Catalyst feeder

A feeding device and catalyst technology, which is applied in transportation, packaging, loading/unloading, etc., can solve the problems of affecting the efficiency and output of hydrogenation reaction, affecting the service life of the catalyst, and the large gap of the catalyst, so that the feeding speed is easy to control, The effect of improving the feeding efficiency and uniform catalyst distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

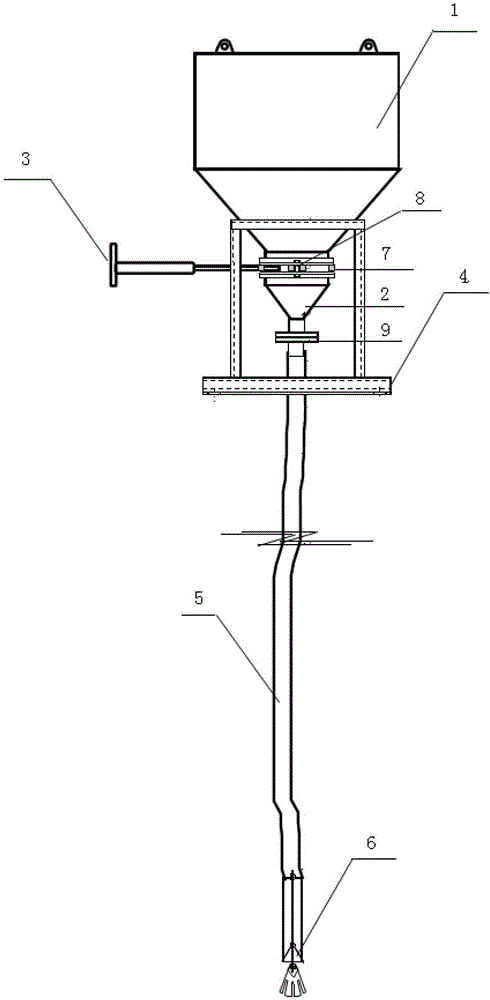

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] The feeding pipe body of the present invention is a hydrogenation primary reactor, the height of the tank body is 17.6 meters, and the diameter is 0.9 meters. The main components in the tank are a catalyst bed, a liquid distributor tray and several catalyst support grids. Before using the device, remove the bolts on the flange D of the top end cover, remove the end cover of the reactor, lift the device to the top of the tank by a crane, and place it on the flange D of the top end cover. The device of the present invention will be described in detail below in conjunction with the accompanying drawings.

