Patents

Literature

35results about How to "Not harmed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

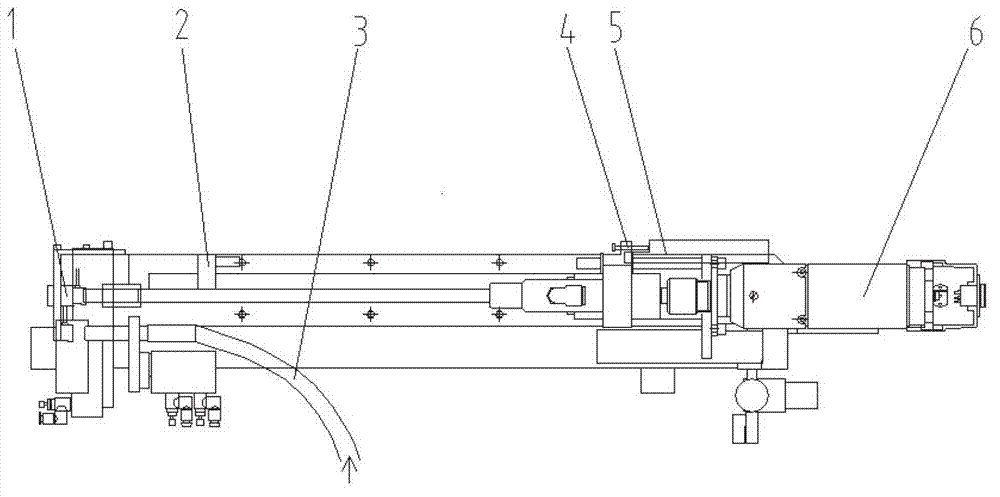

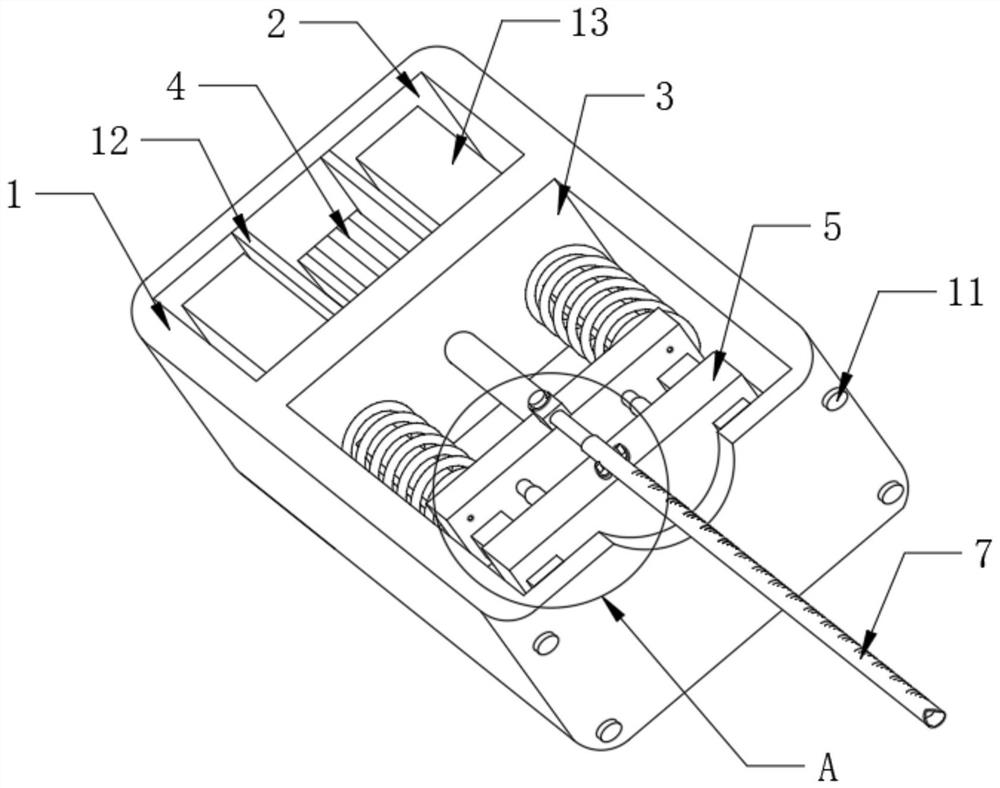

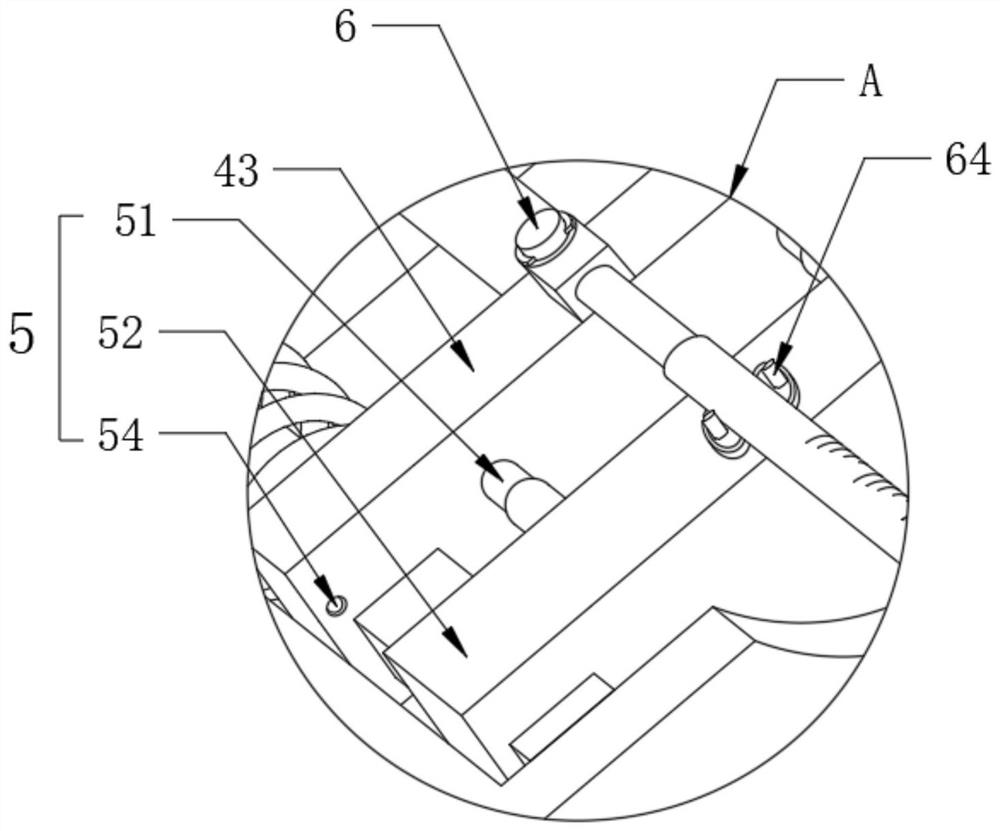

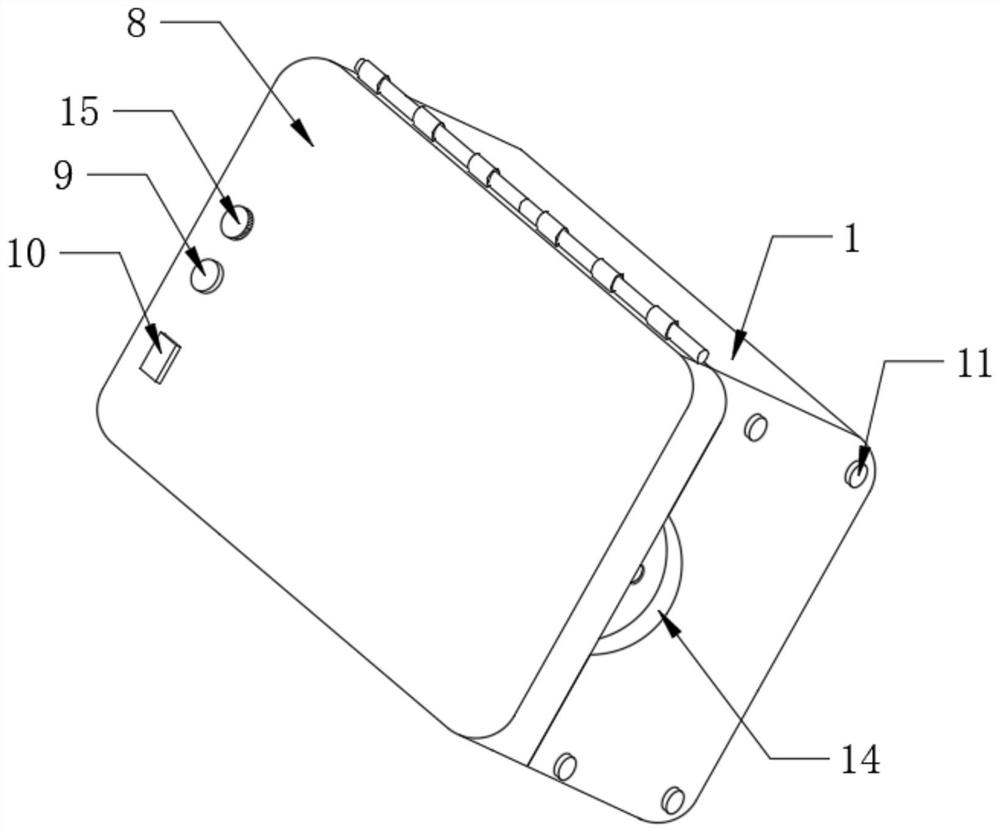

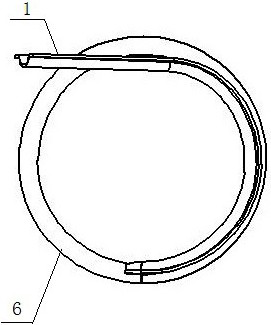

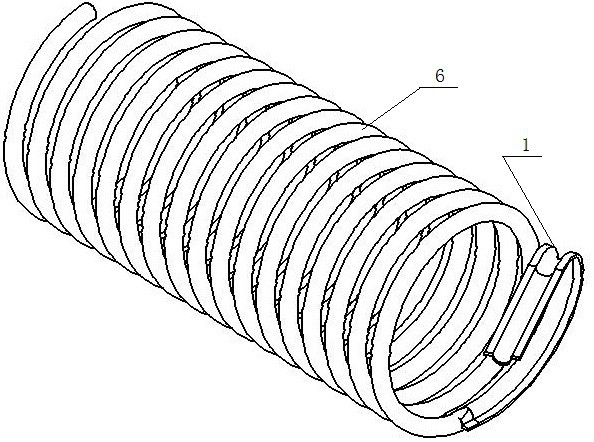

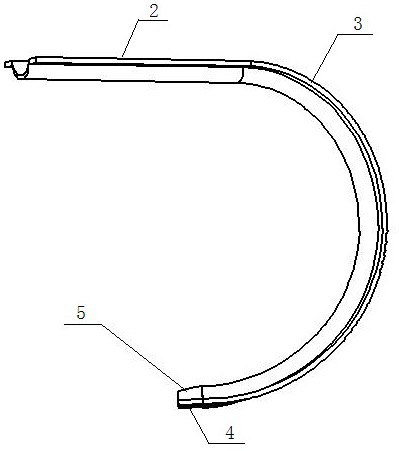

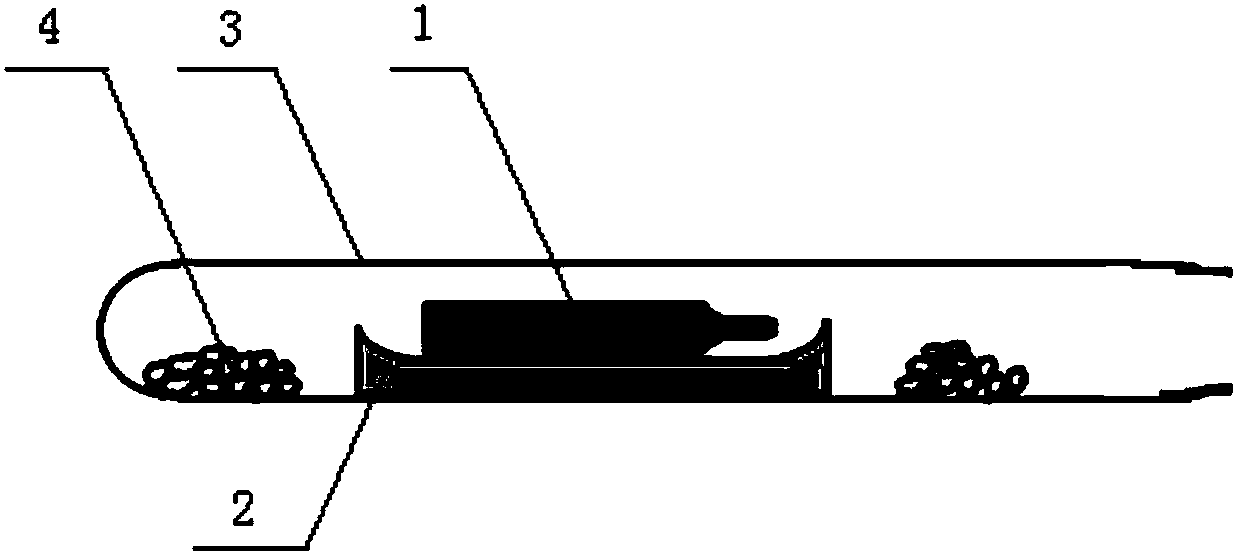

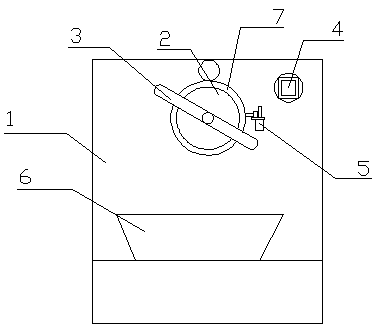

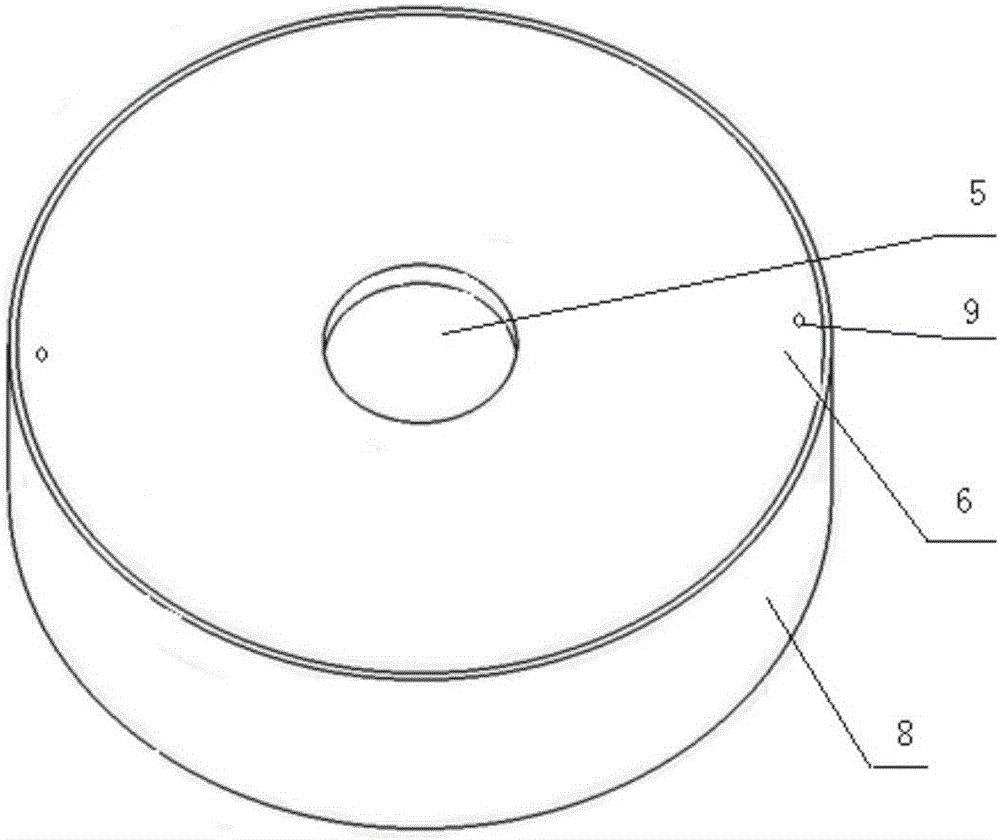

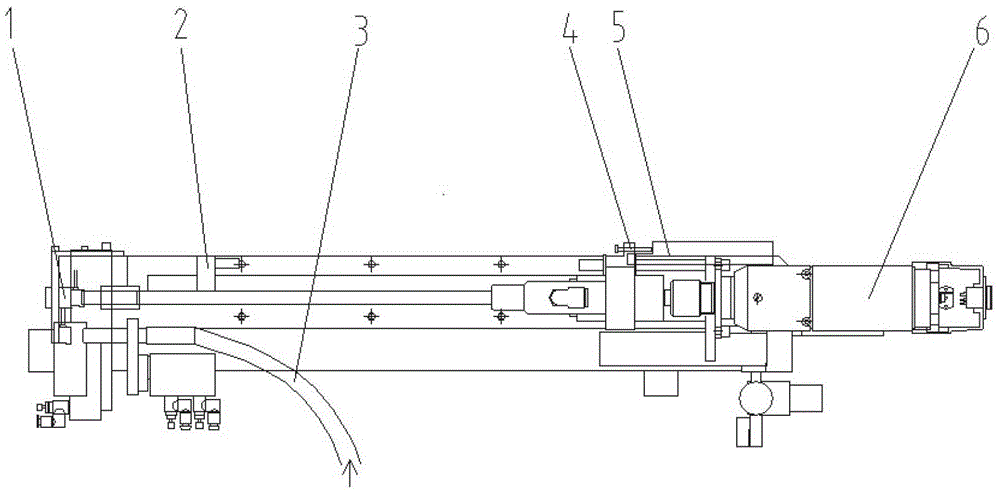

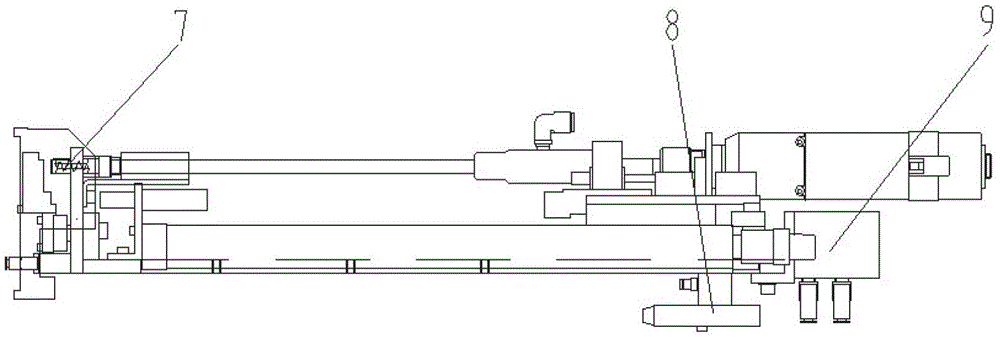

Universal type high-speed intelligent automatic screw fastening mechanism

ActiveCN102922271ADifficulty in simplifying structure and operationImprove work efficiencyMetal working apparatusMechanical engineering

A universal type high-speed intelligent automatic screw fastening mechanism can be used for fastening screws continuously and accurately at any angle, that is, a screw can be fastened horizontally, slantly or from the bottom up. The screw fastening mechanism mainly comprises three parts (namely, a screw pushing device, a screw suction device and a screw fastening device). When the screw fastening mechanism is in operation, a screw supply mechanism wafts the screw into the screw pushing device through a soft charge pipe, and the screw is placed in an accurate posture; the screw pushing device pushes the screw to a required position; a screw taking cylinder in the screw suction device controls a vacuum straw to move to the position where the screw is placed; and a vacuum generator acts to suck the screw. Therefore, the screw is loaded in a suction manner, which solves the problem that during horizontal screw fastening operation, the concave center of the screw cannot be aligned with the center of a screwdriver head, so that the screw is deflected during fastening, and undesirable products are produced. When the screw is sucked by the screw suction device, the screw fastening device moves to a product to be processed under the action of a cylinder, and the screw is screwed through the rotation of the screwdriver to fulfill operation, so that the operation is convenient and fast, and the work efficiency is improved greatly.

