Patents

Literature

31results about How to "Increase the amount of filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

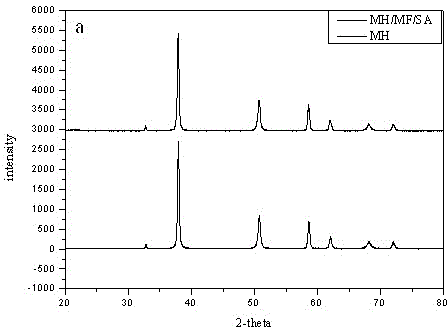

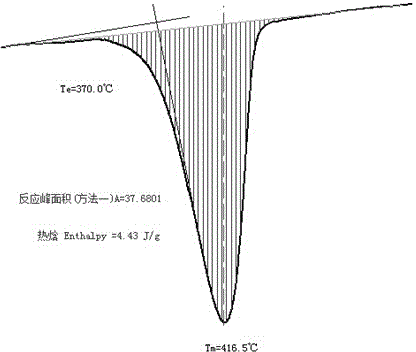

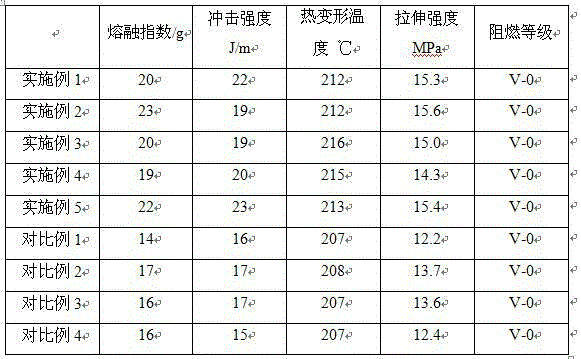

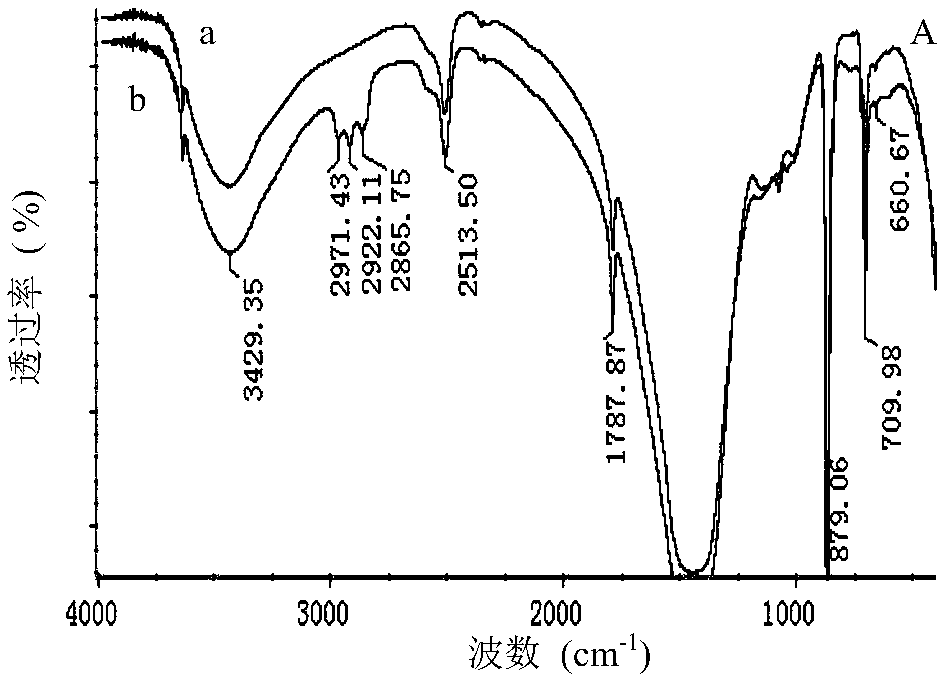

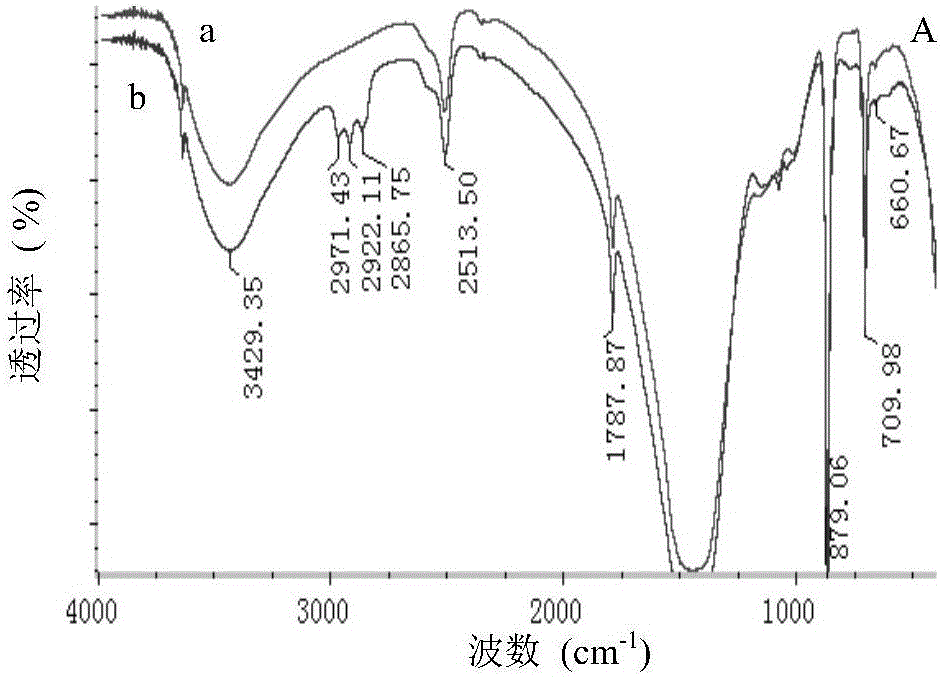

Double-covered magnesium hydroxide fire retardant and preparation method thereof

ActiveCN104804474AGood dispersionGood compatibilityMicroballoon preparationPigment treatment with macromolecular organic compoundsPolyoxymethyleneEngineering

The invention relates to a double-covered magnesium hydroxide fire retardant and a preparation method thereof, which belong to the technical field of fire retardants. The preparation method is characterized in that melamine and formaldehyde are pre-polymerized first, so as to obtain a prepolymer solution, magnesium hydroxide is put into the prepolymer solution and is then filtered and dried, so as to prepare a prepolymer microcapsule which uses the magnesium hydroxide as a core and the melamine and polyformaldehyde as an inner wall, and then the prepolymer microcapsule is put into a stearic acid ethanol solution and is filtered and dried, so as to prepare a double-wall covered fire retardant microcapsule which uses the prepolymer microcapsule as a core and stearic acid as an outer wall. The obtained double-layer magnesium hydroxide microcapsule has good fire resistance, the initial decomposition temperature of the double-layer covered magnesium hydroxide microcapsule is obviously reduced, the thermostability is good in high-temperature conditions, and the dispersibility is good.

Owner:SHANDONG HANGTONG IND & TRADE CO LTD

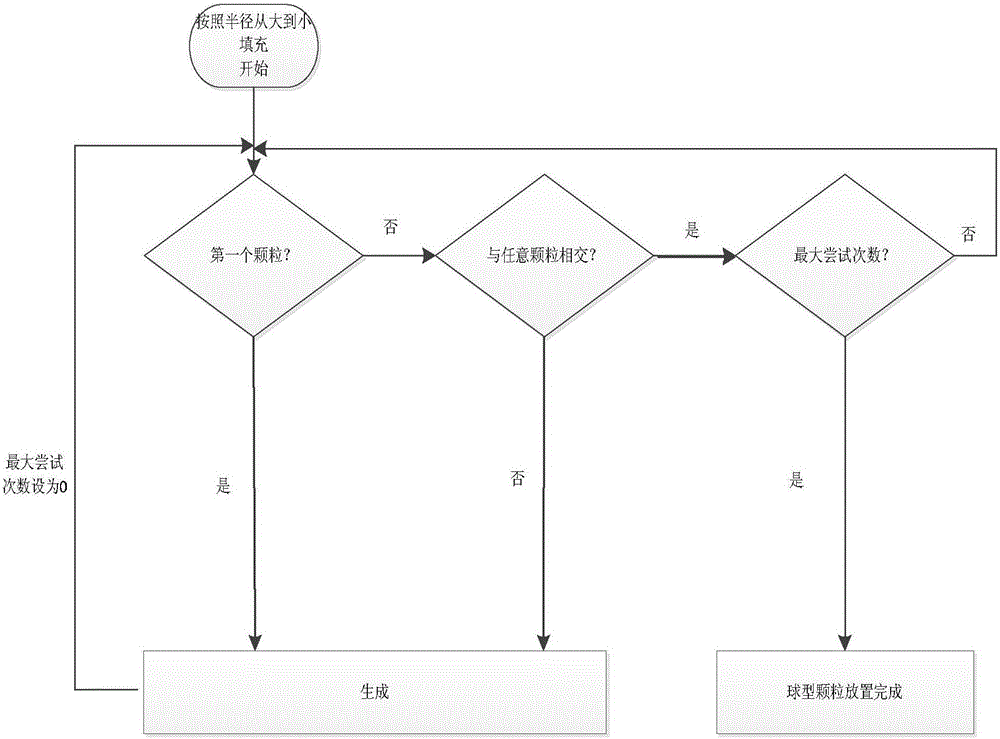

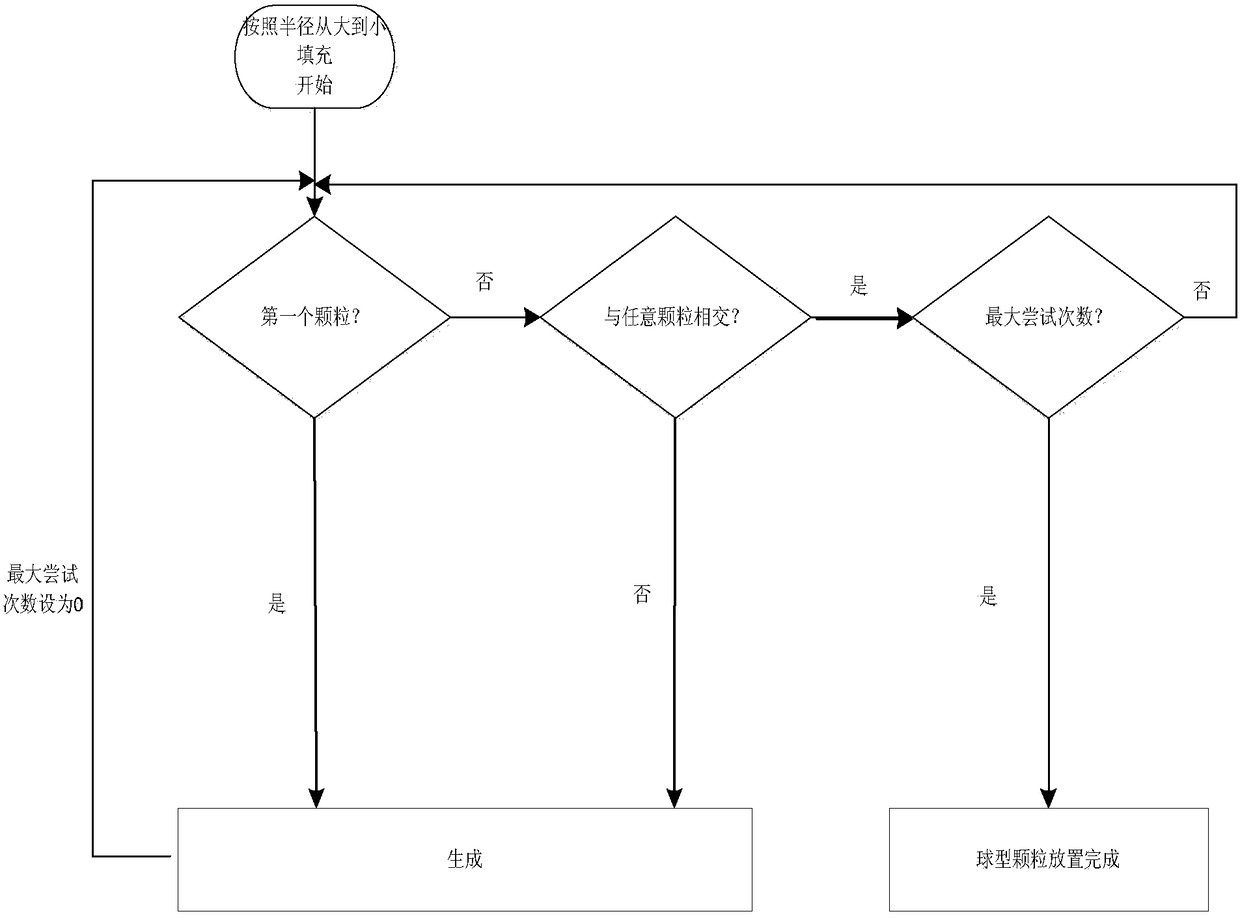

Displacement vector filling method based on energetic material approximate spherical filling maximization

ActiveCN105160052AAvoid large gapsIncrease the amount of fillingSpecial data processing applicationsPhases of clinical researchEnvironmental geology

