Patents

Literature

97results about How to "Increased tensile index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

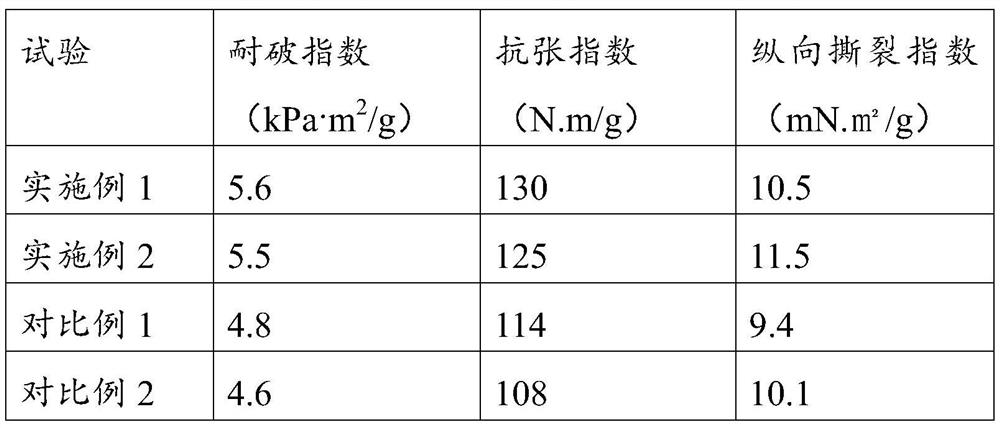

Method for preparing antibacterial paper on the basis of interlayer self-assembling technology

InactiveCN102587196AIncreased tensile indexHigh folding resistanceNon-fibrous pulp additionPaper/cardboardCelluloseFiber

The invention discloses a method for preparing antibacterial paper on the basis of an interlayer self-assembling technology. In the method, cationic polyelectrolyte chitosan biguanide hydrochloride (CGH) with an antibacterial function, and anionic polyelectrolyte carboxymethyl cellulose sodium (CMC) are alternately deposited on the surface of a bleached kraft hardwood fiber to prepare a layered ordered self-assembled multilayer ultrathin film, which can improve the strength property of a paper sheet while endowing the paper sheet with a good antibacterial performance. Through the change of the environment and the technical conditions of an interlayer self-assembling system, multilayer film structures with different properties can be obtained on the surface of the bleached kraft hardwood fiber, the retention of an antibacterial agent on the fiber is improved, and the antibacterial effect of the paper sheet is enhanced; a layered ordered self-assembled nano-film is prepared by taking a negatively-charged fiber as a matrix and controlling the adsorption process of a reverse-phase ion system,; the preparation method is simple in production process, less in equipment investment and high in adaptability; the prepared antibacterial paper has better antibacterial performance and strength property; and antibacterial requirements of household paper and food packaging paper can be met better.

Owner:ZHEJIANG SCI-TECH UNIV

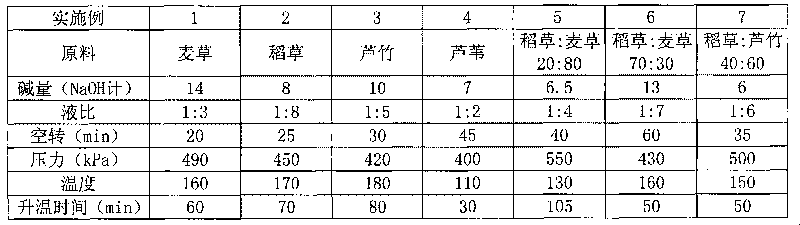

High-air-permeability mixed pulp and household paper made thereof

ActiveCN101760987AEasy to useReduce consumptionNatural cellulose pulp/paperPulping with inorganic basesFiberChemistry

The invention relates to high-air-permeability mixed pulp, which contains high-air-permeability straw pulp. The mixed pulp contains 10-100 percent of high-air-permeability straw pulp and 0-90 percent of other pulp by weight percent. Preferably, the weight percent of the high-air-permeability straw pulp is 30-97 percent and the weight percent of other pulp is 3-70 percent. More preferably, the weight percent of the high-air-permeability straw pulp is 51-95 percent and the weight percent of other pulp is 5-49 percent. The most preferably, the weight percent of the high-air-permeability straw pulp is 71-93 percent and the weight percent of other pulp is 7-29 percent. The other pulp is one or more of wood pulp, bamboo pulp, cotton pulp and secondary fiber. Preferably, the wood pulp and the bamboo pulp are selected. The mixed pulp has the advantages that the drainage capacity is good, the high-speed paper machine can be used during papermaking and the production efficiency is further improved.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Method for removing metal ions of paper pulp and bleaching

The invention relates to a method for removing metal ions of paper pulp and bleaching and relates to a technique for removing metal ions of paper pulp and applications thereof in bleaching, belonging to the technical field of paper making. The method comprises the following steps of: (1) carrying out pretreatment for removing metal ions of the paper pulp, namely under the existence of Mg(CH(3)COO)2, Ca(CH(3)COO)2 and EDTA (disodium ethylene diamine tetraacetate), carrying out bleaching pretreatment to deoxidizing sulfate pulp; and (2) carrying out following no-pollution bleaching, carrying out following secondary bleaching treatment consisting of a peroxyacetic acid bleaching stage and a hydrogen peroxide bleaching stage on the paper pulp after the pretreatment for removing metal ions. The invention is simple and easy to operate and has obvious effect; the removal rate of the metal ions is high, and the removal rate of Mn is 80.5 percent. Compared with the conventional EDTA chelation treatment, the strength performance of the paper pulp can be improved; the Mg(CH3COO)2 and the Ca(CH3COO)2 can replace 60 percent of EDTA, consequently, the accumulative effect toxicity of the conventional chelating agent can be obviously reduced.