Owner:DALIAN YUN MING AUTOMATION TECH

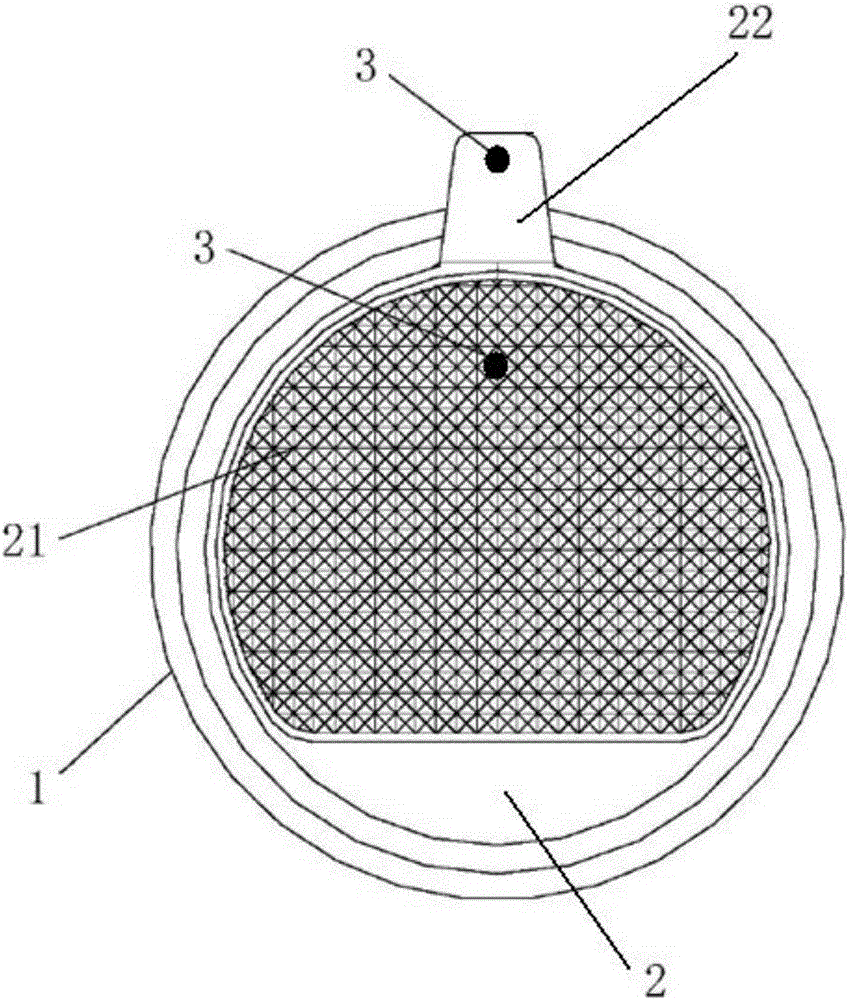

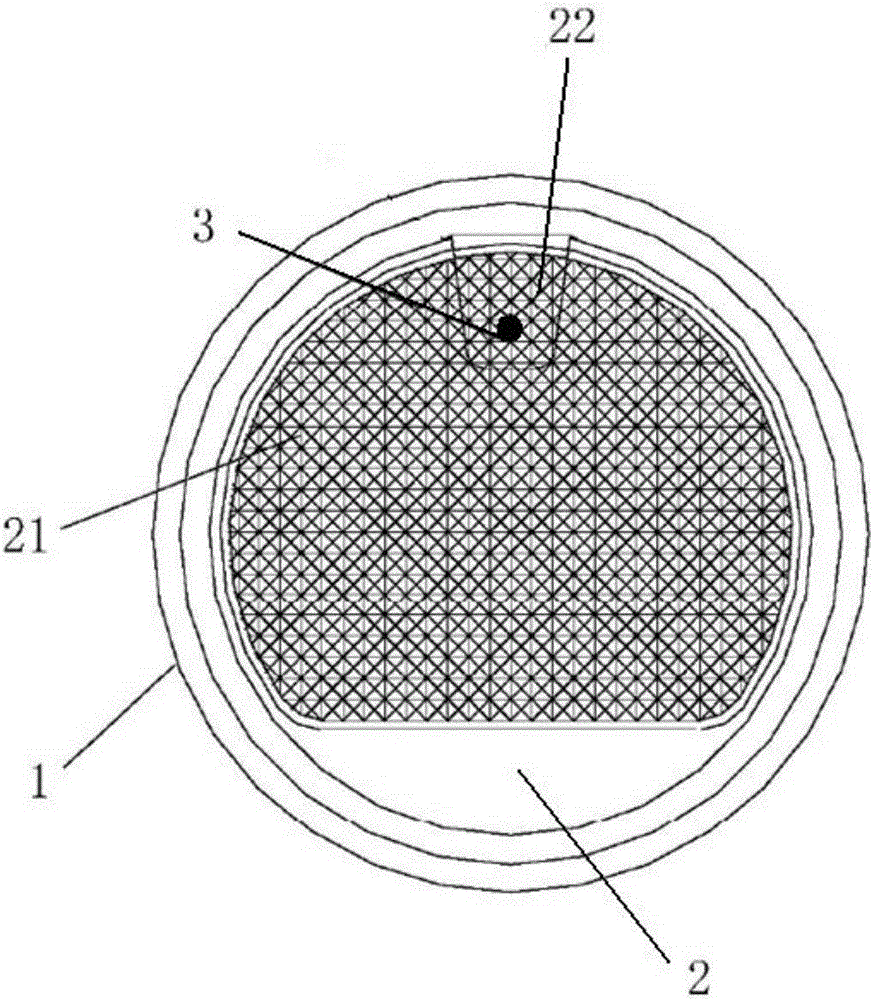

Preparation process and application of green environment-friendly paper

ActiveCN107012740APromote absorptionSo as not to damageSpecial paperBook keepingGreen environmentWastewater

The invention discloses a preparation process and application of green environment-friendly paper, belonging to the field of environment-friendly papermaking technology. According to the invention, a Chinese ink coloring apparatus is employed for uniformly coating the surface of a semi-dried paper web with a color coating in a full-web Chinese ink coloring manner; since the paper web has moisture, the paper web well absorbs Chinese ink during coloring, and a uniform color coating can be formed; thus, green environment-friendly myopia-preventing homework books, exercise books and examination paper of students prepared from produced paper through printing protect the eyesight of students from damage in use of the books and examination paper. A paper machine is employed for drying, compacting and synchronous dye fixation, so the coating on the surface of the paper is fully fused with the paper and is free of peeling. The whole process flow is integrated with a papermaking procedure, the semi-dried paper web is directly subjected to full-web Chinese ink coloring and then to further drying, and the papermaking procedure is integrated with the drying part of a coloring procedure, so drying time is reduced, energy needed in drying is saved, and high efficiency and energy conservation are realized. Produced wastewater is simple in composition and easy to treat.

Owner:四川北彩印务有限公司

Cover easy to tear and manufacturing method thereof

The invention discloses a cover easy to tear and a manufacturing method thereof. The cover easy to tear comprises a cover body provided with an object taking hole, a sealing film and a gummed layer, wherein the sealing film is provided with a sealing film body and a pull sheet, and the gummed layer is arranged on the pull sheet or the sealing film body and used for adhering the pull sheet to the sealing film body. The manufacturing method of the cover easy to tear comprises the steps that a gloss oil layer is formed on the outer surface of aluminum foil and subjected to drying treatment; a heat-seal layer is formed on the inner surface of the aluminum foil; a cursor is printed on the outer surface of the aluminum foil or the gloss oil layer; a gummed area is determined according to the position of the cursor and the gummed layer is formed; the aluminum foil is cut into a shape of the required sealing film, and the gummed layer is located on the pull sheet and / or the sealing film body; the cover body is covered with the sealing film, and the object taking hole of the cover body is sealed; the pull sheet is turned over onto the sealing film body; and the pull sheet adheres to the sealing film body through the gummed layer. The cover easy to tear and the manufacturing method thereof solve the technical problem that a sealing film cracks easily due to a pull sheet and sealing film connection mode in the prior art and have the advantage that the sealing film is not prone to cracks through combination of the pull sheet and the sealing film.

Owner:ZHEJIANG GOLDSTONE PACKING

Tartary buckwheat threshing method

InactiveCN104148134ASo as not to damageNot harmedGrain huskingGrain polishingBiotechnologyPolygonum fagopyrum

The invention relates to the technical field of food processing, in particular to a tartary buckwheat threshing method. According to the technical scheme, the tartary buckwheat threshing method comprises the following steps that (1) dust and impurities of tartary buckwheat raw materials are removed; (2), the tartary buckwheat raw materials are soaked in clean water; (3) the soaked tartary buckwheat is conveyed to a steamer through a hoist, and the tartary buckwheat is steamed through the steamer for 40 to 50 minutes; (4) the steamed tartary buckwheat is placed in a microwave to be dried, wherein the heating temperature is controlled to be at 60 DEG C, and the water content of the tartary buckwheat ranges from 15% to 25%; (5) the dried tartary buckwheat is conveyed into a threshing device to be threshed; (6) separated tartary buckwheat hulls are removed through screening and winnowing; (7) tartary buckwheat kernels are screened out or separated through a gravity husked rice separator. By the adoption of the tartary buckwheat threshing method, original nutritional ingredients of tartary buckwheat can be kept, and over 90% of completed tartary buckwheat kernels can be obtained.

Owner:KUNMING HONGTUDI YINGLONG FOOD PROCESSING

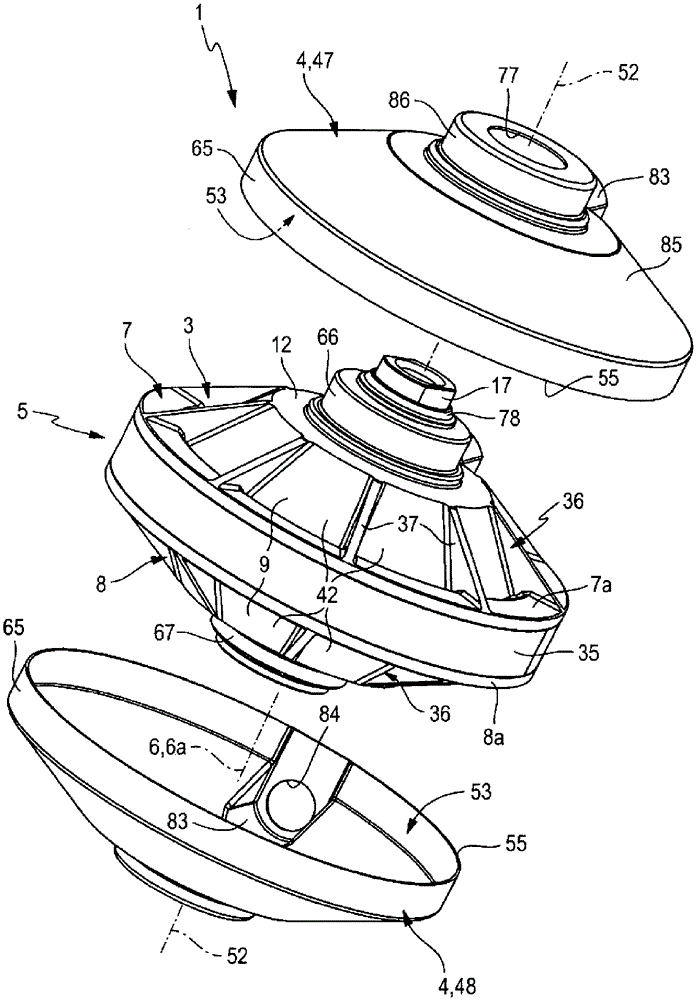

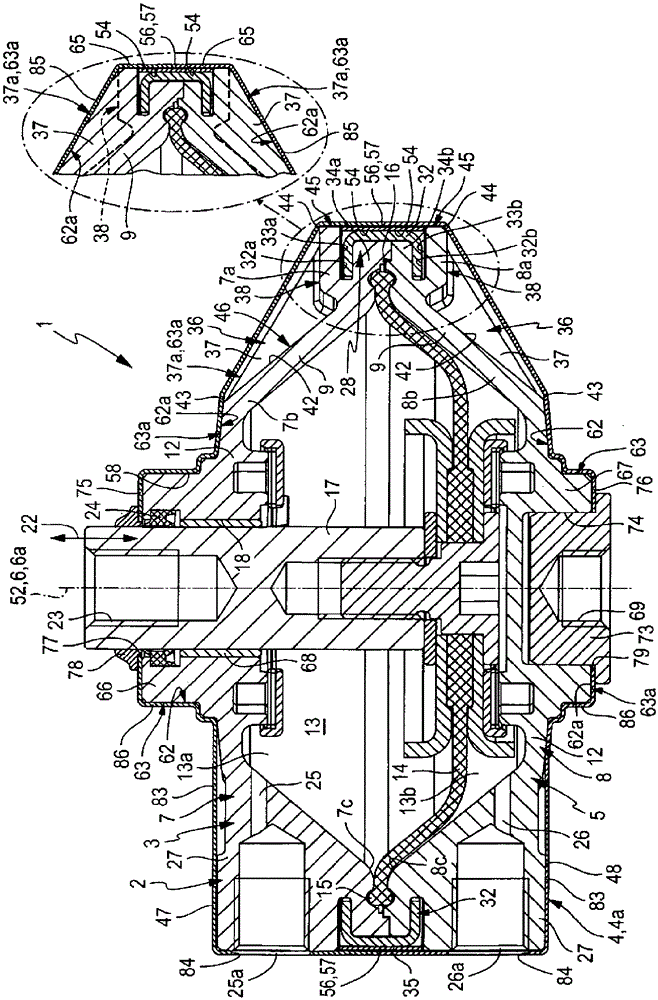

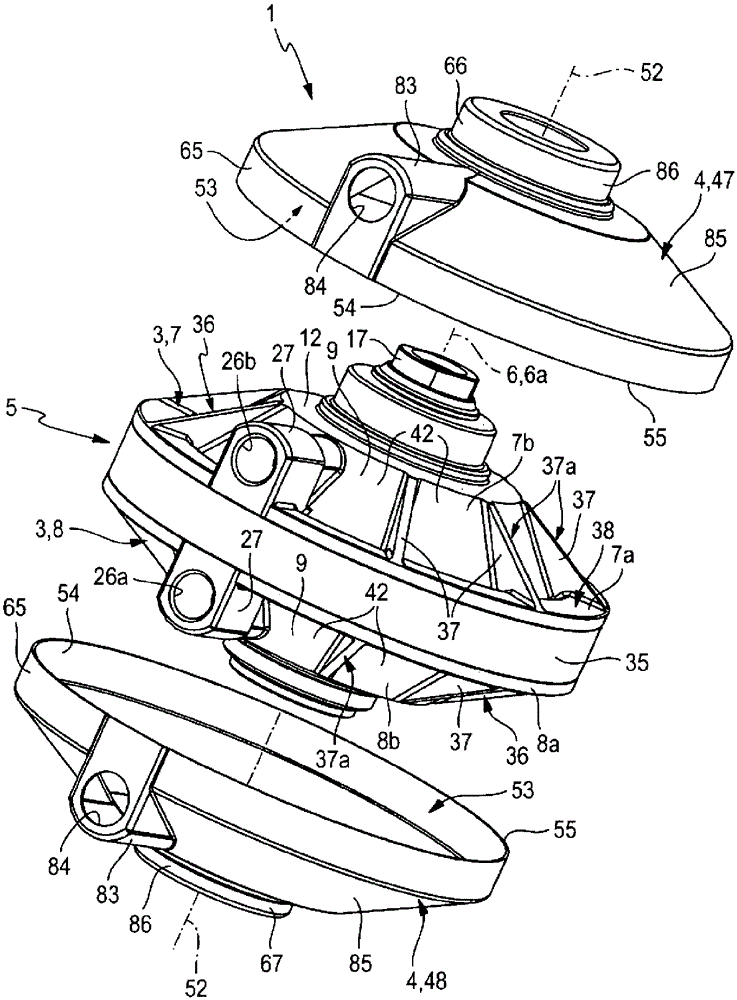

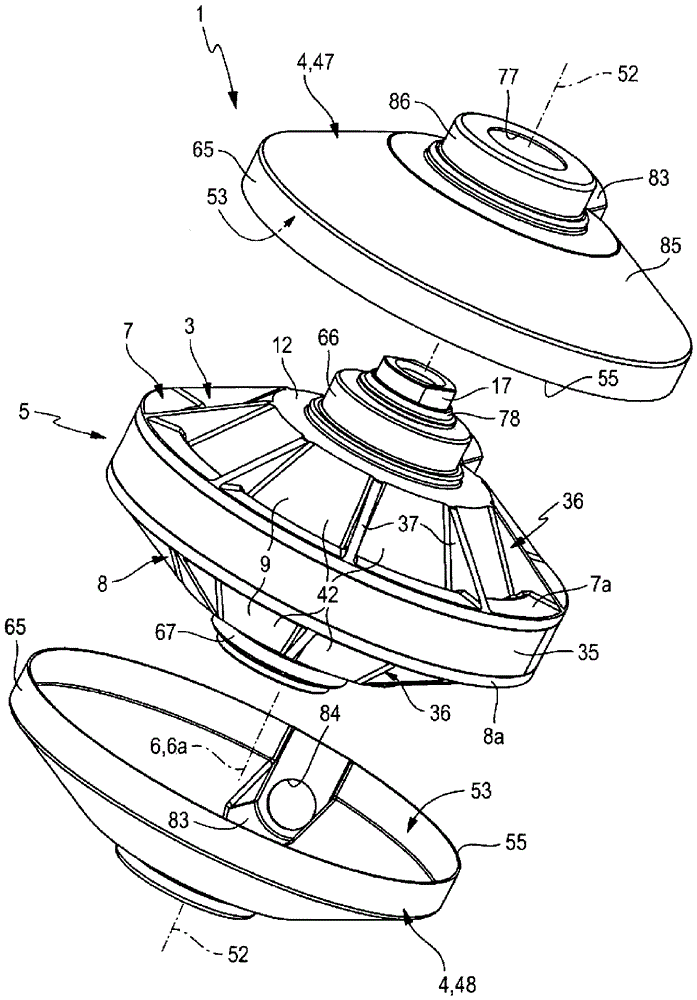

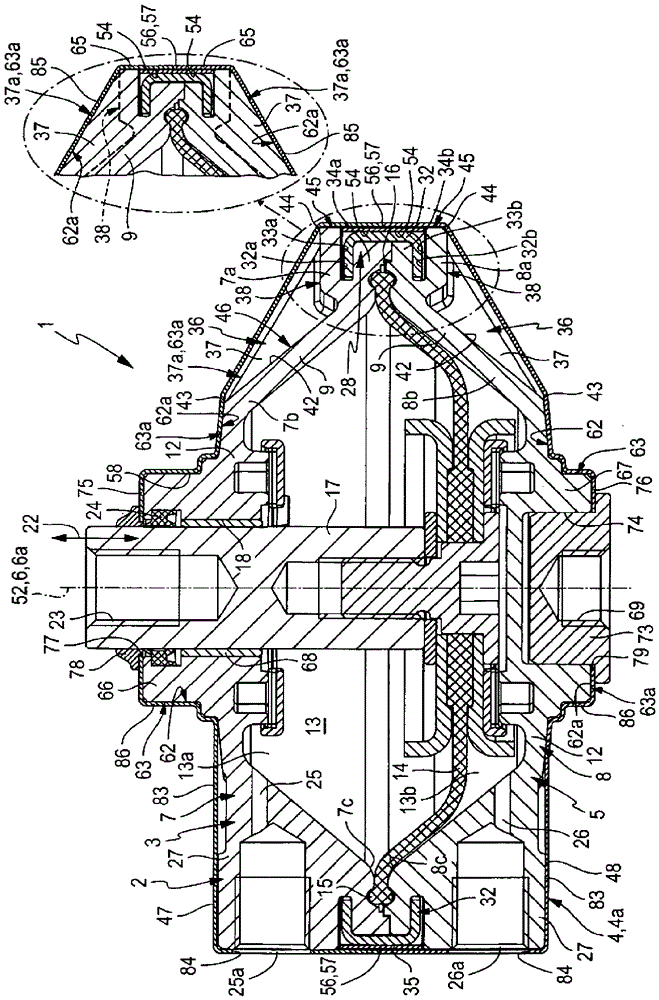

Fluid-actuated diaphragm drive

InactiveCN105408640AImprove rigidityEasy to cleanOperating means/releasing devices for valvesFluid-pressure actuatorsEngineeringFluid pressure

A fluid-actuated diaphragm drive (1) is proposed, with a drive unit (5) whose drive housing (3) consists of two hood-shaped drive housing parts (7, 8) attached coaxially to each other. The drive housing (3) is enclosed on the outside by a fluid-tight envelope housing (4), which is separate from the drive unit (5) and which is composed of two envelope housing parts (47, 48) that are attached to each other and welded to each other in a fluid-tight manner and are made of a stainless steel sheet. At the same time, the envelope housing also forms a support device (4a), which clasps the drive housing and through which the two drive housing parts (7, 8) are axially supported from axially opposite sides, such that the diaphragm drive (1) can be operated with high fluid pressure.