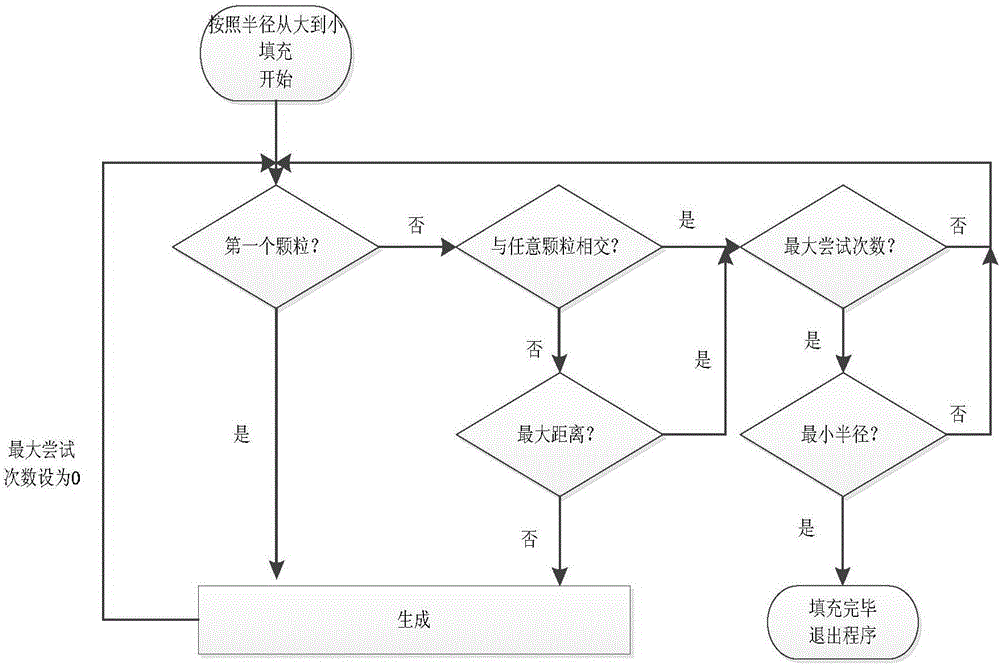

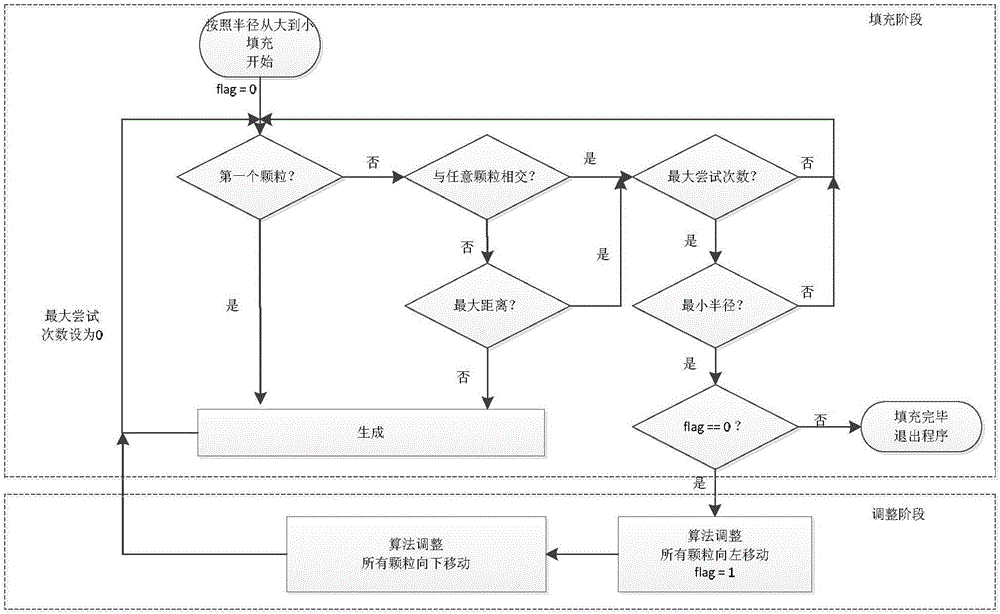

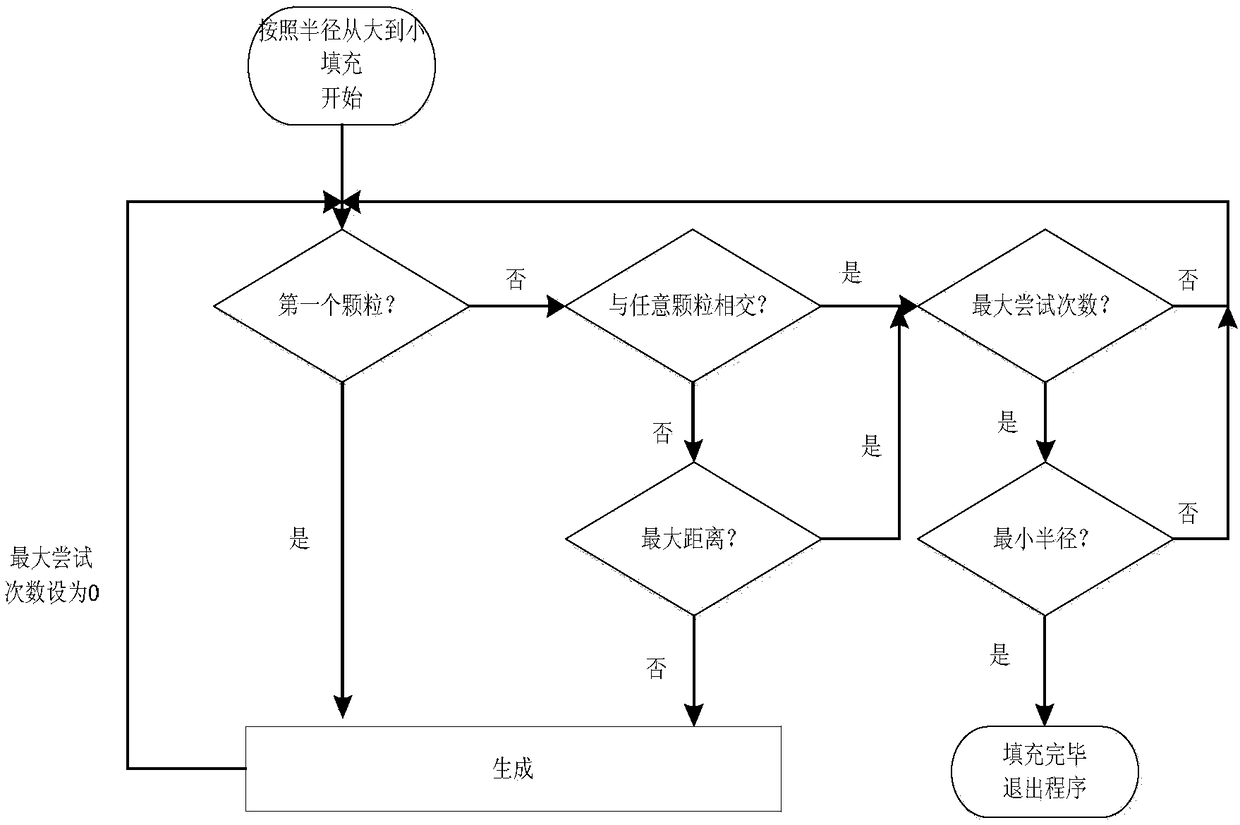

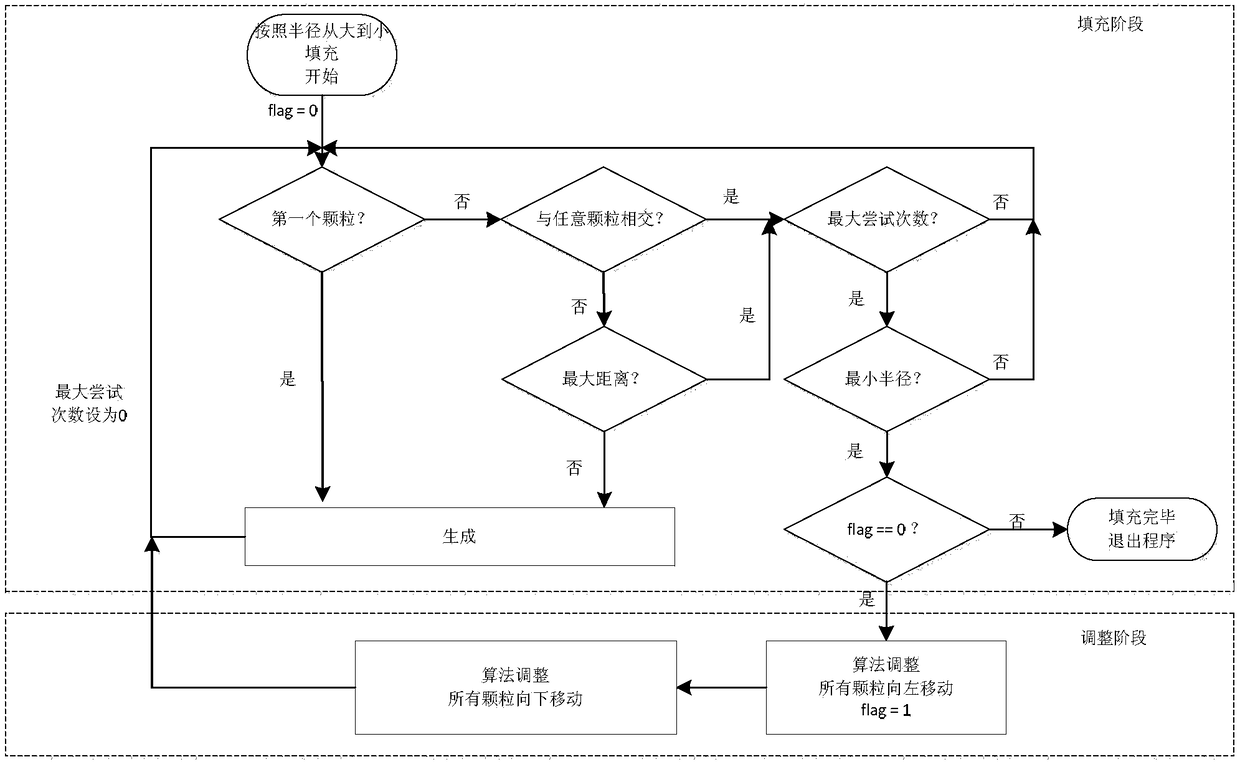

The invention requests to protect a displacement vector filling method based on energetic material approximate spherical filling maximization. The method comprises the following steps: randomly putting spherical particles into a compression cabin according to a radius from big to small, and entering a regulation stage after a spherical particle putting stage is finished; and dividing the regulation stage into three processes, i.e., the spherical particles moves to an x-axis negative direction from small to big according to an x-axis coordinate, moves to a y-axis negative direction from small to big according to a y-axis coordinate and moves to a z-axis negative direction from small to big according to a z-axis coordinate. After the particle movement, gaps among the particles are reduced to a high limit, and the cabin can be continuously filled to increase a filling rate.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

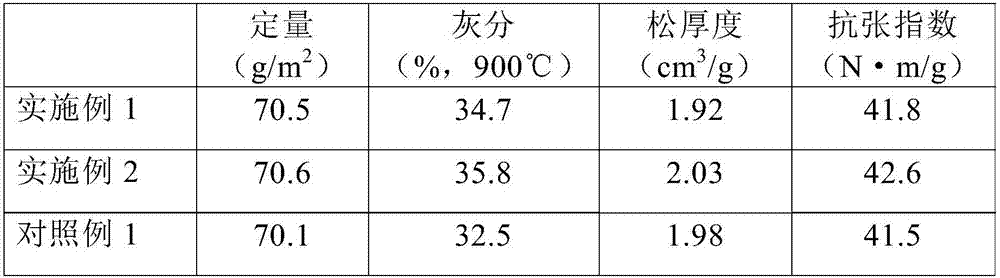

Highly filled flame-retardant paper and preparation method thereof

InactiveCN104532659AIncrease retentionHigh filling volumePaper/cardboardInorganic compound additionStarch solutionPaper sheet

The invention relates to the field of flame-retardant material production, and discloses a highly filled flame-retardant paper, and a preparation method and an application thereof. The preparation method comprises the following steps: beating is carried out, wherein a beating degree of a pulp material is controlled to be 30-50 DEG SR; modified fiber with a carboxyl group content of 1.8-2.5mmol / g, a flame-retardant filling material, a starch solution and a filling material with different proportions are sequentially added into the pulp, wherein the content of the modified fiber is 10-30% of absolute dry pulp, and the starch solution with an amount of 1.0-10kg / ton of absolute dry pulp is added into a paper-making wet-end system mixed pulp tank; the mixture is well mixed, such that a paper-making pulp material is obtained; the paper-making pulp is made into paper on a paper machine; and pressing and drying are carried out, such that the highly filled flame-retardant paper is obtained. According to the invention, the modified fiber with carboxyl group content of 1.8-2.5mmol / g is used as fiber for making paper, such that high filling amount of the paper is realized. The highly filled flame-retardant paper has excellent flame retardant effects of no toxicity, no smoke and the like. Strength and thickness of the obtained paper are both improved. The process of the method is relatively simple.

Owner:王庆艳

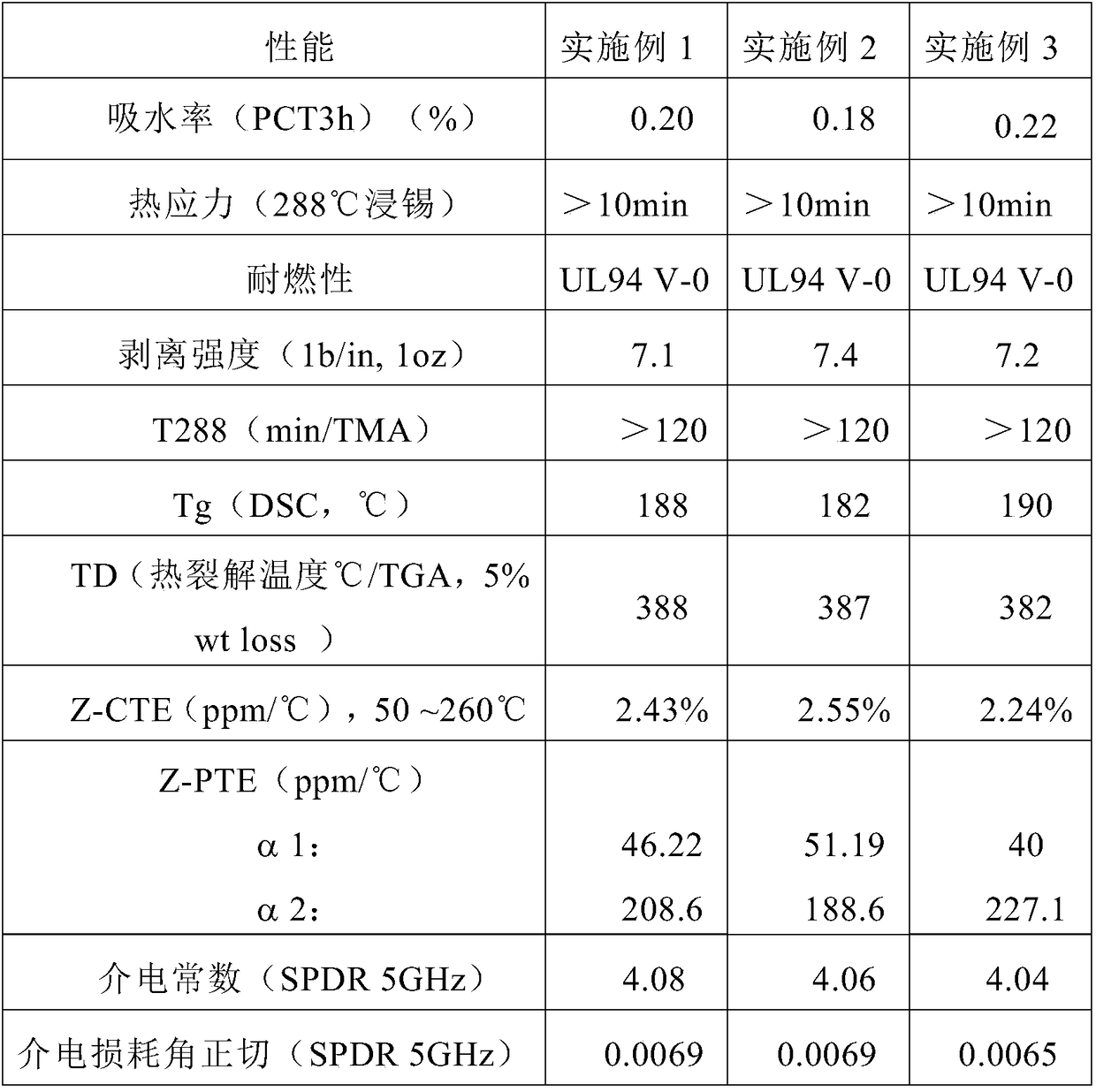

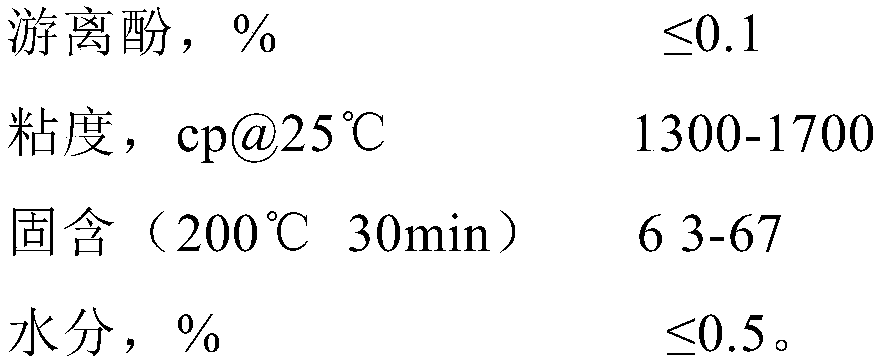

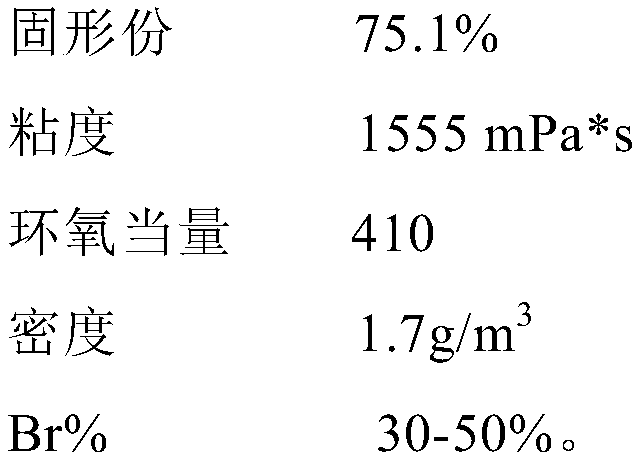

Adhesive for halogen-free high-Tg and low-dielectric type copper-clad plate, and preparation method thereof

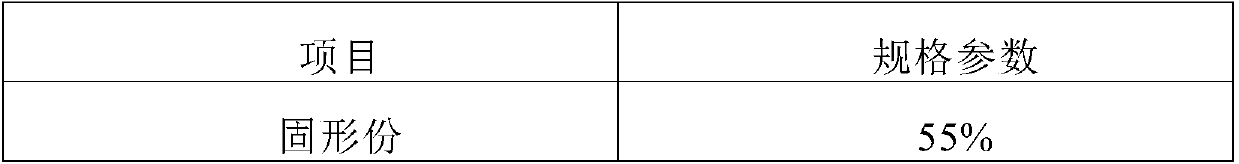

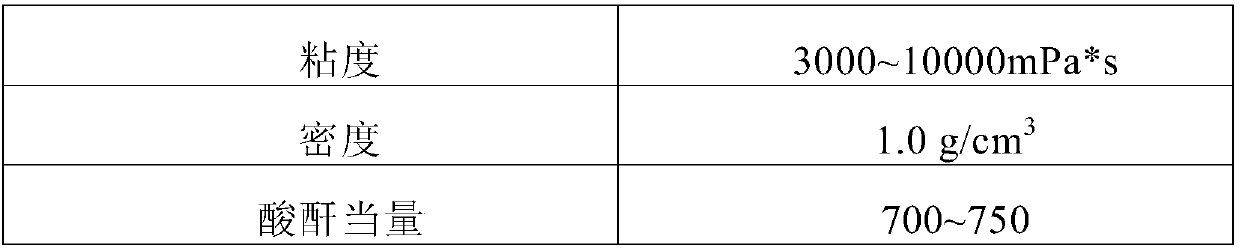

InactiveCN109536107AExcellent dielectric propertiesImprove reliabilityNon-macromolecular adhesive additivesPolyanhydride adhesivesEpoxyOrganic solvent

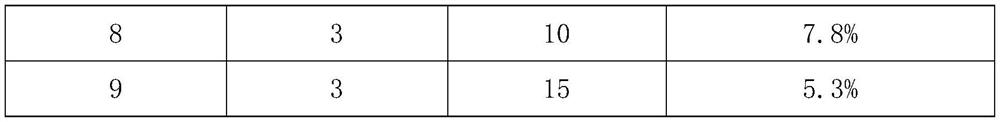

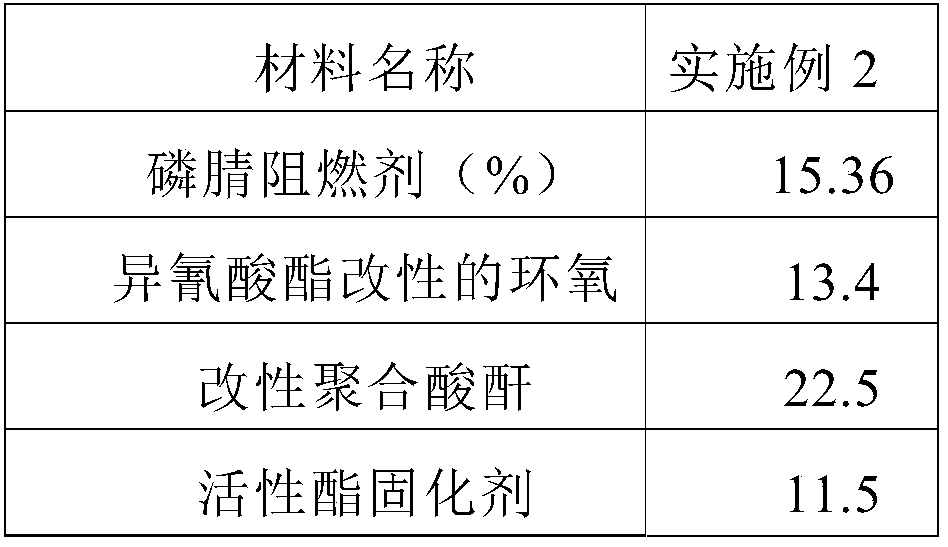

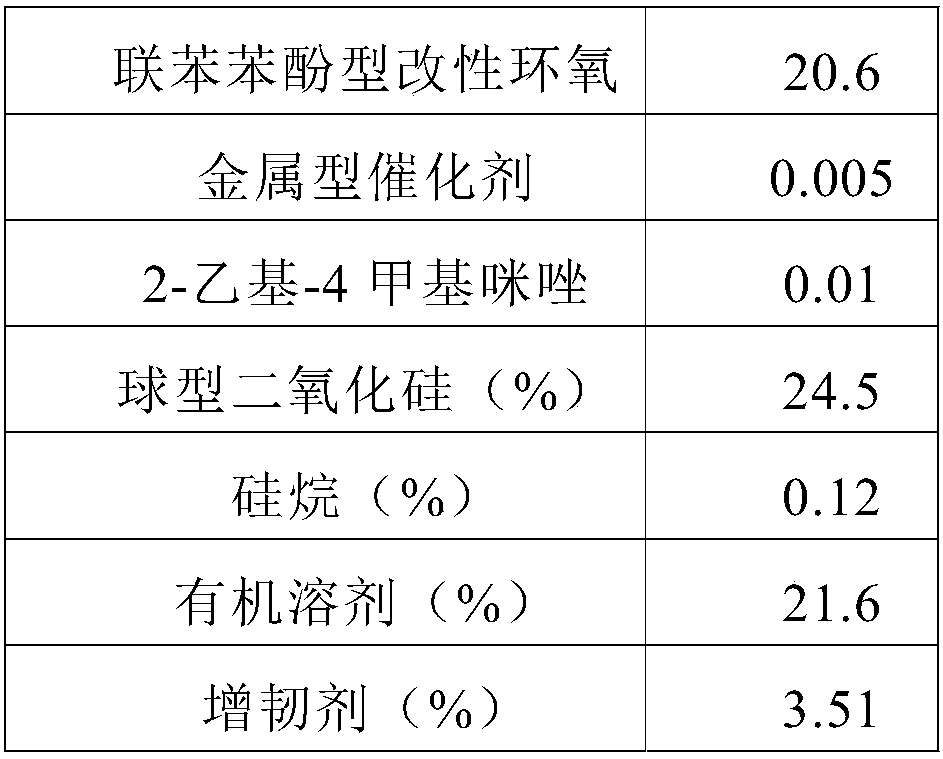

The invention relates to an adhesive for a halogen-free high-Tg and low-dielectric type copper-clad plate, and a preparation method thereof. The adhesive is prepared from, by weight, 2-80 parts of a phosphonitrile flame retardant, 5-80 parts of isocyanate modified epoxy resin, 20-70 parts of modified polymeric anhydride, 5-50 of an active ester curing agent, 5-80 parts of biphenylphenol modified epoxy resin, 0.005-1.0 part of a metal type catalyst, 0.005-1.0 part of an imidazole catalyst, 10-60 parts of an inorganic filler, 0.1-5.0 parts of silane, 1-10 parts of a toughener and 10-60 parts ofan organic solvent. The epoxy glass cloth-based copper-clad plate produced by using the adhesive prepared in the invention has a Tg value of 180 DEG C or above and a Z-axis CTE of 3.0%, or less has aTD of 360 DEG C or above and a T288 of 60 min or above in the heat resistance field, and has a copper foil peel strength (1 OZ) of 1.2 N / mm or above.