Owner:KUNMING UNIV OF SCI & TECH

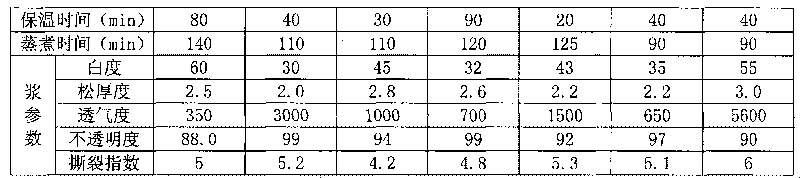

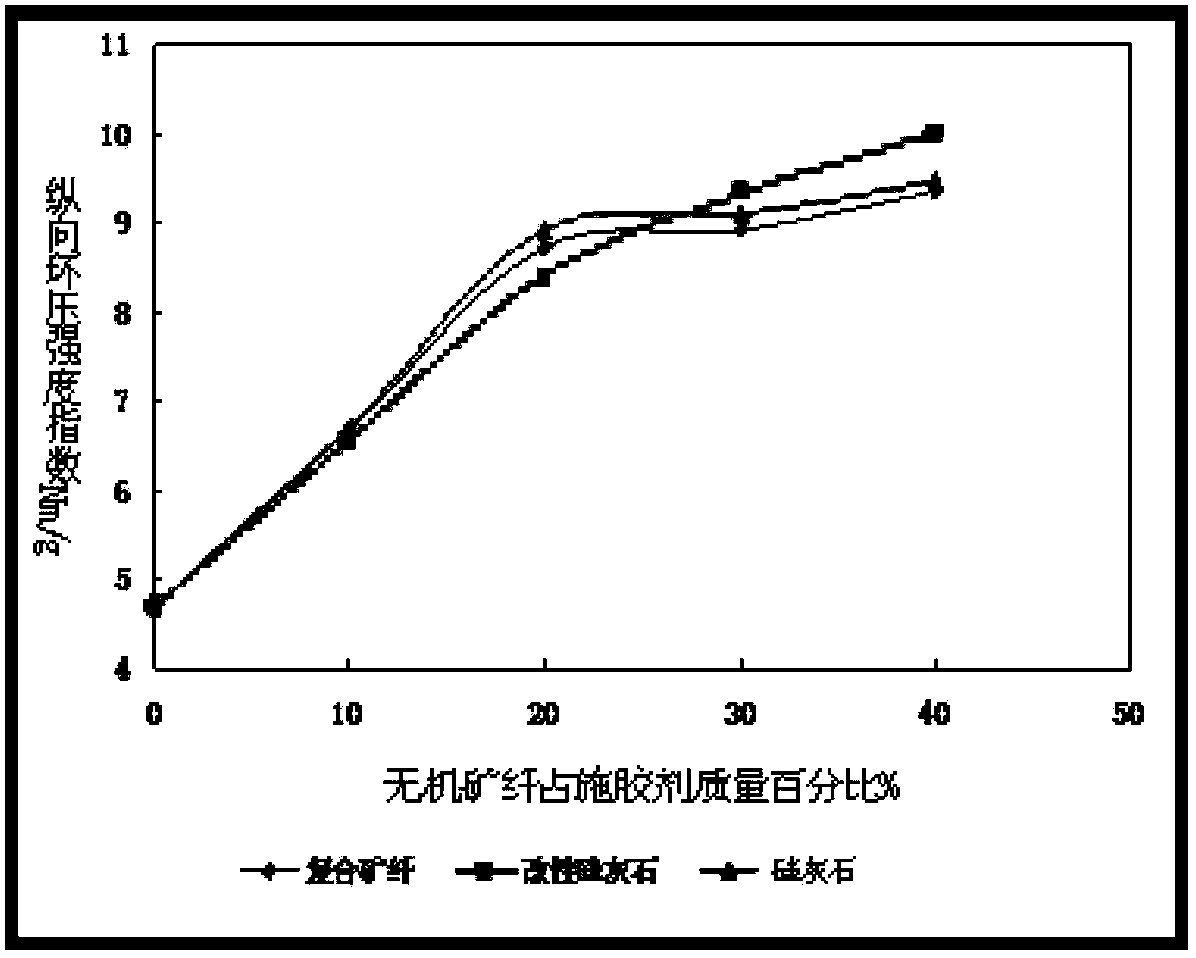

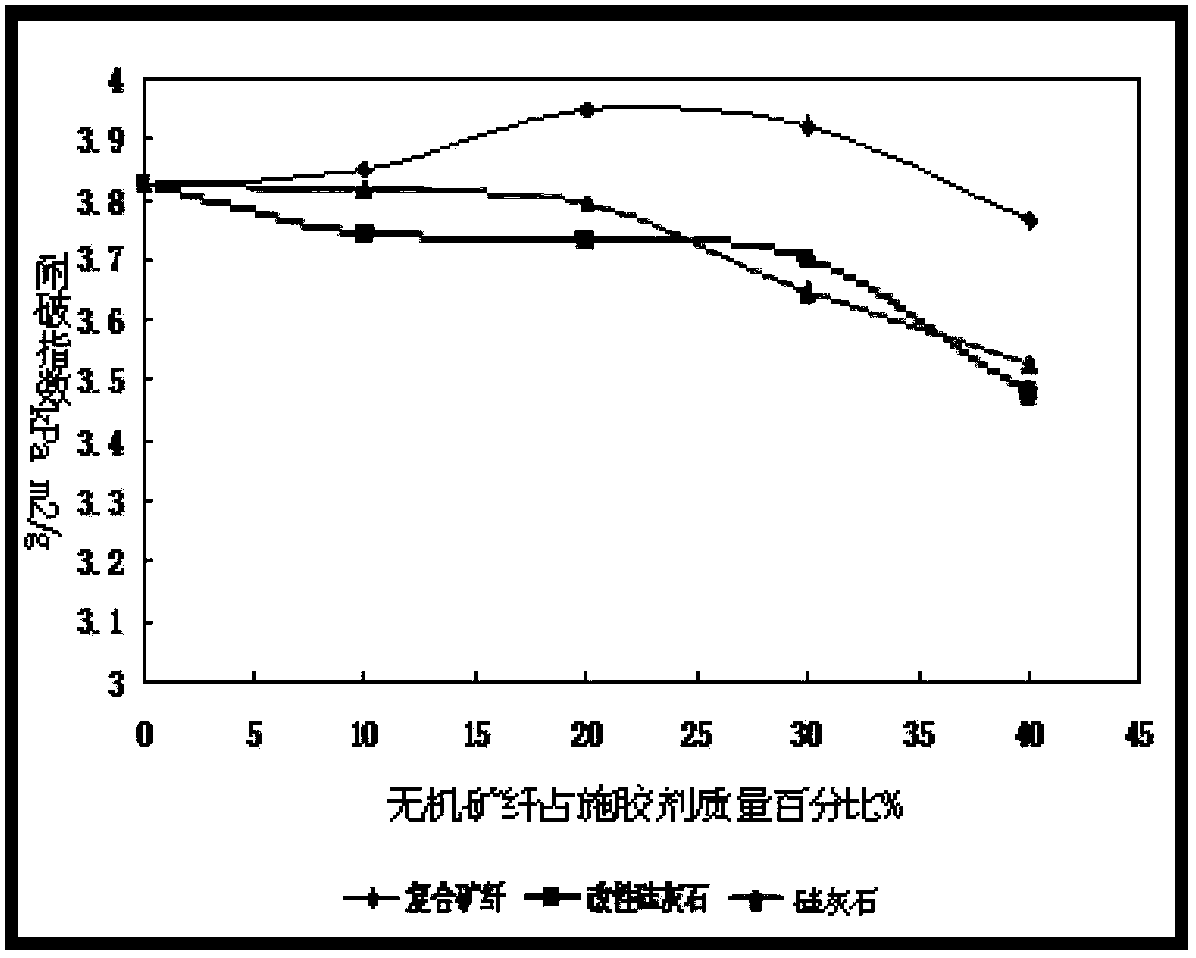

Inorganic mineral fiber ring crush strength-improvement surface sizing agent for papermaking and preparation method thereof

ActiveCN103388286AIncreased ring compressive strengthReduce paper production costsWater-repelling agents additionPapermakingSizing

The invention relates to an inorganic mineral fiber ring crush strength-improvement surface sizing agent for papermaking and a preparation method thereof. The inorganic mineral fiber ring crush strength-improvement surface sizing agent comprises surface sizing starch and inorganic mineral fibers. The mineral fibers comprise composite mineral fibers, modified wollastonite or wollastonite. The inorganic mineral fiber ring crush strength-improvement surface sizing agent comprises 5-40wt% of the inorganic mineral fibers. The norganic mineral fiber ring crush strength-improvement surface sizing agent can greatly improve corrugated paper ring crush strength and improve a tensile index and folding strength of a coated paper.