Owner:FESTO AG & CO KG

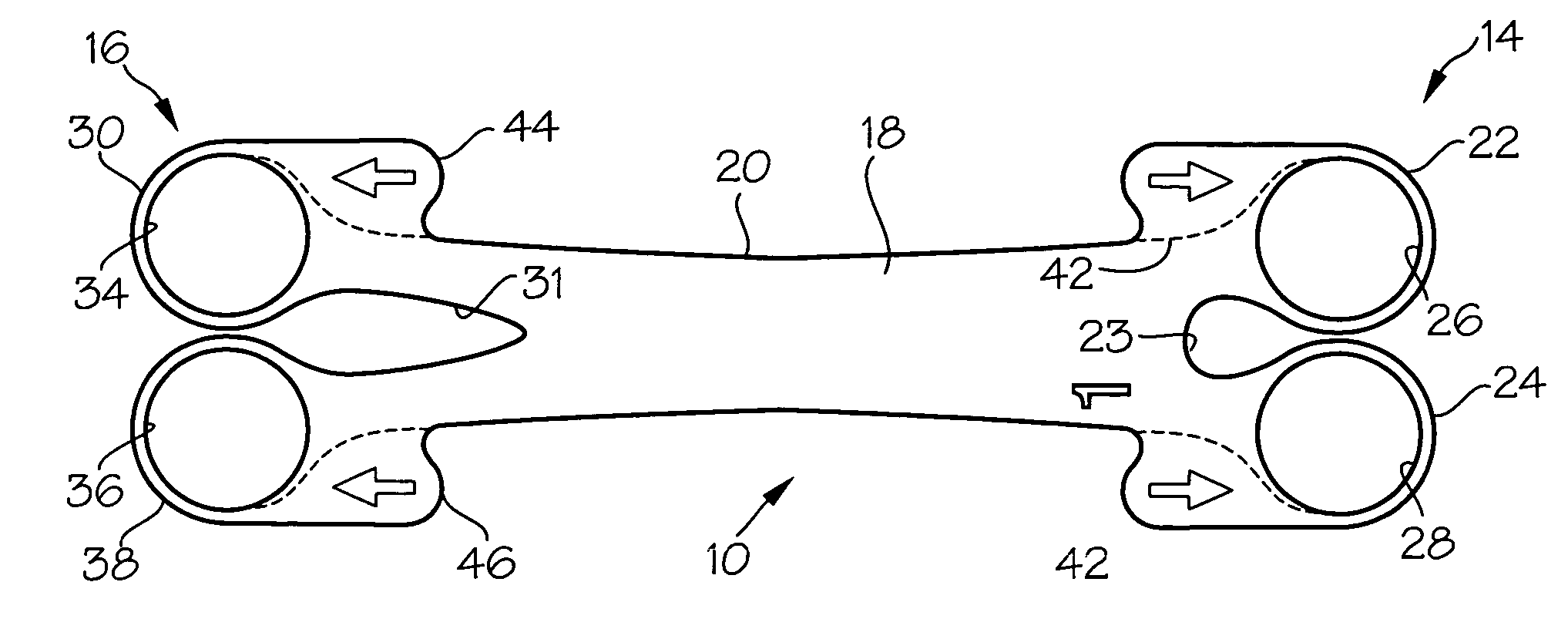

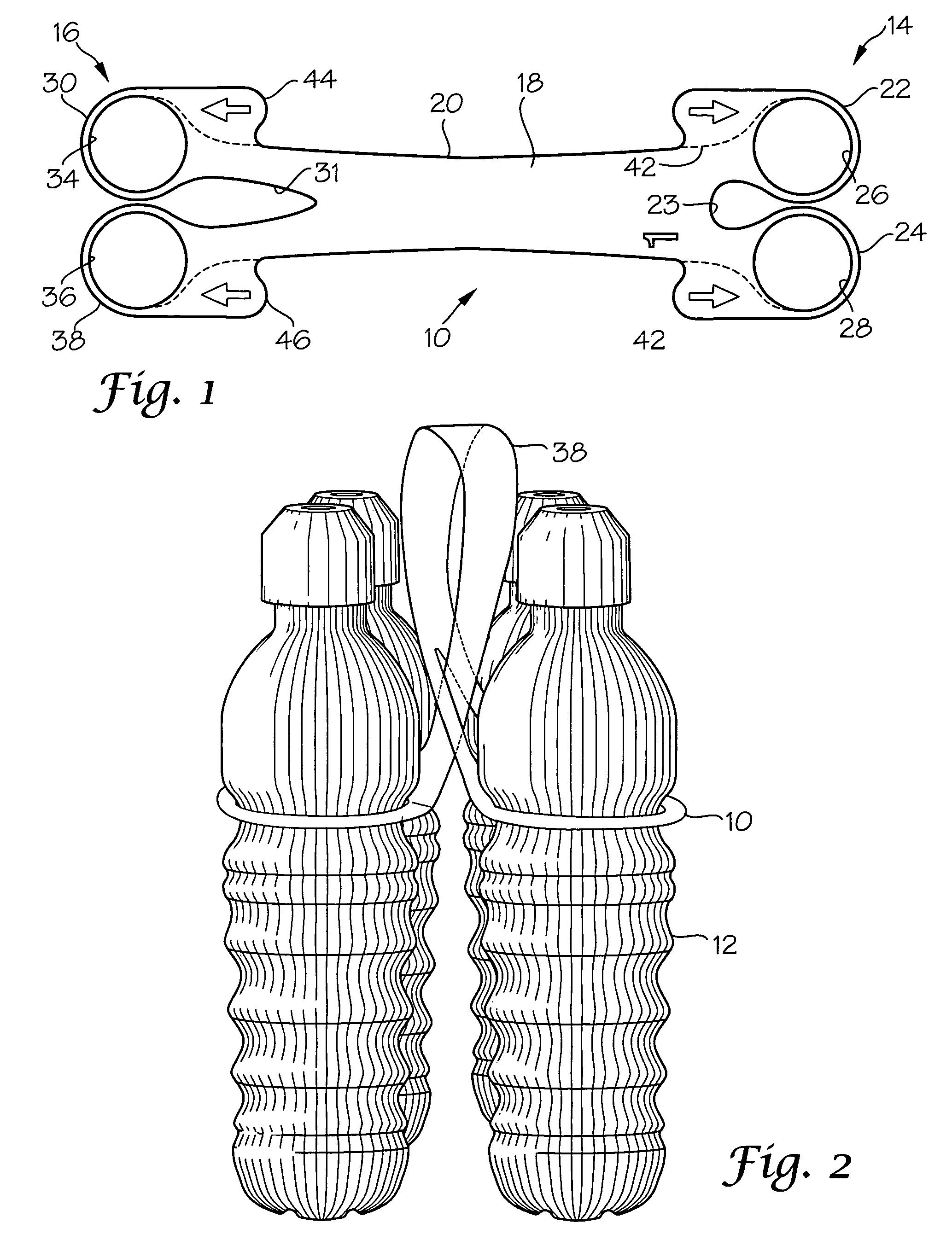

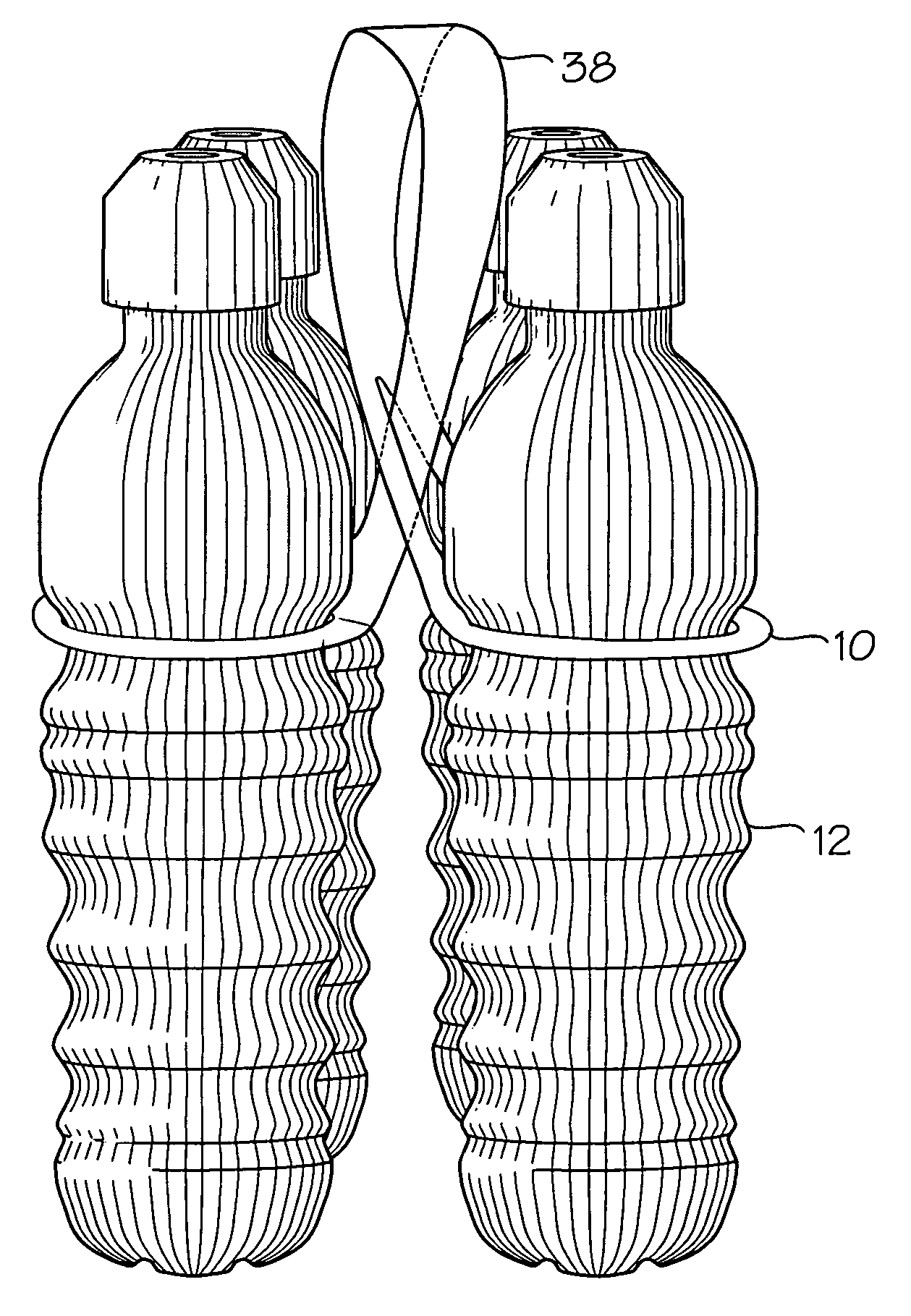

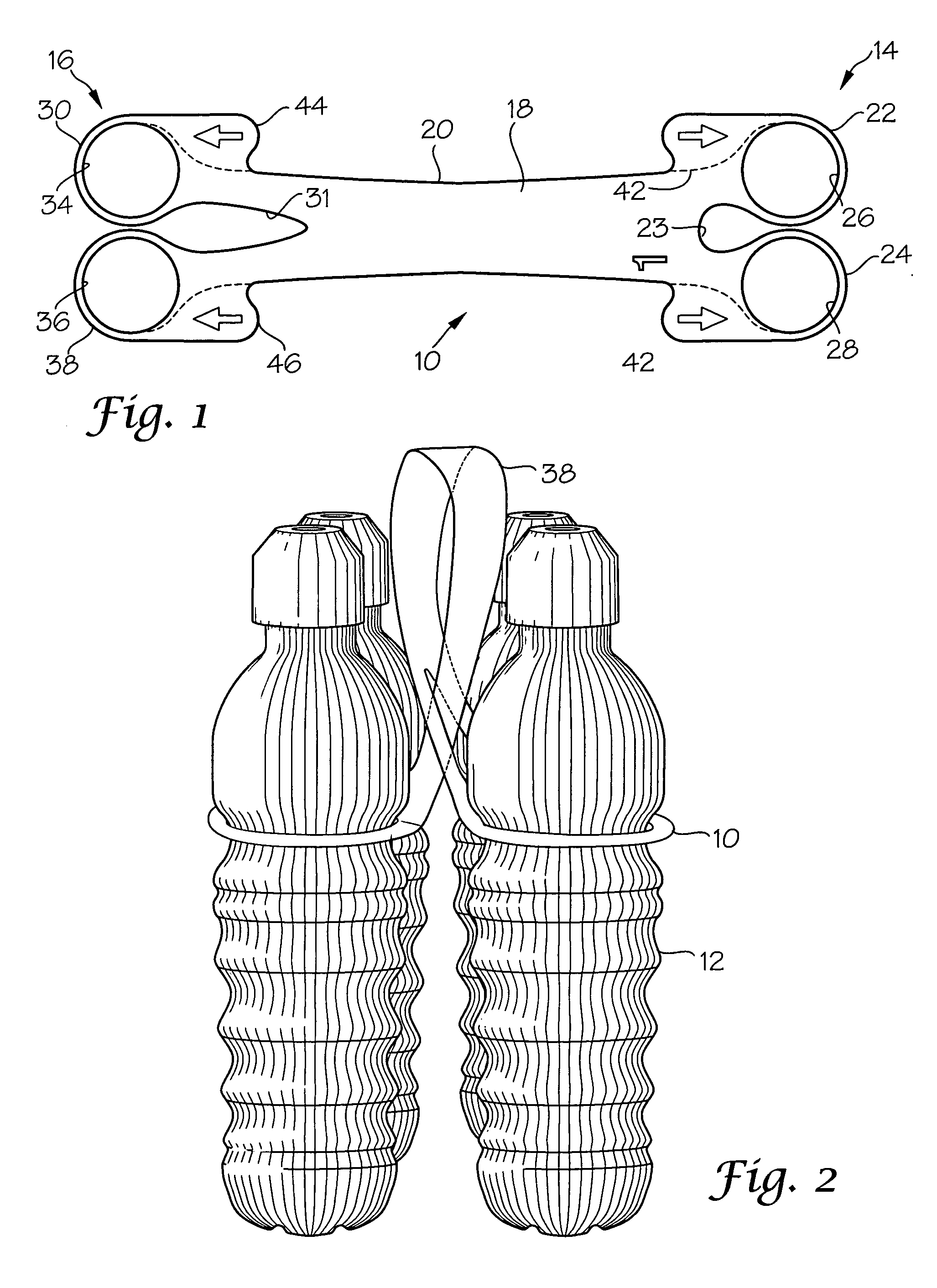

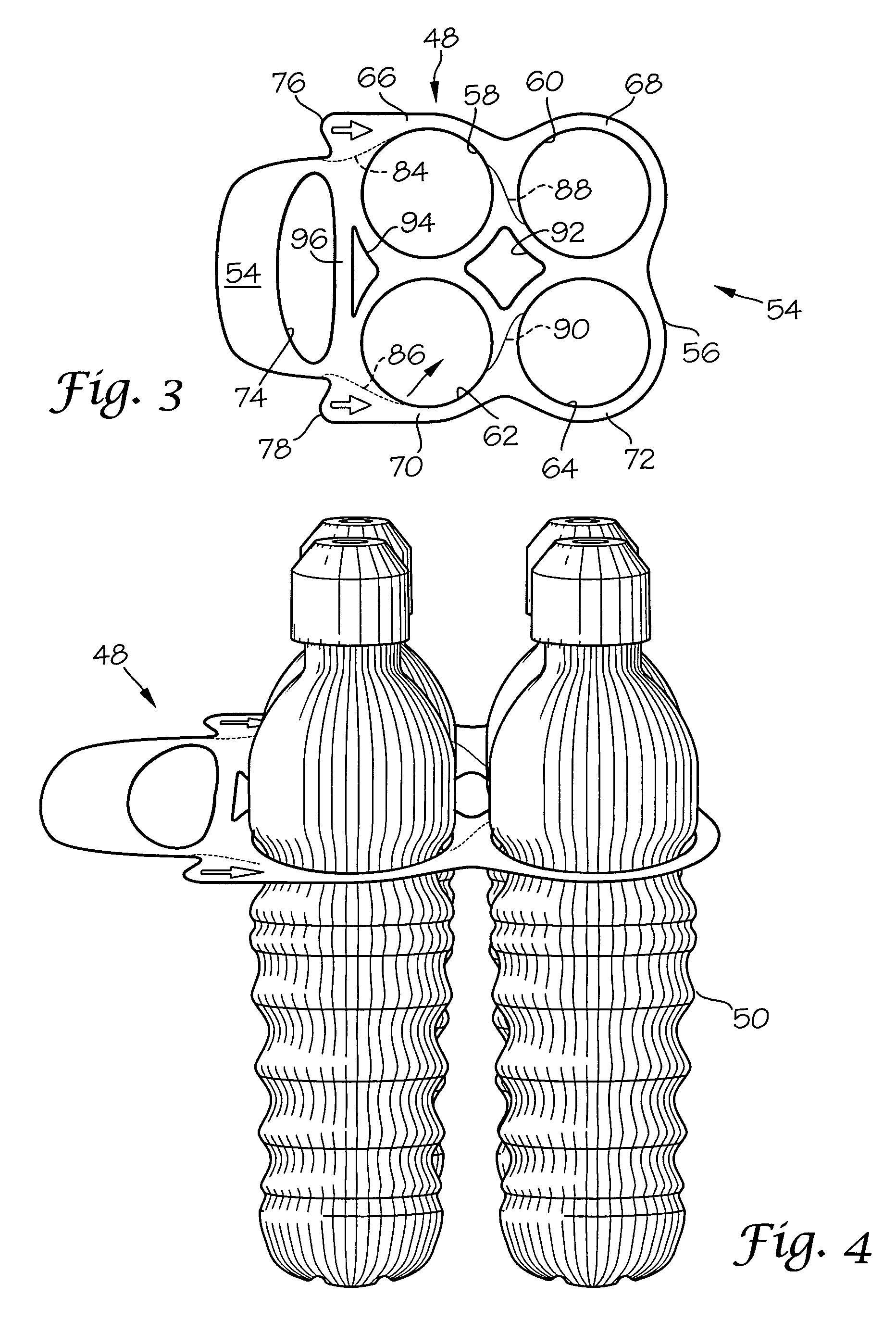

Bottle carrier with handle and pull tab

Owner:DISPLAY INDS

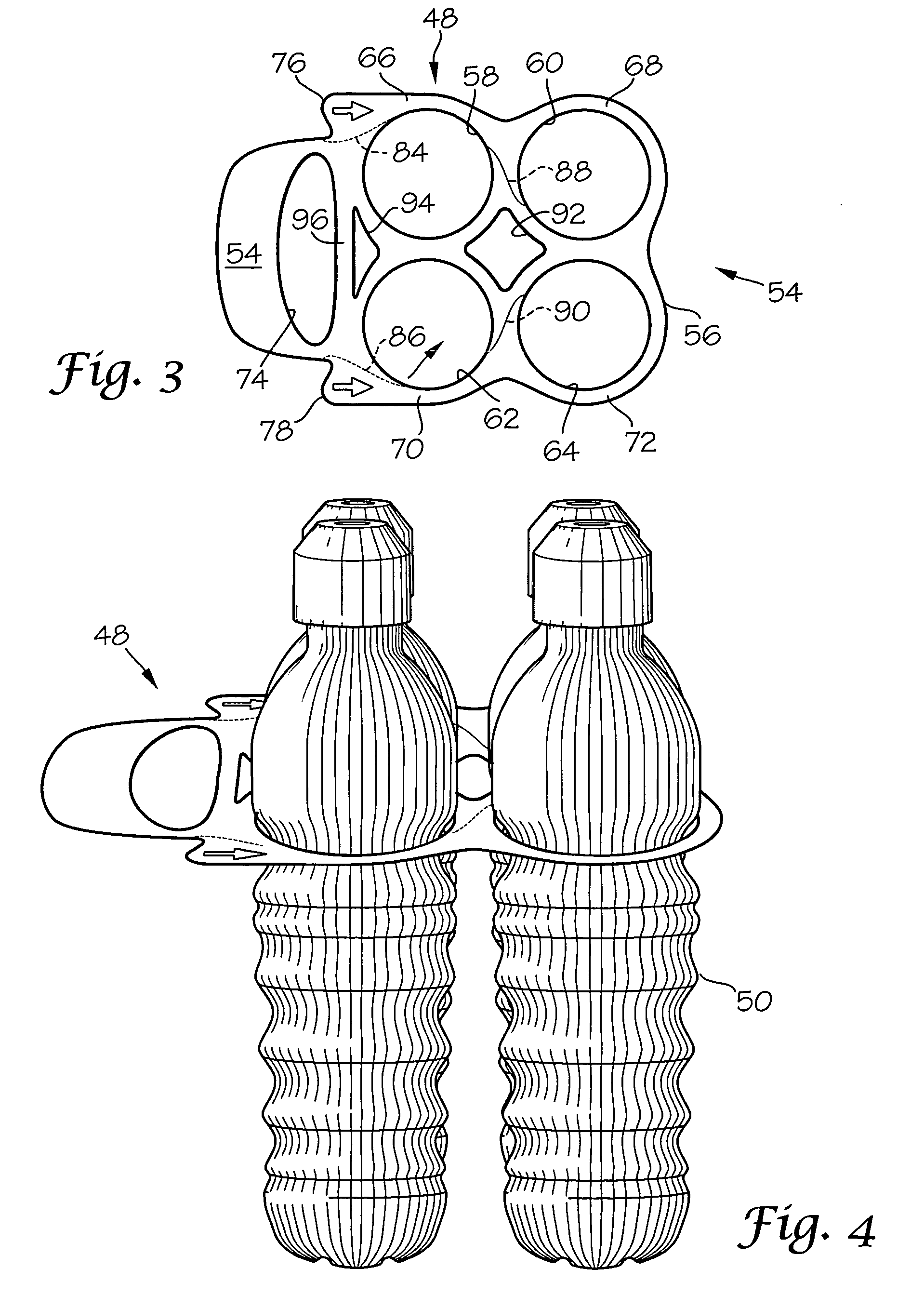

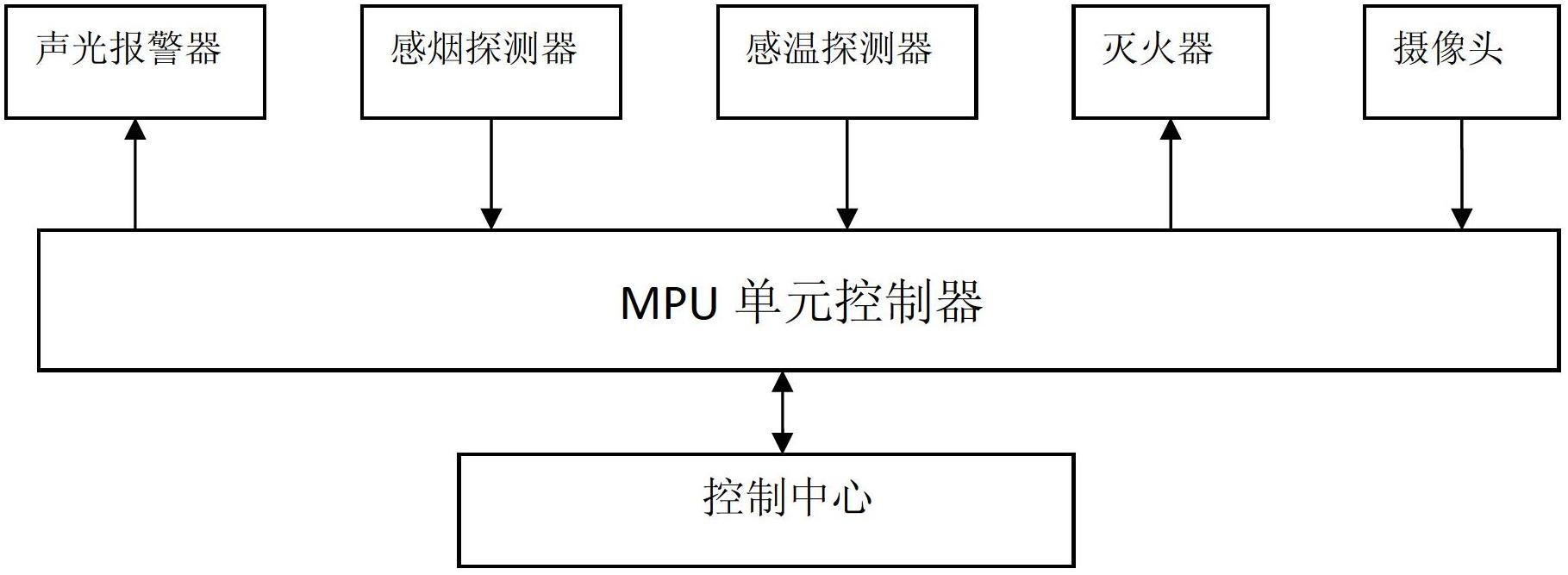

Intelligent fire fighting system used for offshore wind generating set

InactiveCN102698388ALarge scanning angleWide range of detection spectrumFire rescueComputer moduleFire extinguisher