Owner:NANYA NEW MATERIAL TECH CO LTD

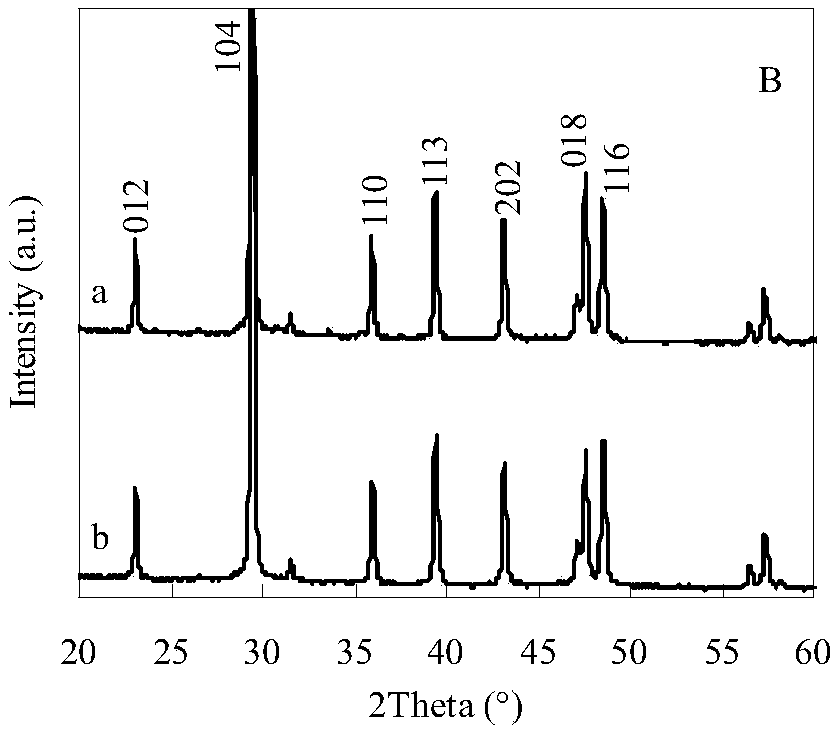

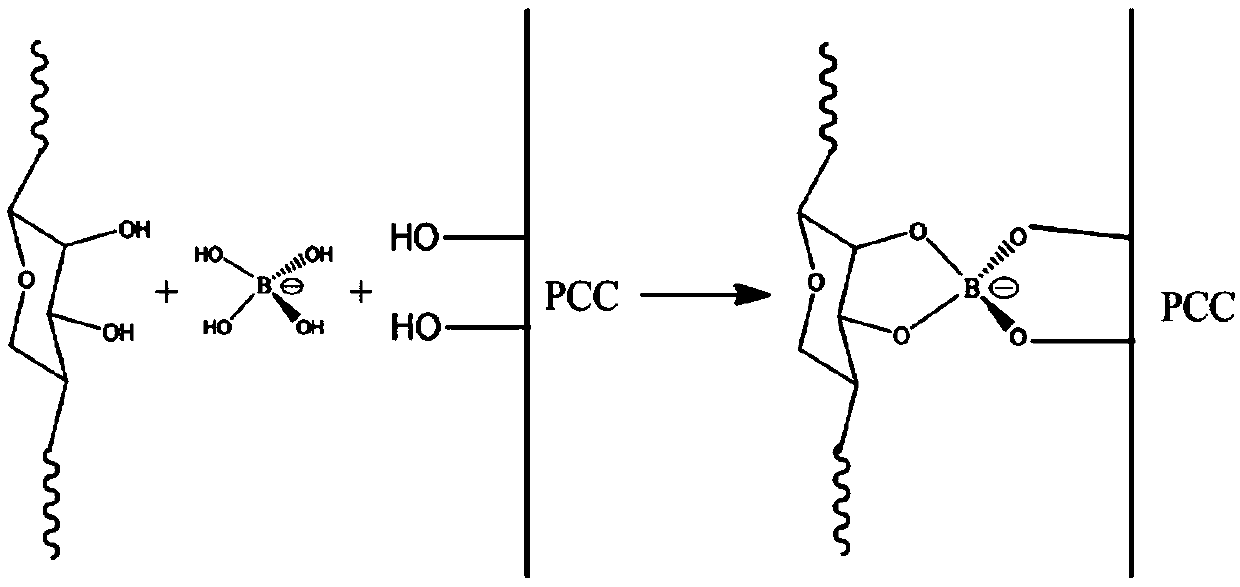

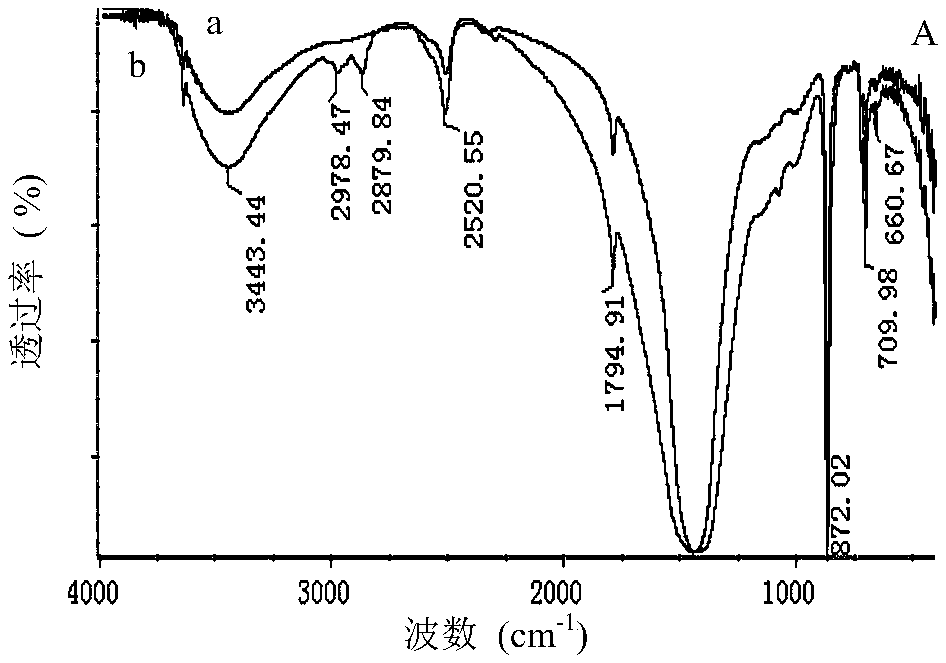

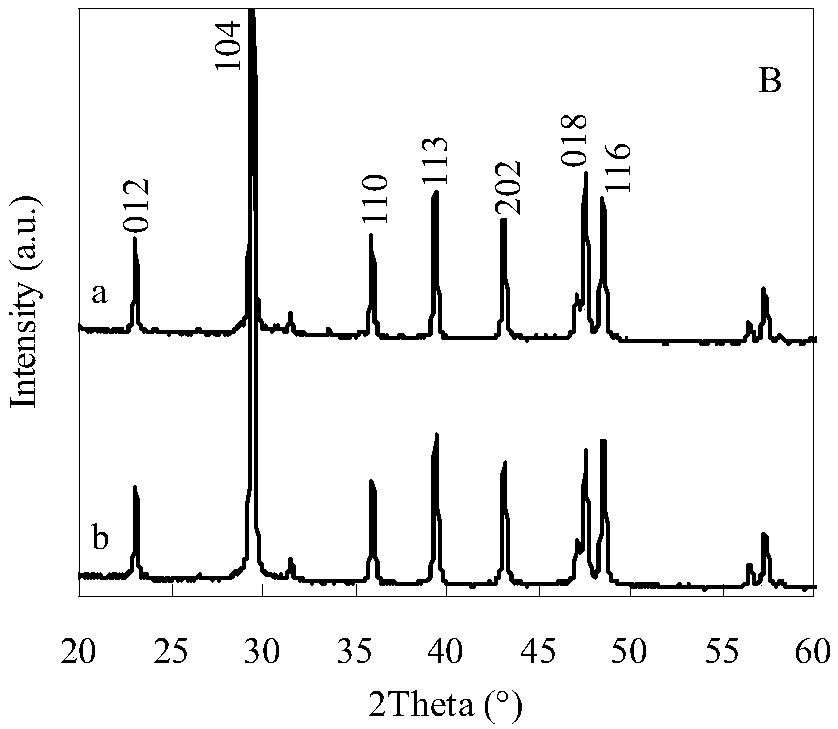

Guar gum-boric acid surface-crosslinking modified precipitated calcium carbonate, preparation method and application thereof, and paper

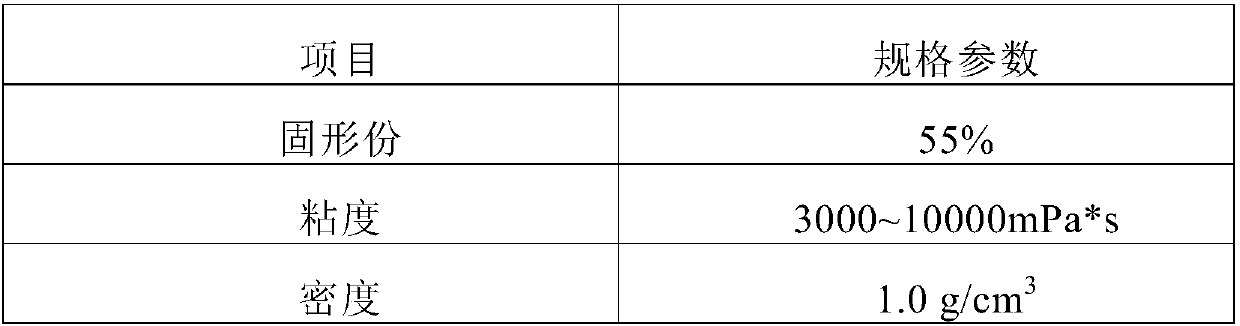

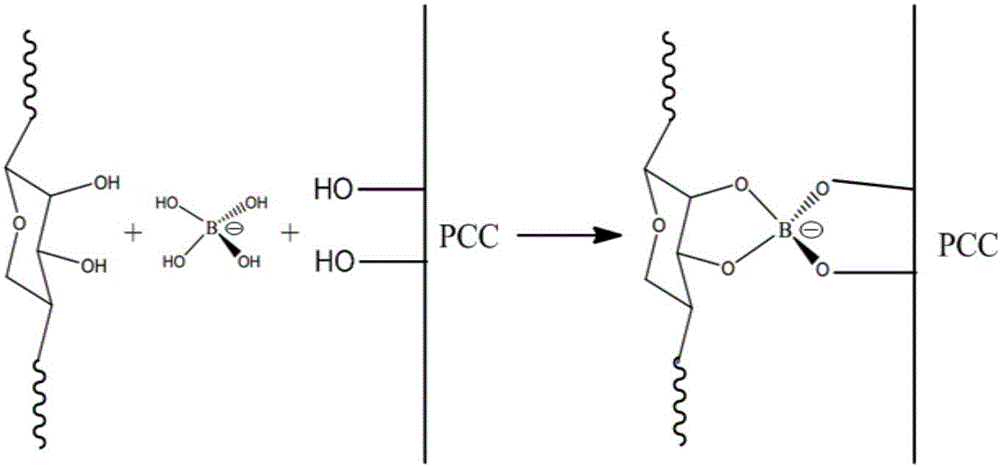

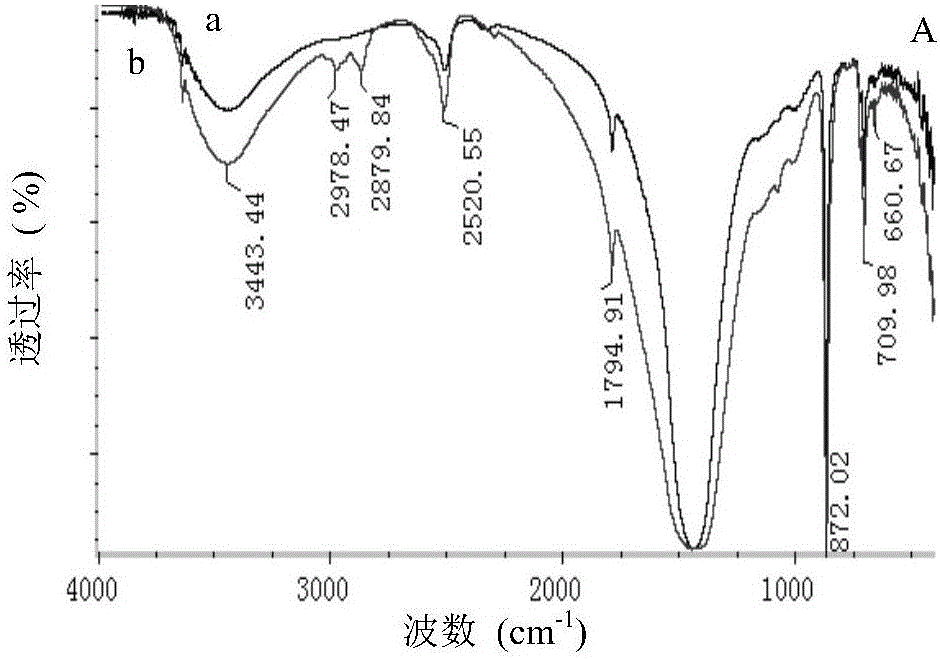

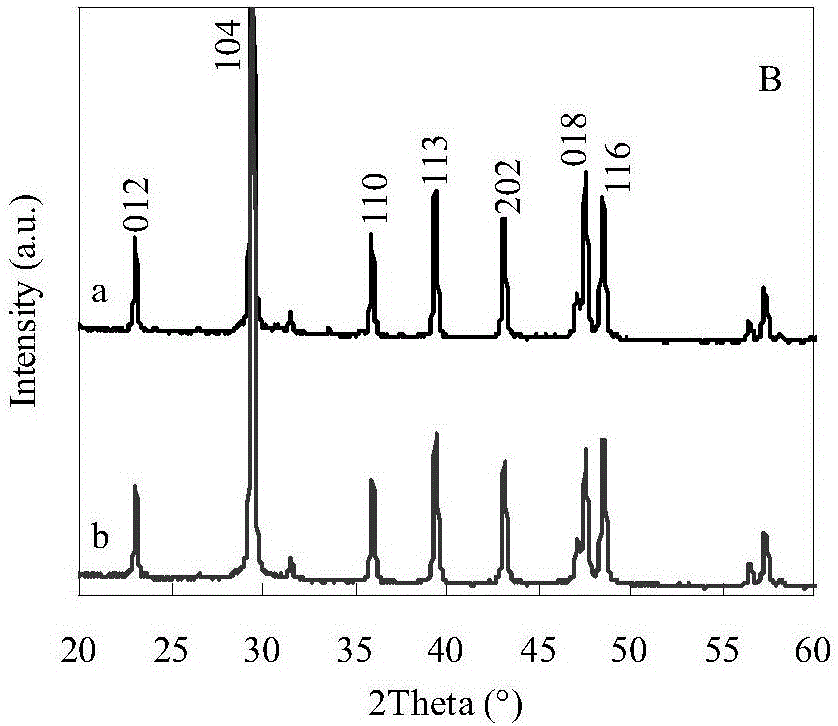

ActiveCN106702811AIncreased tensile indexIncreased burst indexInorganic compound additionPigment treatment with macromolecular organic compoundsPrecipitated calcium carbonateBoric acid

The invention provides a guar gum-boric acid surface-crosslinking modified precipitated calcium carbonate. Guar gum is crosslinked on the surface of the modified precipitated calcium carbonate through boric acid. The invention aims to provide a modified precipitated calcium carbonate which can obviously enhance the tensile index, burst index and tear index of paper and the single-pass retention rate of the filler when being used in the filler of the paper. The invention also provides a preparation method and application of the modified precipitated calcium carbonate. Besides, the invention also provides a paper containing the modified precipitated calcium carbonate.

Owner:WUZHOU UNIV

Preparation method of microcapsule paper

ActiveCN112726277AIncrease the amount of fillingEvenly dispersedNon-fibrous pulp additionPaper/cardboardPulp (paper)Paper sheet

Owner:FUJIAN HENGAN HYGIENE MATERIAL +2

Preparation method of halogen-free high Tg and low dielectric constant copper-clad board

InactiveCN109439257AExcellent halogen-free flame retardant performanceImprove heat resistanceNon-macromolecular adhesive additivesLaminationEpoxyAdhesive

The invention relates to a preparation method of a halogen-free high Tg and low dielectric constant copper-clad board. The preparation method comprises the steps of preparing an adhesive from modifiedepoxy resin and a functional assistant, coating glass fiber cloth with the adhesive, cladding with copper foil, and performing hot pressing to form the halogen-free high Tg and low dielectric constant copper-clad board. Compared with the prior art, Tg of the epoxy glass cloth based copper-clad board is greater than 180 DEG C; Z-axis CTE (coefficient of thermal expansion) is less than 3.0%; for thermal resistance, TD is greater than or equal to 360 DEG C and T288 is greater than 60min; for electrical properties, a dielectric constant (5GHZ) is less than or equal to 4.1 and a dielectric loss (5GHZ) is less than 0.007; in addition, the copper-clad board has very low water absorptivity and good machinability; flame retardance reaches a UL94 V-0 level; and the board can fully meet requirementsof halogen-free and leadless processing and high composite board production in the field of high-frequency and high-speed PCBs (printed circuit boards).