Owner:大连环球矿产股份有限公司

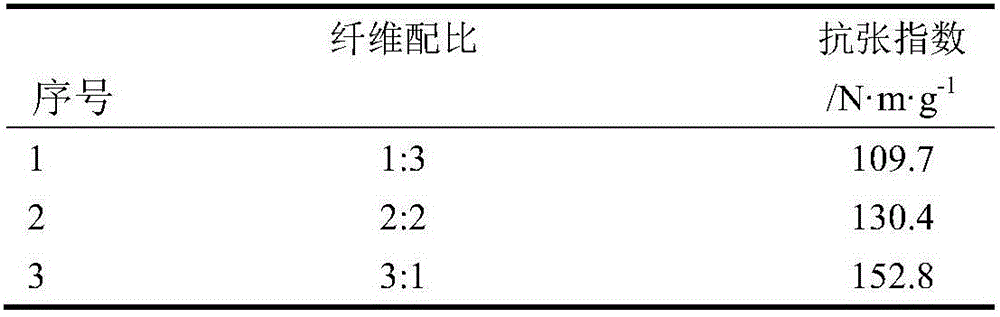

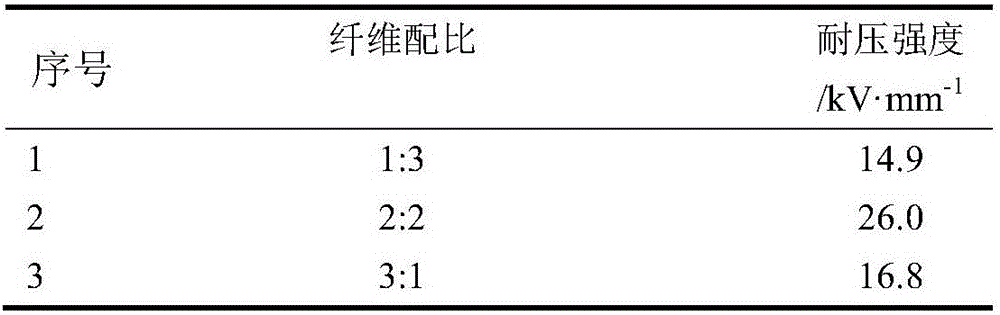

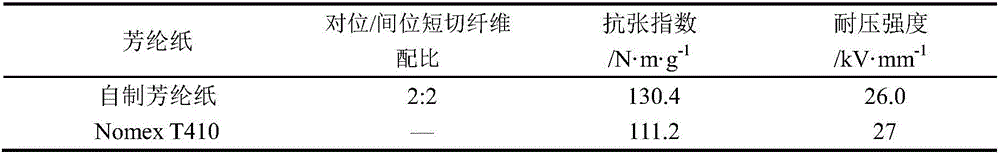

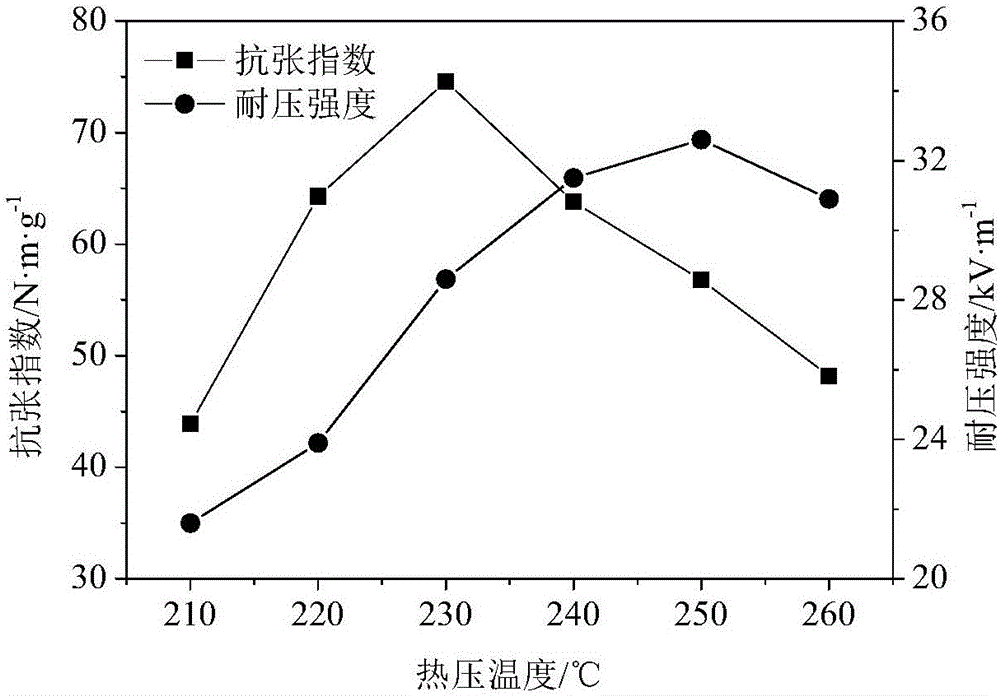

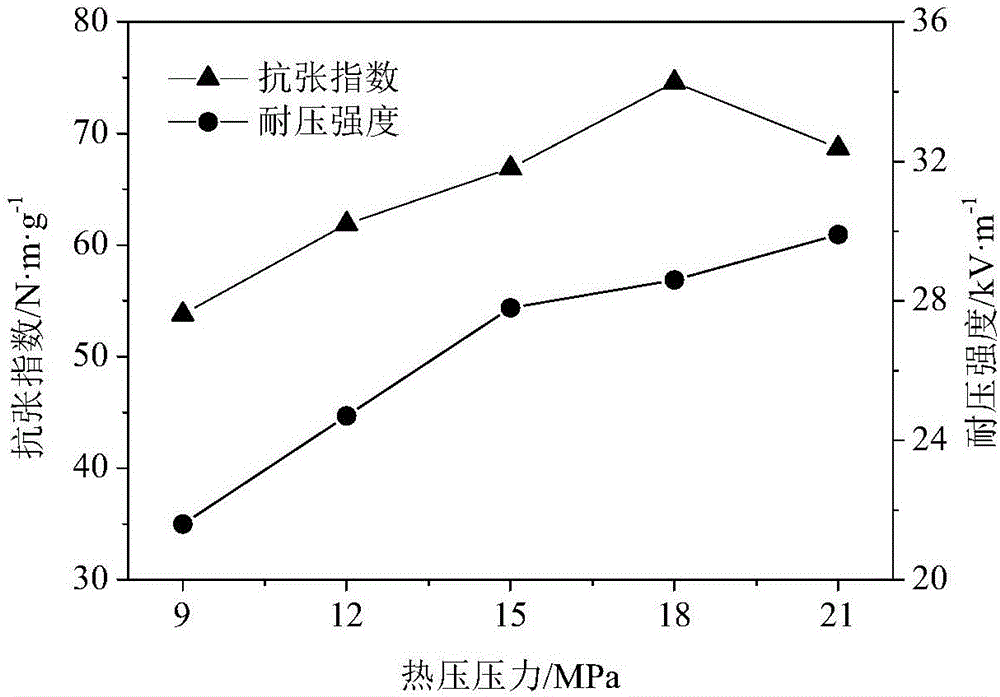

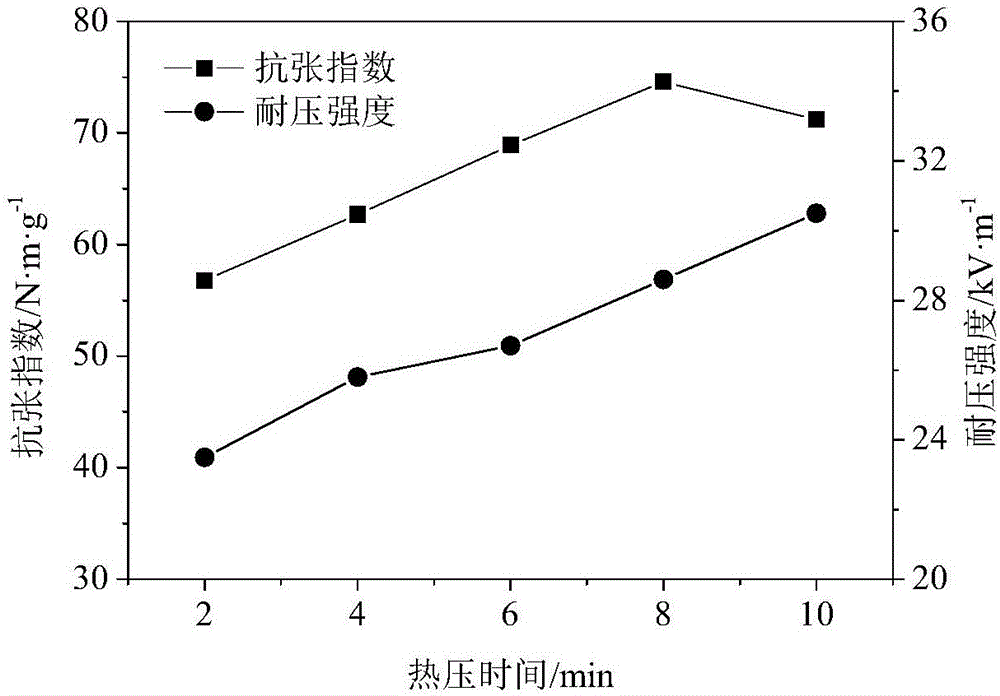

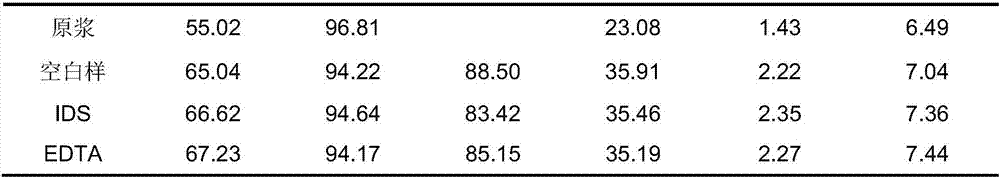

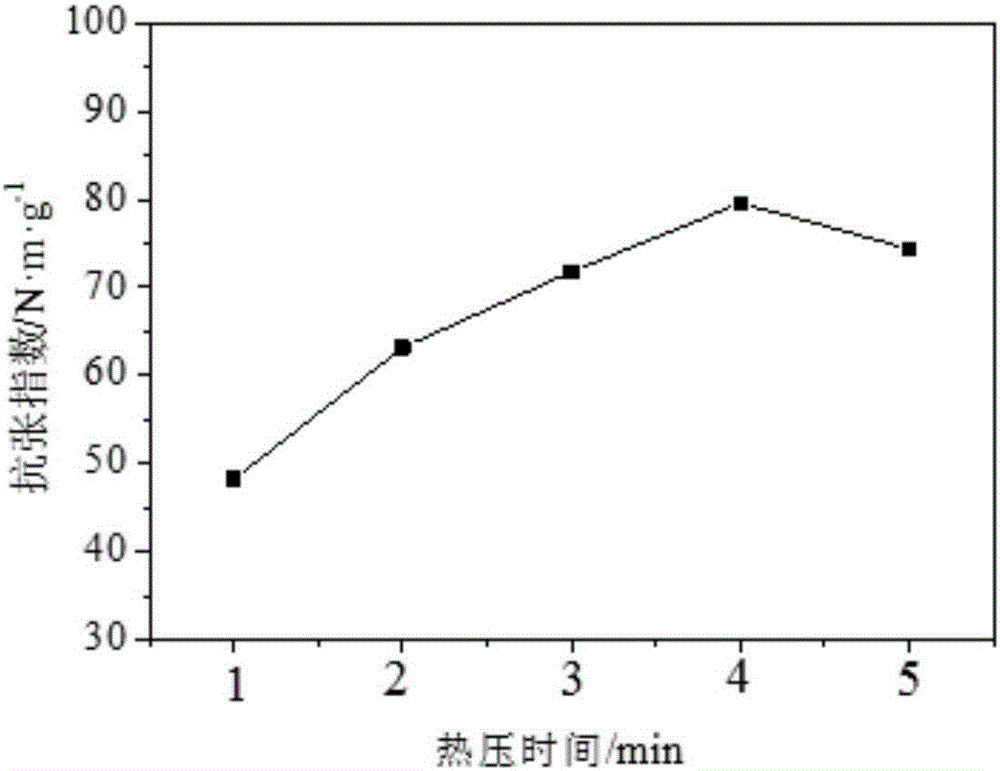

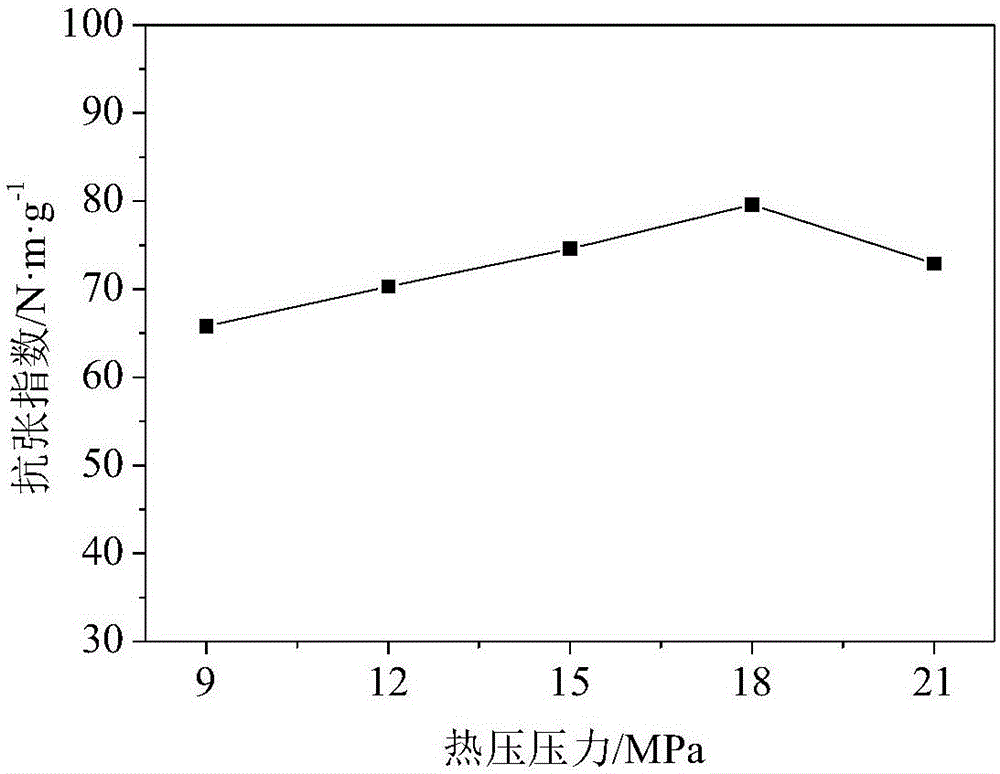

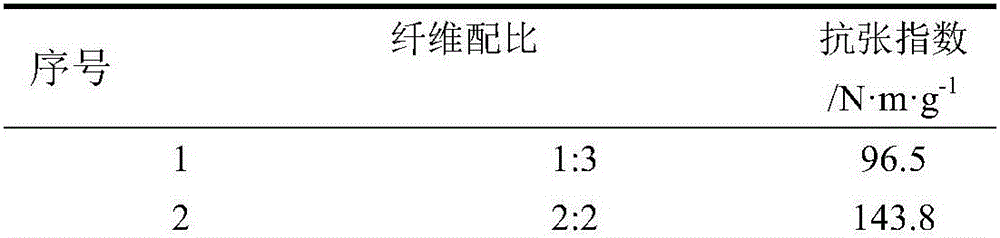

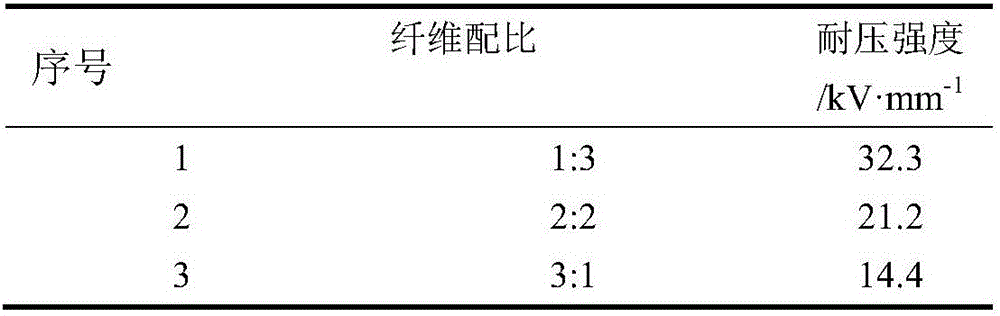

Preparation method of para-aramid and meta-aramid electrical insulation paper

ActiveCN106223129AIncreased tensile indexHigh strengthPlastic/resin/waxes insulatorsSpecial paperElectrical insulation paperHigh intensity

The invention discloses a preparation method of para-aramid and meta-aramid electrical insulation paper. The method comprises the following steps that para-aramid chopped fibers are preprocessed for use; meta-aramid chopped fibers are preprocessed; the preprocessed para-aramid chopped fibers and the preprocessed meta-aramid chopped fibers are mixed in a fluffer for primary defibering; then meta-aramid pulp fibers are added for secondary defibering; lastly, a dispersing agent is added for third defibering, and suspension liquid is obtained; the obtained suspension liquid is injected into a sheet forming device for dewatering forming, and body paper of the aramid electrical insulation paper is obtained after pressing and drying treatment; the obtained body paper of the aramid electrical insulation paper is subjected to hot press molding, and the aramid electrical insulation paper is obtained. According to the preparation method of the aramid electrical insulation paper, different ratios of the para-aramid chopped fibers to the meta-aramid chopped fibers are adopted, and the aramid electrical insulation paper with high strength and good dielectric properties is prepared.

