Preparation method of microcapsule paper

A technology of microcapsules and paper sheets, applied in the directions of microcapsule preparation, microsphere preparation, papermaking, etc., can solve the problems of loss of microcapsules, low filling amount of microcapsules, and insignificant effect of mixing and papermaking, and achieves increased interlayer bonding. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Softwood and hardwood chemical pulp board, beating degree 40-50°SR; cationic polyacrylamide content 0.03-0.05% mass fraction (retention aid);

[0025] A paper former is used to make thin paper with a basis weight of 15-20g / m2, and the CNF / microcapsule encapsulation system is added between two wet paper webs through the interlayer filling process, and then pressed and dried, using nanocellulose and A large number of hydroxyl groups on the surface of the microcapsules form hydrogen bonds with the upper and lower paper webs, which can not only make the connection between the upper and lower layers tighter, but also allow the microcapsules to be completely filled into the paper without causing a large amount of microcapsules to be lost. to all add fill effects.

[0026] The preparation process of CNF / microcapsule encapsulation system is as follows:

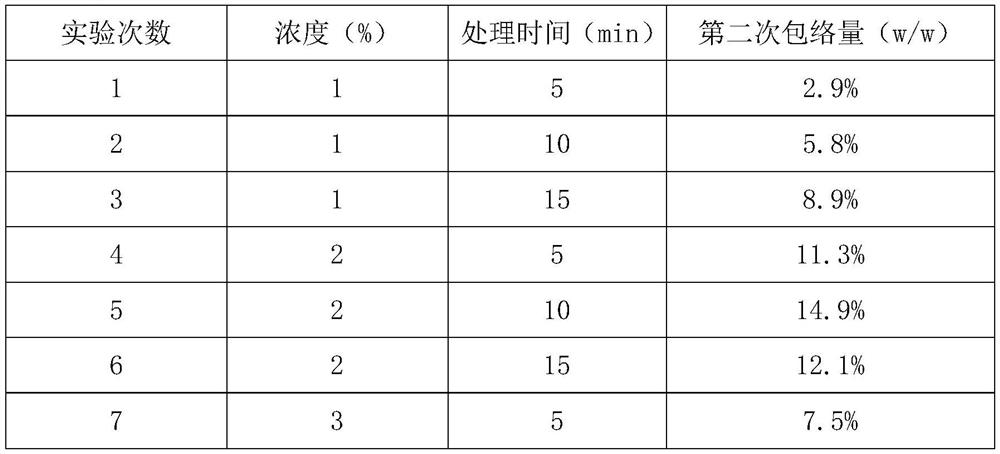

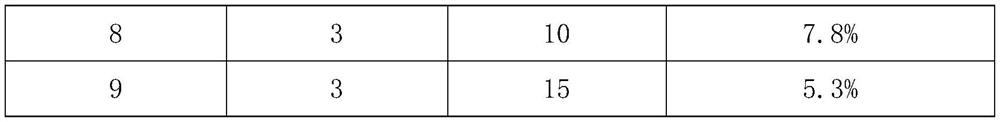

[0027] (1) Mix and stir the nanofibrillated cellulose with a solid content of 1-3% and β-cyclodextrin as the main body (addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com