Owner:NANYA NEW MATERIAL TECH CO LTD

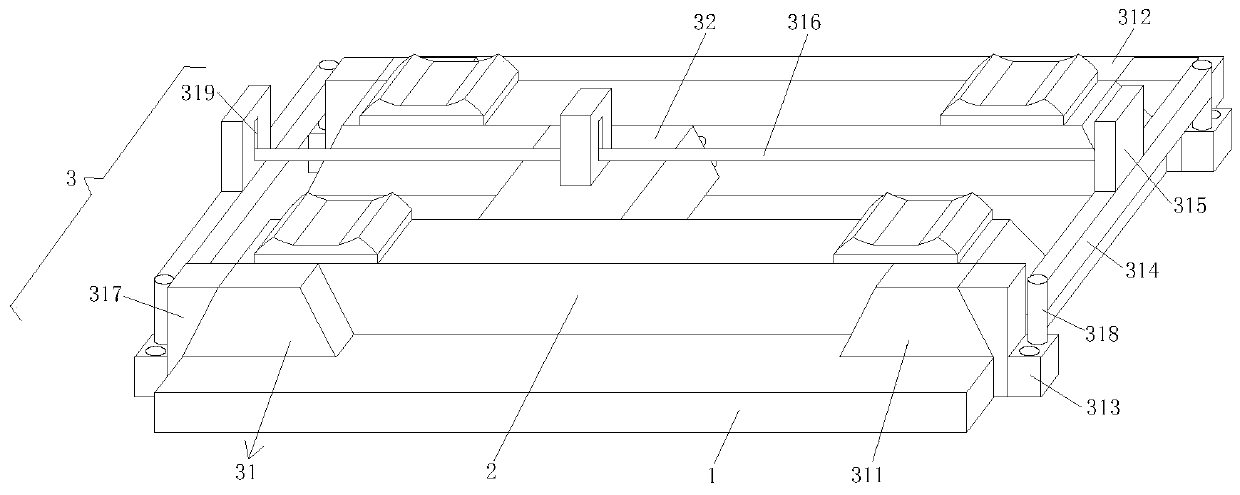

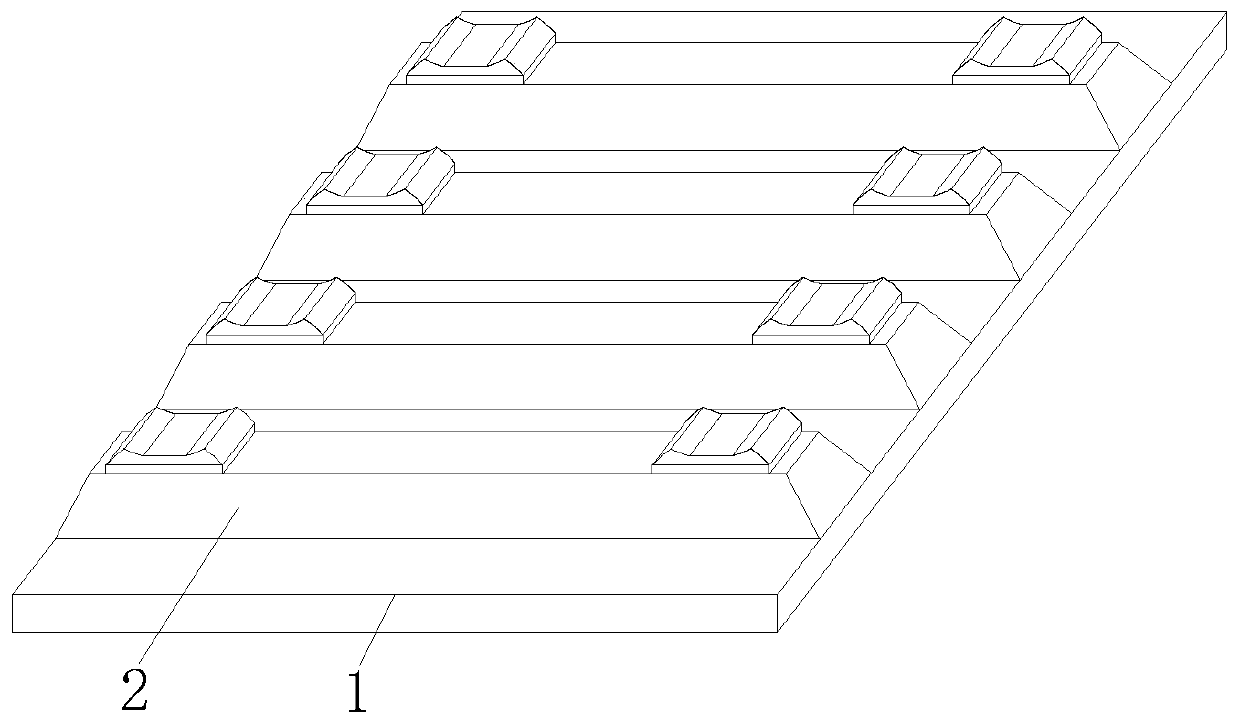

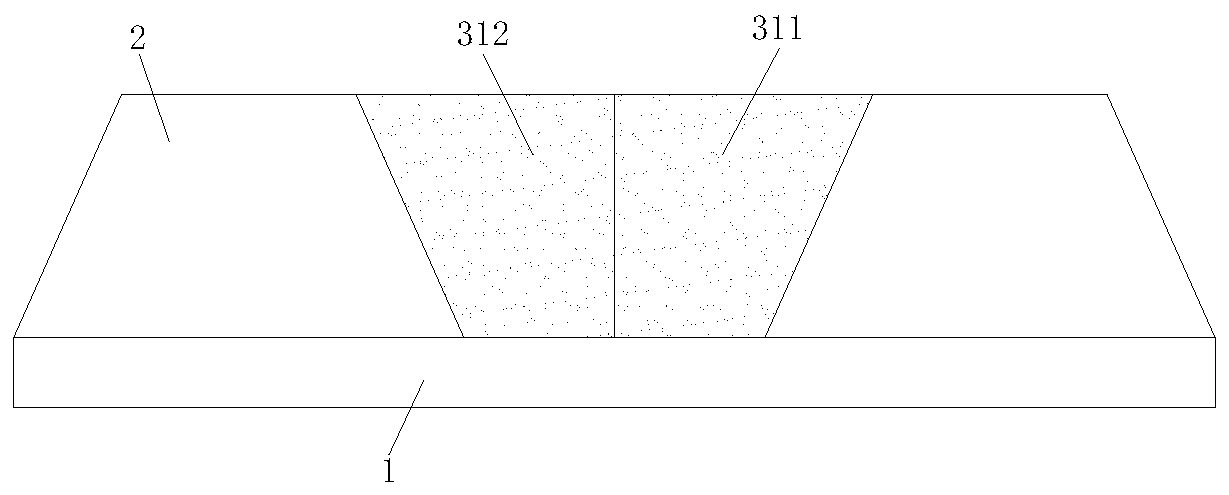

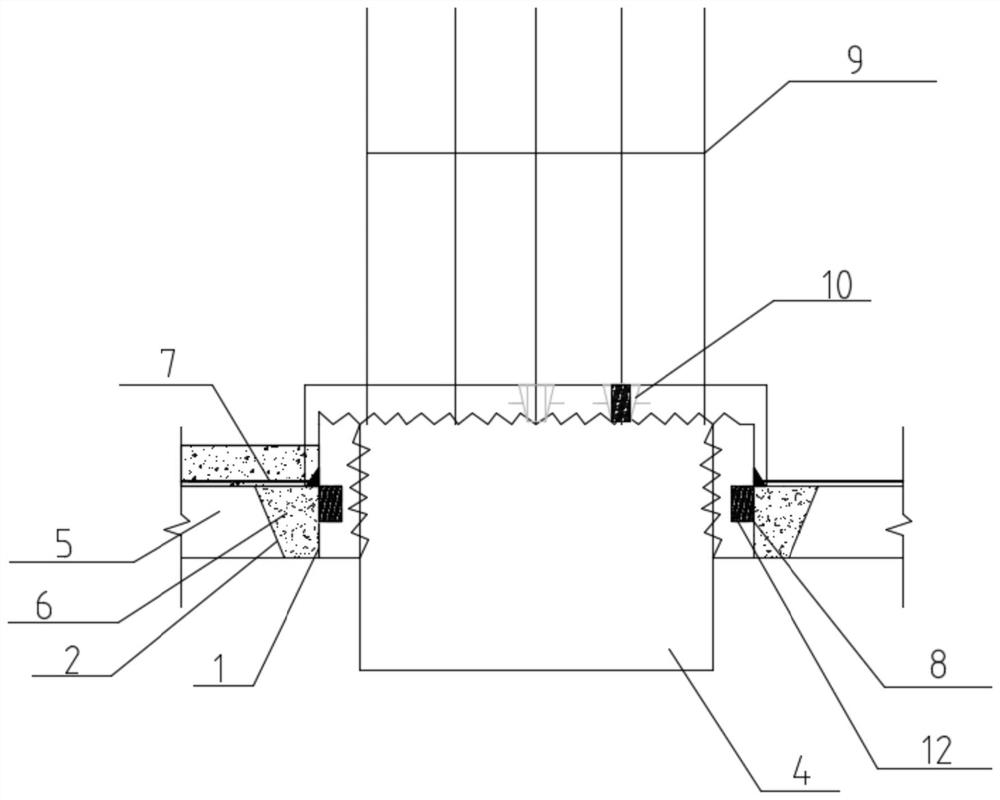

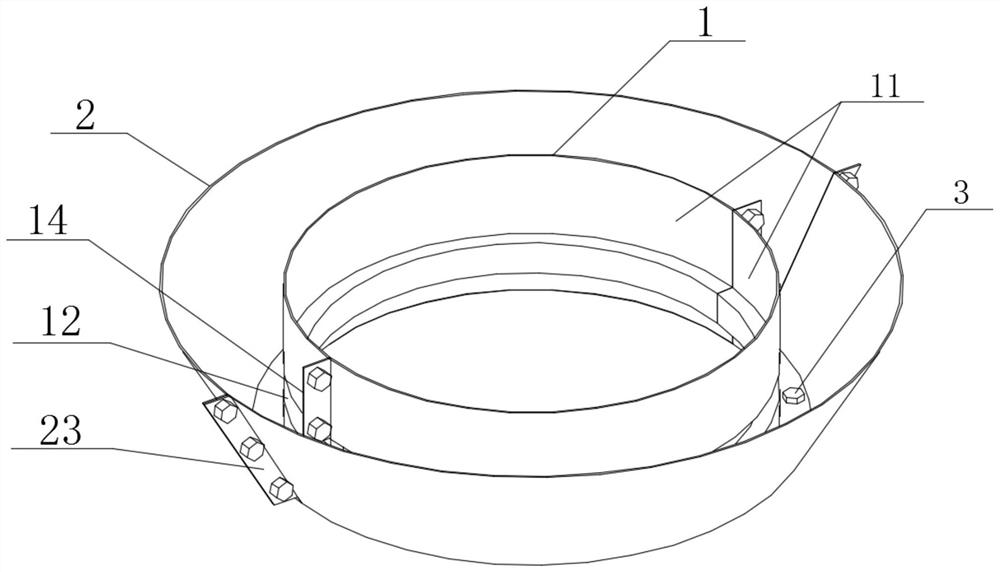

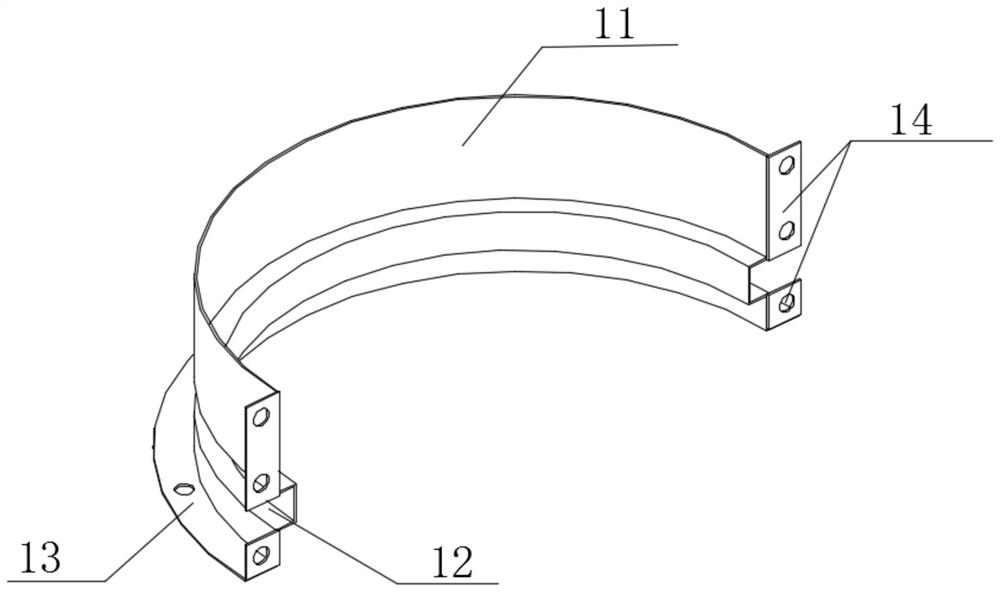

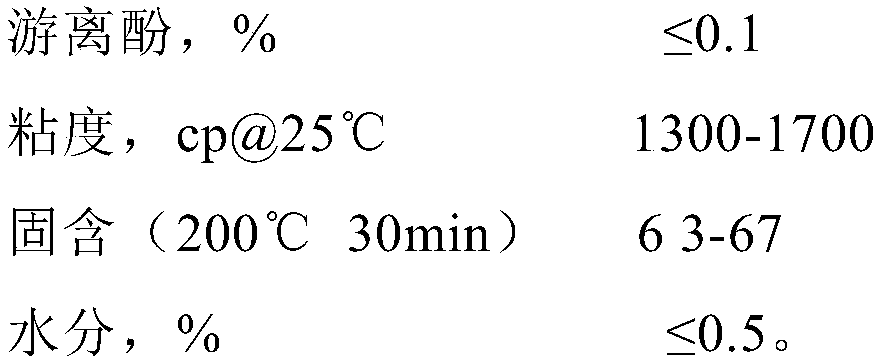

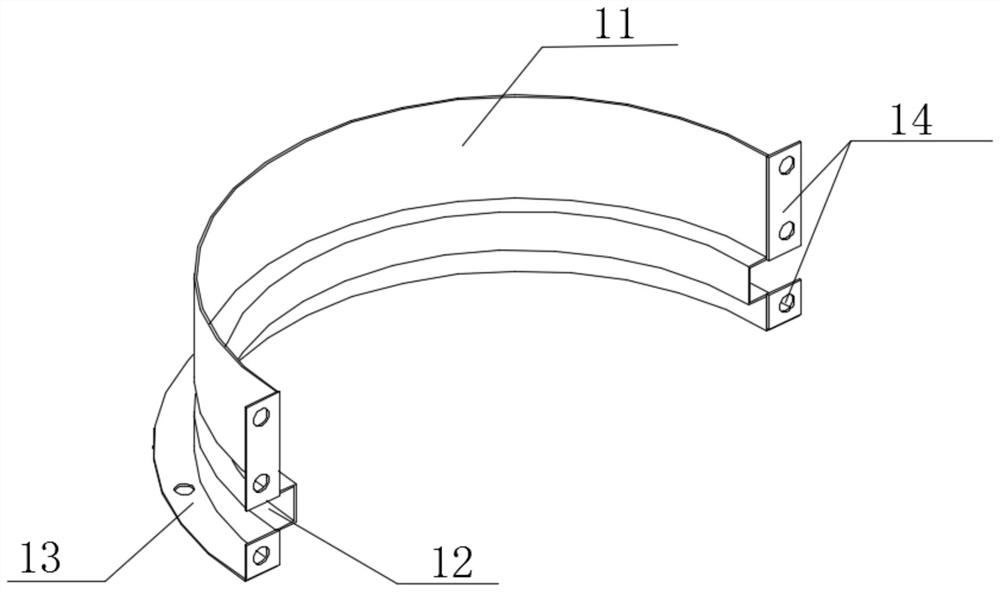

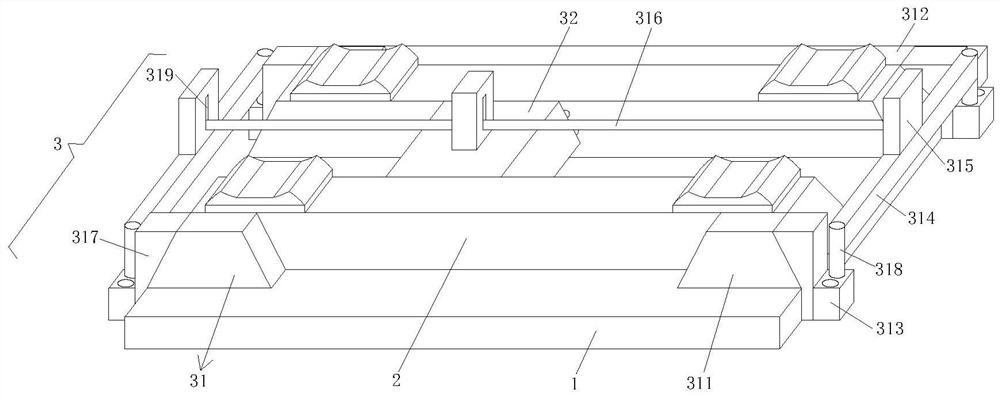

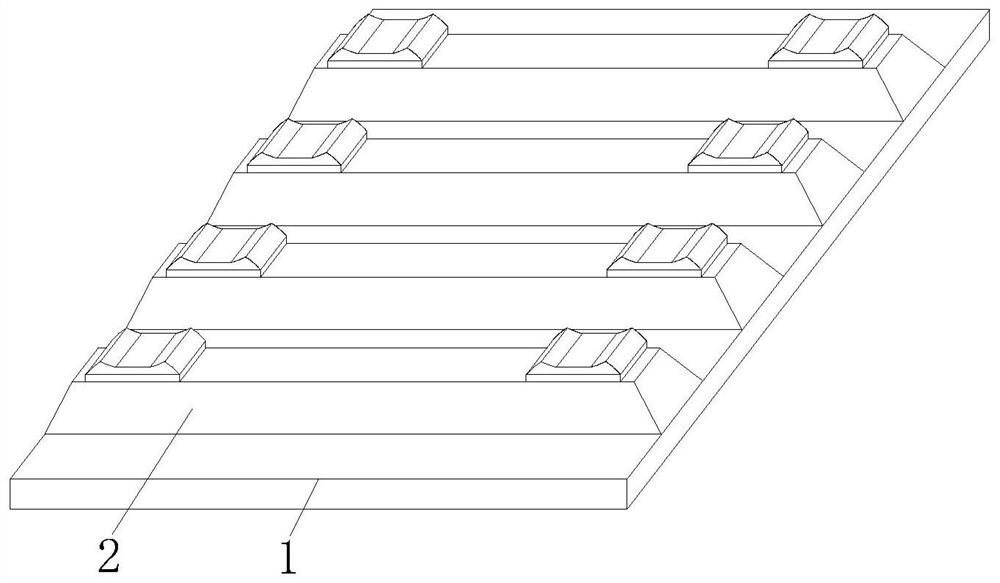

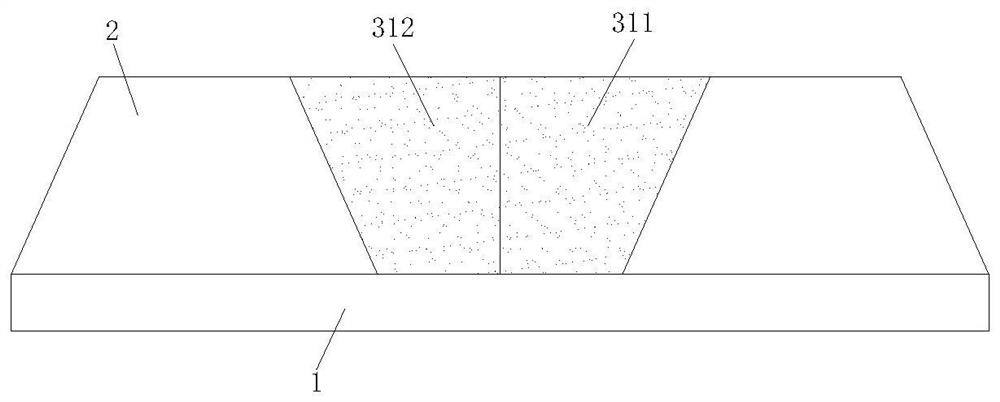

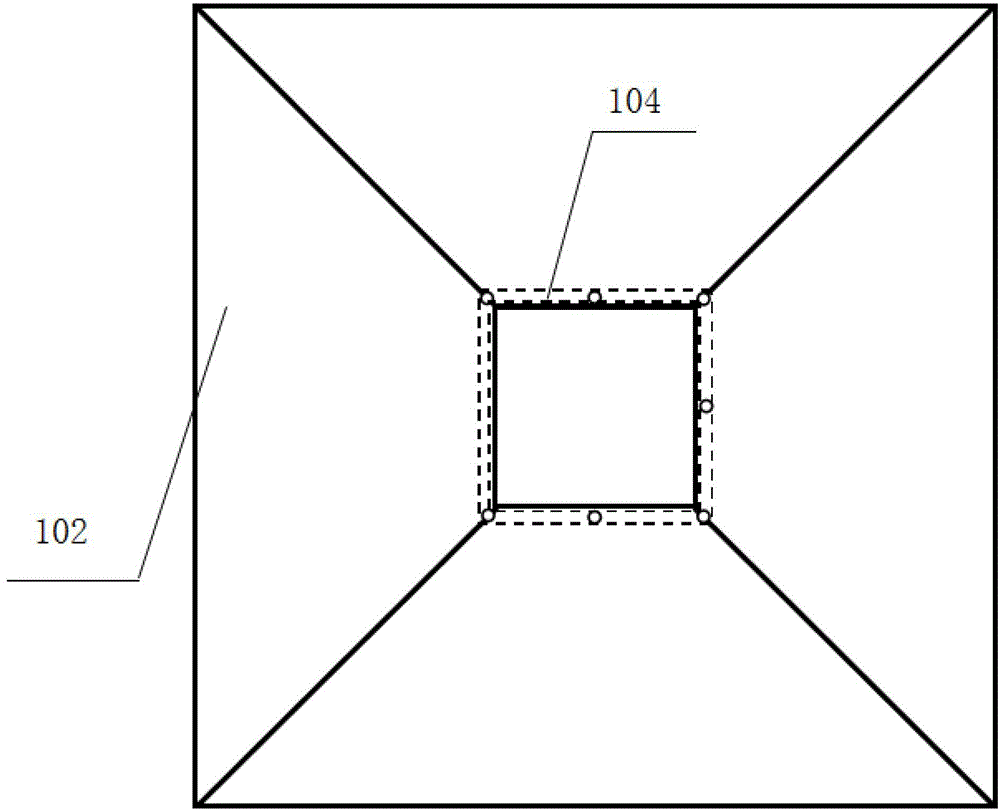

Double-block type ballastless track bridge base transverse template positioning device

ActiveCN110219251APrevent deviationIncrease frictionBridge erection/assemblySelf adaptiveTRACK FIELD

The invention discloses a double-block type ballastless track bridge base transverse template positioning device that comprises a bridge base, a trapezoidal transverse template and a fixing device; the fixing device comprises a parallel fixing mechanism and a movable pressing mechanism, wherein the movable pressing mechanism is installed on the parallel fixing mechanism, and the movable pressing mechanism comprises a parallel pressing mechanism and a self-adaptive moving mechanism; the positioning device relates to the ballastless track field. According to the double-block type ballastless track bridge base transverse template positioning device, the fixing device convenient to fit and combine can be designed according to the shape and the installation mode of the transverse template; themoving trend of automatic sedimentation of the movable pressing mechanism on the fixing device is utilized to enhance the relevance of each template and the fixing device, so that the problems that the positioning device used by a common transverse template is difficult to associate with a plurality of transverse templates are solved; and when concrete is poured, the time difference of a deviationtrend of the transverse templates easily affects the concrete pouring efficiency can be effectively solved.