Owner:湖北城东再生资源科技发展有限公司

Method for pre-treating wood chips by hot water before preparing chemi-mechanical pulp and pulping method by using same

ActiveCN103790057AReduce consumption costReduce manufacturing costPretreatment with water/steamPre treatmentWoodchips

The invention relates to a method for pre-treating wood chips by hot water before preparing chemi-mechanical pulp. The method comprises the following steps: after soaking the wood chips, spirally extruding the wood chips; adding water into the wood chips which are spirally extruded, carrying out self-hydrolyzing pre-treatment on a mixture of the wood chips and water, and obtaining a pre-hydrolysate and the wood chips after self-hydrolyzing pre-treatment; and collecting the extruded wood chips as a raw material of chemi-mechanical pulp to obtain the wood chips after pre-treatment by hot water. The pre-treatment method provided by the invention fully uses existing part of equipment in the pulping industry without external complex equipment, and only water, small amount of dilute acids and ethanol are used without purchasing other chemicals, so that the pre-treatment process can be realized, thereby greatly saving the comprehensive production cost. Meanwhile, the method is beneficial for effectively combining pulping and papermaking with bio-refinery by existing enterprises.

Owner:TIANJIN UNIV OF SCI & TECH

Method for preparing powdery amphoteric guar gum derivative

ActiveCN101871180AImprove conversion rateMild reaction conditionsReinforcing agents additionPaper/cardboardPolymer scienceOrganic solvent

The invention discloses a method for preparing powdery amphoteric guar gum derivative having high degree of substitution, which adopts a semidry method and completes the cationization and anionized reactions of guar gum in a same reactor at the same time. The method comprises the following steps of: preparing sodium hydroxide into solution by using an alcohol / water mixture; spraying the solution into guar gum raw powder; adding a powdery quaternized reagent into the alkaline guar gum with stirring; and reacting the mixture with a carboxyalkylation reagent to obtain the product. The method has the advantages of completing the cationization and anionized reactions of the guar gum in the same reactor at the same time, no need for the separation and purification of intermediate products, directly performing subsequent reactions, fully utilizing reaction heat in a synthesis process, reducing energy consumption and solving the problems of high cost, difficult post treatment and low product degree of substitution of modified guar gum prepared by an aqueous method or an organic solvent method in the prior art along with characteristics of the semi-dry method.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Whitewater processing method

ActiveCN103086534AReduce concentrationReduce turbidityMultistage water/sewage treatmentWater/sewage treatment by neutralisationCationic polymerizationPapermaking

The invention relates to a whitewater processing method comprising the steps that: the pH value of the whitewater is regulated to 8-14; a certain amount of a mixed solution of a flocculating agent and a cationic polymer is added to the whitewater, until the total mass concentration of the flocculating agent and the cationic polymer in the whitewater is 1000-3000ppm. In the mixed solution, the mass concentration of the flocculating agent is 1-5%, and the mass concentration of the cationic polymer is 0.1-0.5%. According to the invention, papermaking whitewater is processed by using the whitewater processing method provided by the invention, and is then used in preparing slurry. Therefore, paper one-time retention rate and filler retention rate can be substantially improved, and paper bursting index and tensile strength index are improved to a certain extent. Also, when the slurry is used in papermaking, concentration, turbidity, conductivity, and COD of collected under-mesh whitewater are greatly reduced, such that whitewater recycling time can be increased.

Owner:GOLD EAST PAPER JIANGSU

Preparation method of polyester meta-position aramid fiber composite paper

ActiveCN106223103AHigh crystallinityIncreased tensile indexPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperPolyesterPolyethylene terephthalate glycol

The invention discloses a preparation method of polyester meta-position aramid fiber composite paper. The method comprises the following steps: pretreating PET (polyethylene terephthalate) chopped fibers; carrying out primary fluffing on the pretreated PET chopped fibers by using a fluffer; adding meta-position aramid fiber pulp fibers, and carrying out secondary fluffing; finally adding a dispersing agent, and carrying out tertiary fluffing to obtain a suspension; injecting the suspension into a paper former, and carrying out dewatering forming, pressing and drying to obtain polyester meta-position aramid fiber composite paper base paper; injecting the suspension into a paper former, carrying out dewatering forming, pressing, and drying to obtain aramid fiber electric-insulation paper base paper; and carrying out hot pressing on the obtained polyester meta-position aramid fiber composite paper base paper. The preparation method can maximally utilize the chopped fibers with high strength and polyester fibers with lower softening temperature as binding fibers, thereby enhancing the strength property and insulating property of the meta-position aramid fiber paper.

Owner:SHAANXI UNIV OF SCI & TECH

Aramid fiber/polyimide fiber composite insulation paper with excellent breakdown resistance and preparation method thereof

InactiveCN107354808APrevent hydrolysis reactionEffective bondageAgeing prevention agents additionPlastic/resin/waxes insulatorsBreakdown strengthSurface oxidation

The invention discloses aramid fiber / polyimide fiber composite insulation paper with excellent breakdown resistance. The preparation method comprises the following steps: performing surface oxidation heat treatment on aluminum nitride, thereby enhancing the hydration resistance; performing protonation pretreatment on polyimide chopped fibers, performing pulping, putting a mixture of the polyimide short fiber pulp and chopped aramid fibers into a fiber fluffer, performing fluffing treatment, adding the aluminum nitride suspension, performing mixing, making base paper on a paper sheet former, and performing isothermal boosting hot pressing treatment to obtain the composite insulation paper. The aluminum nitride powder is subjected to heat treatment in an oxidizing atmosphere, so that a compact Al2O3 film is formed on the surface, thereby effectively preventing the hydrolysis reaction of the aluminum nitride; the aluminum nitride powder is mixed with the mixed fiber pulp, so that the small-size aluminum nitride powder is uniformly dispersed in the insulation paper, thereby filling up abundant gaps in the fiber paper structure; and interface traps are formed between the nanoparticles and fibers, thereby implementing effective binding on charges, and enhancing the breakdown strength of the insulation paper.

Owner:徐昌霞

Little-chlorine and little-pollution bleaching process for paper pulp biomimetic pretreatment

The invention relates to a little-chlorine and little-pollution bleaching process for paper pulp biomimetic pretreatment, in particular to a little-chlorine element chlorine-free bleaching (ECF) process for the paper pulp biomimetic pretreatment. The process is a novel little-pollution bleaching technology in the paper pulp biomimetic pretreatment and belongs to the technical field of paper making. The process mainly comprises the following steps of: (1) carrying out metal salen biomimetic pretreatment to paper pulp bleaching, wherein metal salen, pyridine, H2O2 and O2 are used for carrying out bleaching pretreatment to oxygen-removal kraft pulp in alkaline condition; and (2) carrying out subsequent little-chlorine and little-pollution bleaching, wherein paper pulp after the biomimetic pretreatment undergoes three-section bleaching treatment, i.e., a chlorine dioxide bleaching section, a chelation treating section and a hydrogen peroxide bleaching section. The process is simple and easy to implement, has remarkable effect and can improve the whiteness and the property of the paper pulp. Compared with the conventional little-chlorine bleaching procedures, the bleaching process uses less chlorine. Compared with the conventional CEH bleaching, the bleaching process can reduce the time for pulping.

Owner:KUNMING UNIV OF SCI & TECH

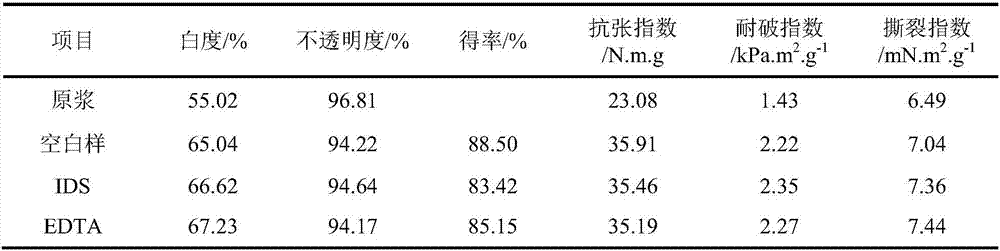

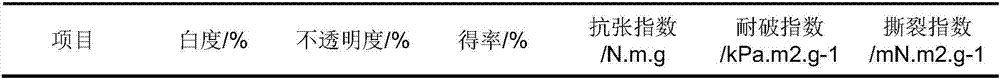

Method of applying green chelating agent in paper pulp hydrogen peroxide bleaching

The invention discloses a method of applying a green chelating agent in paper pulp hydrogen peroxide bleaching, and belongs to the technical fields of pulping and papermaking engineering. Specifically, after paper pulp is diluted to a concentration of 5%-10%, IDS with a mass percentage of 0.8%-1.2% of the absolute dry content of the paper pulp is added, mixing is performed uniformly, at the same time the chelation treatment temperature is controlled at 60-80 DEG C, and the reaction time is 50min-70min. According to the method provided by the invention, the IDS is used as the chelating agent for chelating treatment and pulp hydrogen peroxide bleaching, the bleaching effect is equivalent to that of hydrogen peroxide bleaching used conventional chelating agent EDTA, the whiteness of bagasse pulp can be improved by 2-4%, the tensile index can be improved by 5-6%, the burst resistant index can be improved by 20-23%, and the tear index can be improved by 8-10%; and the whiteness of waste paper deinking pulp can be improved by 2-4%, the burst index can be improved by 6-11%, and the tear index can be improved by 4-6%. The method provided by the invention can be used in the production process of paper pulp hydrogen peroxide bleaching.

Owner:SOUTH CHINA UNIV OF TECH

Paper-making pulping method by using kenaf aggregate

ActiveCN102021859AReduce dosageReduce pollutionNon-woody plant/crop pulpCellulose material pulpingPulp (paper)Sodium silicate

The present invention relates to a paper-making pulping method by using kenaf aggregates. Concretely, the present invention provides a paper-making pulping method by using kenaf aggregates which comprises the following steps: (a) soaking the kenaf aggregates in water or an aqueous solvent at a temperature of 70-100 DEG C for 5-180 min, cooling the soaked kenaf aggregates to the temperature of 5-50 DEG C, and pulverizing to obtain the pulverized kenaf aggregates; (b) soaking the kenaf aggregates obtained through step (a) at a temperature of 70-90 DEG C for 60-300 min with the presence of 2.0-7.0 wt% of sodium hydroxide, 2.0-5.0 wt% of hydrogen peroxide, 0.05-3.0 wt% of sodium silicate, and 0.05-2.0 wt% of magnesium sulfate; (c) performing the refining and latency procedure to the chemically treated pulp so as to obtain kenaf aggregate paper pulp.

