Ceramic oxidation pipe used in carbon isotope of natural gas analysis

A carbon isotope, ceramic oxidation technology, applied in the direction of chemical analysis using combustion, can solve the problems of poor methane oxidation effect, unstable analysis data, small reaction surface area, etc., to improve analysis precision and accuracy, increase reaction contact The effect of large area and contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

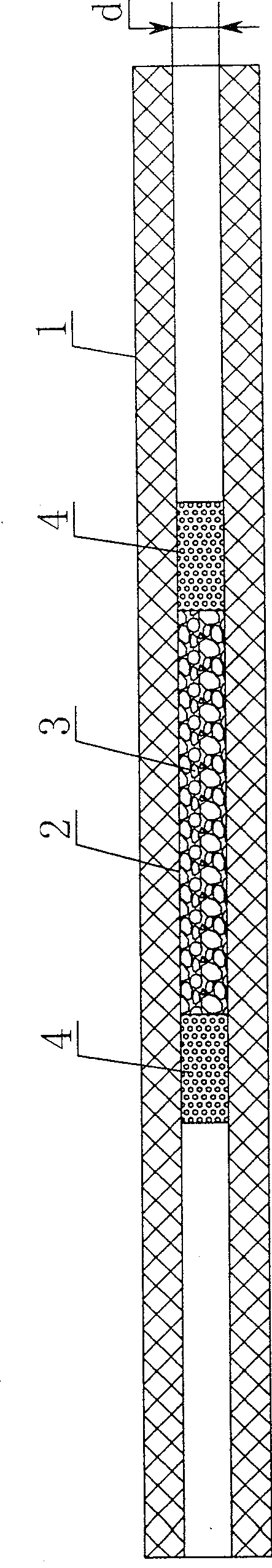

[0018] participate image 3 As shown, the ceramic oxidation tube for carbon isotope analysis of natural gas of the present invention includes a ceramic tube body 1. The high temperature zone 2 of the tube body 1 is filled with copper oxide particles 3, and the particle size of the copper oxide particles 3 is 0.3-0.5 mm ; The inner diameter of the tube body 1 is 1.2 ~ 1.5mm, and there are also pure copper particle regions 4 on both sides of the high temperature zone 2 in the tube.

[0019] The specific use method of the oxidation tube of the present invention is the same as that of the traditional oxidation tube, but when heating, the temperature of the high temperature zone 2 only needs to be heated to 850°C, and the methane gas in the sample can get a good reaction effect with the copper oxide particles 3 ; At the same time, using the heat transfer of the ceramic tube body 1, the pure copper particle area 4 can reach a reaction temperature of about 550 ℃, so that the hydrogen sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com