Owner:中南建设集团有限公司

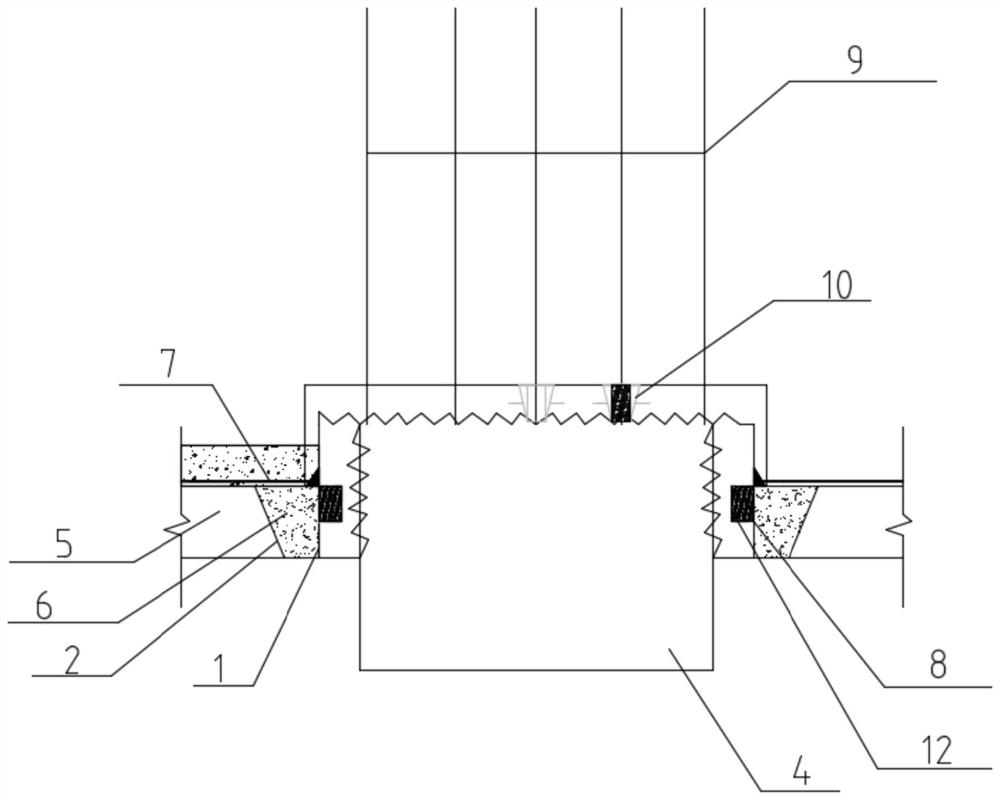

Construction method for pile head secondary forming waterproof construction

ActiveCN111663575AAvoid risk of leakageAvoid hidden dangersProtective foundationBulkheads/pilesArchitectural engineeringRebar

The invention discloses a construction method for pile head secondary forming waterproof construction, and relates to the technical field of waterproof construction of a cast-in-place concrete pile head. The construction method comprises the steps of breaking a pile head; assembling a pile head secondary forming tool type mold; arranging the mold; carrying out pile head secondary forming and cushion layer concrete pouring; dismantling the mold; arranging expansion water stop strips; sealing waterproof mortar; carrying out bottom plate waterproof construction; brushing cement-based capillary crystallization on to the pile head; and arranging pile head exposed steel bars and a plastic sleeve factice crack pouring tool type mold and the like. One pile head secondary forming tool type mold andthe plastic factice crack pouring tool type mold are designed in a targeted mode, through the implantation of the technical scheme, the technical problem that the leakage risk exists at waterproof cross positions between the pile head and a bottom plate can be effectively solved, so that the leakage risk and hidden danger existing in pile head waterproof construction are prevented, the secondaryrepairing cost caused by leakage of the waterproof pile head is reduced, resources are saved, and the secondary forming construction efficiency of the pile head and the waterproof construction qualityof the pile head are improved.

Owner:CHINA MCC5 GROUP CORP

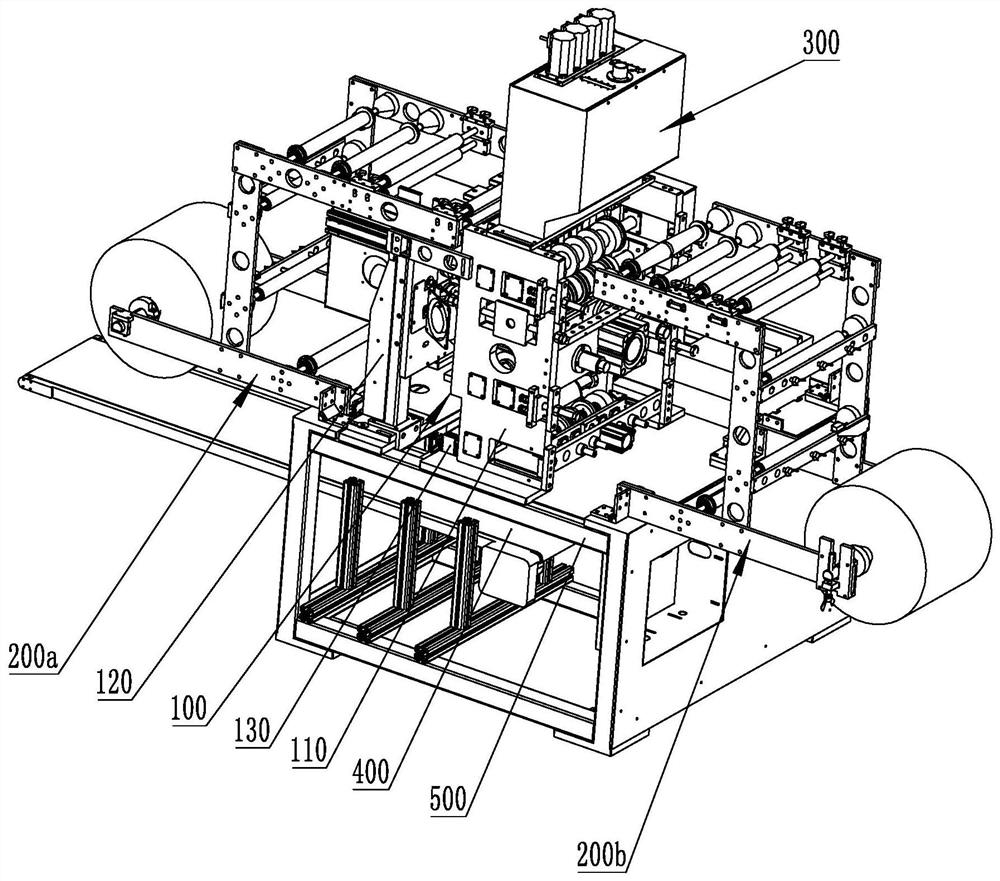

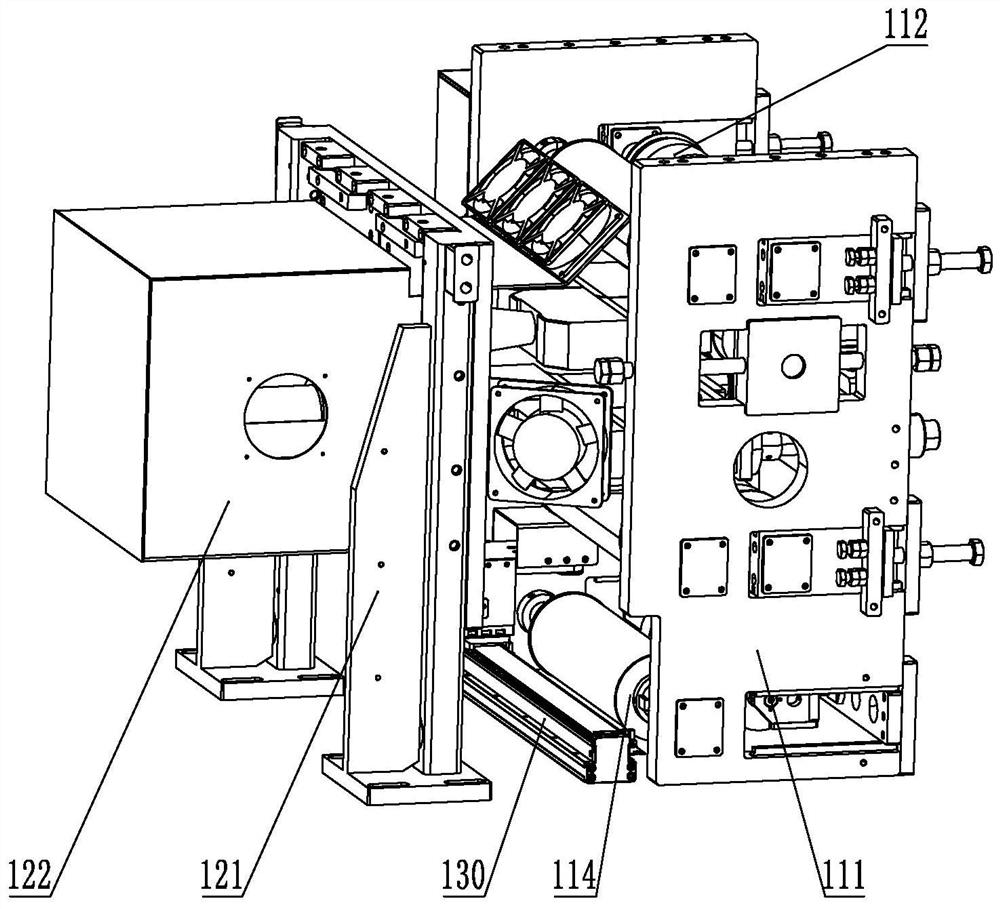

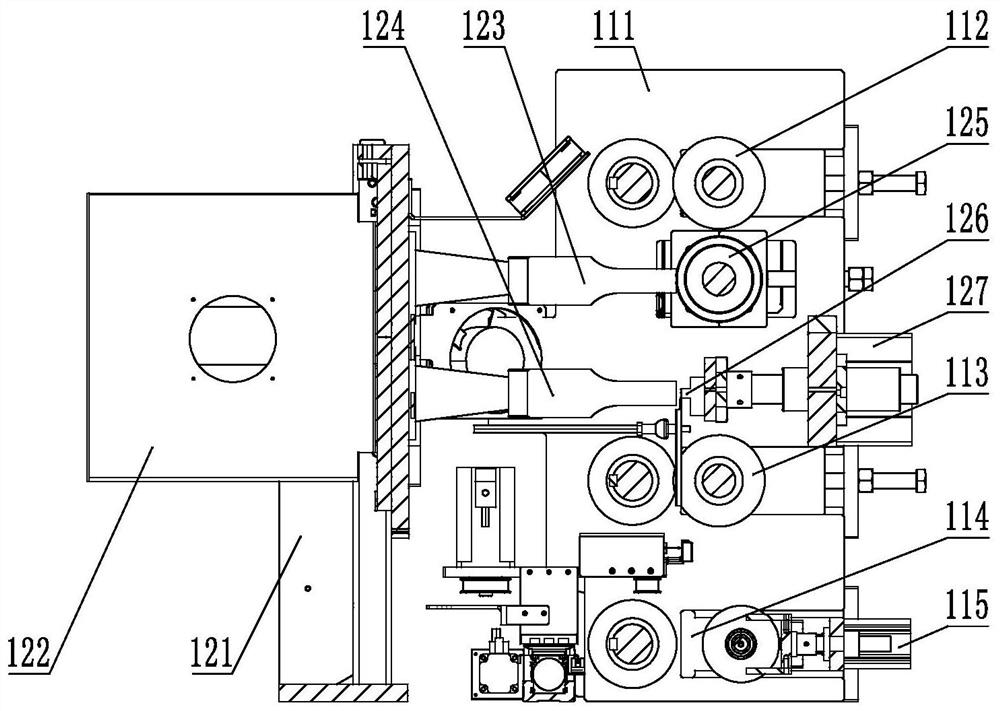

Bag making and material filling equipment

PendingCN113320724AHigh precisionSolve low production efficiencyBag making operationsPaper-makingAutonomationWelding

The invention belongs to the technical field of automatic production equipment, and particularly relates to bag making and material filling equipment. The bag making and material filling equipment comprises a bag making device, a first material belt feeding mechanism, a second material belt feeding mechanism and a material filling device. The bag making device comprises a main transmission mechanism, a welding mechanism and a cutting mechanism. The main transmission mechanism comprises a transmission support, an upper clamping roller assembly, a lower clamping roller assembly, a cutting clamping roller assembly and a rotary driving mechanism, wherein the upper clamping roller assembly, the lower clamping roller assembly and the cutting clamping roller assembly are sequentially installed on the transmission support in the vertical direction. The welding mechanism comprises a welding main machine which is provided with a first welding bottom film and a second welding bottom film, and further comprises a welding roller which is rotatably installed on the transmission support and corresponds to the first welding bottom film, a welding flat film which is slidably installed on the transmission support and corresponds to the second welding bottom film, and a flat welding driving mechanism. And at least two annular welding parts which are arranged at intervals in the axial direction are arranged on the welding roller. According to the bag making and material filling equipment, the bag making and material filling processes are automatically completed by the bag making and material filling equipment, and the problem of low production efficiency of an existing bag making and material filling mode is solved.

Owner:WEIFANG LOKOMO PRECISION IND

Papermaking method

InactiveCN107059460AIncrease the amount of fillingReduce manufacturing costSpecial visual effect coatingsInorganic compound additionCalcium silicatePapermaking

The invention provides a paper making method, comprising: using sodium silicate solution to infiltrate the first paper pulp, then adding milk of lime and a catalyst to react, and controlling the calcium-silicon ratio in the reaction system to be 0.6-0.9, after the reaction is completed , adjusting the pH value of the reaction product to 9-11 to obtain a composite slurry; adding the above composite slurry to the second pulp to form a papermaking system, and papermaking is performed on the papermaking system. The papermaking method provided by the invention solves the problems of high consumption of active calcium silicate plus filling paper chemical additives and easy lint and powder loss in the existing paper, improves the quality of paper products, and further improves the application of active calcium silicate in papermaking technology.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Adhesive for copper-clad plates suitable for automobiles, and preparation method thereof

InactiveCN109536099AImprove the conditions required for curingImprove reliabilityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesMaterials preparationOrganic solvent

The invention relates to an adhesive for copper-clad plates suitable for automobiles, and a preparation method thereof. The adhesive is prepared from, by weight, 30-70 parts of linear phenolic resin,10-60 parts of isocyanate modified epoxy resin, 10-60 parts of brominated modified epoxy resin, 0.5-10 parts of an amine curing agent, 0.01-0.10 part of 2-ethyl-4-methylimidazole, 0.1-1.5 parts of silane, 2-20 parts of a toughener, 20-70 parts of an organic solvent and 10-80 parts of an inorganic filler through two steps of material preparation and adhesive mixing. Compared with the prior art, thepreparation method can effectively improve material curing conditions, shorten the curing time and improve the reliability after curing by adopting a double-curing system and utilizing the synergistic curing of the phenolic curing agent and the amine curing agent according to a unique ratio.

Owner:NANYA NEW MATERIAL TECH CO LTD

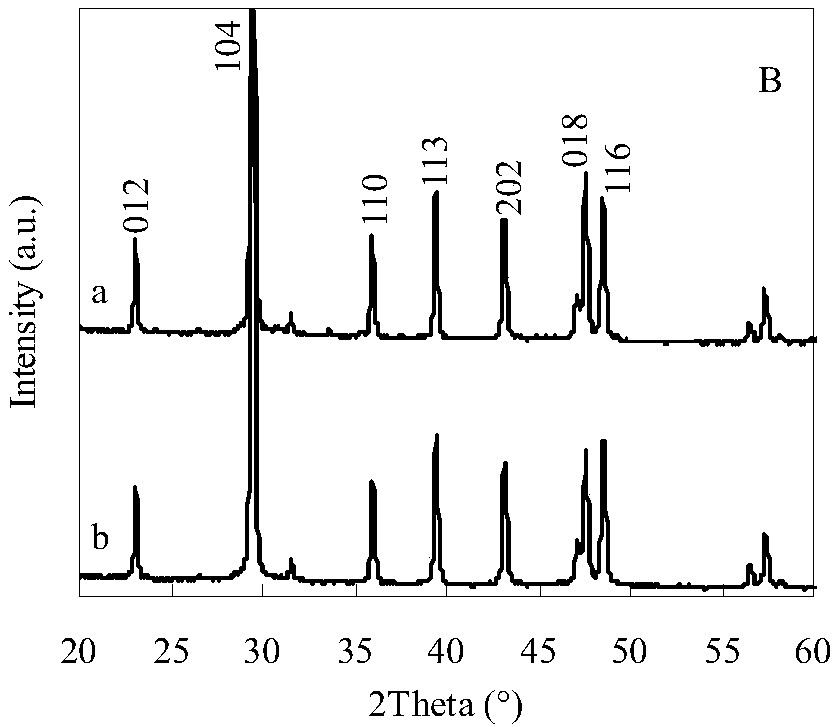

Self-retention heavy calcium carbonate and preparation method thereof

InactiveCN101913639BIncrease bulkBulk effectCalcium/strontium/barium carbonatesPigmenting treatmentFiller ExcipientCalcite

Owner:刘立新

A construction method for secondary forming waterproof construction of pile head

ActiveCN111663575BThe production principle is simpleEasy accessProtective foundationBulkheads/pilesArchitectural engineeringRebar

The invention discloses a construction method for pile head secondary molding waterproof construction, and relates to the technical field of concrete pouring pile pile head waterproof construction; the construction method includes the following steps: pile head breaking-pile head secondary molding tool mold assembly ‑Mold installation‑Pile head overmolding and cushion concrete pouring‑Mould removal‑Installation of expansion waterstops‑Waterproof mortar closure‑Floor waterproofing construction‑Pile head brushing with cement-based permeation crystallization‑Installation of pile head exposed reinforced plastic casing oil Paste potting tool molds, etc. From this, a set of pile head secondary forming tool molds and plastic ointment potting tool molds were designed. Through the implementation of this technical solution, the waterproof cross position between the pile head and the bottom plate can be effectively solved. There is a technical problem of leakage risk, which prevents the leakage risk and hidden dangers of the pile head waterproof construction, reduces the secondary repair cost of the pile head waterproof due to leakage, saves resources, and improves the construction efficiency and efficiency of the pile head secondary forming construction. Pile head waterproof construction quality.