Owner:SHANGHAI ZHONGWEI BIOCHEM

Method for preparing aramid composite paper from aromatic polysulphone

ActiveCN106223104AIncrease binding areaTightly boundPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperPre treatmentAramid

The invention discloses a method for preparing aramid composite paper from aromatic polysulphone. The method particularly comprises the following steps that PSA chopped fibers are pretreated; the pretreated PSA chopped fibers are subjected to first-time defibering through a defibering machine; meta-aramid pulp fibers are added for second-time defibering; a dispersing agent is added for third-time defibering, and suspension liquid is obtained; the obtained suspension liquid is injected into a paper sheet forming machine to be dewatered and formed, and after squeezing and drying treatment is conducted, the aramid composite paper raw paper is obtained; the obtained aramid composite paper raw paper is subjected to hot press molding, and the aramid composite paper is obtained. According to the preparation method of the aramid composite paper, the high-strength characteristic of the chopped fibers can be utilized to the maximum limit, and the strength performance of the meta-aramid paper is improved.

Owner:SHAANXI UNIV OF SCI & TECH

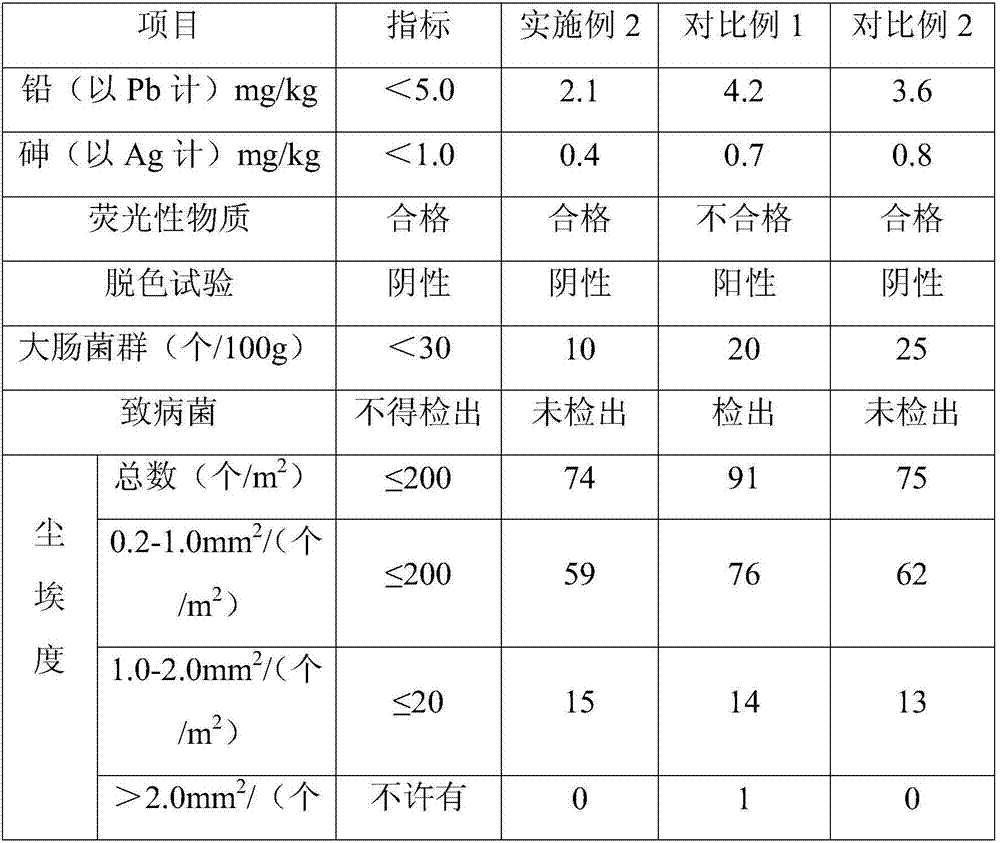

Preparation method of finished hemp and bamboo toilet paper product

ActiveCN107184132AHigh yieldHigh whitenessRadiation/waves wood treatmentWood treatment detailsPapermakingToilet paper

The invention discloses a preparation method of a finished hemp and bamboo toilet paper product, and belongs to the technical field of papermaking. The finished hemp and bamboo toilet paper product is prepared through secondary pretreatment, washing, screening, pulping, filter pressing, re-grinding, dirt removing and degassing, screening, squeezing, drying, calendaring, winding, rewinding, cutting, packaging and the like. The brightness, tensile index and softness of toilet paper prepared through the method are obviously higher than those of toilet paper prepared in the prior art. Unbleached hemp and bamboo paper pulp is used for producing the environment-friendly product, the produced toilet paper does not have any irritation or adverse effect on skin of the human body, and the toilet paper is more environmentally friendly and more sanitary.

Owner:广西金荣纸业有限公司

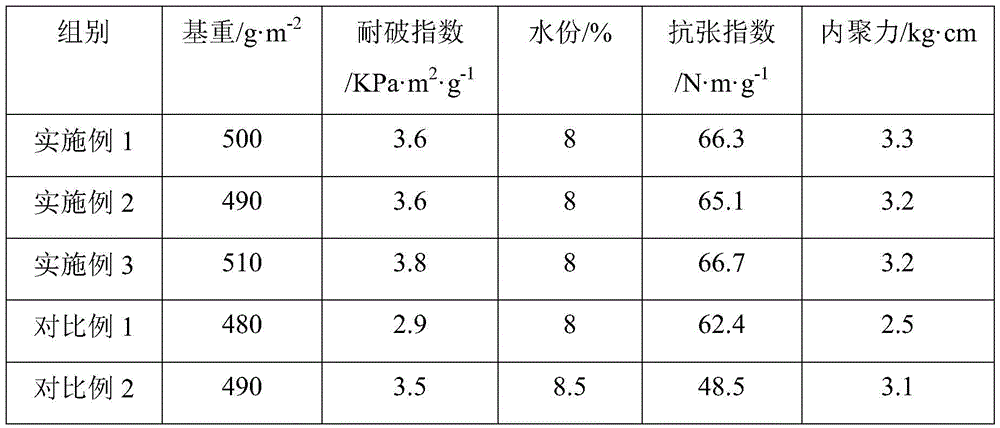

Fiber and filler mixed enzymatic defibrination method

The invention relates to a fiber and filler mixed enzymatic defibrination method which comprises the steps of high concentration and low concentration series beating, paste and filler premixed beating, and paste and beating enzyme premixed beating. Firstly, pre-treating fibers by beating enzyme, so as to enable the fibers to be soft and convenient to beat; secondly, adding fillers when concentrating the paste into a higher concentration through a press master; and conducting beating through a high consistency refiner. According to the method provided by the invention, fiber intensity is improved through three modes, tensile strength, bursting strength, folding endurance and cohesion of paper can be efficiently improved; identical paper strength can be maintained under the condition of improving 2 percent to 3 percent of paper ash, furthermore, beating energy consumption can be greatly decreased under the action of beating enzyme. Through the application of the method in a paper mill, macrofiber usage can be decreased, paper ash part can be improved, cost of a ton of paper can be greatly decreased, and product competitiveness can be improved.

Owner:HAINAN JINHAI PULP & PAPER

White paperboard and method for manufacturing same

ActiveCN105568748AIntensity effectReduce harmful ingredientsVegetable material additionPulp bleachingFiberPaperboard

The invention discloses a white paperboard and a method for manufacturing the same. The white paperboard comprises, by weight, 85-95 parts of mixed fibers, 6-8 parts of persimmon peel extract and 15-22 parts of semi-chemical pulp. The mixed fibers include mango tree fibers and bamboo fibers, a mass ratio of the mango tree fibers to the bamboo fibers is 15-16:2-3, the lengths of the mango tree fibers are 0.85 mm, and the widths of the mango tree fibers are 0.02 mm. The white paper board and the method have the advantages that the shortcoming of existing white paperboards in the aspect of elasticity can be overcome by the aid of the white paperboard with a low formaldehyde content, the white paperboard is difficult to fluff and high in smoothness, and printing ink is easy to attach onto the white paperboard.

Owner:苏州福羊自控科技有限公司

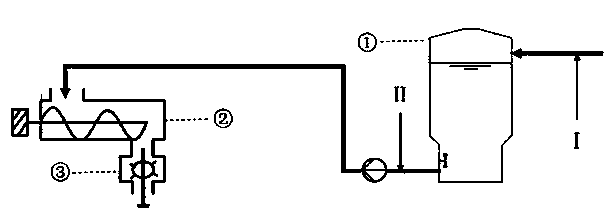

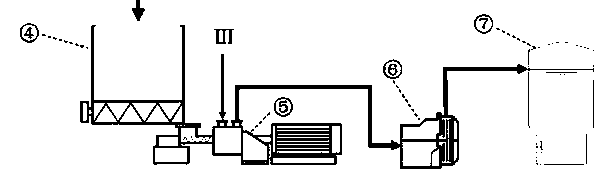

Method for deinking mixed office waste paper through composite biological enzyme

InactiveCN103485227APromote swellingReduce connectionsPaper recyclingWaste paper working-upPulp and paper industrySlurry

The invention discloses a method for deinking mixed office waste paper through composite biological enzyme. The method comprises the steps as follows: office waste paper is torn into 25*25 mm scraps with hands, and the scraps are soaked for 10 min and placed in a horizontal type hydrapulper for fluffing, so that standby pulp is obtained; the standby pulp is placed in the hydrapulper, water is added, the temperature is raised, the pH is adjusted, the composite biological enzyme and a surface active agent are added, and the mixture is mixed with the slurry; and finally, the slurry is poured into a flotation device, water is added for adjusting the slurry concentration to be 0.5%, the pH is adjusted to 8.0-8.5, an air pump and a slurry recycle switch of the flotation machine are switched on, and flotation is timed when a bubble pops out of a flotation tank; and after flotation, aeration and slurry recycle are stopped, and the slurry is poured into a filter bag to be squeezed, dried and dispersed for sheet making. According to the method, the waste paper dust degree is greatly reduced, the Eric value is decreased, and at the same time, the tensile index and the burst index of the paper are improved, so that the paper can have higher application values.

