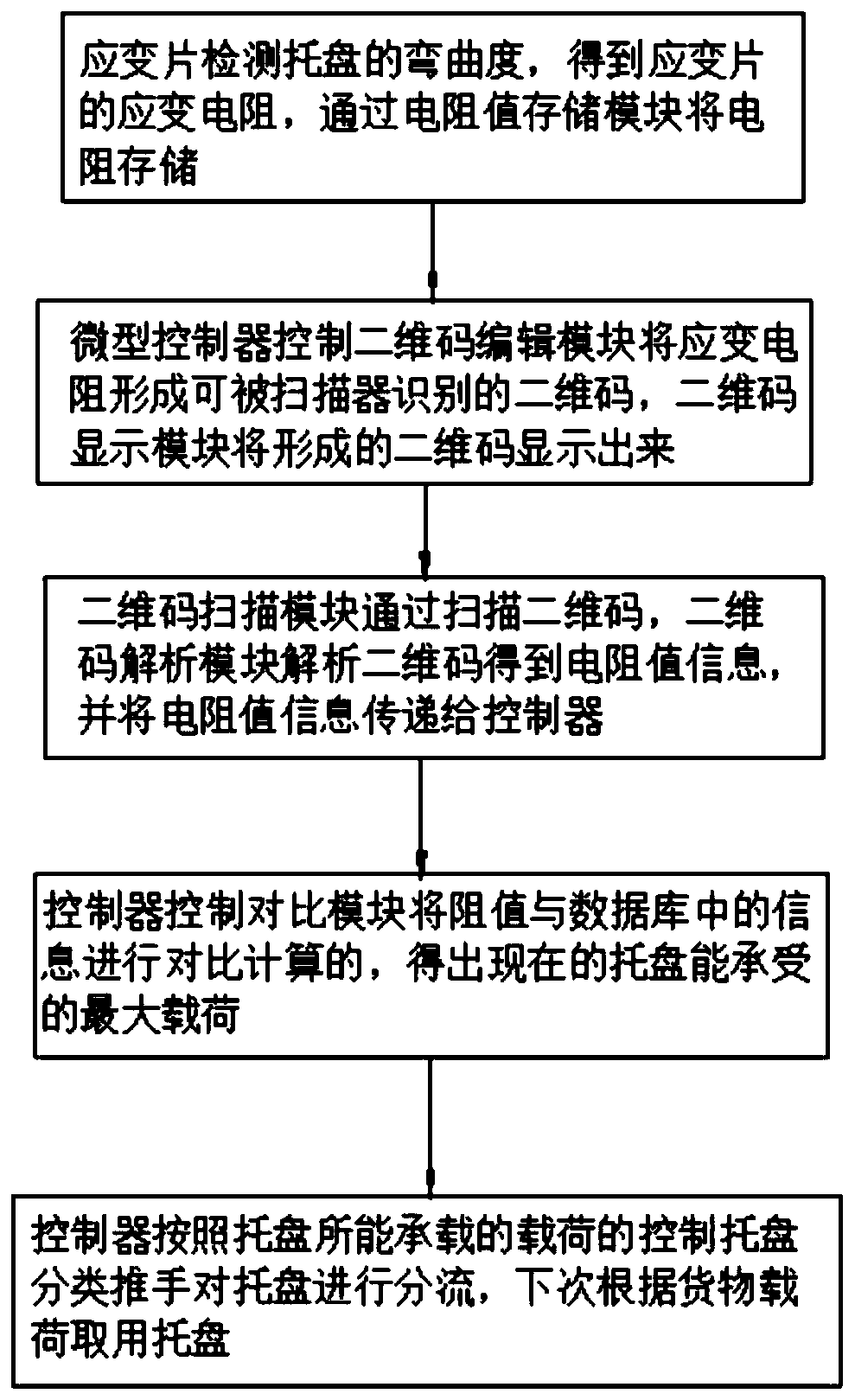

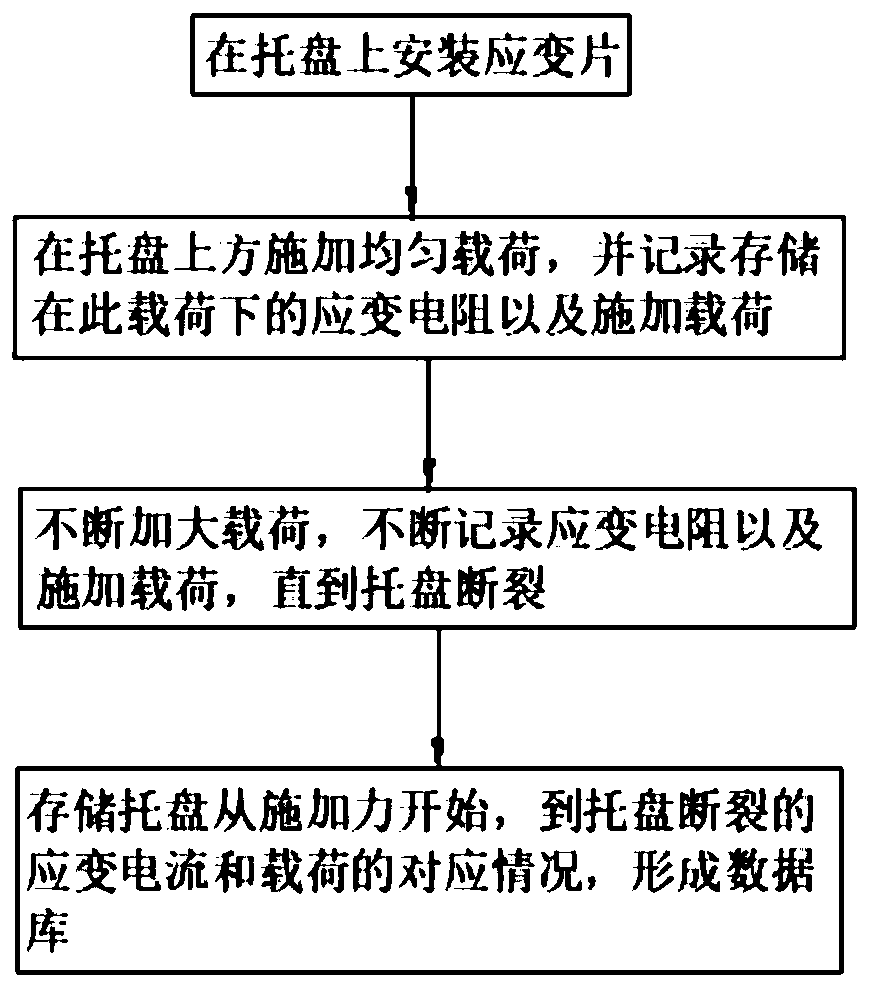

[0048] refer to figure 1 , a standardized pallet cycle management platform based on NB-LOT technology, including a data collection terminal and a pallet management terminal for managing pallet recycling. The data collection terminal is installed on the pallet and collects pallet bending data. The pallet management terminal is used to collect pallets information to classify the load carrying weight of the pallet.

[0049] Specifically, the data acquisition terminal includes: a strain gauge 21 , a resistance value storage module, a microcontroller, a two-dimensional code editing module and a two-dimensional code display module, which are electrically connected in sequence.

[0050] refer to Figure 7-Figure 8The position of the data acquisition terminal on the tray is arranged as follows: the strain gauge 21 is embedded in the tray 2, the output device 4 is embedded in one side of the tray 2, and the output device 4 is provided with a resistance value storage module, a micro T...

Embodiment 2

[0073] A cargo classification system, ref. Figure 6 , comprising an electronic label, an electronic label sensing terminal 32, a transportation controller, a cargo sorting module, an information output module and a pallet management terminal, the electronic label is matched with the electronic label sensing terminal 32, the electronic label sensing terminal 32, the transport The controller is electrically connected to the goods sorting module in turn, and the transportation controller is also connected to the information output module, and the information output module is connected to the central controller of the pallet management end.

[0074] Further, different from Embodiment 1, the tray outputter 4 in this embodiment is also provided with an electronic label fixing place 42 for clamping or affixing an electronic label carrying cargo information.

[0075] Further, refer to Figure 11 , a cargo sorting device based on the above cargo sorting system, comprising a cargo loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com