Owner:CHINA MCC5 GROUP CORP

Treatment method of filler calcium carbonate in polyurethane leather

InactiveCN104098929BGood dispersionImprove fusion effectPigment treatment with non-polymer organic compoundsStearic acidChemistry

The invention discloses a processing method for calcium carbonate as filler in polyurethane leather. The processing method for calcium carbonate comprises the steps as follows: stearic acid is dissolved in a DMF (dimethyl formamide) solvent, and then calcium carbonate is added in the solvent for sufficient mixing and infiltrating; infiltrated calcium carbonate is put in a double-roller extruder to be extruded for 2-10 times, and calcium carbonate as the filler in polyurethane leather is obtained; and a mass ratio of calcium carbonate, stearic acid to DMF is 1: (0.01-0.03): (0.3-0.6), and the double-roller extrusion condition is that the roller distance is not larger than 2 mm. The addition amount of obtained calcium carbonate in the polyurethane leather can be increased under the premise that the leather performance is guaranteed, the polyurethane leather cost is reduced, and the large market demand is met.

Owner:江苏宁翔新材料有限公司

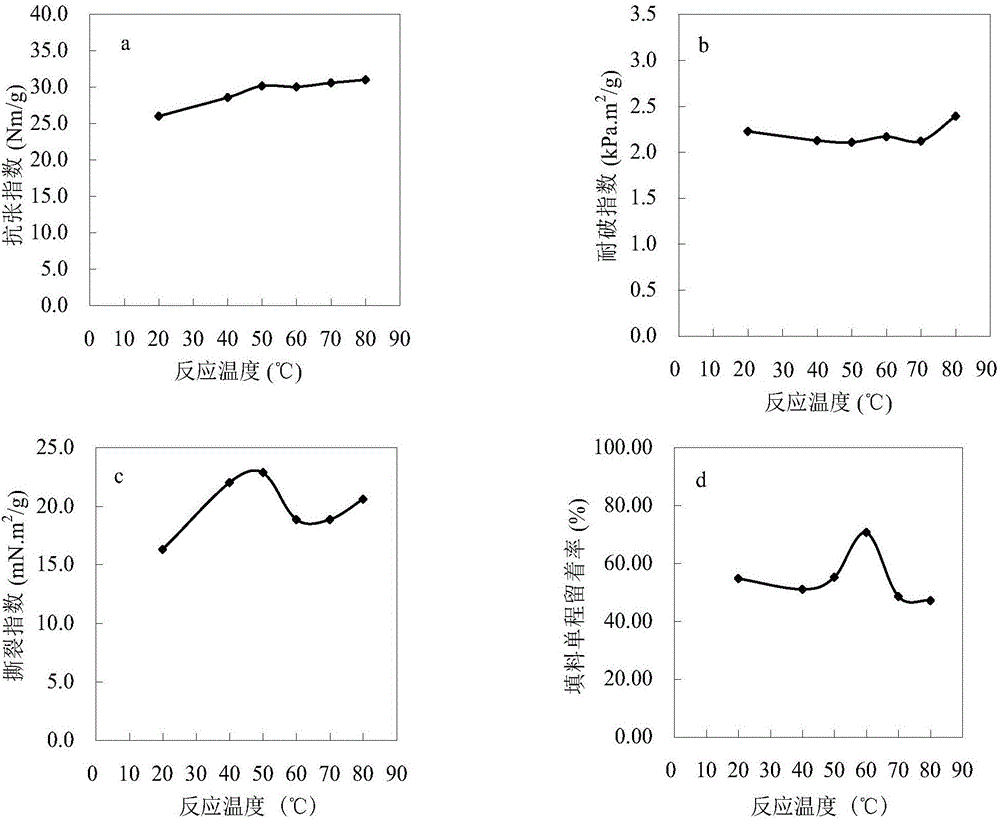

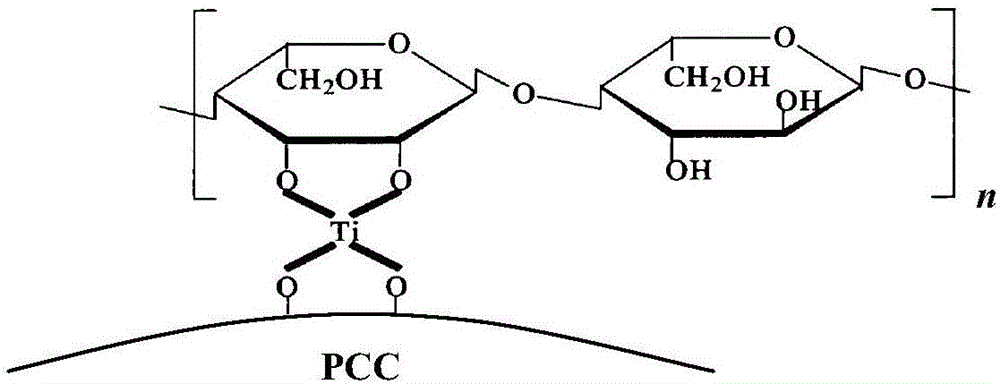

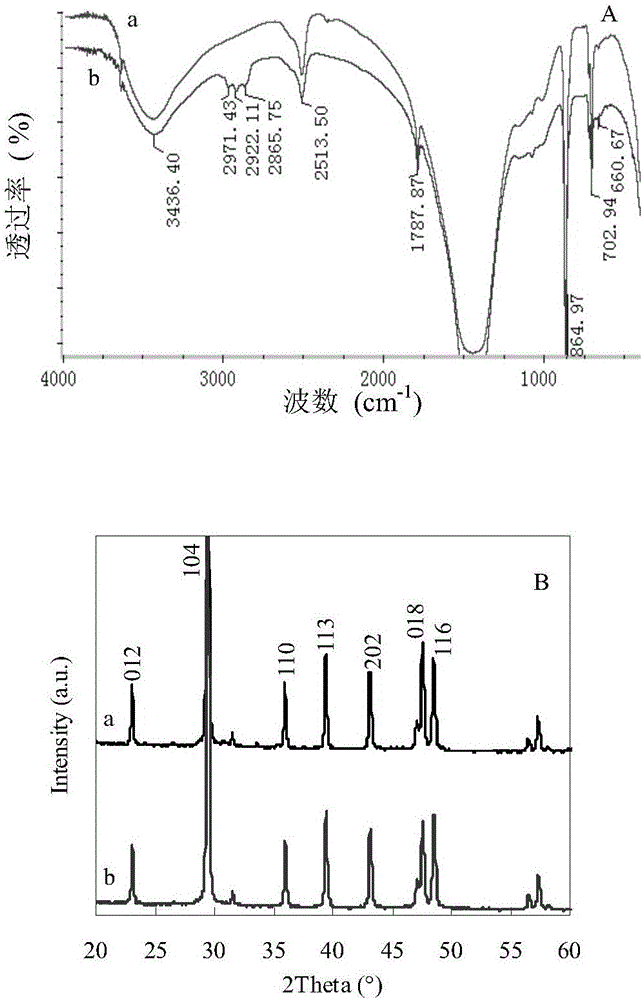

Sesbania gum organic titanium surface crosslinking modified precipitated calcium carbonate, preparation method and application thereof and paper

ActiveCN106800802AIncreased tensile indexIncreased burst indexInorganic compound additionPigment treatment with macromolecular organic compoundsOne passTitanium surface

The invention provides sesbania gum organic titanium surface crosslinking modified precipitated calcium carbonate. Sesbania gum is in crosslinking to the surface of the modified precipitated calcium carbonate through organic titanium. The invention aims at providing the modified precipitated calcium carbonate which can obviously improve tensile index, burst index and tear index of paper when being applied to paper as filler and improve the filler one-pass retention. Meanwhile, the invention further provides a preparation method and application of the modified precipitated calcium carbonate. In addition, the invention further provides paper containing the modified precipitated calcium carbonate.

Owner:WUZHOU UNIV

Method for increasing filling amount of paper product

PendingCN113445357AIncrease the amount of fillingReduce addInorganic fibres/flakesDefoamers additionWater filterBiochemical engineering

The invention discloses a method for increasing the filling amount of a paper product, the method comprises the following steps: premixing plant fibers, chemical fibers and a filler, adding latex to realize the modification of filler particles and fibers by the latex, adding a retention aid, a wet strength agent and a defoaming agent, fully acting, and diluting to a certain concentration to be used for the production of a high-filling paper product. The latex, the retention aid and the chemical fibers are added, so that the fibers are bonded with filler particles, and the water filtering performance of the pulp and the filling amount of a paper product are remarkably improved. Compared with a traditional filling mode, the maximum filling amount of the paper product produced by the method can reach 85wt.%. The method has the advantages of simplicity in operation, low additive amount, high water filtering speed and suitability for continuous production, and has a good commercial prospect.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

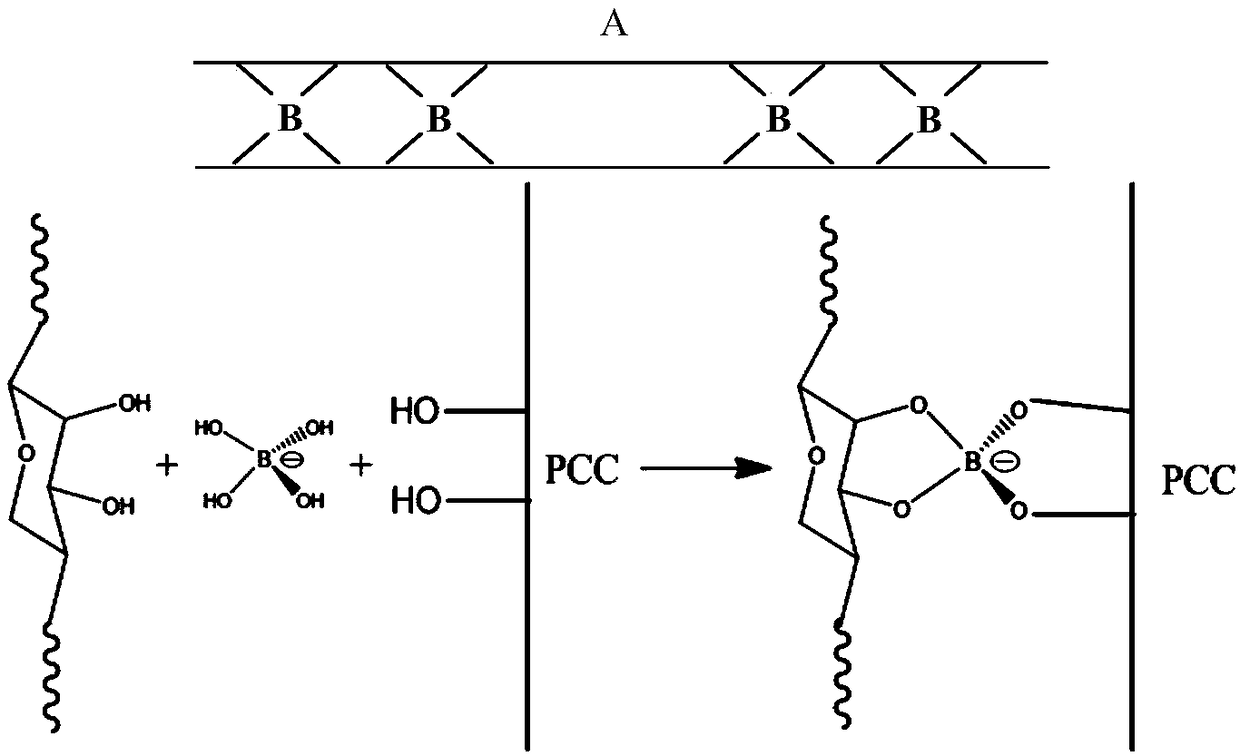

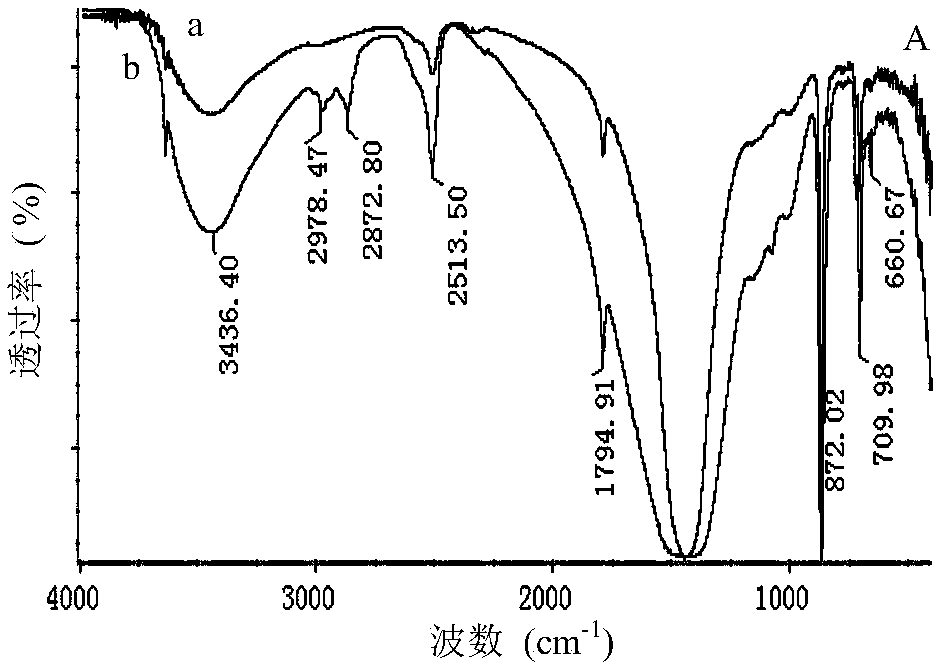

Konjac gum organic boron surface cross-linked modified precipitated calcium carbonate, preparation method, application and a kind of paper

ActiveCN106758502BIncreased tensile indexIncreased burst indexInorganic compound additionPigment treatment with macromolecular organic compoundsCross-linkPrecipitated calcium carbonate

The invention provides modified precipitated calcium carbonate prepared by crosslinking konjac gum on the surface through organic boron. The surface of modified precipitated calcium carbonate is crosslinked with the konjac gum through the organic boron. The invention aims to provide modified precipitated calcium carbonate which can significantly improve the tensile index, the burst index and the tear index of paper and the one-way retention rate of a filler when being applied to the filler in the paper. The invention further provides a preparation method and application of modified precipitated calcium carbonate. In addition, the invention further provides the paper containing modified precipitated calcium carbonate.

Owner:WUZHOU UNIV

Composite modified attapulgite special for filling paper products and method for preparing same

InactiveCN101338535BImprove bindingImprove evennessInorganic compound additionMaterials scienceSurface modified

The invention discloses a modified composite attapulgite clay special for paper wadding and a method for producing the same. The modified composite attapulgite clay is composed of attapulgite clay, light / heavy calcium carbonate, and 1.5-2.5% of surface modifier based on the mass of the mixture, wherein mass ratio of the attapulgite clay to the calcium carbonate is 1:1-1.5. The method comprises: firstly selecting attapulgite clay deposit, in which mass percent of attapulgite clay is more than 30%, secondly, preforming of the attapulgite clay by a twin screw extruder, airing or drying until themass percent of water is less than 5%, and then crushing the preformed attapulgite clay to 4.5 mu m; subsequently, adding the calcium carbonate into a mixer, wherein the thickness of the calcium carbonate is 4.5 mu m, whiteness is more than 85, and the mass ratio is 1-1.1-1.5 based on the attapulgite clay; finally, adding the surface modifier of 1.5-2.5% based on the mass of the mixture and blending the mixtures for 10-30 minutes at 60-80 DEG C. to obtain the modified composite attapulgite clay. Accordingly, the modified composite attapulgite clay of the invention is applicable for paper wadding, which can obviously increase the retention and the intension of the paper articles, as well as better protect the environment.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