The invention provides an intelligent fire fighting system used for an offshore wind generating set, which is used for carrying out remote intelligent control and fire fighting on the offshore wind generating set to better protect the safety of the offshore wind generating set. The intelligent fire fighting system comprises an MPU (Micro Processor Unit) controller, a control center, an alarm, a detection module and a fire extinguisher, wherein the MPU controller and the control center are mutually connected; the alarm, the detection module and the fire extinguisher are respectively connected with the MPU controller; and the MPU controller is used for processing detection information of the detection module, transmitting processed information to the control center and controlling the opening of the fire extinguisher according to a control command returned by the control center.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

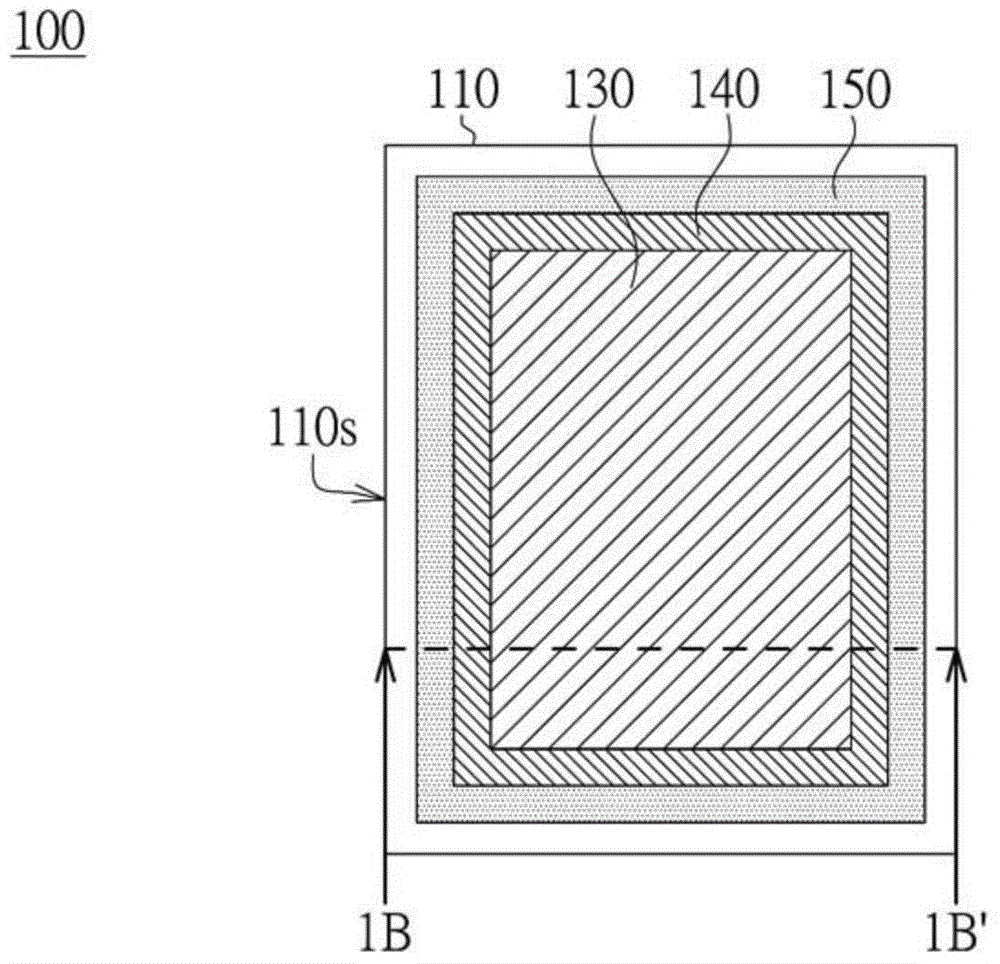

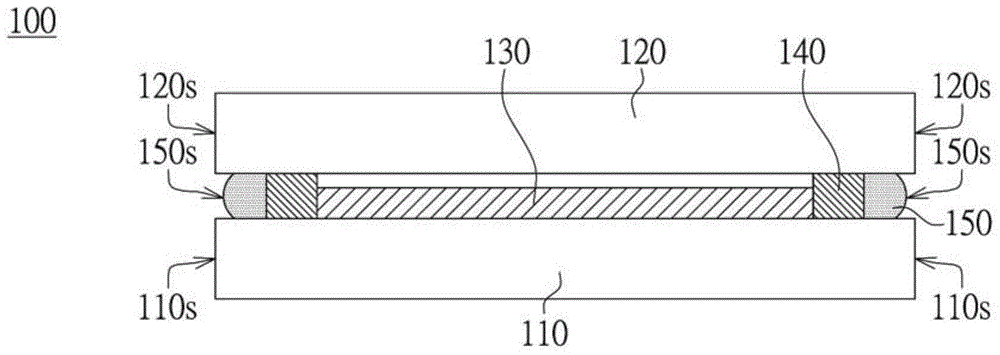

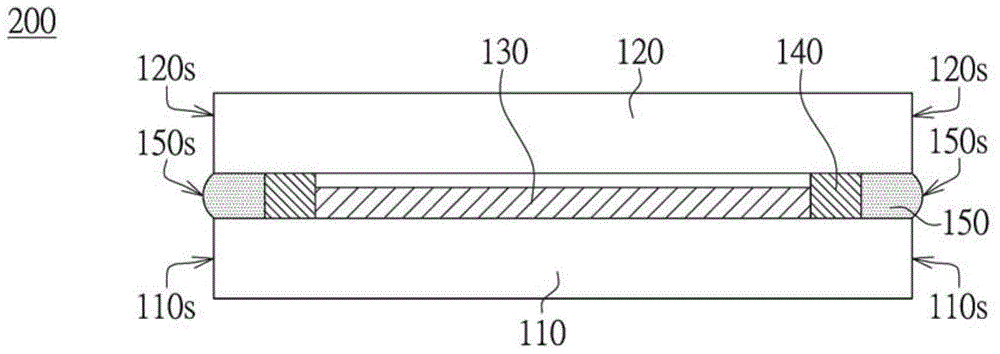

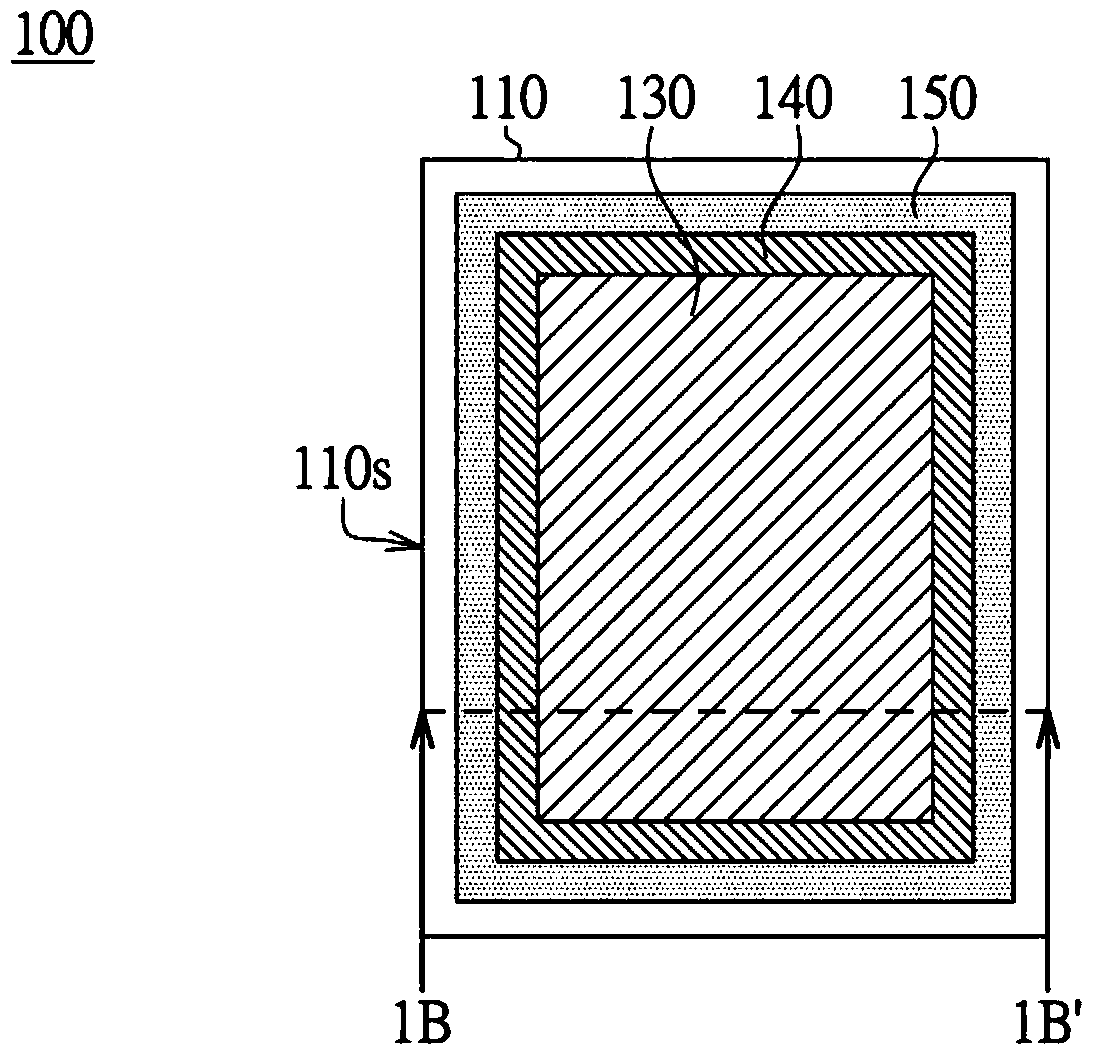

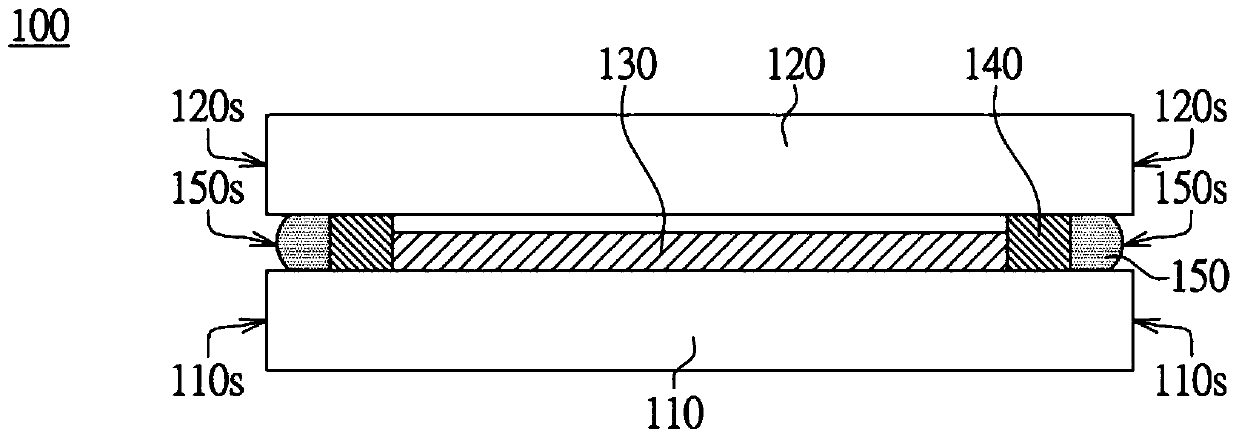

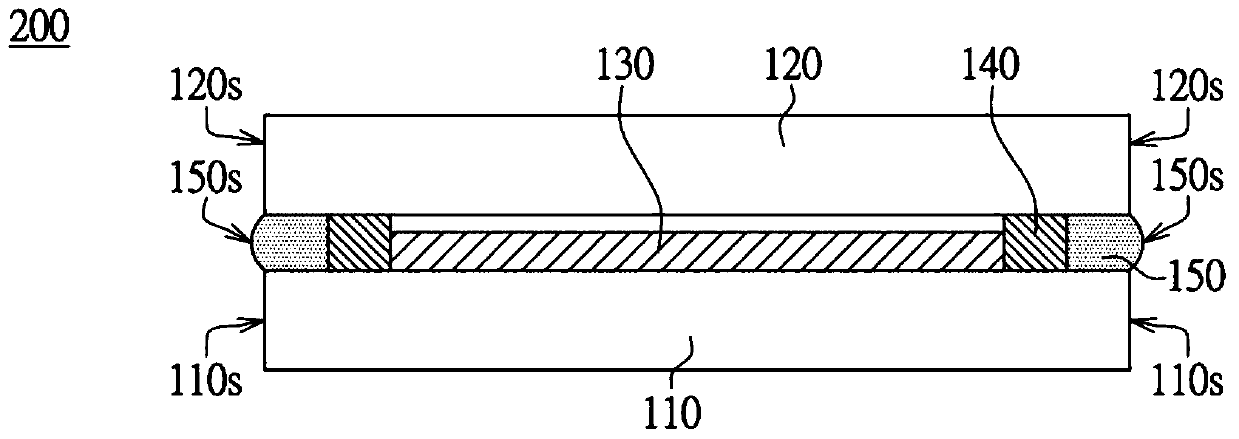

Display device and manufacture method thereof

ActiveCN105990373AExtend your lifeSo as not to damageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention discloses a display device and a manufacture method thereof. The display device comprises a first substrate, a second substrate, a display medium, a sealing layer and an etching barrier layer, wherein the second substrate is opposite to the first substrate, the display medium is positioned between the first substrate and the second substrate, the sealing layer surrounds the display medium and abuts against the substrate and the second substrate, the etching barrier layer surrounds the sealing layer and abuts against the substrate and the second substrate, and at least one sidewall of the etching barrier layer includes an arc shaped protruded surface.