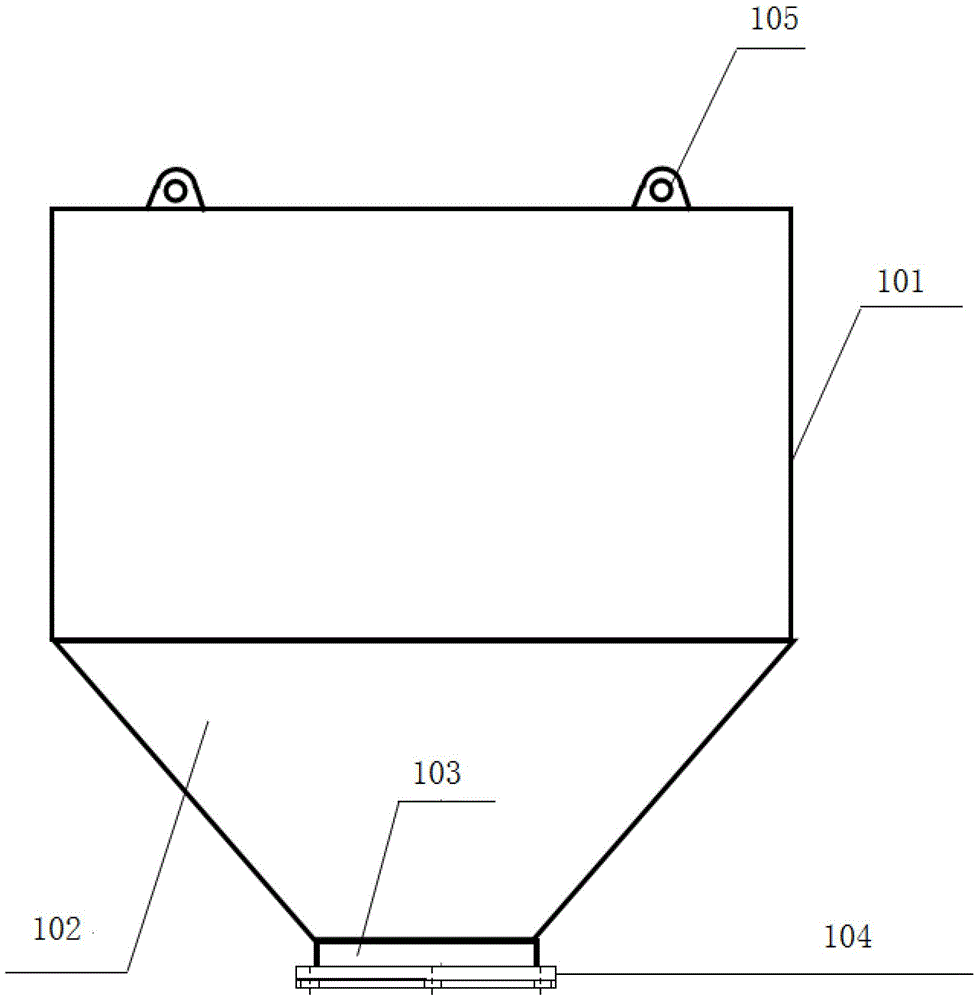

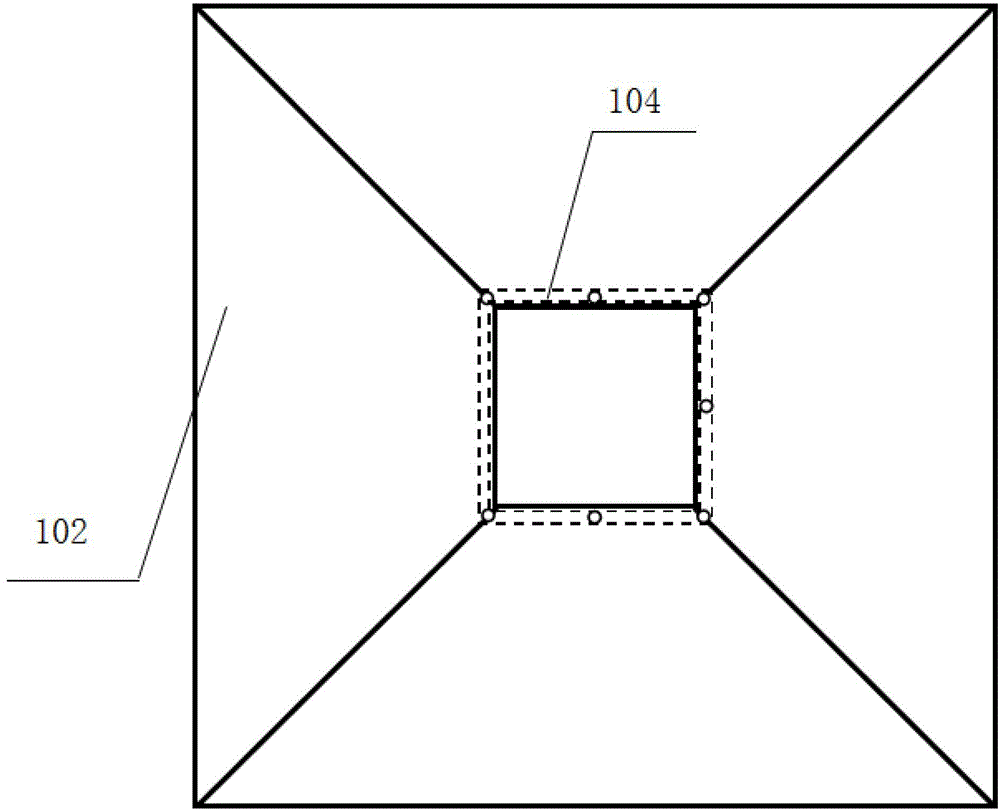

[0030] Such as figure 1 , The structural diagram of the benzene hydrogenation catalyst feeding device of the present invention, the device is composed of a feed bin 1, a buffer bin 2, a feed switch valve 3, a feed bin b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com