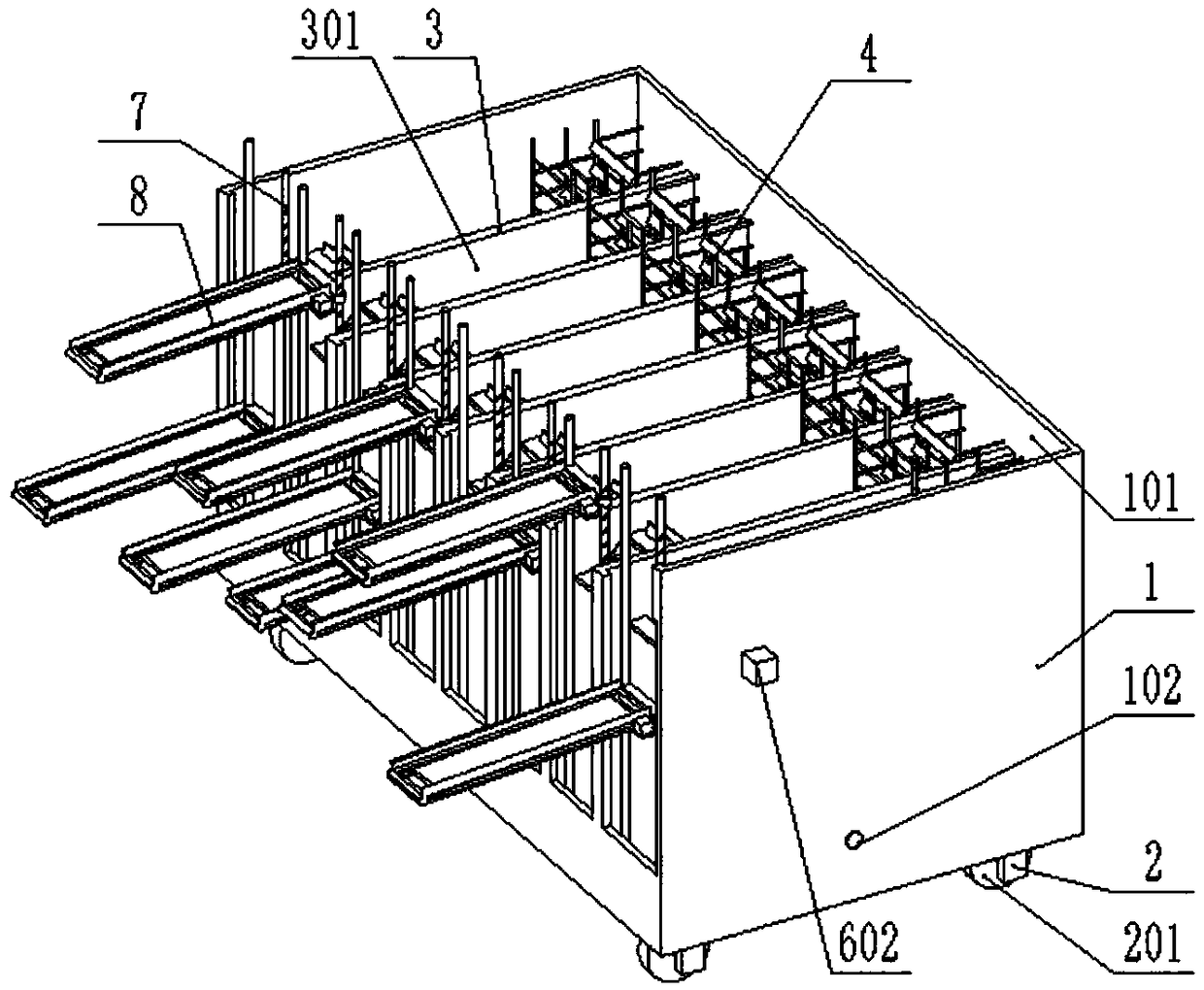

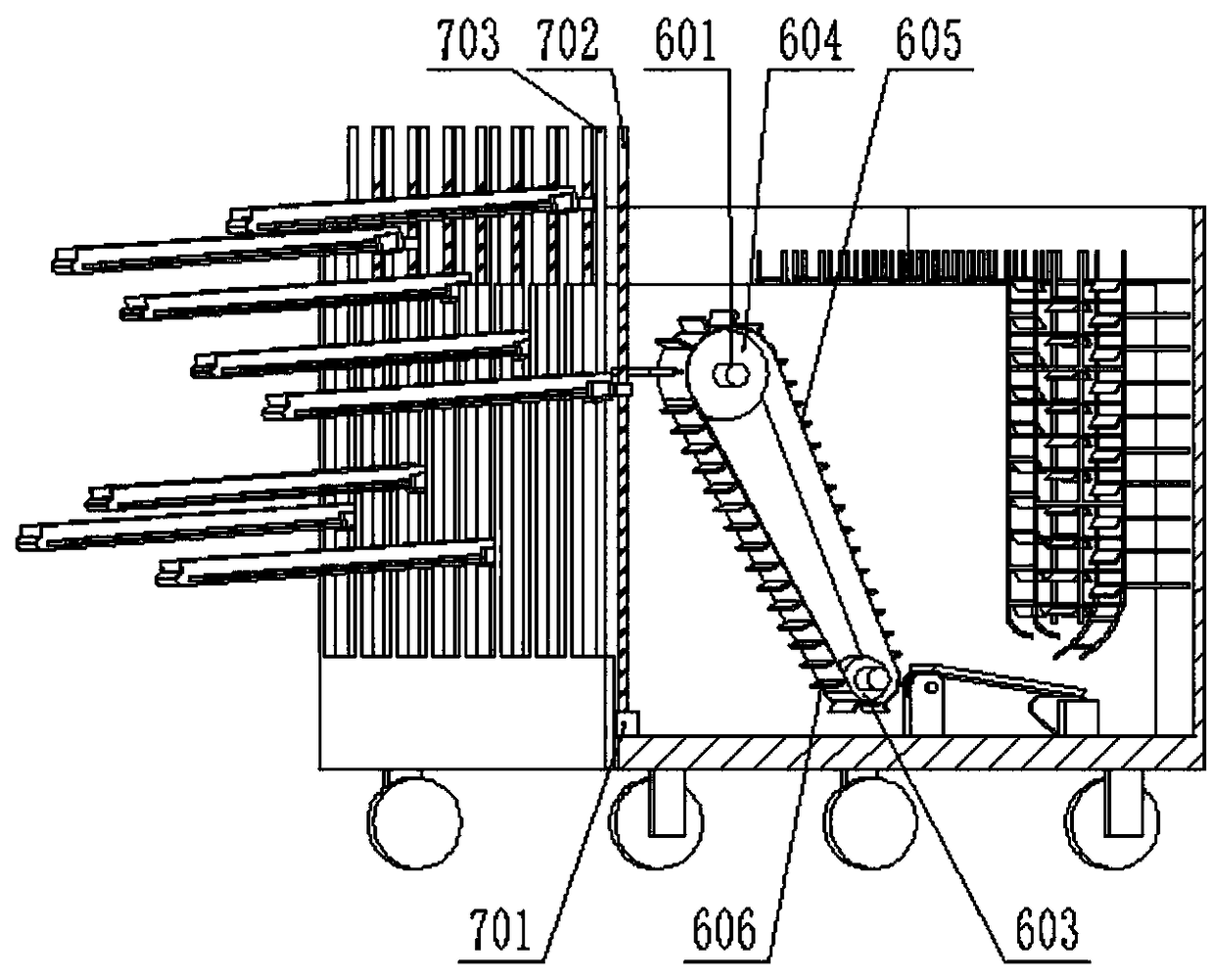

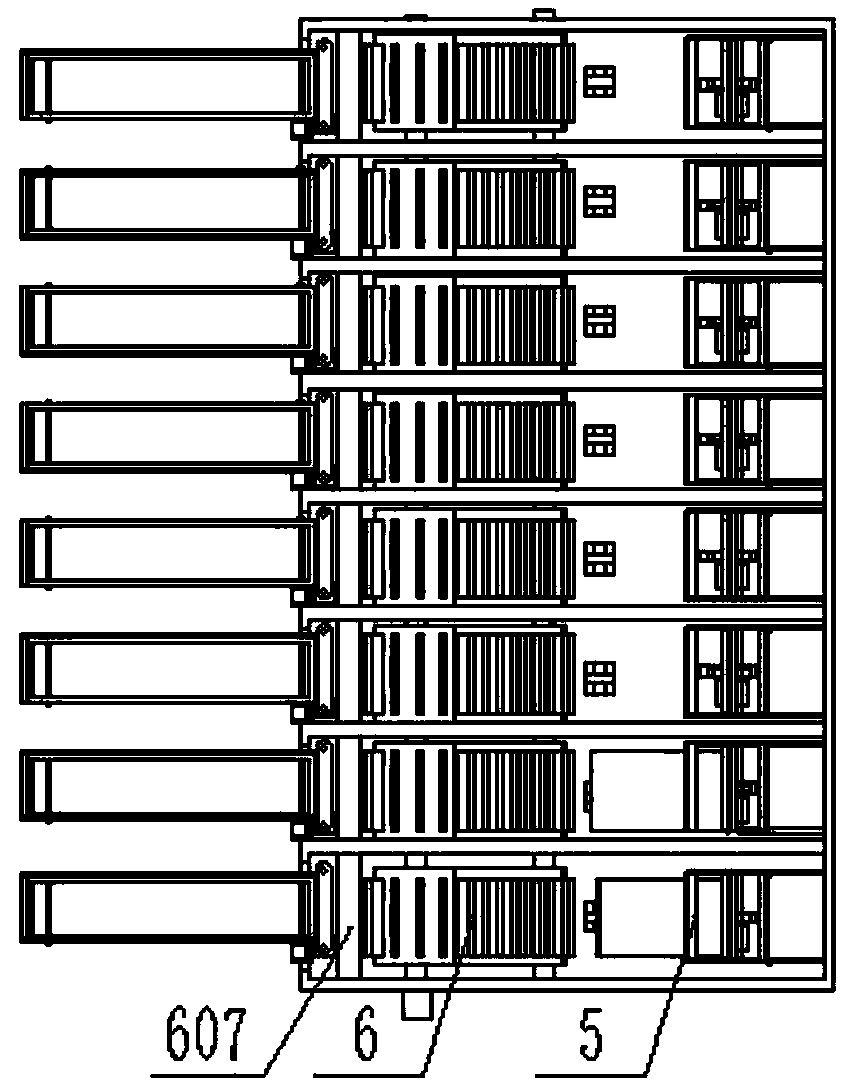

A special supply device for beverage vending machines

ActiveCN108053555BAchieve up and downIncrease the number of bloomsCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringPulley

The invention provides a goods supply device special for a drink vending machine, and belongs to the field of food equipment. The goods supply device comprises a cart body, foot stools, clapboards, containing mechanisms, guiding mechanisms, hoisting mechanisms, lifting mechanisms and feeding mechanisms, the inside of the cart body is hollow and is provided with a hollow chamber, belt pulley shaftgrooves are formed in the left side and the right side of the cart body, the foot stools are arranged at the four corners of the bottom of the cart body and are provided with wheels, the clapboards are equidistantly arranged inside the cart body, partition chambers are formed among the clapboards, the containing mechanism is fixedly connected to the rear portion of each partition chamber, the guiding mechanisms are arranged at the lower portions of the containing mechanisms, the hoisting mechanisms are arranged at the front portions of the guiding mechanisms, the lifting mechanisms are arranged at the front sides inside the partition chambers, and the feeding mechanisms are movably connected to the lifting mechanisms. The containing mechanisms are fixedly connected to the rear portions ofall the partition chambers, the guiding mechanisms are arranged at the lower portions of the containing mechanisms, classified placing of all different drinks is well achieved inside the cart body, and the drinks can slide on the hoisting mechanisms along the guiding mechanisms.

Owner:长沙中谷智能设备制造有限公司

Coumarin borax surface cross-linking modified precipitated calcium carbonate and its preparation method, application and a kind of paper

ActiveCN106758501BIncreased tensile indexIncreased burst indexInorganic compound additionPigment treatment with macromolecular organic compoundsCross-linkPrecipitated calcium carbonate

The invention provides modified precipitated calcium carbonate for crosslinking fenugreek gum on the surface through borax. Fenugreek gum is crosslinked on the surface of modified precipitated calcium carbonate through borax. The invention aims to provide modified precipitated calcium carbonate which can obviously increase the tensile index, the burst index, the tearing index and the filling one-way retention rate of paper when being applied to filling of the paper. Moreover, the invention further provides a preparation method and application of modified precipitated calcium carbonate; and furthermore, the invention further provides a piece of paper containing modified precipitated calcium carbonate.

Owner:WUZHOU UNIV

Guar gum boric acid surface cross-linking modified precipitated calcium carbonate and its preparation method, application and a kind of paper

ActiveCN106702811BIncreased tensile indexIncreased burst indexInorganic compound additionPigment treatment with macromolecular organic compoundsPrecipitated calcium carbonateBoric acid

Owner:WUZHOU UNIV

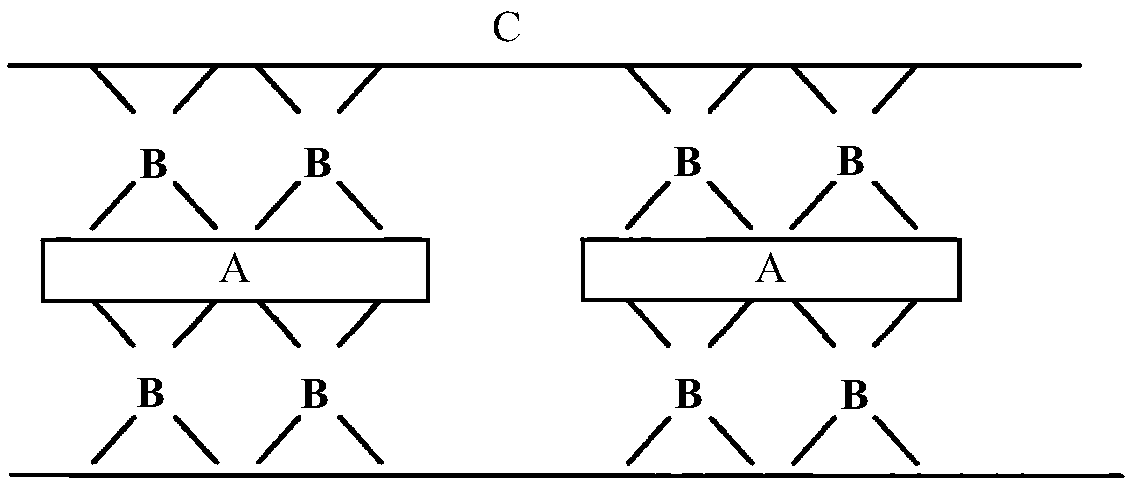

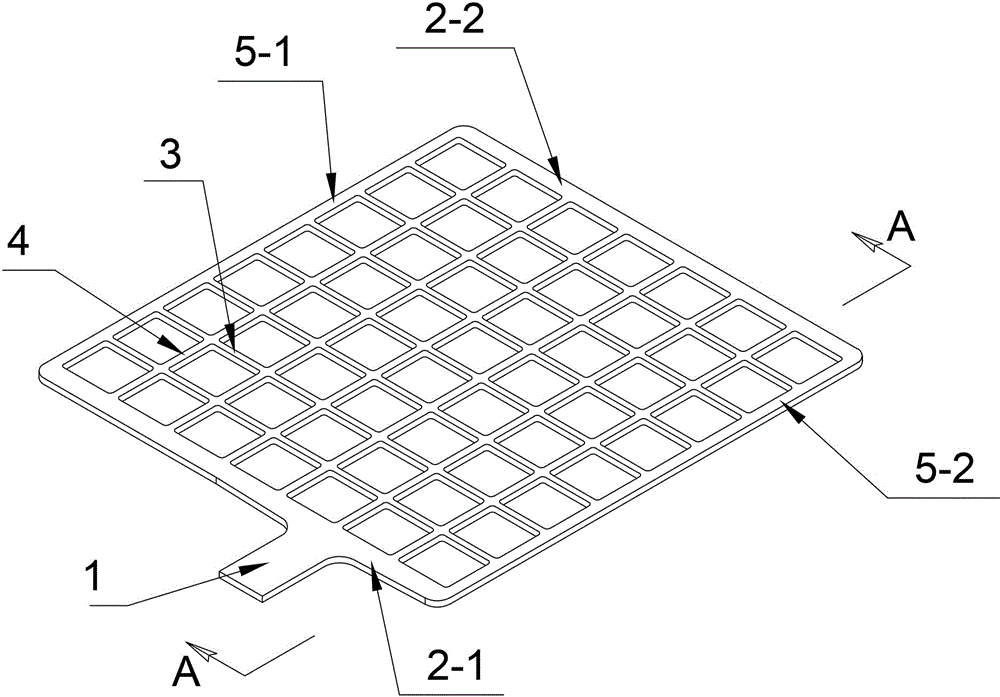

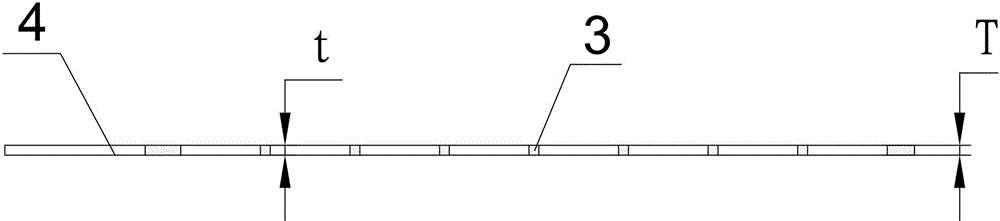

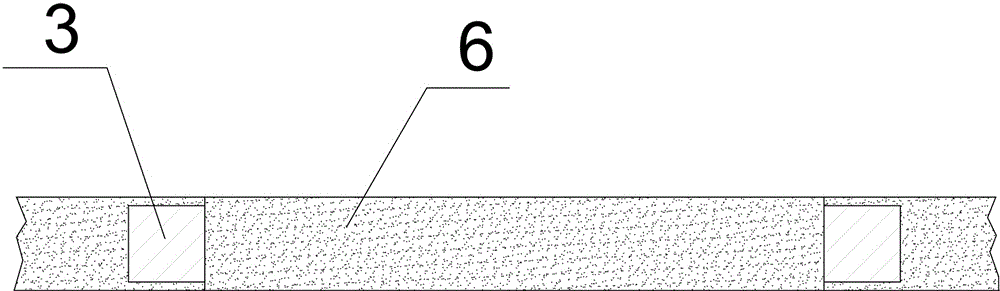

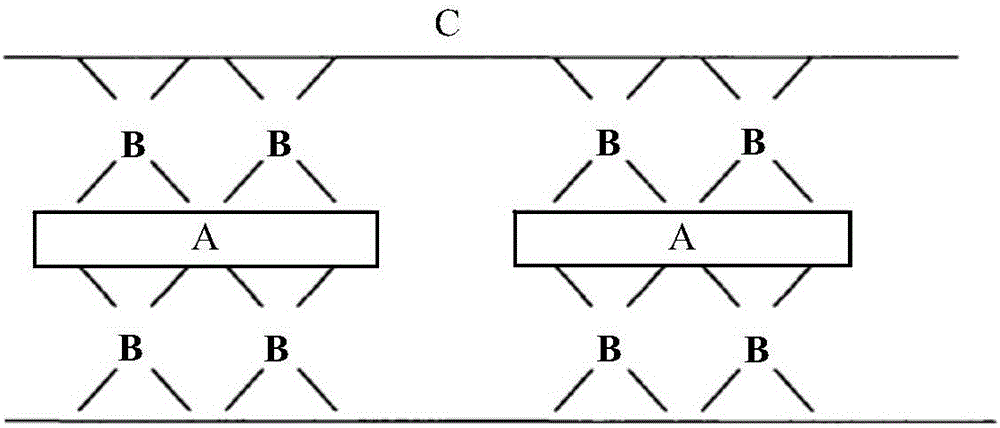

Lead-acid battery curved panel grid

ActiveCN103633335BIncrease coating thicknessIncrease the amount of fillingElectrode carriers/collectorsCurve shapeEngineering

The invention discloses a curved plate grid of a lead-acid storage battery. The curved plate grid comprises a frame, a plurality of ribs arranged inside the frame and a lug arranged on the frame, wherein the frame comprises longitudinal frames and transverse frames, and the ribs comprise longitudinal ribs and transverse ribs; the longitudinal ribs and the transverse ribs are interwoven into a rib net; the longitudinal frames and the longitudinal ribs or transverse ribs are of a continuous curve shape with obvious crests and troughs; the transverse ribs are of a straight line, and are positioned between the adjacent crests and troughs of the longitudinal ribs; an included angle is formed between the upper surfaces or lower surfaces of the transverse ribs and a plane of the grid. Compared with an existing grid, the curved plate grid has the advantage that the coating thickness of an active material is greatly increased on the basis that the existing grid and the curved plate grid are equal in weight, so that the full-filling quantity of the active material is increased, and the specific energy of the lead-acid storage battery is increased; the bonding strength between the active material and the grid can be greatly enhanced, the active material is favorably prevented from falling off, and thus the service life of the lead-acid storage battery is prolonged.