Owner:INNOLUX CORP

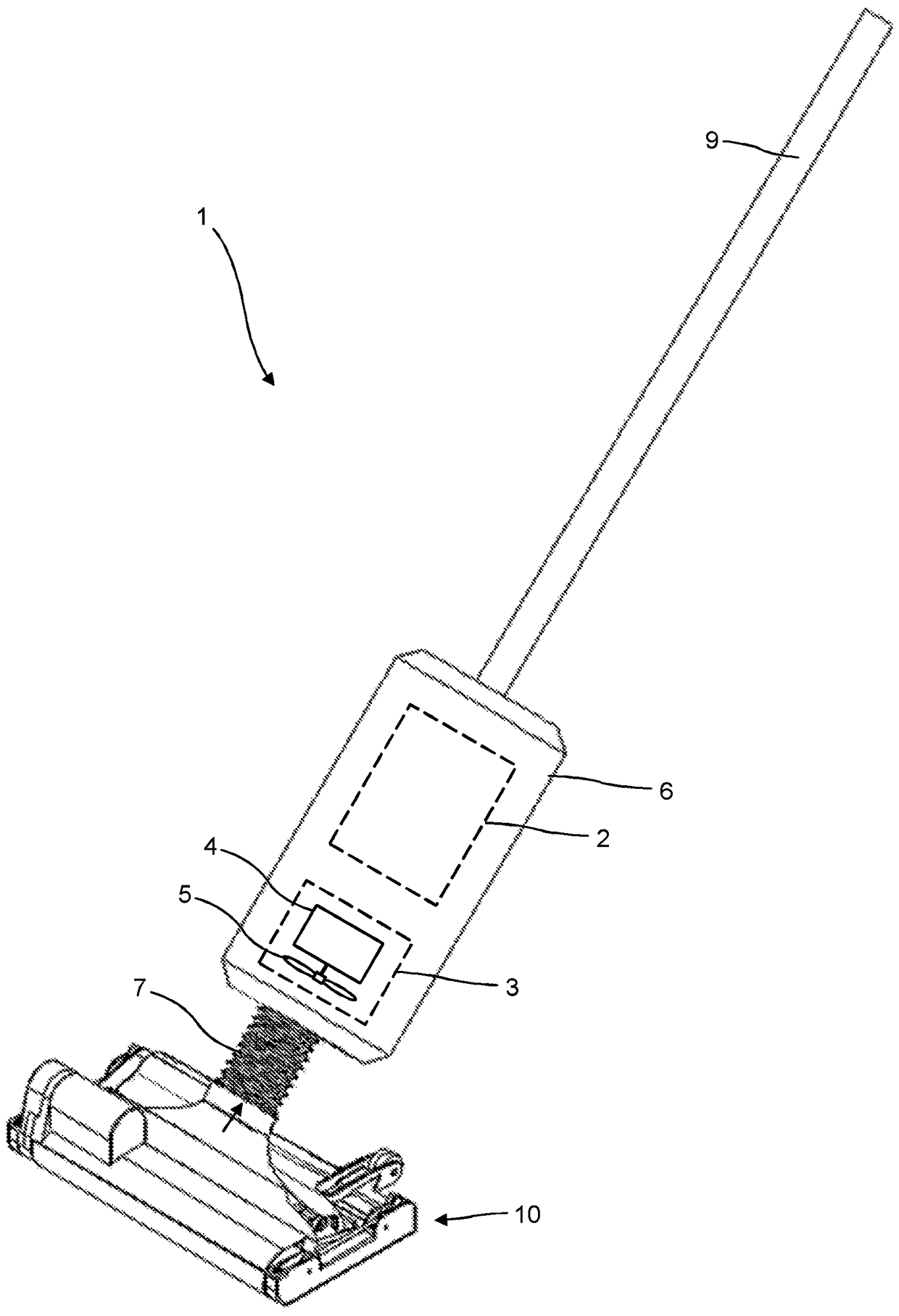

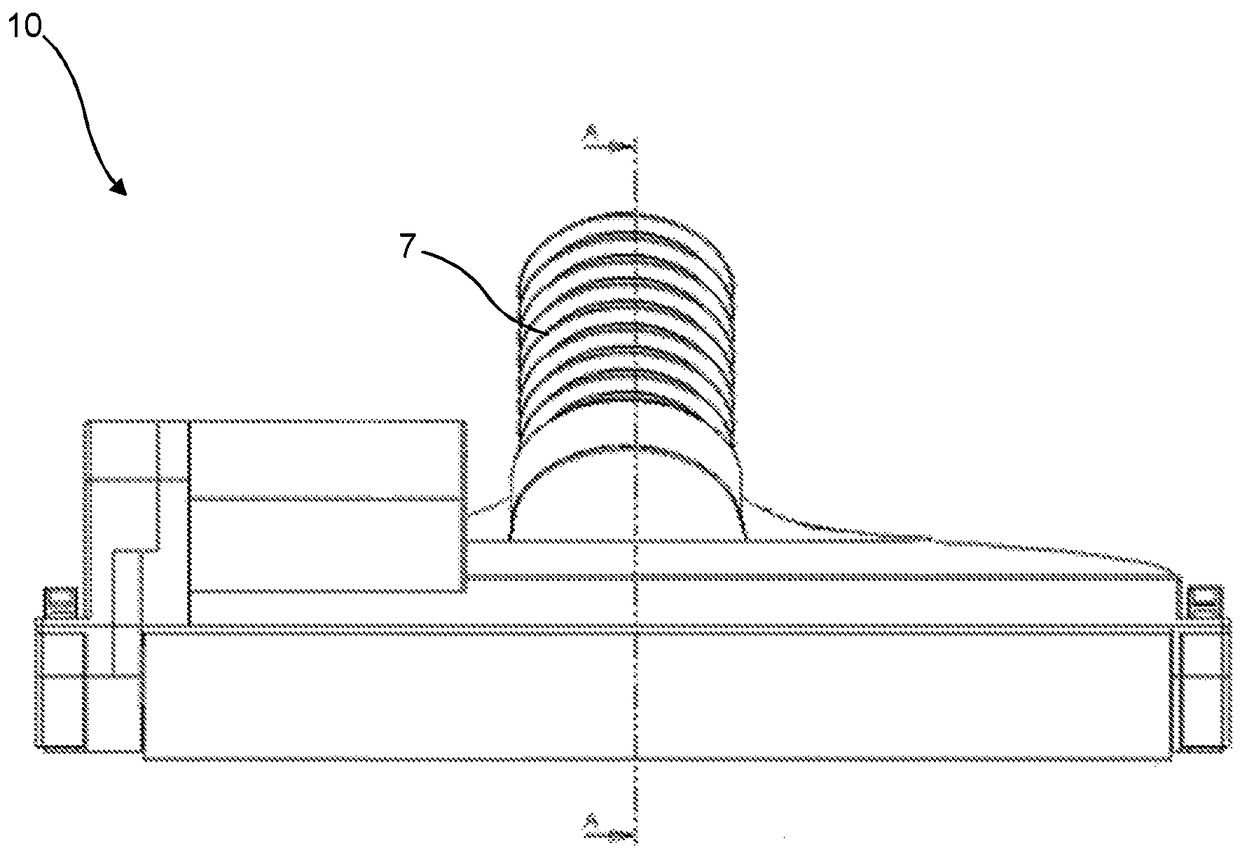

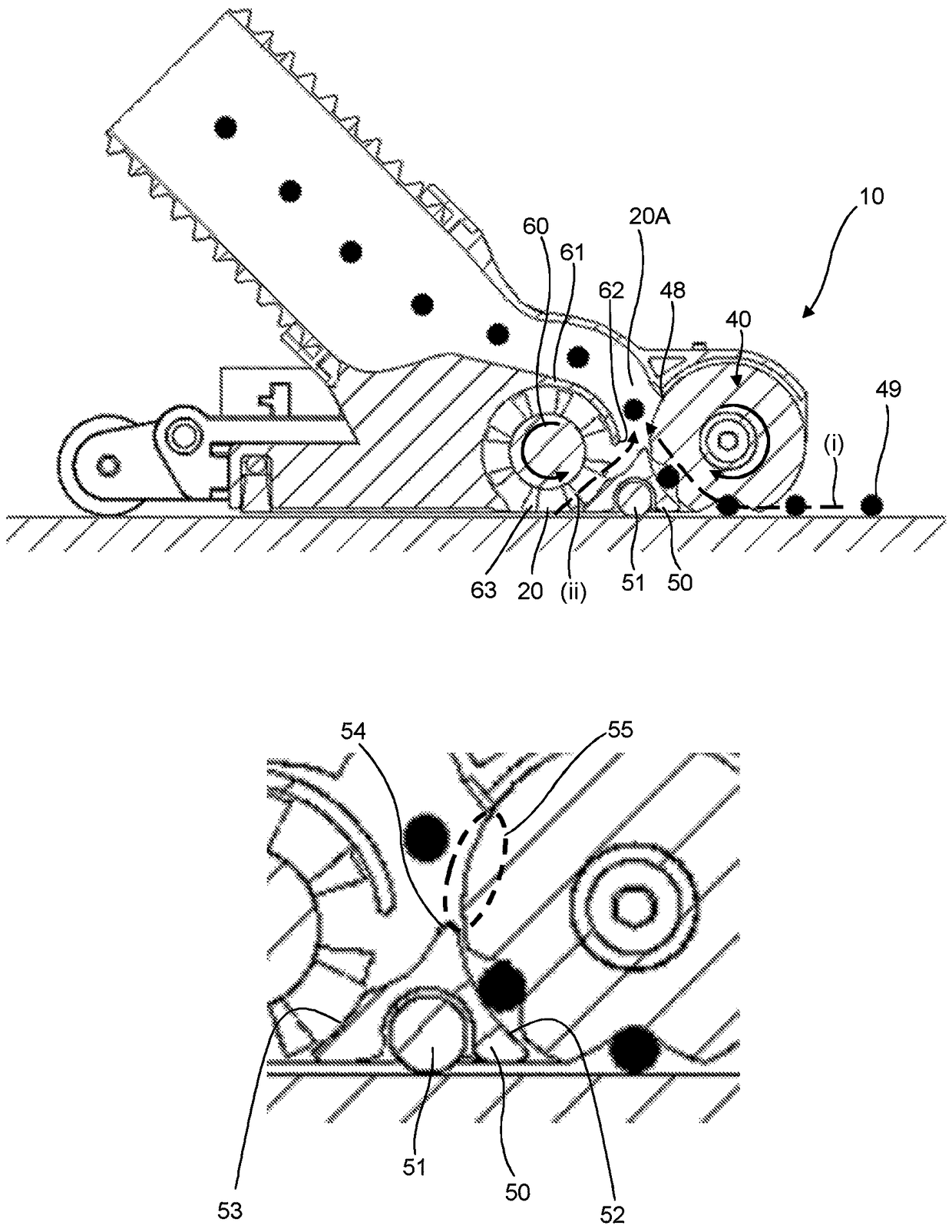

Cleaner head

A cleaner head 10 for a vacuum cleaner has a suction inlet 20 defined in the lower face of a housing 11 and a suction passageway 20A through the housing 11. A rotatable sealing element 40 is located at a front of the housing 11. The rotatable sealing element 40 has a rotational axis 41 which is parallel to the lower face of the cleaner head. An agitator 60 is positioned rewards of the rotatable sealing element 40. The suction passageway 20A is located between the agitator 60 and the rotatable sealing element 40.

Owner:LUPE TECH LTD

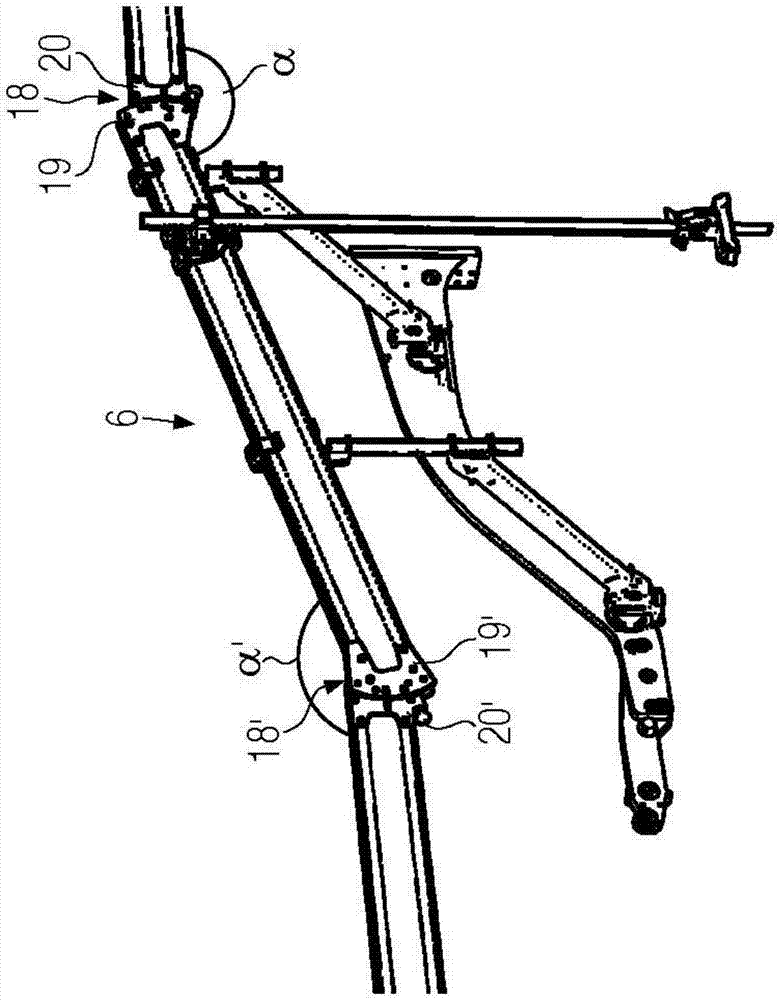

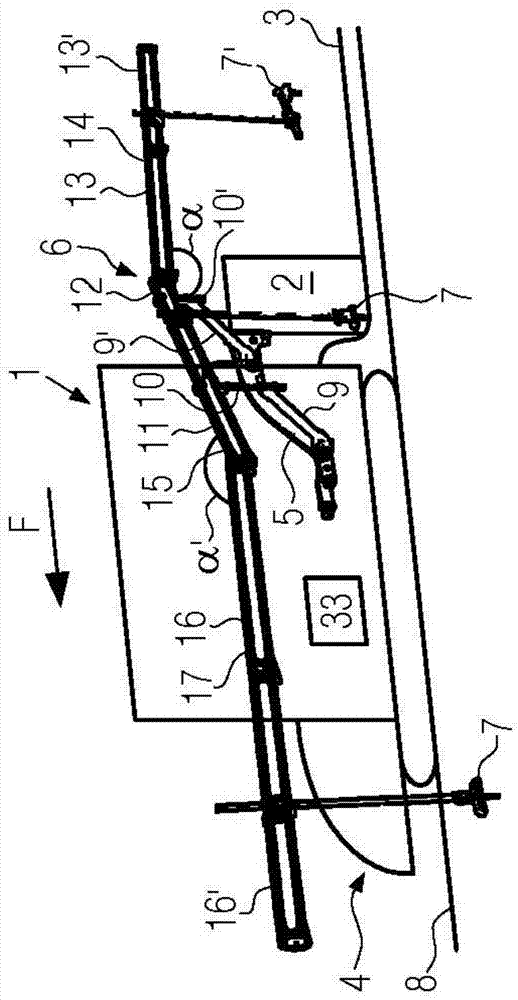

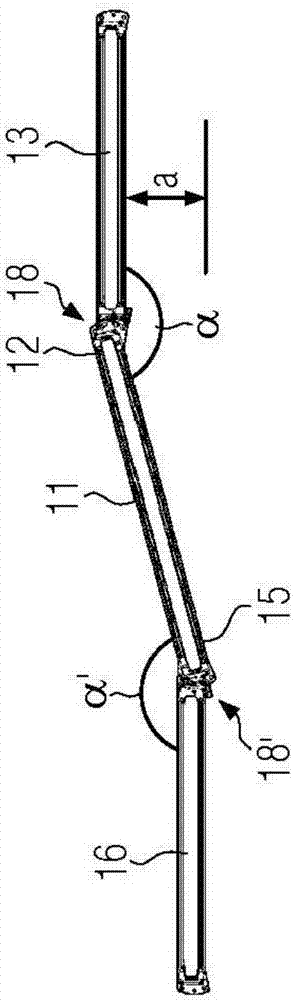

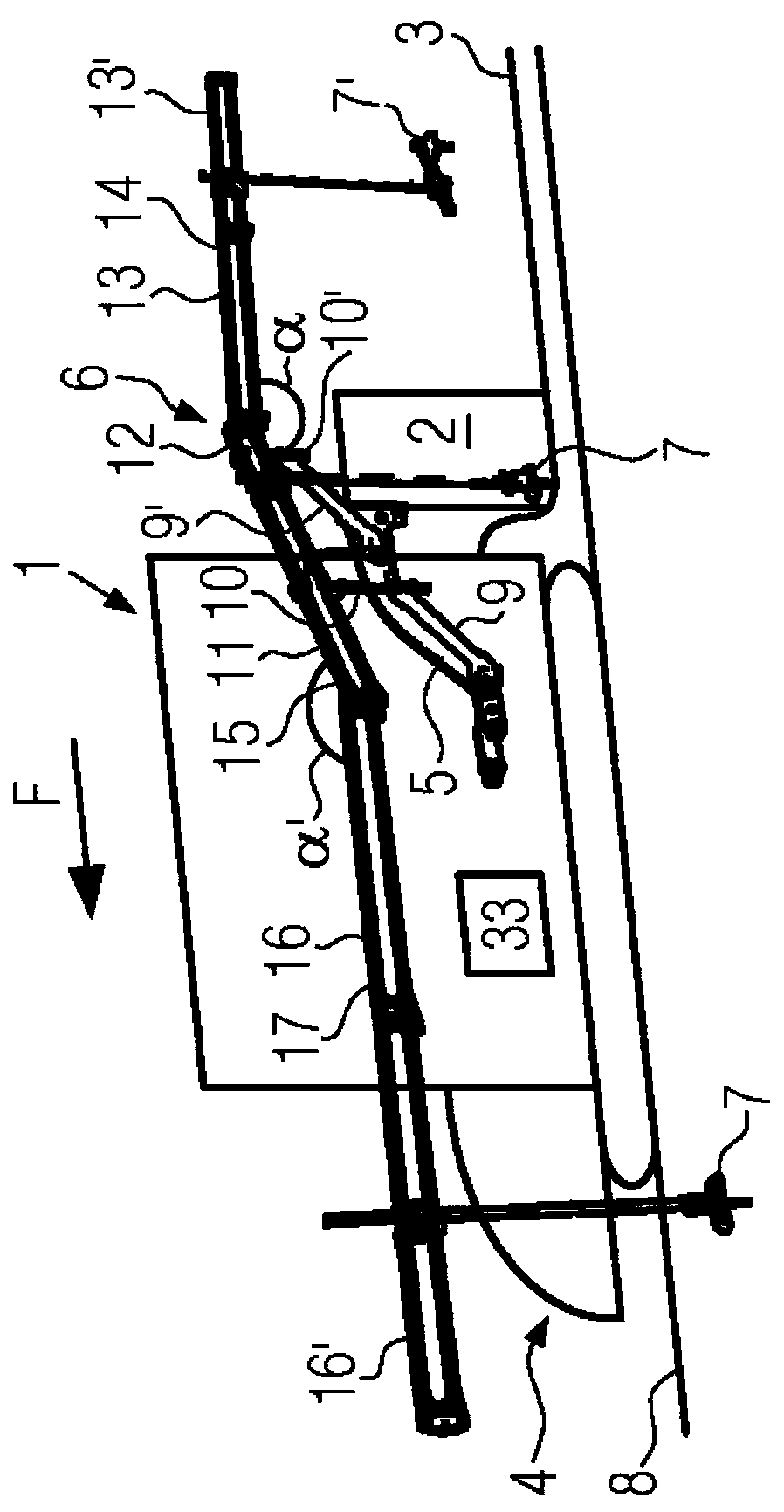

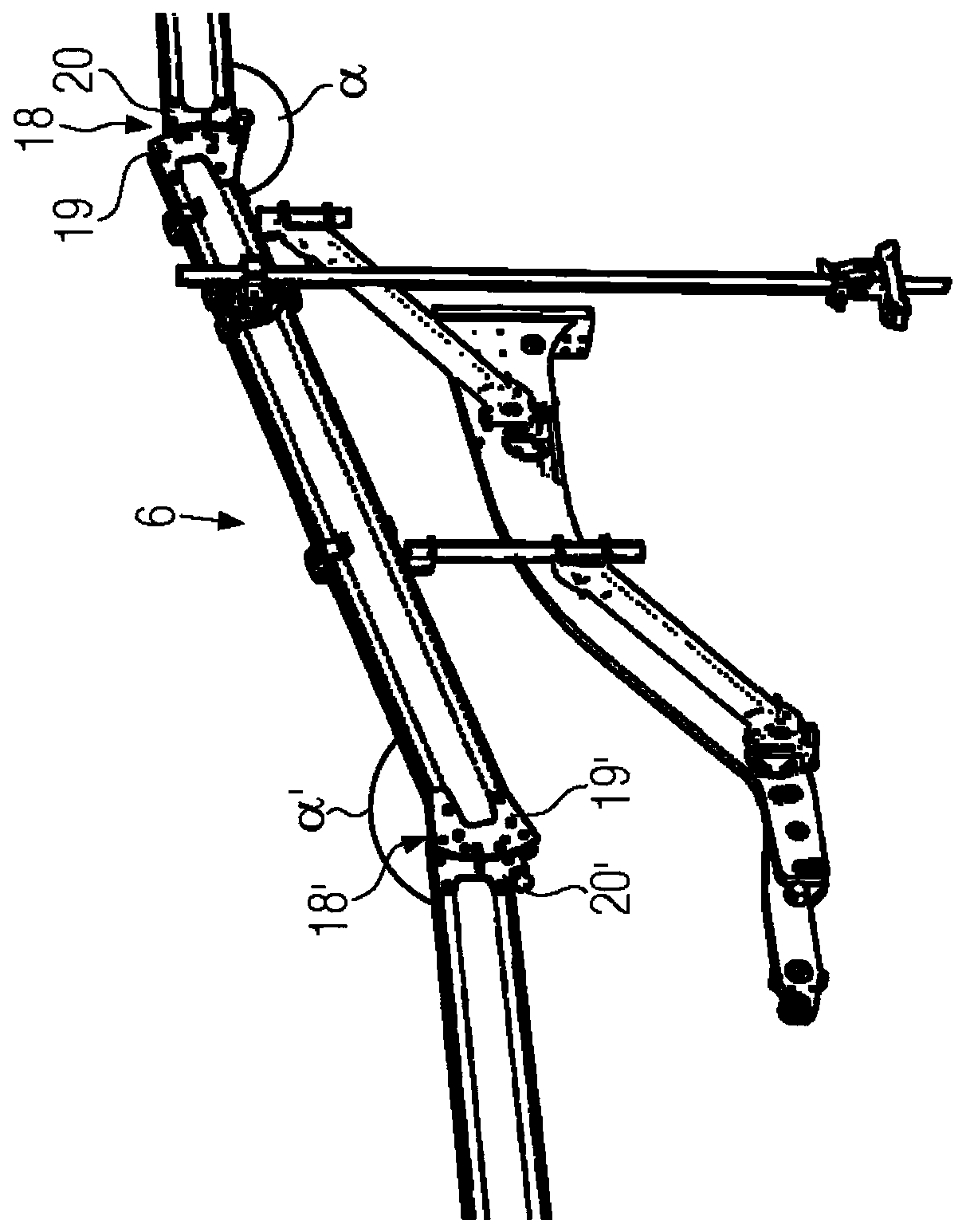

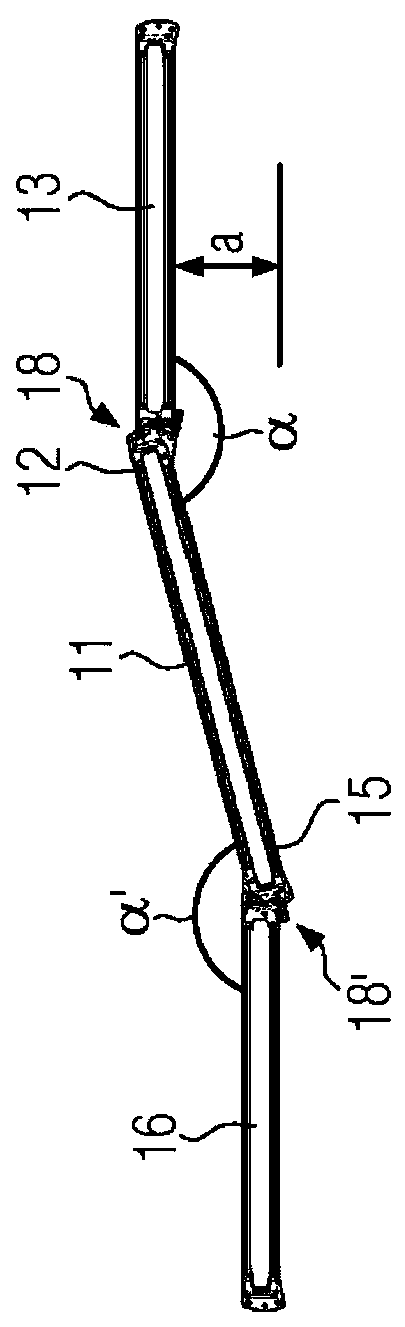

Road finisher with support device

The disclosure relates to a road paver (1) with a support device. The road paver is provided with a height-adjustable screed (2) for installing a pavement layer and at least one support device (6) for carrying and positioning at least one sensor unit (7). The support device (6) comprises a center bar (11), at least one extension bar (13) for the center bar (11), and at least one attachment unit (18) which detachably attaches the extension bar (13) to one end (12) of the center bar (11). The center bar (11) and the extension bar (13) are by way of the attachment unit (18) relative to one another when viewed in the vertical projection plane at a first mounting angle ([alpha]) connectable to one another, and the center bar (11) and the extension bar (13) are by way of the attachment unit (18) connectable to one another when viewed in the vertical projection plane at at least one further mounting angle ([beta]).