Owner:FUJIAN AGRI & FORESTRY UNIV

Preparation method of polyester/para-position/meta-position aramid composite electric insulating paper

InactiveCN106120474AHigh compressive strengthHigh strengthPlastic/resin/waxes insulatorsSpecial paperPolyesterPolyethylene terephthalate glycol

The invention discloses a preparation method of polyester / para-position / meta-position aramid composite electric insulating paper. The preparation method specifically comprises the following steps: pre-treating PET (Polyethylene Terephthalate) chopped fibers for later use; pre-treating PPTA (Poly(p-phenylene terephthalamide)) chopped fibers; mixing the pre-treated PET chopped fibers and the pre-treated PPTA chopped fibers and carrying out first time of defibering in a defibering machine; then, adding PMIA (Poly(m-phenyleneisophthalamide)) pulp fibers and carrying out second time of defibering; finally, adding a dispersant and carrying out third time of defibering to obtain suspending liquid; injecting the obtained suspending liquid into a paper molding device and dehydrating and molding; squeezing and drying to obtain aramid composite paper raw paper; and carrying out hot press molding on the aramid composite paper raw paper to obtain the aramid composite paper. According to the preparation method of the aramid composite paper, disclosed by the invention, the high-strength property of the chopped fibers can be utilized to the greatest extent and polyester fibers have a relatively low softening temprature so that the strength property and the dielectric property of the aramid paper are improved.

Owner:SHAANXI UNIV OF SCI & TECH

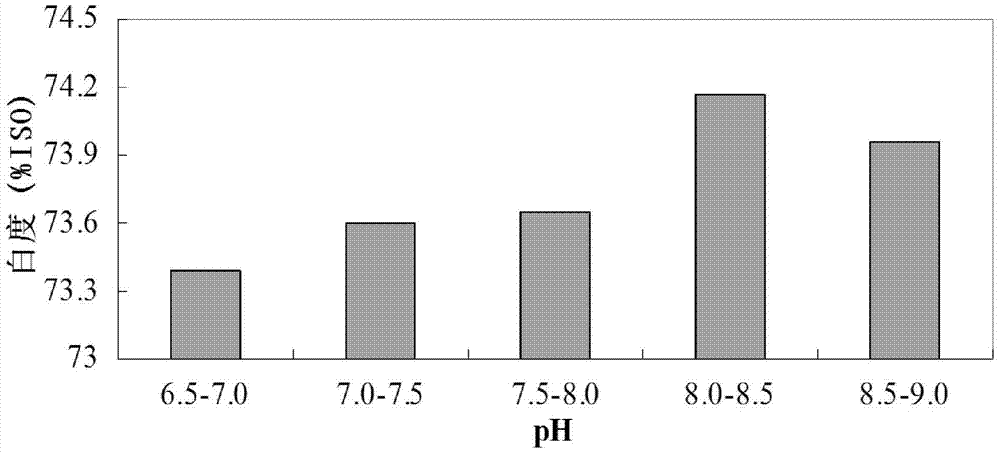

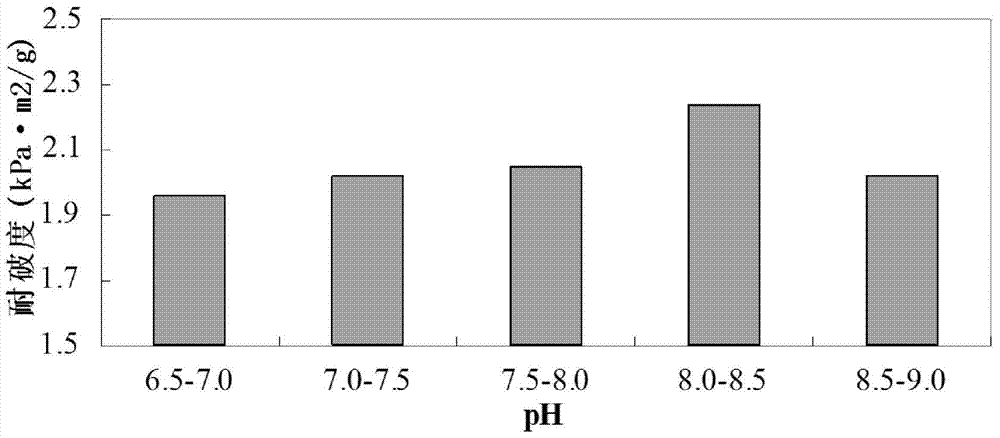

Method for improving strength of waste paper fiber by constructing nano-polyelectrolyte multilayer films

InactiveCN102242524AAchieve surface modificationImprove physical strengthReinforcing agents additionPaper/cardboardFiberCationic polyelectrolytes

The invention discloses a method for improve strength of waste paper fiber by constructing nano-polyelectrolyte multilayer films. In the method, a nanoscale polyelectrolyte multilayer film structure is formed on the surface of regenerated fiber by means of electrostatic layer-by-layer self-assembly of anionic and cationic polyelectrolyte on the surface of the waste paper fiber. The method has thebeneficial effects that by changing consumption of the polyelectrolyte, regulating and controlling the electrolyte multilayer film structure and adjusting the pH value of an electrostatic layer-by-layer self-assembly environmental system, the polyelectrolyte multilayer films with different properties can be obtained on the surface of the regenerated fiber so as to increase fiber bonding quantity;electrostatic attraction between anions and cations is taken as a film-forming driving force to prepare the ordered lamellar self-assembled multilayer ultra-thin films by means of alternate deposition of monomolecular layers in opposite ionic systems, and the preparation process has the advantages of simple conditions and strong adaptability and can realize surface modification of the waste paperfiber reused for a plurality of times; and strength of the finished paper prepared from the waste paper fiber after electrostatic layer-by-layer self-assembly modification is obviously enhanced, and drainage property of paper pulp is obviously improved.

Owner:湛江市吉城纸业有限公司

Method for increasing paper strength using collagenous fiber

Leather waste in leather solid-waste is washed, defatted by an ordinary degreasing agent then put and crushed in a pulping machine to be diluted with water hydrolyzed, and dispersed with homogenizer to small particles after adding MgO to get collagen fiber pulp. Soft wood or broad-leaved wood pulp plate is soaked and dispersed in a beater and ground to 35 deg. SR-40 deg SR beat degree to get wood pulp. 5%-10% total mass percentage of the collagen fiber pulp is mixed with the wood pulp according to bone-dry pulp to be formed by hand an a Kayser paper formation device, squeezed with a press and dried in vacuum under 70 deg.C-105 deg.C to get paper.

Owner:SHAANXI UNIV OF SCI & TECH

Method of improving performance of recycled paper pulp

The invention relates to the technical field of wrapping paper processing, and discloses a method of improving the performance of recycled paper pulp. Waste and old corrugated paper is taken as the main raw pulp accounting for 70 to 80% of recycled paper pulp; the residue is mixed recycled paper pulp of other materials; 1.0 to 1.5 wt% of nano cellulose fibrous organic pulp is added into the recycled paper pulp, cellulose rich in crop straws is used to prepare nano fiber filaments, the tensile index and burst index are increased, the performance of paper prepared from waste paper pulp is improved, and the utilization rate of waste and old resources is increased.

Owner:HEFEI LONGFA PACKING CO LTD

Chlorine dioxide bleaching process for reducing content of organic chloride in waste water

InactiveCN101306860ASimple technologyAdd lessWater/sewage treatment by oxidationChlorine dioxideHydrogen

The invention provides a chlorine dioxide bleach method for reducing the content of organic chlorine in effluent. The method is a technology of reducing the content of organic chlorine in element free chlorine (ECF) bleaching effluent and improving the performance of a bleaching pulp, belongs to the papermaking technical field and mainly comprises the following steps of: 1) adding aminosulfonic acid or DMSO addition agent under an appropriate chlorine dioxide bleach technique; 2) bleaching wood pulp and bleaching deoxidation sulfate wood pulp in the presence of NaOH, CIO2 and the addition agent; 3) conducting subsequent totally chlorine-free (TCF) wood pulp bleach and then conducting subsequent two-stage bleach ( a chelated treatment stage and a hydrogen bleach stage) treatment on the bleached wood pulp. The method is easy to operate, has obvious effect, can reduce the content of organic chlorine in DQP bleaching effluent and improve the performance criterions of DQP bleaching paper pulp such as whiteness and tensile index, etc.

Owner:KUNMING UNIV OF SCI & TECH

Non-wood unbleached pulp food warp paper and preparation method thereof

ActiveCN107090737ALow costReduce manufacturing costNon-fibrous pulp additionFlexible coversPaper sheetPapermaking

The invention discloses a non-wood unbleached pulp food wrap paper and a preparation method thereof. Slurry of the non-wood unbleached pulp food wrap paper is prepared from unbleached straw pulp and unbleached bamboo pulp, the fixed quantity of the wrap paper ranges from 45 g / m<2> to 65 g / m<2>, and the content of synthetic papermaking additives accounts for 0.5%-2.5% of oven dry stock. The wrap paper is safe and environmentally friendly, the natural color of plant fiber is kept, dust and chips do not exist, no hazardous substance is produced in a papermaking technology, the waste water treatment cost is lowered, and the production cost is low.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Preparation method of high-breakage-resistance kraft paper

ActiveCN112878089AHigh longitudinal tear indexIncreased tensile indexWater-repelling agents additionPulp beating methodsManufacturing engineeringFiber

The invention discloses a preparation method of high-breakage-resistance kraft paper, which comprises the following steps: fiber raw materials are subjected to mixing and disintegrating, desanding, high-concentration pulping, low-concentration pulping, net forming, squeezing and drying, wherein the concentration of the high-concentration pulping is 30-35%, the concentration of the low-concentration pulping is 4.8-6%, and the concentration of net forming is 0.15-0.25%. The kraft paper with good water absorption, high longitudinal tear index, high burst index and high tensile index can be prepared through the preparation method, indexes of the kraft paper are far away from those of common kraft paper in supermarkets, and the preparation method is suitable for papermaking of the kraft paper with low gram weight of 40g / m < 2 >-140g / m < 2 > and is simple in preparation process.