Owner:BAODING GOLDEN SUNLIGHT POWER EQUIP TECH

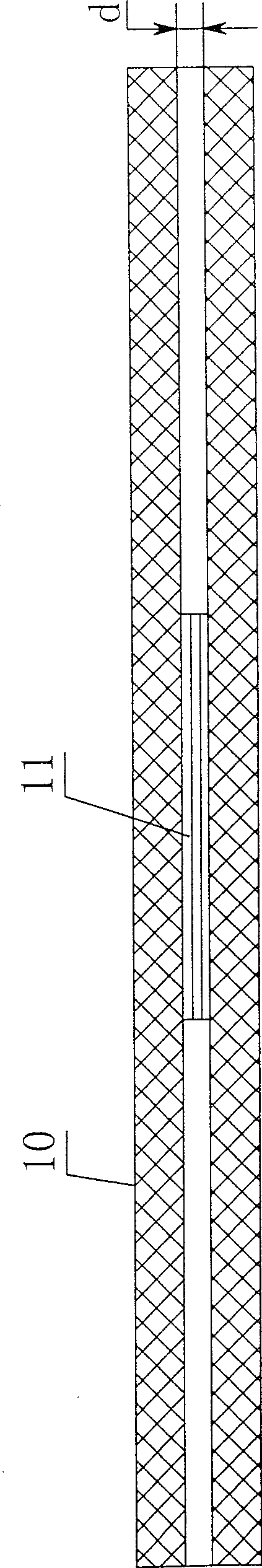

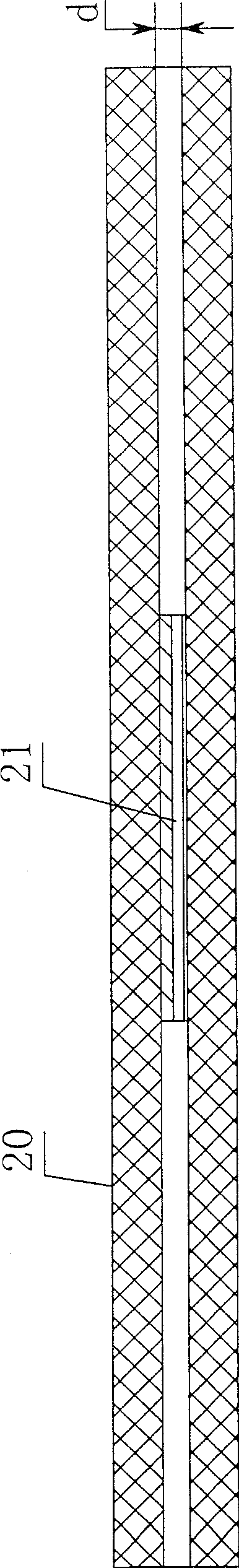

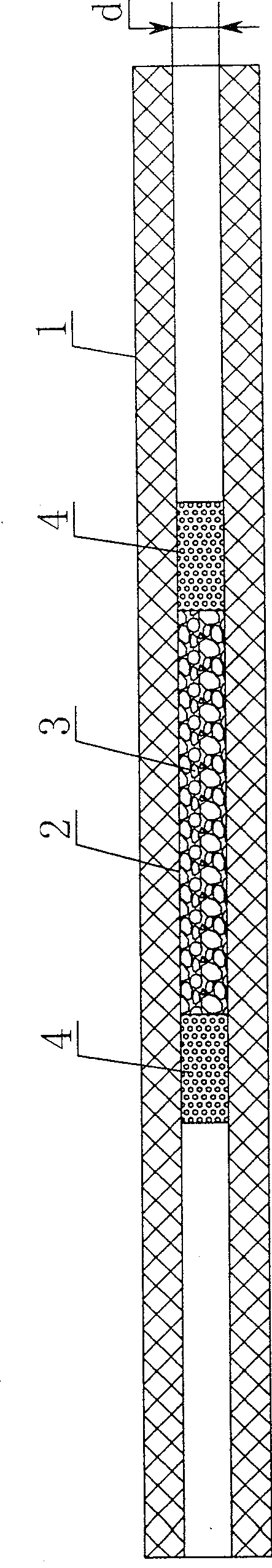

Ceramic oxidation pipe used in carbon isotope of natural gas analysis

InactiveCN100526879CIncrease the amount of fillingIncrease the reaction contact areaChemical analysis using combustionGas analysisIsotope

The invention discloses a ceramic oxidation tube for the analysis of natural gas carbon isotopes, and aims to provide an oxidation tube with good oxidation effect, stable analysis data and long service life. There are copper oxide particles, and the particle size of copper oxide particles is 0.3-0.5mm; the inner diameter of the pipe is 1.2-1.5mm, and there are also pure copper particle areas on both sides of the high-temperature area in the pipe; the oxidation pipe of the present invention is used for natural gas carbon isotope analysis experiments .

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Modified precipitated calcium carbonate prepared by crosslinking konjac gum on surface through organic boron, preparation method and application thereof and paper

ActiveCN106758502AIncreased tensile indexIncreased burst indexInorganic compound additionPigment treatment with macromolecular organic compoundsPrecipitated calcium carbonateBoron

The invention provides modified precipitated calcium carbonate prepared by crosslinking konjac gum on the surface through organic boron. The surface of modified precipitated calcium carbonate is crosslinked with the konjac gum through the organic boron. The invention aims to provide modified precipitated calcium carbonate which can significantly improve the tensile index, the burst index and the tear index of paper and the one-way retention rate of a filler when being applied to the filler in the paper. The invention further provides a preparation method and application of modified precipitated calcium carbonate. In addition, the invention further provides the paper containing modified precipitated calcium carbonate.

Owner:WUZHOU UNIV

A double-block ballastless track bridge base transverse formwork positioning device

ActiveCN110219251BPrevent deviationIncrease the amount of fillingBridge erection/assemblyRailway track constructionTrackwayClassical mechanics

Owner:中南建设集团有限公司

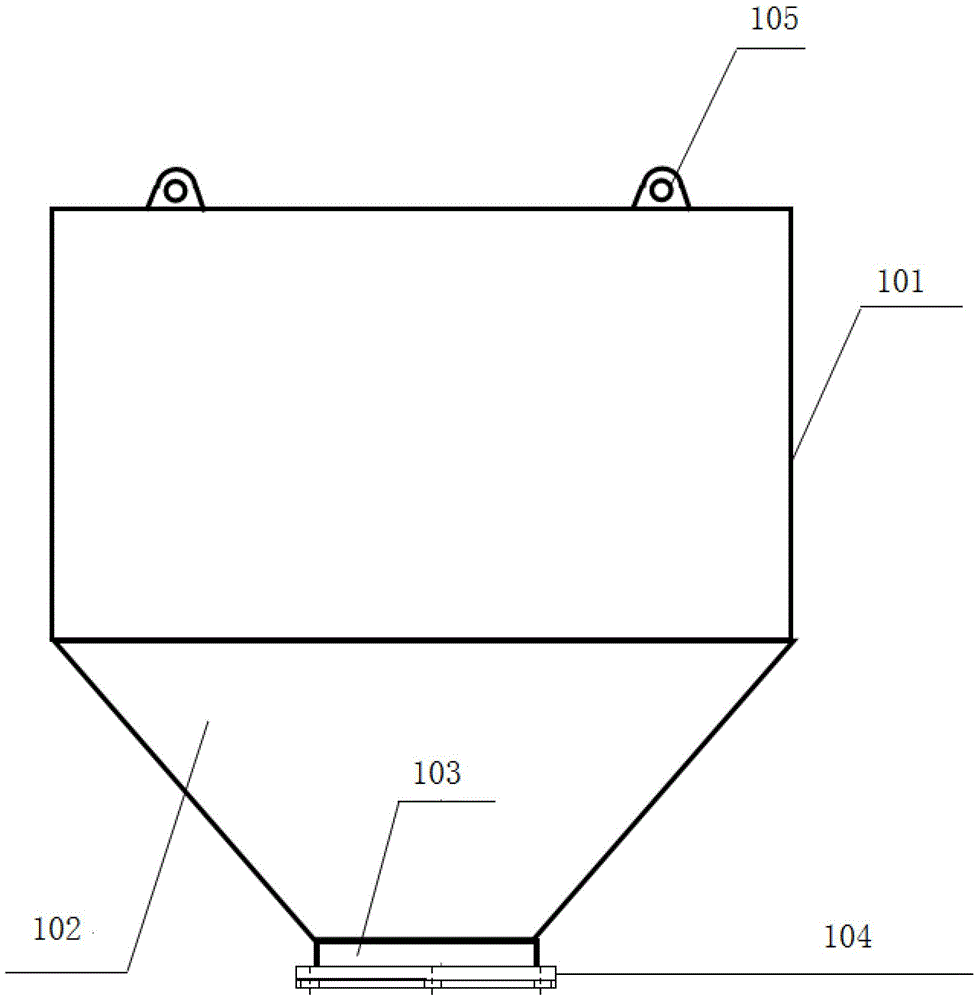

Preparation method of microcapsule paper

ActiveCN112726277BIncrease the amount of fillingEvenly dispersedNon-fibrous pulp additionPaper/cardboardCellulosePolymer science

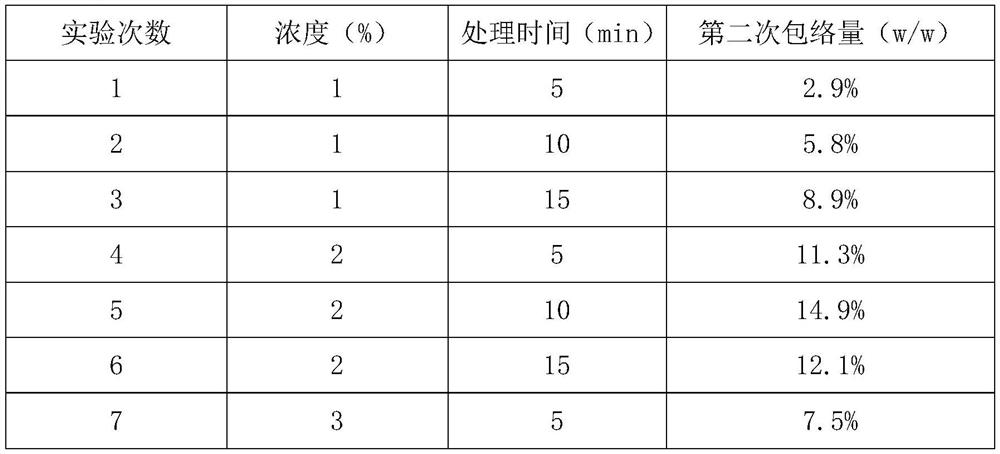

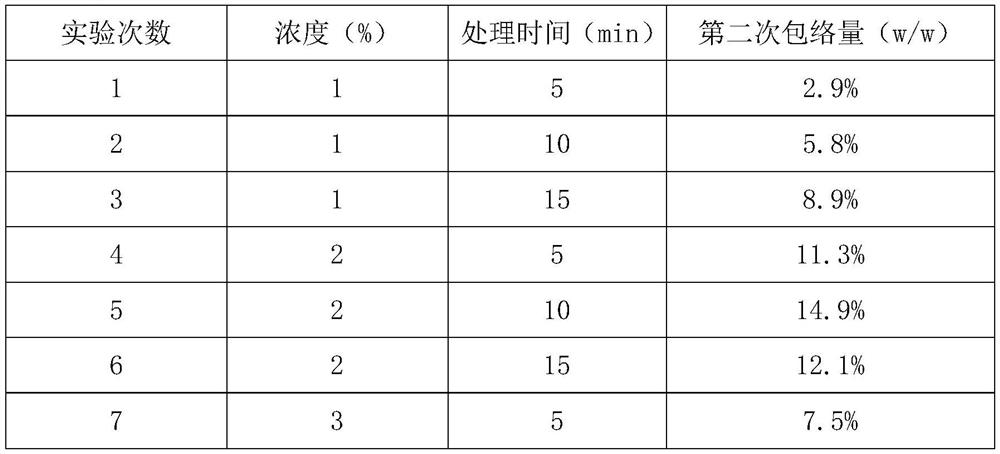

The invention discloses a preparation method of microcapsule paper. The method comprises the following steps: 1) using a sheet former to make a thin wet paper web with a weight of 15-20g / m2; 2) adding the microcapsule enveloping system between two wet papers through an interlayer filling process, 3) High-enveloping microcapsule paper is prepared by pressing and drying processes; wherein, the preparation method of the microcapsule enveloping system is: 21) Microcapsules with nano-fibrillated cellulose and β-cyclodextrin as the main body Mix and stir; form a CNF / microcapsule dispersion system; 22) at room temperature, add 1-3% lithium acrylate solution to the CNF / microcapsule dispersion system for pretreatment for 5-15min; 23) pretreat the CNF / microcapsule The dispersion system is centrifugally washed to neutrality; 24) Microcapsules with a solid content of 10%-15% are reenveloped in the washed CNF / microcapsule dispersion system, and the synergistic dispersion effect is supplemented by ultrasonic waves and stirring. The step-by-step enveloping microcapsule pre-enveloping system of the present invention can make the filling amount of microcapsules much higher than the content of microcapsules in paper made by mixing common pulp and microcapsules.

Owner:FUJIAN HENGAN HYGIENE MATERIAL

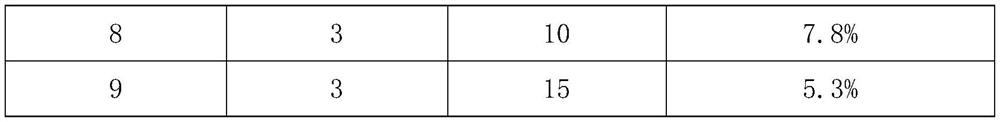

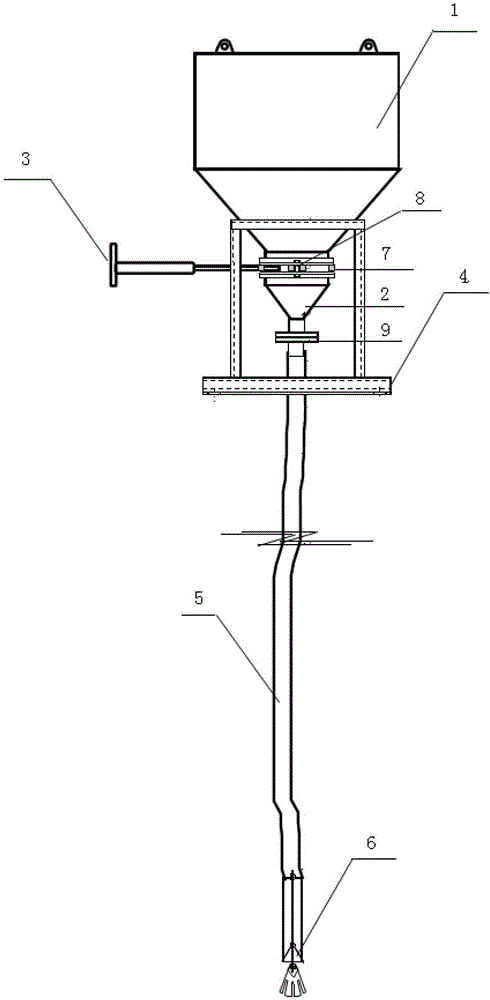

Catalyst feeder

InactiveCN103449197BIncrease resistanceAvoid mechanical damageLoading/unloadingEngineeringDistributor

The invention discloses a catalyst feeding device which comprises a feed bin, a buffering bin, a feeding switching valve, a feed bin base, a conveying pipe and a distributor. The feed bin is positioned above the buffering bin and connected with the buffering bin through a bolt, and two sides of the bolt are respectively provided with a cushion block. The feeding switching valve is arranged between the feed bin and the buffering bin, the conveying pipe is a corrugated plastic hose, the upper end of the conveying pipe is connected with the buffering bin, the conveying pipe penetrates a central hole in the bottom of the feed bin base, the lower end of the conveying pipe is sleeved on the outer side of a distributing pipe of the distributor, and the lower portion of the buffering bin is placed in a frame of the feed bin base. The catalyst feeding device has the advantages that mechanical damage can be effectively prevented in the catalyst feeding process, catalysts are uniformly distributed, feeding speed is conveniently controlled, and the like.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

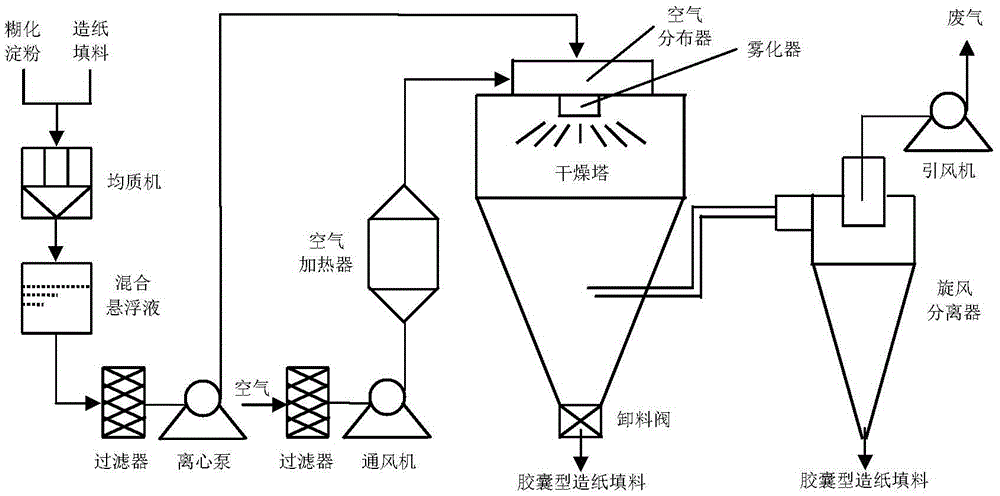

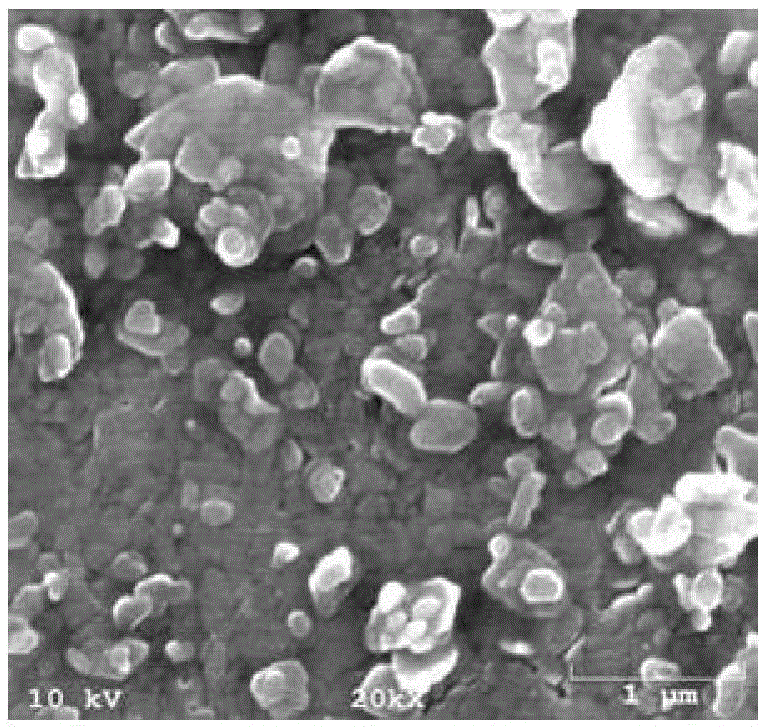

Method for preparing capsule-type paper-making filler by spray-drying starch

The invention discloses a method for preparing capsule type papermaking filler by spray drying of starch. The method comprises the following steps: weighing starch with a certain quantity, evenly dispersing by water, and carrying out gelatinization; weighing papermaking filler with a certain quantity, dispersing by water, and homogenizing; mixing the papermaking filler with the homogenized starch, and homogenizing; carrying out spray drying on mixture of the papermaking filler and the gelatinized starch, and packing a starch layer onto the surface of papermaking filler particle to obtain the starch-packed capsule type papermaking filler. The method has the characters of simple technology, low cost, easiness in operation, obvious modification effect and the like. Compared with the unmodified papermaking filler, the capsule type papermaking filler can improve the filling quantity of paper, save the plant fiber raw materials, observably improve the physical strength performance of filling paper, and improve the quality of the final paper product.

Owner:FUJIAN AGRI & FORESTRY UNIV

Displacement vector filling method based on approximate spherical filling of energetic materials

ActiveCN105160052BAvoid large gapsIncrease the amount of fillingSpecial data processing applicationsFilling materialsClassical mechanics

The present invention claims to protect a displacement vector filling method based on the approximate spherical filling of energetic materials, which includes the steps of randomly placing spherical particles into the compression chamber according to the radius from large to small, and after completing the spherical particle placement stage , enter the adjustment stage; the adjustment stage is divided into three processes, that is, the spherical particles move to the negative direction of the x-axis according to the x-axis coordinates from small to large, and then move to the negative direction of the y-axis according to the y-axis coordinates from small to large, and finally press The z-axis coordinates move from small to large in the negative direction of the z-axis; in the present invention, after the above-mentioned particle movement, the inter-particle gaps are minimized, and the cabin can continue to be filled to increase the filling rate.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com