Owner:JOSEPH VOEGELE AG

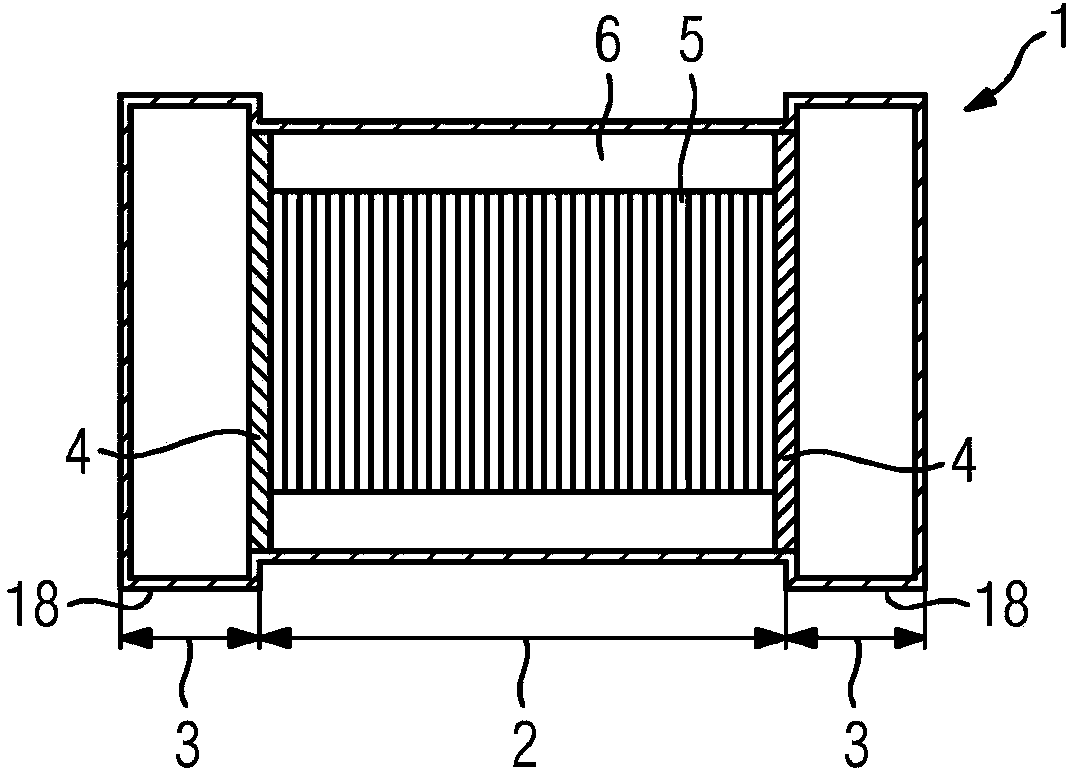

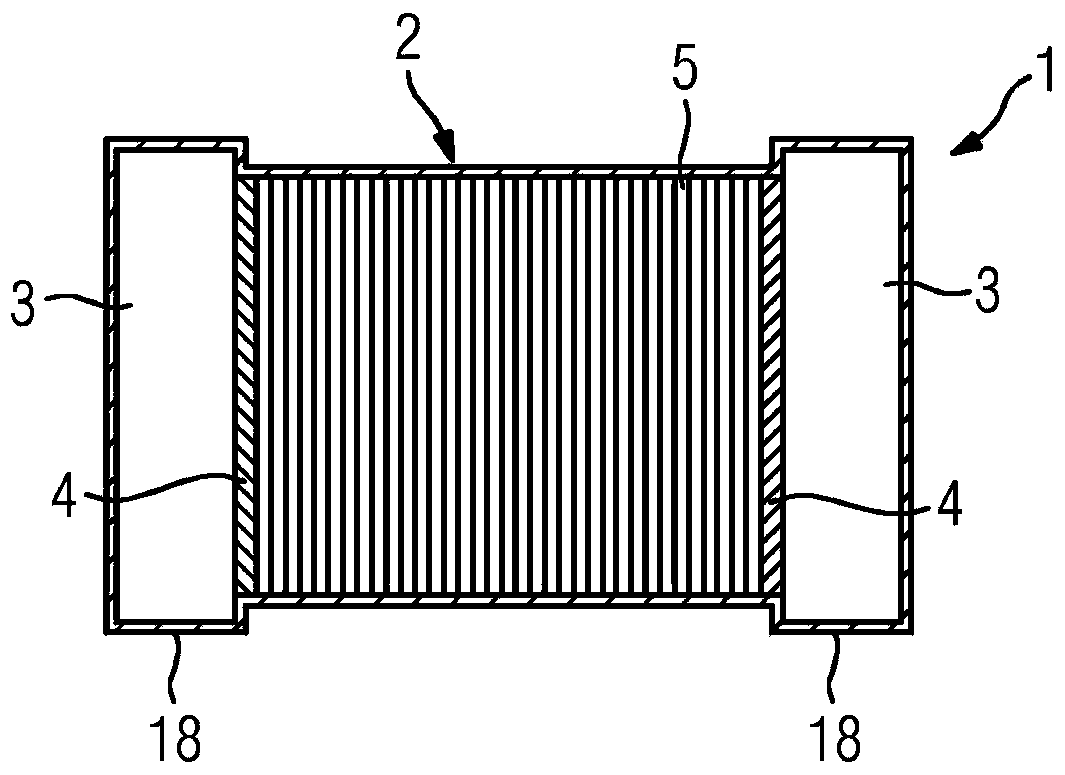

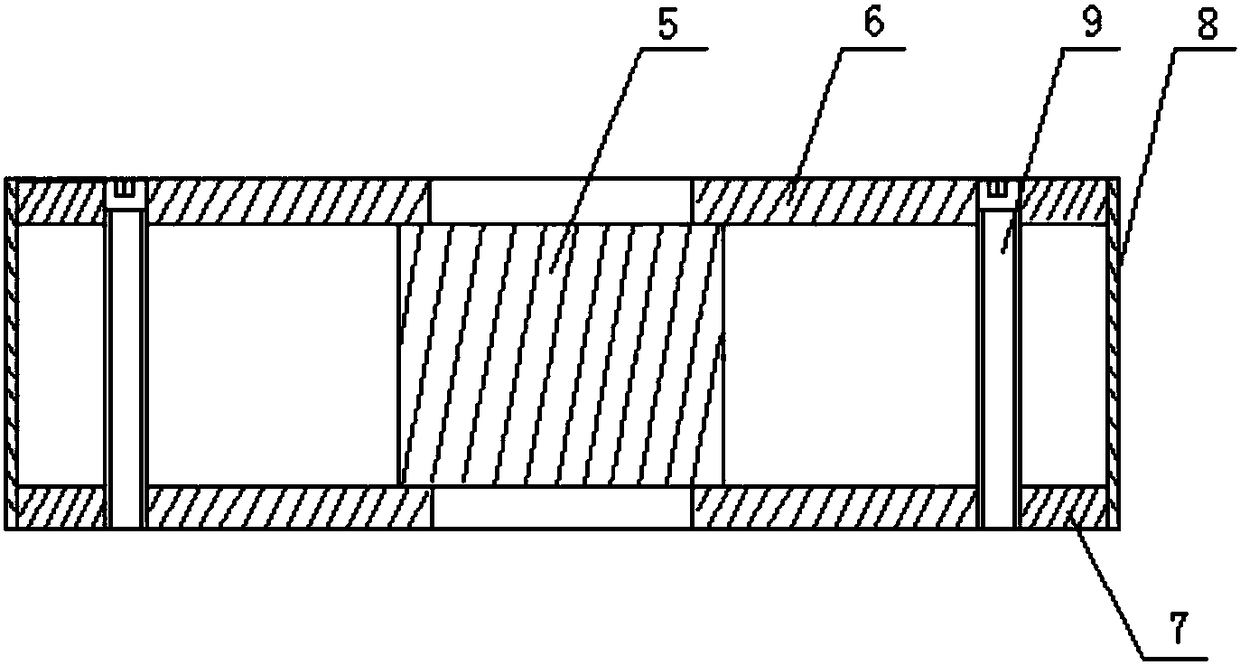

Self-supporting housing of a dynamo-electric machine

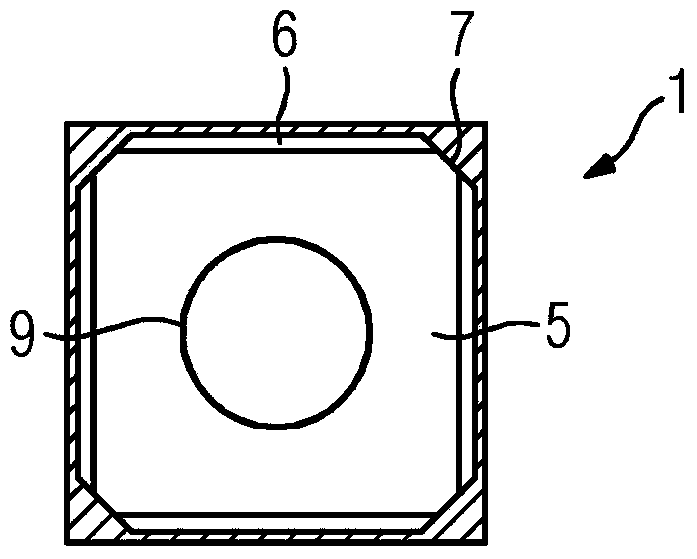

ActiveCN103548240ANot harmedMagnetic circuit stationary partsCooling/ventillation arrangementElectric machineEngineering

The invention relates to a self-supporting housing (1) of a laminated core (5) of a stator (22) in a dynamo-electric machine (23), said housing (1) having the following features: a laminated core section (2) surrounding the laminated core (5) which is formed by axially stacked sheets and includes at least one pressure plate (4) on its faces, the inside of the laminated core section (2) being designed such that a laminated core (5) having a basic shape of an octagonal cross-section can be accommodated in the laminated core section, wherein shorter sides (25) and longer sides (24) of the laminated core alternate in the peripheral direction; at least one connecting section (3) in the axial extension of the laminated core section (2) in order to dispose additional elements and / or devices on the housing (1); contact zones (7) on the inside of the laminated core section (2) in order to dispose and secure the laminated core (5) in such a way that a gap (6) is formed between the contact zones (7).

Owner:SIEMENS AG

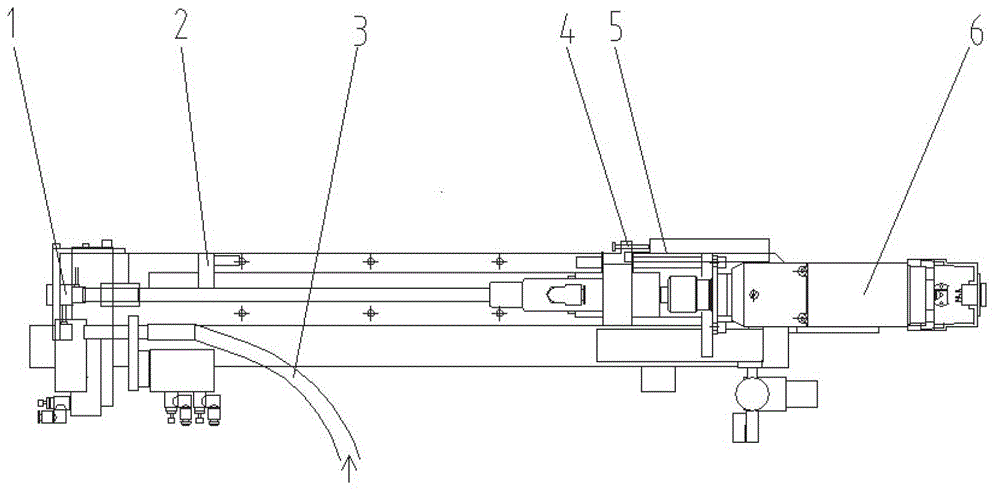

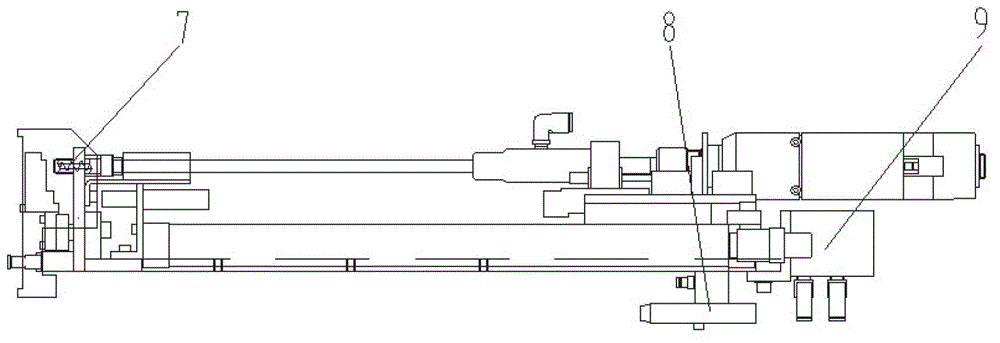

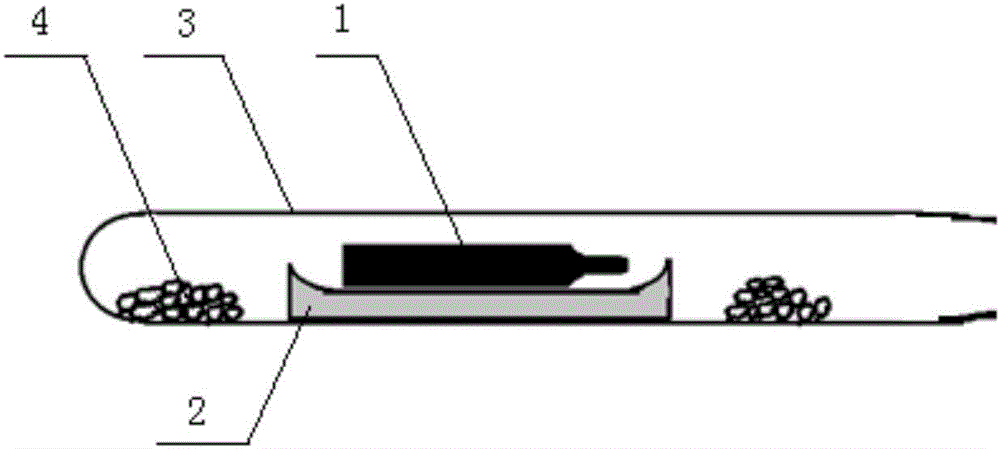

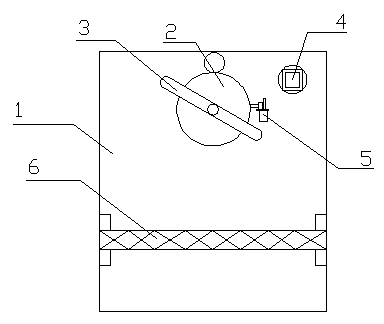

Universal type high speed intelligent automatic screw fastening mechanism

InactiveCN102941470ADetect floating lock phenomenonSimple structureMetal working apparatusMechanical engineeringPhysics

Provided is a universal type high speed intelligent automatic screw fastening mechanism. The mechanism can be used for conducting continuous accurate screw fastening operation in the transverse direction, the inclined direction and the direction from bottom to top at any angle. The mechanism mainly comprises a screw pushing device, a screw absorbing device and a screw fastening device. When the mechanism works, a screw is blown to the screw pushing device by a screw supply mechanism through a flexible material pipe and is placed in accurate gesture. After the screw pushing device pushes the screw in place, a screw cylinder control vacuum straw in the screw absorbing device is utilized to move towards the screw placing position, simultaneously a vacuum generator acts to absorb the screw and achieve absorbing screw installation. The screw fastening mechanism resolves the problem that the screw recessed position center cannot be aligned with the screw blade center in the screw fastening operation in the transverse direction and the like, inclination occurs in the screw fastening mode, and poor products appear. After the screw is absorbed by the absorbing device, the screw fastening device is moved towards a product to be processed under the effect of the cylinder, a screw driver rotates to locking the screw tightly to finish operation. The mechanism is convenient and quick and greatly improves working efficiency.

Owner:DALIAN YUN MING AUTOMATION TECH

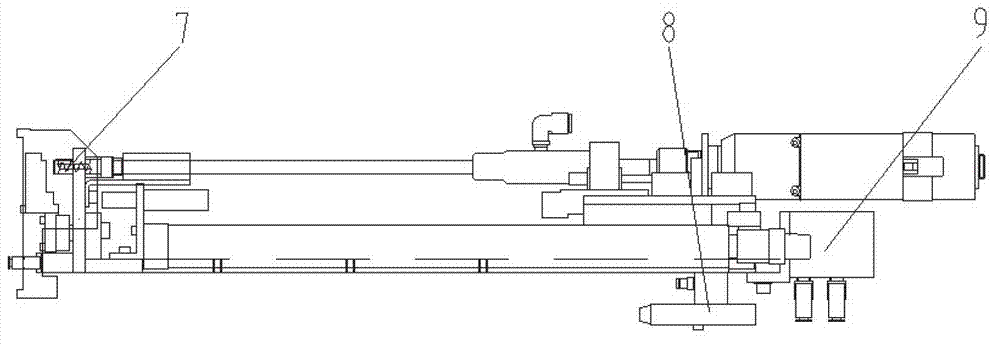

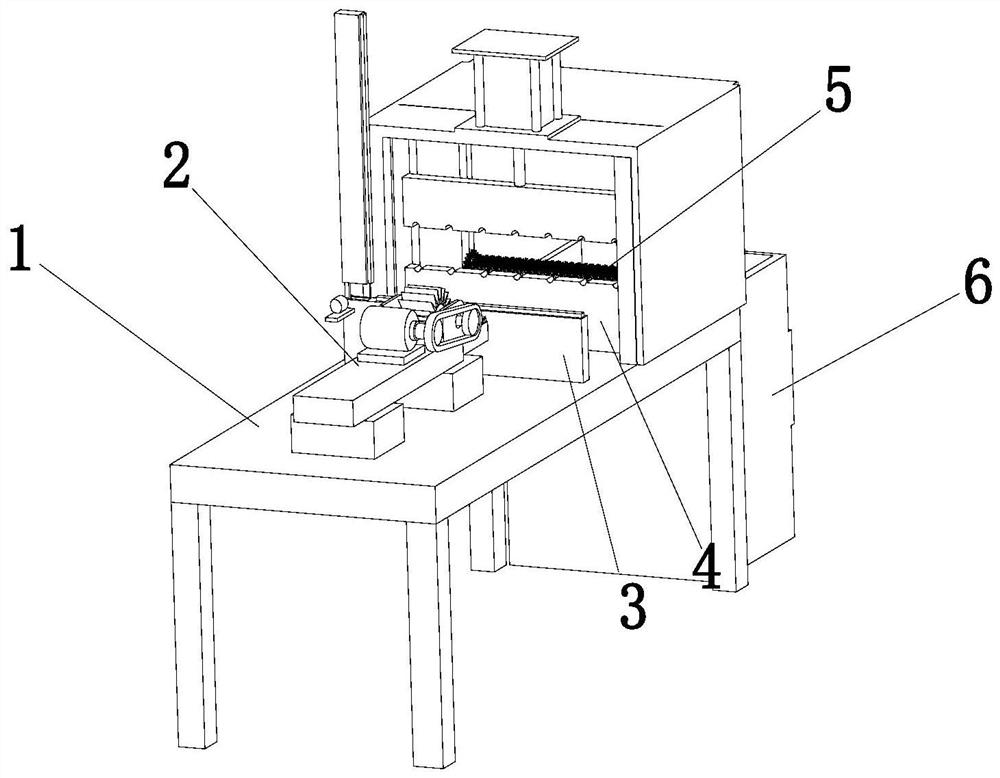

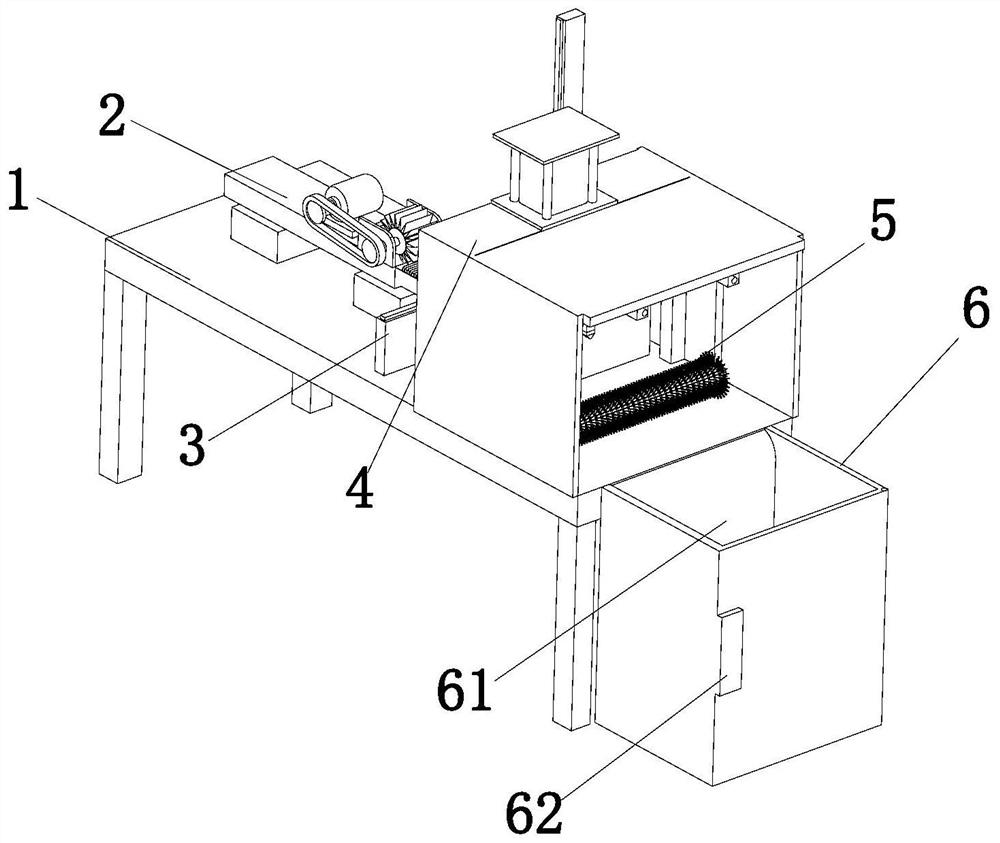

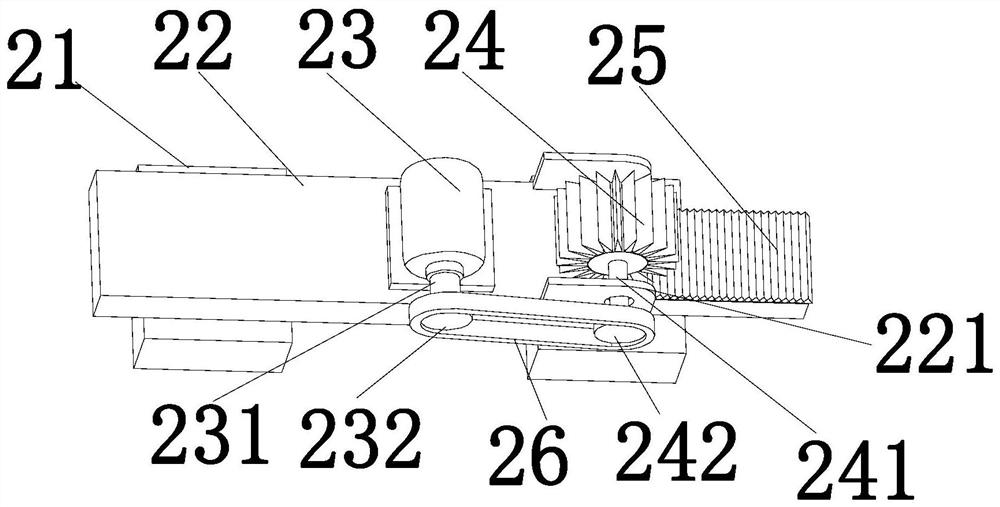

Process for automatic removal of rose thorns

InactiveCN111670714AImprove removal efficiencyReduce labor intensityCleaning using toolsThorn removersProcess engineeringRose flower