Owner:SHANYING PAPER (GUANGDONG) CO LTD

Paper pulp preparation method

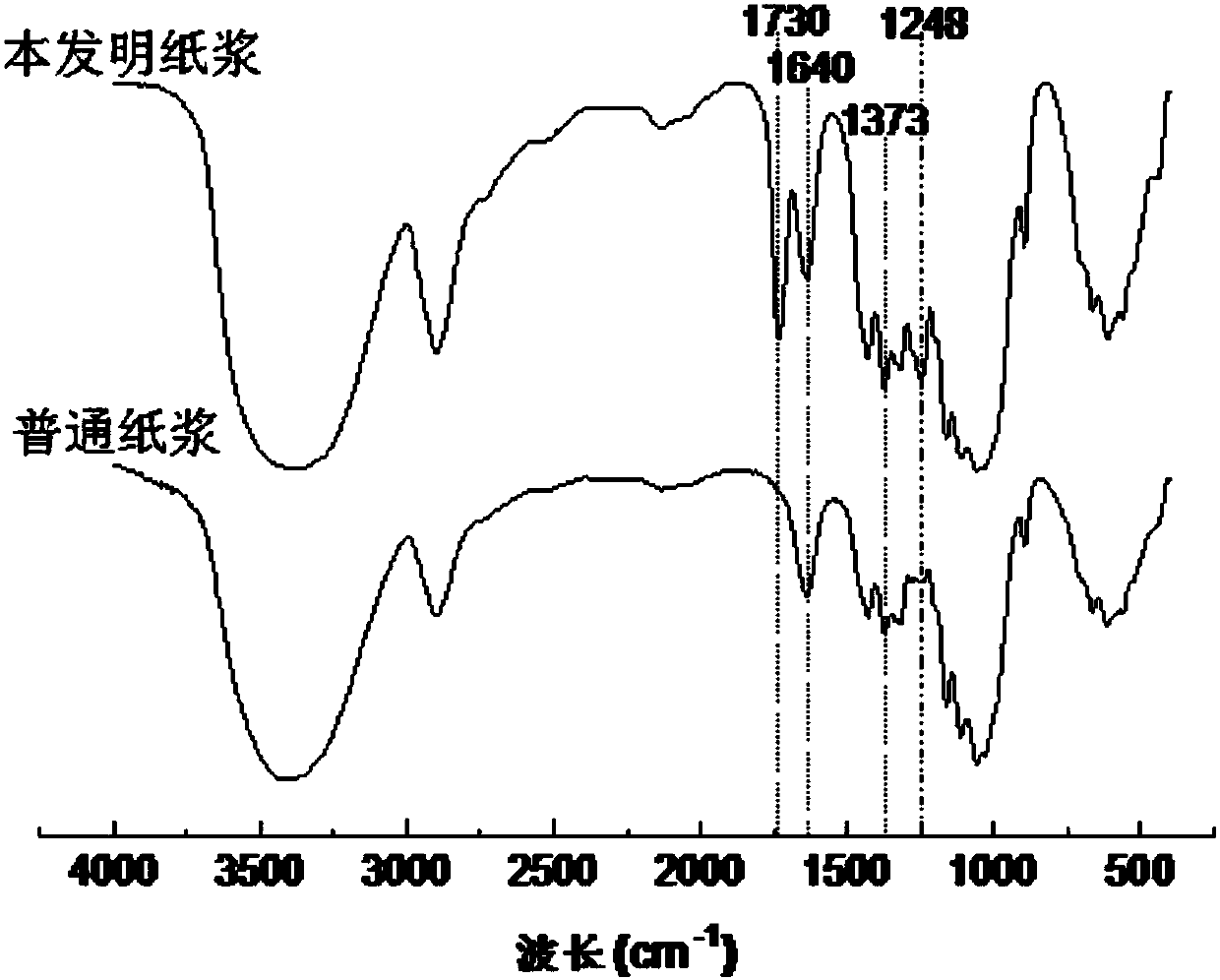

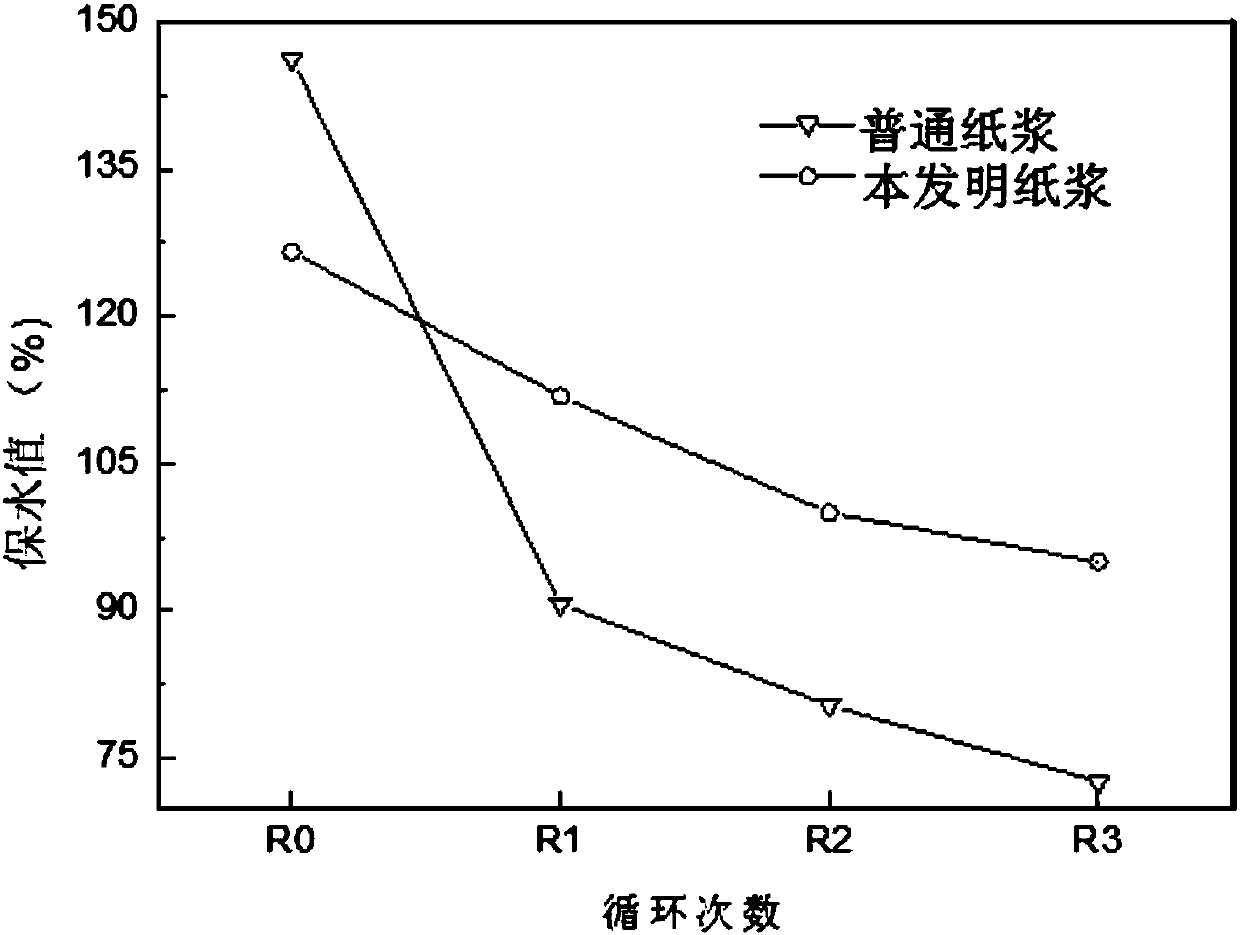

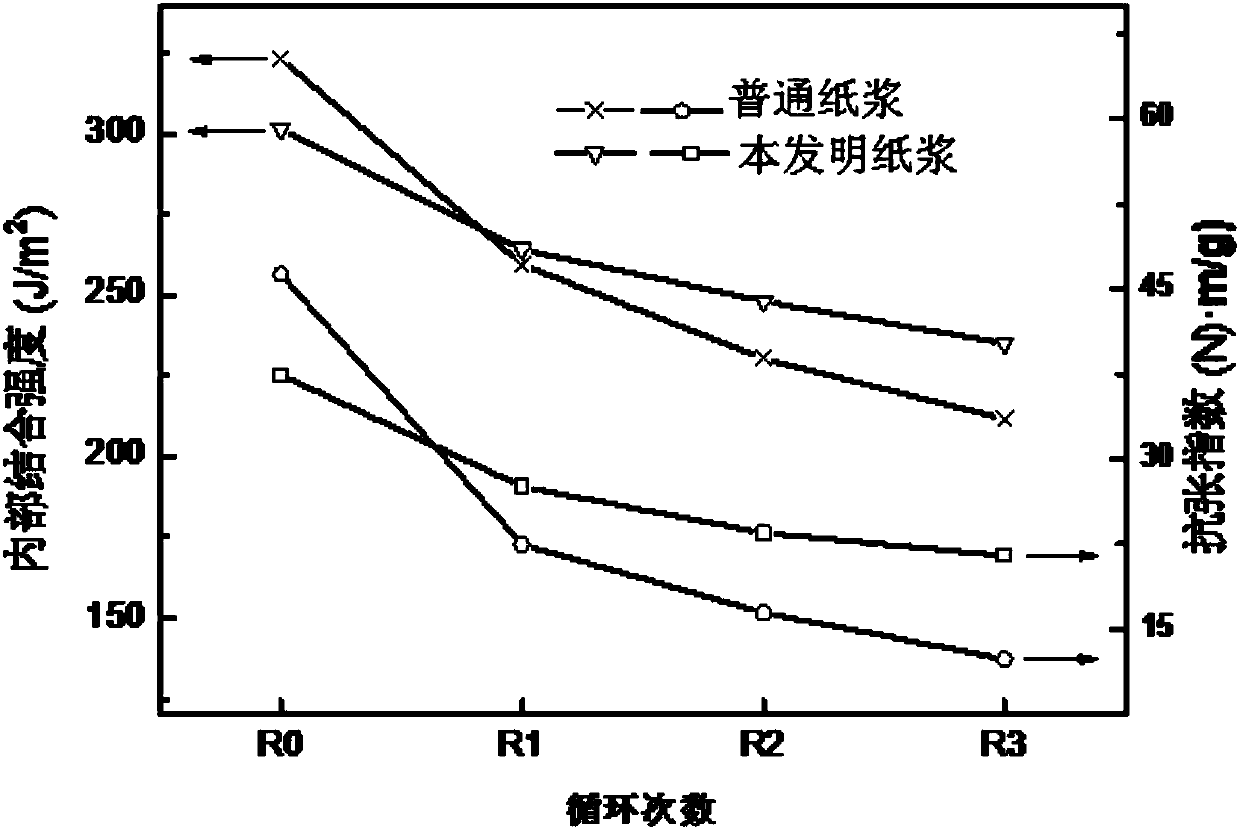

ActiveCN107892720AIncreased tensile indexHigh internal bonding strengthNon-fibrous pulp additionPaper/cardboardWater contentChemistry

The invention discloses a paper pulp preparation method which comprises the following steps: Step one, obtaining cellulose, preparing fiber pulp, adjusting the water content of the obtained fiber pulpto 50-70 wt%; and Step two, adding excess acetic anhydride into the fiber pulp according to the water content for hydrolysis reaction under the conditions of the temperature not higher than 70 DE C;adjusting the mass ratio of cellulose, acetic anhydride and acetic acid in the hydrolysis system to 1: (2-3): (8-12) for esterification reaction under the conditions of the temperature higher than 80DEG C. The water-containing fiber pulp can be directly taken as an object of treatment, the cellulose is modified with the acetic anhydride in a water phase without adding of other chemical aids, andan acetyl group is moderately introduced to reduce chemical pulp crystallinity, increase water retention value, increase layer-to-layer bond strength and improve long resistance index, and the effectis still good after many times of use.

