Fiber and filler mixed enzymatic defibrination method

A technology of mixing enzymes and fibers, which is applied in the field of paper production, can solve the problems of paper quality decline, less cleaning, and continuous investment costs outweigh the gains, and achieve the effects of improving cohesion, improving paper quality, and improving tensile index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

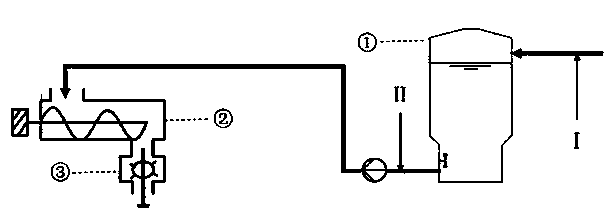

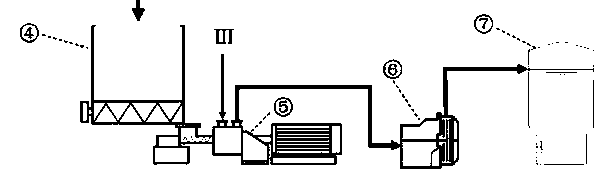

[0029] The fiber and filler mixed enzymatic refining technology of the present invention is used for refining bleached kraft pulp. The original freeness of the pulp is about 560ml, and the concentration of the loose pulp is 4.5%. After the loose pulp is completed, the pulp is directly transported to the pulp storage tank ( ), the refining enzyme (I) is transferred from the pulper to the pulp storage tank ( ) at the inlet of the transfer pump, the amount added is 200ppm, and the volume of the storage tank is 2000m 3 , under the output of 300 tons / day, in order to keep the refining enzyme (I) acting on the fiber (before entering the refiner) for 4 hours, it is necessary to maintain the slurry storage tank ( ) liquid level is about 50%; the filler (II) adopts GCC, and the particle size content of less than 2 μm is required to be between 60% and 65%. The amount of filler (II) added is 15%. Sent to the squeezer, the squeezer is a single-screw squeezer, its maximum output is 35...

Embodiment 2

[0033] Using the same slurry as in Example 1, its original freeness was about 560ml. Under the same conditions as in Example 1, the bulk concentration, the amount of refining enzyme and filler, and the squeezing concentration are all the same, and the power of the first high-consistency refining is changed to 750kw, so that the freeness of the pulp after high-consistency grinding is reduced to 460± 20ml, then diluted to 5% concentration and refined with a low consistency refiner, the final freeness is controlled within the range of 420±20ml.

[0034] After using this invention, compared with the two-stage low concentration and conventional addition of GCC used before, under the same 20% paper ash content, the tensile strength of the paper of this invention is 27% higher than the latter, and the cohesion is 42% higher than the latter. Under this effect, the factory can reduce the amount of long-fiber pulp or increase the ash content of paper, and the economic benefits are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com