The invention relates to the technical field of rose processing technologies, in particular to a process for automatic removal of rose thorns. The process includes the following steps: Step 1, loadingand fixing the roses which need thorn removal; Step 2, performing automatic thorn removal on the roses; Step 3, cleaning the thorns of the roses automatically; and Step 4, taking out the thorn-removed roses. The process has ingenious design, smooth connection is formed among mechanism, the daily production capacity of a machine is equivalent to the production capacity of 6-8 persons, the efficiency is improved greatly, and significant economic values can be obtained.

Owner:赖梅凤

Apparatus for weed control

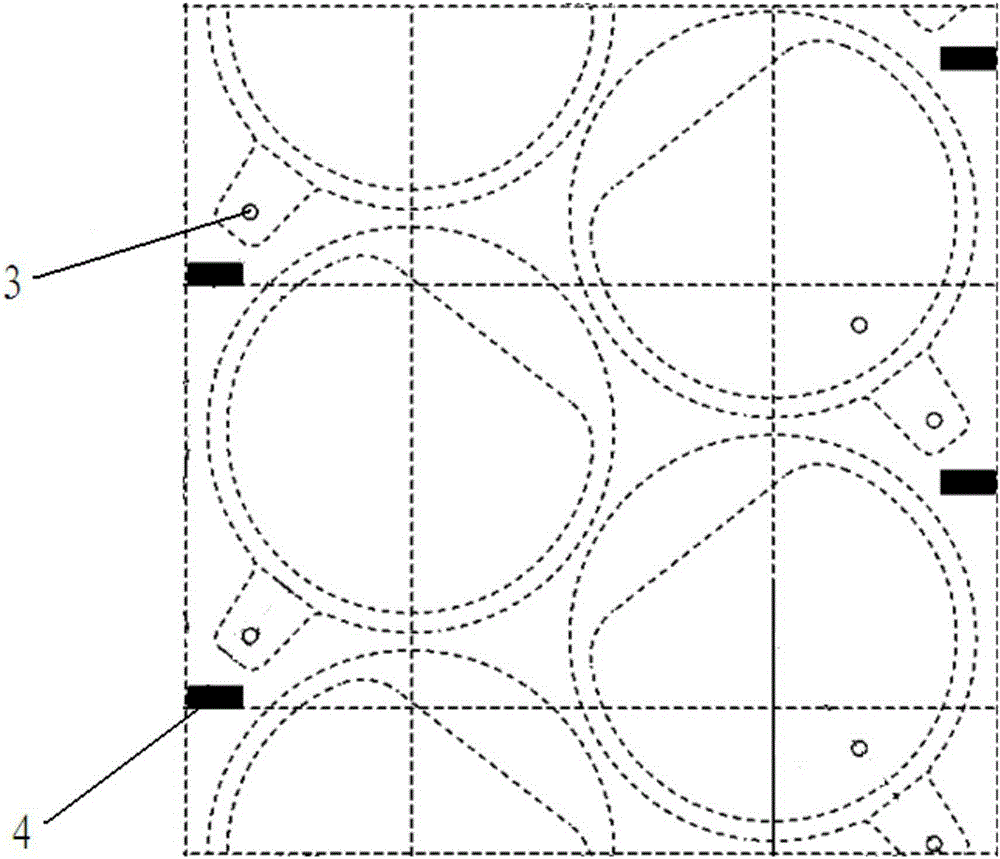

PendingUS20210015087A1Easy to controlReduce total usageProgramme controlImage enhancementAgricultural scienceAgricultural engineering

An apparatus for weed control includes a processing unit with a least one sensor data of an environment. The processing unit analyzes at least some of the at least one sensor data to determine at least one ground property for each of a plurality of locations of the environment. The processing unit determines a power setting for activation of at least one electrode based weed control unit for each of the plurality of locations. The determination of the power setting for activation of the electrode based weed control unit comprises utilization of the at least one ground property associated with that location. An output unit outputs information useable to activate the at least one electrode based weed control unit.

Owner:BAYER AG

Bottle carrier with handle and pull tab

Owner:SANDERS DENISE

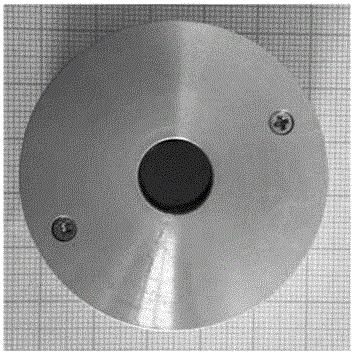

Endoscope puncture tool for digestive endoscopic surgery

ActiveCN112137657AAdjust insertion depthAdjustable lengthSurgical needlesVaccination/ovulation diagnosticsPuncture BiopsyEndoscopic surgery

The invention discloses an endoscope puncture tool for a digestive endoscopic surgery. The endoscope puncture tool comprises a handle; the handle is provided with a power cavity and a mounting cavity;a percussion device is installed in the mounting cavity; the percussion device is connected with a length adjusting mechanism; the upper portion of the length adjusting mechanism is connected with amounting mechanism; the mounting mechanism is connected with a puncture device; the percussion device drives the puncture device to conduct biopsy sampling; the length adjusting mechanism is used foradjusting the placement depth of the puncture device; the mounting mechanism is used for being rapidly connected with the puncture device; the puncture device is used for conducting puncture biopsy sampling on a patient; and the percussion device comprises a hydraulic cylinder, an ejector rod, a push plate, a sliding block and a reset spring. According to the endoscope puncture tool, the placementdepth of the puncture device can be adjusted, the length of a biopsy needle sampling groove can be adjusted, automatic percussion sampling is achieved, and whether the puncture device is placed in place or not can be judged.

Owner:SUZHOU FRANKENMAN MEDICAL EQUIP

Preparation method of regenerated buckwheat tea

The invention relates to the technical field of food, and particularly relates to a preparation method of regenerated buckwheat tea. The method comprises the following steps: cleaning dried buckwheat; putting the cleaned buckwheat into a steeping tank by virtue of an elevator and soaking the buckwheat for 5.5-6.5 hours; putting the soaked buckwheat into a steamer by virtue of the elevator, and steaming the buckwheat with steam for 40-50 minutes; drying the steamed buckwheat until the moisture content of the buckwheat is 15%-25%; husking the dried buckwheat in a machine by a roller husking method, separating buckwheat seeds from buckwheat shells, and separating dust from the buckwheat by a vibrating screen on the husking machine, thereby finishing purifying and dedusting of the buckwheat; classifying the separated buckwheat seeds, and preparing powder in various forms by virtue of a grading pulverizer; separating the powder at various grades, kneading dough from the powder, and pelletizing and frying the various powder; and screening fried tea grains, and removing excessive powder by sieving. The buckwheat tea prepared by the method is high in nutritive value and good in mouthfeel.

Owner:KUNMING HONGTUDI YINGLONG FOOD PROCESSING

A kind of green environmental protection type anti-myopia workbook paper preparation process

ActiveCN107012740BPromote absorptionSo as not to damageSpecial paperBook keepingGreen environmentWastewater

Owner:四川北彩印务有限公司

Acid rain corrosion resistant exterior wall paint

InactiveCN104178007AStrong adhesionKeep the original colorAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinAcid rain

The invention discloses an acid rain corrosion resistant exterior wall paint. The exterior wall paint is composed of the following components: a main paint containing 40.0-55.0% of hydroxyl acrylic resin, 0.1-0.8% of a dispersing agent, 0.1-0.8% of a flatting agent, 0.1-1.0% of a defoaming agent, 0.1-1.0% of a foam removal agent, 0.01-25.0% of titanium dioxide, 10.0-40.0% of a filler, 0.5-2.0% of an anti-settling agent, 2.0-10.0% of xylene and 2.0-10.0% of high boiling point DBE; a curing agent containing 30.0-55.0% of an isocyanic acid vinegar curing agent, 10.0-30.0% of xylene and 10.0-50.0% of butyl acetate; and a diluent containing 10.0-90.0% of xylene and 10-90% of butyl acetate. A construction ratio of main paint to curing agent to diluent is 100:20:20. The exterior wall paint provided by the invention can reduce and mitigate damages on external walls of buildings due to acid rain and cracking of concrete wall.

Owner:铜仁市光彩漆业有限公司

Adjustable resistance knob repair method

ActiveCN109830350BSolve replacementEasy to installResistor manufactureAdjustable resistorsElectrical resistance and conductanceEngineering

The present invention relates to a maintenance method for an adjustable resistance knob. The maintenance method for an adjustable resistance knob utilizes a sliding head guide to slide a resistance core onto a resistance coil, and includes the following steps: 1. Grasp the handle of the sliding head guide, and The buffer protection connector of the sliding head guide extends into the inside of the resistance coil and is fixed on the coil track; 2. The gap of the sliding head of the resistance core is stuck outside the arc groove at the handle of the sliding head guide, and the handle of the resistance core is rotated clockwise , the gap of the sliding head of the resistance core slides along the rail of the gap of the sliding head until it slides to the buffer protection connector of the slider guide; 3. The gap of the sliding head of the resistance core slides through the buffer protection connector and slides smoothly onto the coil track; 4. Hold the slider guide handle and remove the slider guide. The invention solves the problem of replacing the resistance core, realizes that the resistance core can be conveniently installed in the resistance coil, and the resistance core is not damaged, and the replacement difficulty is small.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

A kind of manufacturing method of nonlinear crystal gallium selenide component

ActiveCN106192010BReduce defect densityEffectively fixedPolycrystalline material growthAfter-treatment detailsTransmittanceIngot

The invention provides a method for manufacturing a non-linear crystal gallium selenide component, relates to a method for manufacturing crystal components, and aims to solve the technical problems that existing GaSe crystal has low transmittance and is easily deformed and split when being used. The method comprises the following steps: 1, etching the surface of GaSe crystal ingot, cleaning and drying; 2, putting the crystal ingot into a boat, putting the boat in the middle of a quartz tube, and putting GaSe polycrystal powder at two ends of the boat; or putting the GaSe polycrystal powder at one end of the boat, and putting Se at the other end of the boat; vacuumizing the quartz tube, sealing, and putting into a resistance furnace in a single-temperature region; 3, annealing; 4, cutting the annealed crystal ingot, and trimming to form a GaSe crystal block along the C-axial direction; and 5, fixing the GaSe crystal block at the hole of a metal base with glue, coating a polytetrafluoroethylene coat, adding an upper cover, and connecting the base and the upper cover with a fixed nut to obtain a GaSe component. The component can be used in a laser.

Owner:HARBIN INST OF TECH

Road paver with support

The invention relates to a road paver (1) with a support device having a height-adjustable screed (2) for laying a road layer and at least one for carrying and positioning at least one sensor unit (7) Support device (6), wherein said support device (6) comprises a central rod (11), at least one extension rod (13) for said central rod (11), and said extension rod (13) is detachable Attached to at least one attachment unit (18) at one end (12) of said central rod (11), wherein said central rod (11) and said extension rod (13) pass through the attachment unit (18) when Connectable to each other at a first mounting angle (α) relative to each other when viewed in a vertical projection plane, and wherein said central pole (11) and said extension pole (13) pass through an attachment unit (18) when viewed in a vertical can be connected to each other at at least one further installation angle (β) when viewed in the projection plane.

Owner:JOSEPH VOEGELE AG

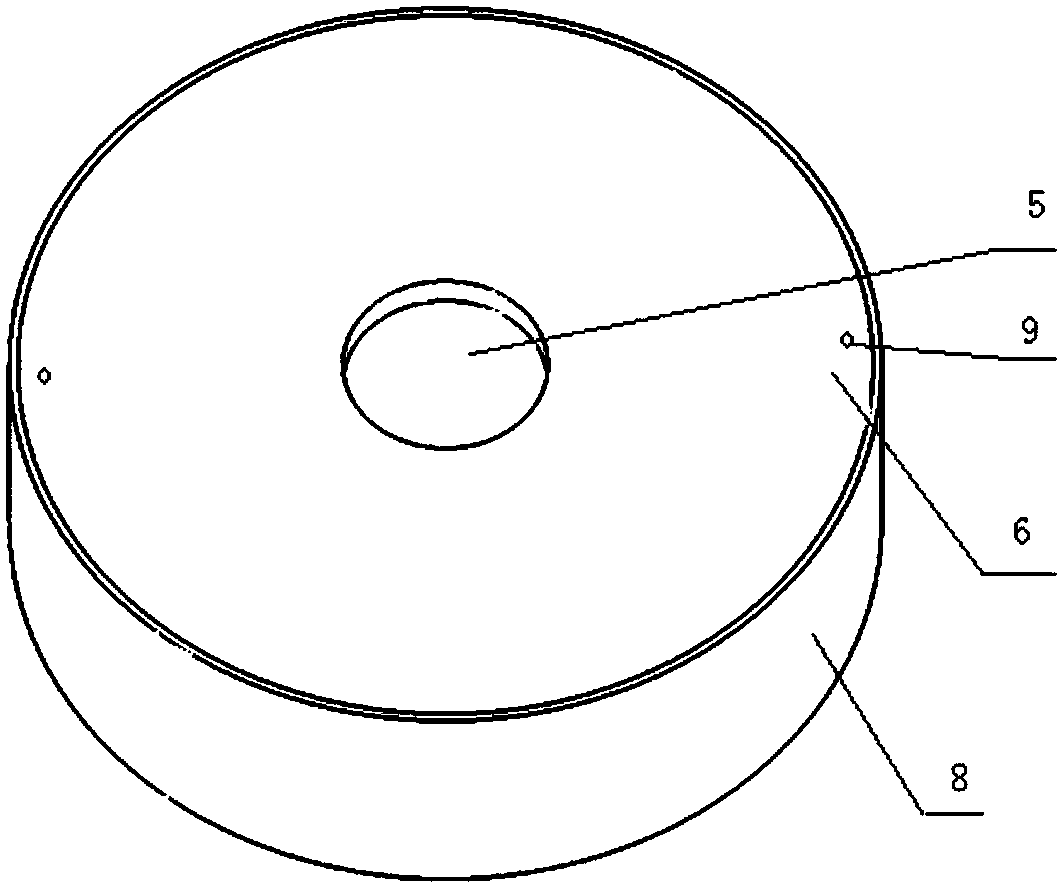

Winding machine with elastic protection function

The invention relates to a winding machine, in particular to a winding machine with the elastic protection function. The winding machine comprises a rack, a winding mechanism, an unwinding mechanism, a leading-in device, a shearing mechanism and a hopper, wherein the winding mechanism, the leading-in device and the shearing mechanism are fixed to the rack, the unwinding mechanism is arranged on the winding mechanism, the hopper is fixedly connected to the rack, and a protective layer is arranged at the outer edge of the winding mechanism and is an elastic rubber layer. The winding machine can effectively prevent an iron core from being damaged in the winding process, reduces cost and improves effectiveness.