Owner:GUANGDONG IND TECHN COLLEGE

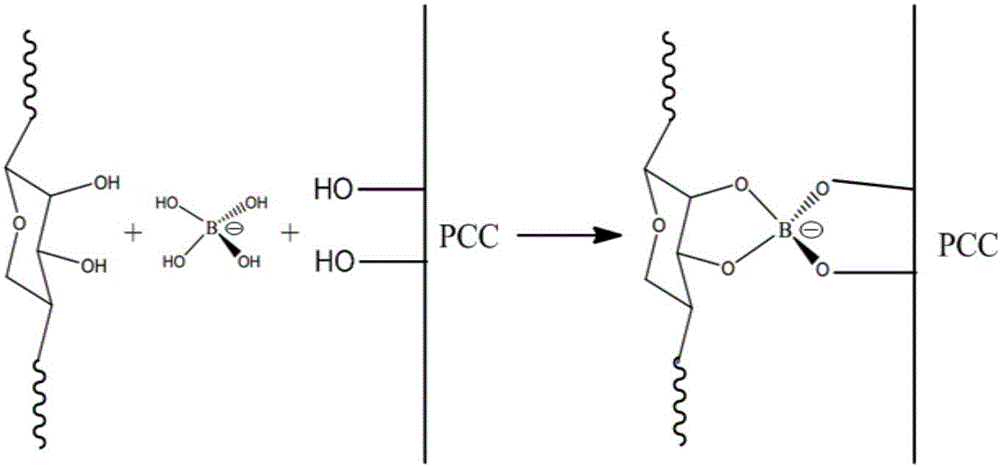

Guar gum-boric acid surface-crosslinking modified precipitated calcium carbonate, preparation method and application thereof, and paper

ActiveCN106702811AIncreased tensile indexIncreased burst indexInorganic compound additionPigment treatment with macromolecular organic compoundsPrecipitated calcium carbonateBoric acid

The invention provides a guar gum-boric acid surface-crosslinking modified precipitated calcium carbonate. Guar gum is crosslinked on the surface of the modified precipitated calcium carbonate through boric acid. The invention aims to provide a modified precipitated calcium carbonate which can obviously enhance the tensile index, burst index and tear index of paper and the single-pass retention rate of the filler when being used in the filler of the paper. The invention also provides a preparation method and application of the modified precipitated calcium carbonate. Besides, the invention also provides a paper containing the modified precipitated calcium carbonate.

Owner:WUZHOU UNIV

Corona-resistant aramid fiber/mica insulation paper and preparation method thereof

InactiveCN114214867ALarge specific surface areaImprove the interface binding forceNon-fibrous pulp additionPlastic/resin/waxes insulatorsAramidCeramic materials

The invention provides corona-resistant aramid fiber / mica insulation paper and a preparation method of the corona-resistant aramid fiber / mica insulation paper. The preparation method comprises the following steps: 1, defibering aramid chopped fibers, polyoxyethylene and water, and then adding aramid fibrid for defibering to obtain first slurry; 2, muscovite slices are added into the first slurry for defibering, second slurry is obtained, and the total mass ratio of the aramid chopped fibers, the aramid fibrids and the muscovite slices in the second slurry is 0.04%-0.07%; and step 3, sequentially performing dehydration forming, squeezing, drying and hot pressing on the second slurry to obtain the aramid fiber / mica insulation paper. The high-temperature-resistant and corona-resistant white mica sheets are added into the manufacturing process of the aramid paper, so that the corona resistance of the aramid paper is greatly improved, the problem that the aramid paper is easy to age due to repeated electric shock under high temperature and high pressure is solved, and the application requirement of equipment for long insulation life cycle is met.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of epoxy resin surface sizing agent and surface sizing technology

InactiveCN102733261AIncreased tensile indexImprove stiffnessWater-repelling agents additionPaper/cardboardPhenyl groupUltimate tensile strength

The invention relates to a preparation method of an epoxy resin surface sizing agent and a surface sizing technology. A bisphenol-A epoxy resin contains a lot of phenyl groups, epoxy groups and isopropyl groups. Through use of the bisphenol-A epoxy resin, the epoxy resin surface sizing agent has good rigidity and reactivity. The preparation method comprises that an aqueous bisphenol-A epoxy resin, an epoxy resin curing agent and oxidized starch are prepared into the epoxy resin surface sizing agent according to a certain ratio. The preparation method and the surface sizing technology concretely comprise the following steps of gelatinization of oxidized starch, preparation of an epoxy resin system, preparation of a surface sizing liquid, and surface sizing of a paper. In surface sizing of a paper, through use of the epoxy resin surface sizing agent, tensile indexes, surface strength and stiffness of the paper can be improved and fluff-falling and powder-falling are avoided.

Owner:NANJING FORESTRY UNIV

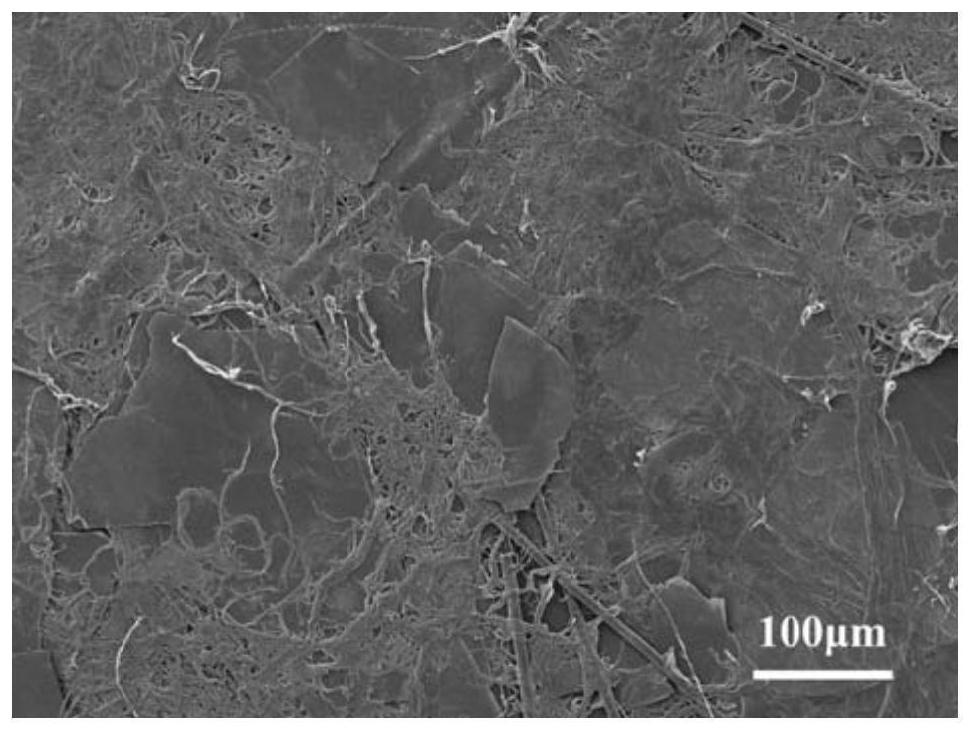

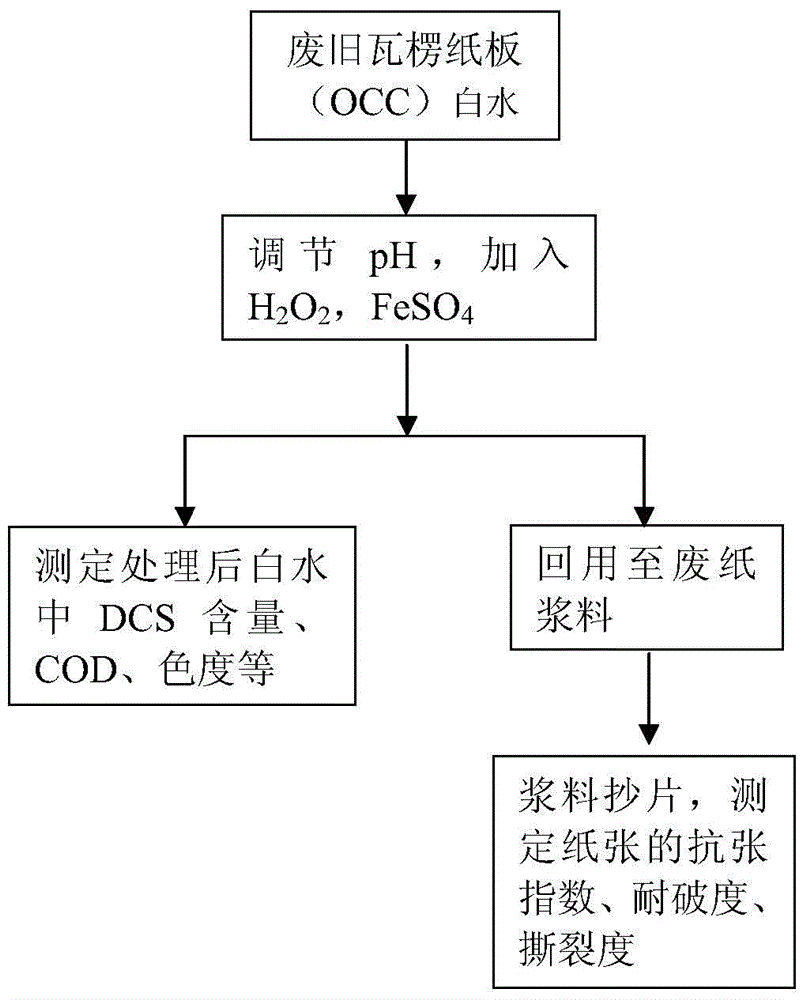

Waste corrugated board white water treatment method

InactiveCN104803506AReduce the content of soluble matterReduce DCS contentMultistage water/sewage treatmentWaste water treatment from plant processingBursting strengthFlocculation

The invention discloses a waste corrugated board white water treatment method. The method comprises the following steps: adjusting pH of waste corrugated board white water to be 4-6, adding a certain amount of FeSO4 and H2O2 in a stirring state, and carrying out aeration, flocculation and filtering so as to complete the white water process, wherein the concentrations of FeSO4 and H2O2 in the white water is 350-450 mg / L and 180-240 mg / Lm respectively and the reaction time is 30 min. Since white water is treated through the method, the DCS content, COD and chromaticity of the waste corrugated board white water are obviously reduced, and the white water can be reused for preparation of waste corrugated board slurry; in addition, the tensile index, bursting strength, tear resistance and other properties of the waste slurry are improved.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com