Owner:CHANGZHOU JIAHONG PACKAGING

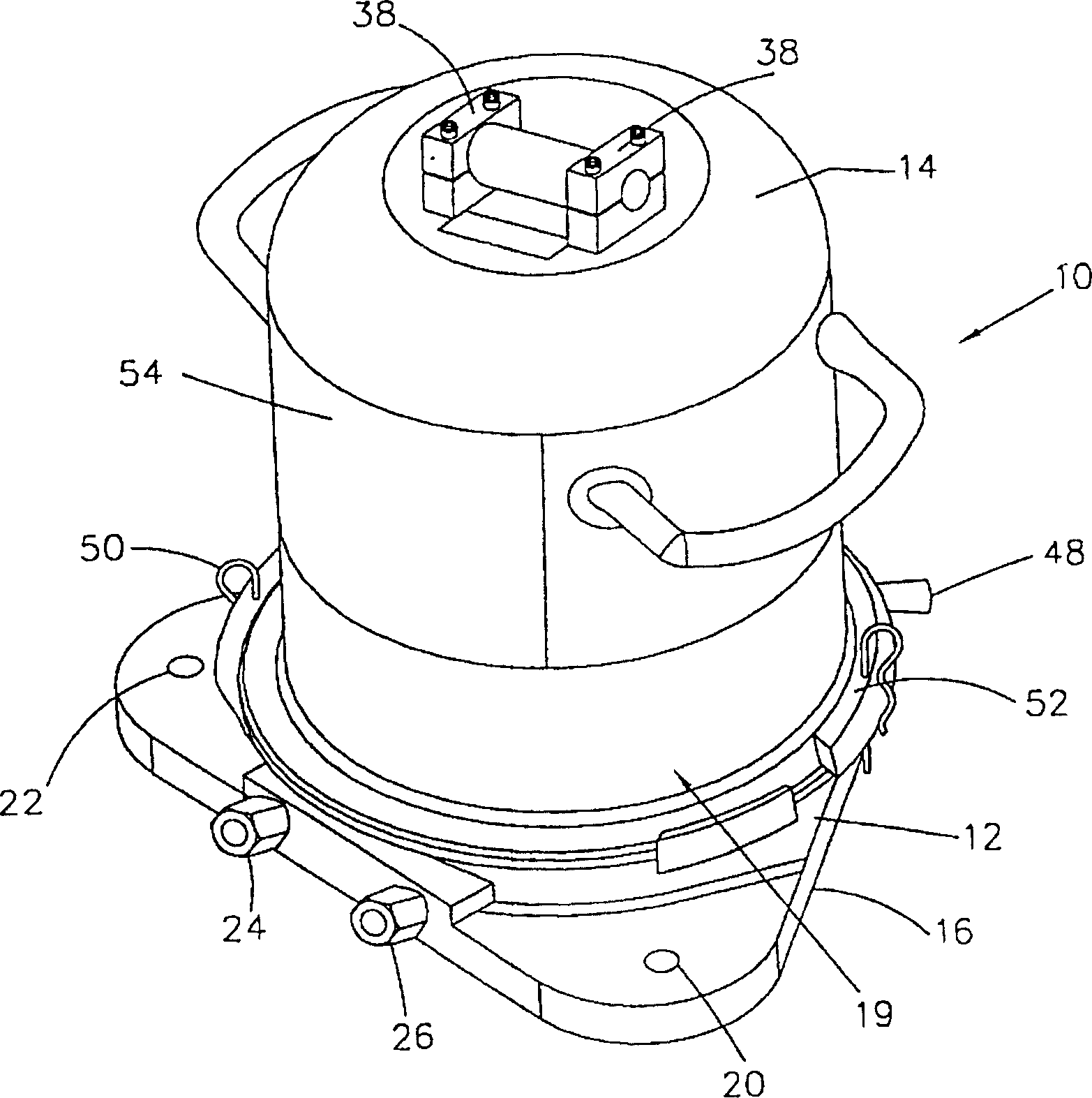

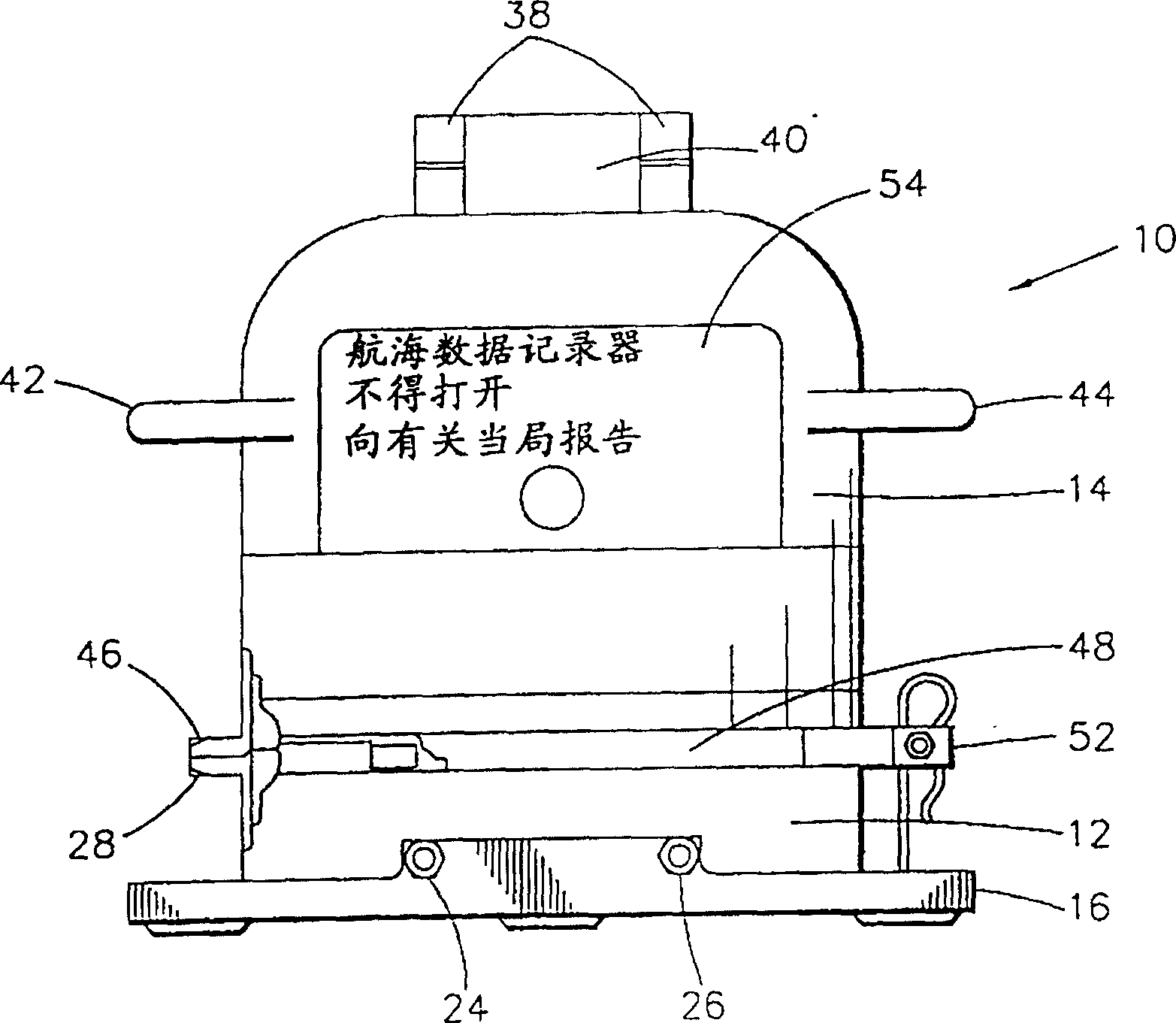

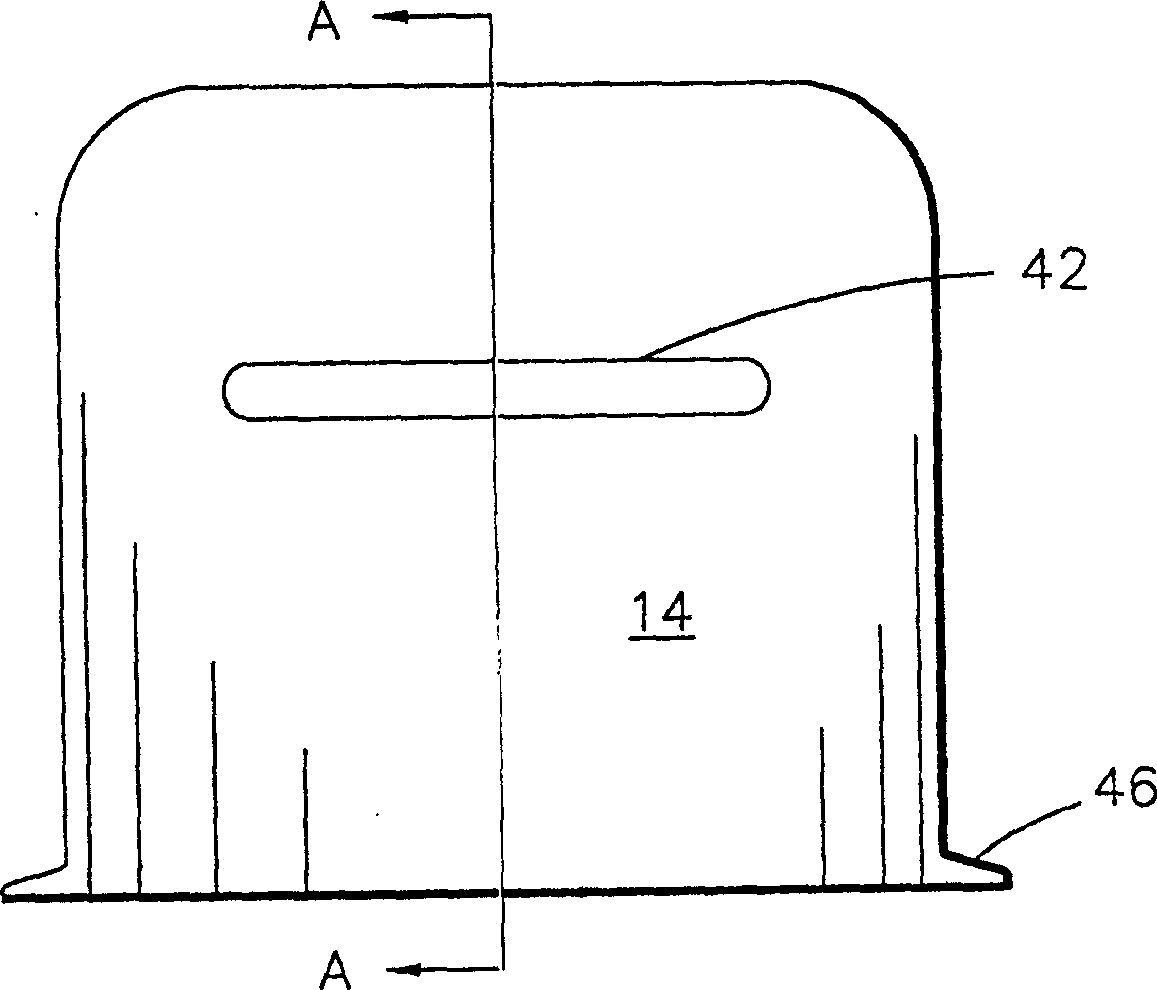

Hard navigation data recorder

InactiveCN1284701CNot harmedAuxillariesRegistering/indicating working of vehiclesCommunications systemPenetration force

A hardened voyage data recorder comprising two subsystems: a removable non-volatile memory and a base containing the electronics and firmware for communicating with the data readout system and accessing the memory. According to the present invention, the memory is a stacked BGA memory protected within a "boiler body" designed to withstand a relatively long-term low temperature fire environment. Boiler blocks and storage modules are designed to withstand the penetrating forces associated with marine accidents. The cable leads from the storage are arranged such that the structural integrity of the boiler body is not compromised.

Owner:L 3 COMM CORP

Display device and manufacturing method thereof

ActiveCN105990373BExtend your lifeSo as not to damageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention discloses a display device and a manufacturing method thereof. The display device includes a first substrate, a second substrate, a display medium, a sealant layer and an etching barrier layer. The second substrate is paired with the first substrate, and the display medium is located between the first substrate and the second substrate. The sealant layer surrounds the display medium and is in contact with the first substrate and the second substrate. The etching barrier layer surrounds the sealant layer and abuts the first substrate and the second substrate, wherein at least one side wall of the etching barrier layer has an arc-shaped convex surface.

Owner:INNOLUX CORP

Fluid-actuated diaphragm drive

InactiveCN105408640BSolder connection realizationNot harmedOperating means/releasing devices for valvesFluid-pressure actuatorsEngineeringRust

The invention relates to a fluid-actuated diaphragm drive (1), which has a drive unit (5), the drive housing (3) of which consists of two cage-shaped drive housings that lie coaxially against each other Pieces (7, 8) are formed. The drive housing (3) is surrounded on the outside by a separate, fluid-tight casing (4) with respect to the drive unit (5), which consists of two casing parts which are mounted against each other and welded to each other in a fluid-tight manner (47, 48), and the cladding shell is formed from rust-proof steel sheets. The cladding shell also forms at the same time support means (4a) clamping said drive housing, by means of which support means the two drive housing parts (7, 8) are supported axially from mutually axially opposite sides, whereby The diaphragm drive ( 1 ) can be operated with high fluid pressure.

Owner:FESTO AG & CO KG

Method for manufacturing non-linear crystal gallium selenide component

ActiveCN106192010AReduce defect densityEffectively fixedPolycrystalline material growthAfter-treatment detailsTransmittanceIngot

The invention provides a method for manufacturing a non-linear crystal gallium selenide component, relates to a method for manufacturing crystal components, and aims to solve the technical problems that existing GaSe crystal has low transmittance and is easily deformed and split when being used. The method comprises the following steps: 1, etching the surface of GaSe crystal ingot, cleaning and drying; 2, putting the crystal ingot into a boat, putting the boat in the middle of a quartz tube, and putting GaSe polycrystal powder at two ends of the boat; or putting the GaSe polycrystal powder at one end of the boat, and putting Se at the other end of the boat; vacuumizing the quartz tube, sealing, and putting into a resistance furnace in a single-temperature region; 3, annealing; 4, cutting the annealed crystal ingot, and trimming to form a GaSe crystal block along the C-axial direction; and 5, fixing the GaSe crystal block at the hole of a metal base with glue, coating a polytetrafluoroethylene coat, adding an upper cover, and connecting the base and the upper cover with a fixed nut to obtain a GaSe component. The component can be used in a laser.

Owner:HARBIN INST OF TECH

Universal high-speed intelligent automatic screw fastening mechanism

ActiveCN102922271BSimple structureSolve the problem of lockingMetal working apparatusEngineeringMechanical engineering

A universal type high-speed intelligent automatic screw fastening mechanism can be used for fastening screws continuously and accurately at any angle, that is, a screw can be fastened horizontally, slantly or from the bottom up. The screw fastening mechanism mainly comprises three parts (namely, a screw pushing device, a screw suction device and a screw fastening device). When the screw fastening mechanism is in operation, a screw supply mechanism wafts the screw into the screw pushing device through a soft charge pipe, and the screw is placed in an accurate posture; the screw pushing device pushes the screw to a required position; a screw taking cylinder in the screw suction device controls a vacuum straw to move to the position where the screw is placed; and a vacuum generator acts to suck the screw. Therefore, the screw is loaded in a suction manner, which solves the problem that during horizontal screw fastening operation, the concave center of the screw cannot be aligned with the center of a screwdriver head, so that the screw is deflected during fastening, and undesirable products are produced. When the screw is sucked by the screw suction device, the screw fastening device moves to a product to be processed under the action of a cylinder, and the screw is screwed through the rotation of the screwdriver to fulfill operation, so that the operation is convenient and fast, and the work efficiency is improved greatly.

Owner:DALIAN YUN MING AUTOMATION TECH

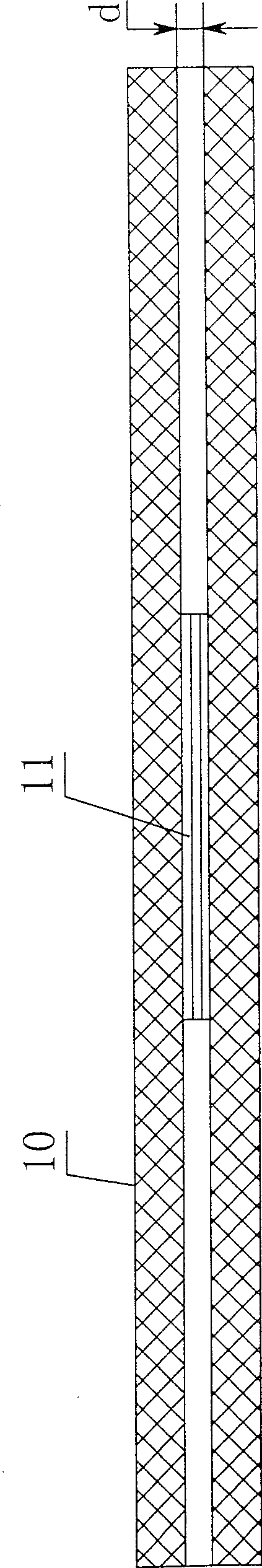

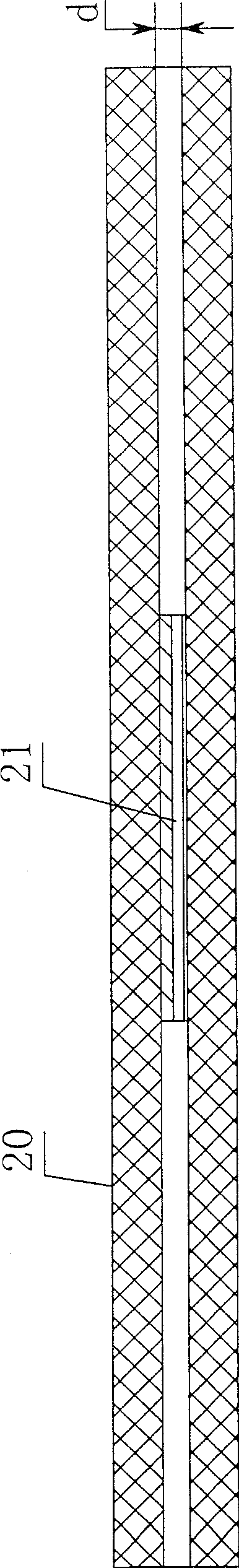

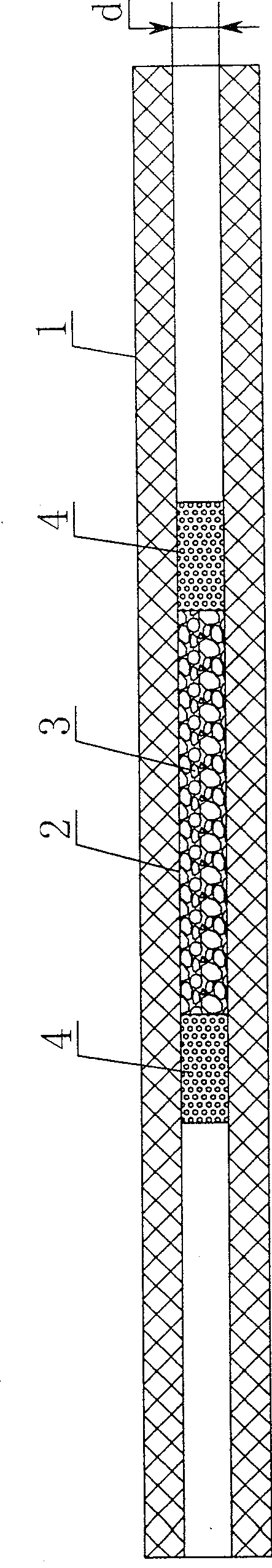

Ceramic oxidation pipe used in carbon isotope of natural gas analysis

InactiveCN100526879CIncrease the amount of fillingIncrease the reaction contact areaChemical analysis using combustionGas analysisIsotope

The invention discloses a ceramic oxidation tube for the analysis of natural gas carbon isotopes, and aims to provide an oxidation tube with good oxidation effect, stable analysis data and long service life. There are copper oxide particles, and the particle size of copper oxide particles is 0.3-0.5mm; the inner diameter of the pipe is 1.2-1.5mm, and there are also pure copper particle areas on both sides of the high-temperature area in the pipe; the oxidation pipe of the present invention is used for natural gas carbon isotope analysis experiments .

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Receiving net type winding machine

InactiveCN103632830ASo as not to damageNot harmedInductances/transformers/magnets manufactureWinding machinePulp and paper industry

The invention relates to a winding machine, in particular to a receiving net type winding machine. The receiving net type winding machine comprises a machine frame, a winding mechanism, a material returning mechanism, a guide-in device and a shearing mechanism. The winding mechanism, the guide-in device and the shearing mechanism are fixed to the machine frame, and the winding mechanism is provided with the material returning mechanism. A receiving net is fixedly connected to the machine frame through a fixing frame. The receiving net type winding machine can effectively protect iron cores against damage when the iron cores fall, and therefore the cost is saved, and the effect is improved.

Owner:CHANGZHOU JIAHONG PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

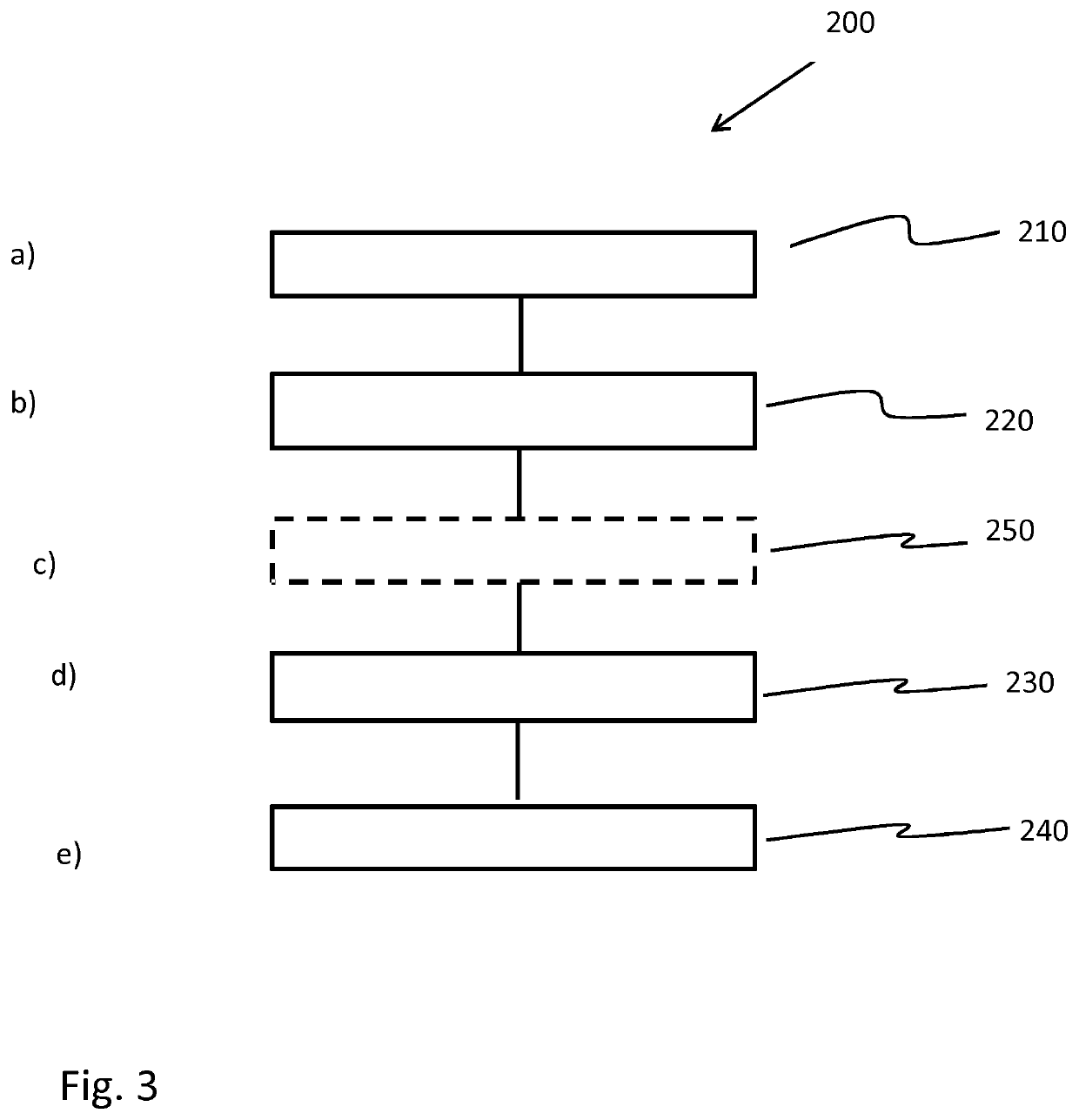

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com