Method for deinking mixed office waste paper through composite biological enzyme

A technology of compounding biological enzymes and office waste paper, which is applied in the processing of waste paper, papermaking, paper recycling, etc., can solve the problems of large consumption of deinking agent and surfactant, inability to achieve efficient deinking, and environmental problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) The office waste paper (the main components are laser printing paper, electrostatic copy paper, color laser printing paper and waste ledgers, provided by Fujian Youlanfa Paper Group, the specific composition is: the weight percentage is 46% of laser printing paper, Electrostatic copy paper 51%, color laser printing paper 1.9%, waste ledger 1.1%) are manually torn into 25*25mm pieces, soaked for 10 minutes, placed in a horizontal hydraulic pulper for 20 minutes until the fibers are basically dissociated, and dried by drying Squeeze dry, disperse and store in plastic bags for later use;

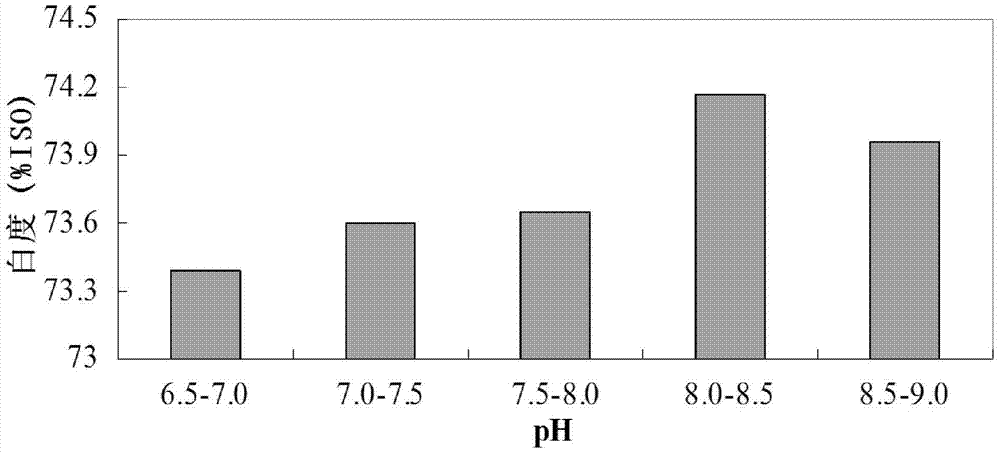

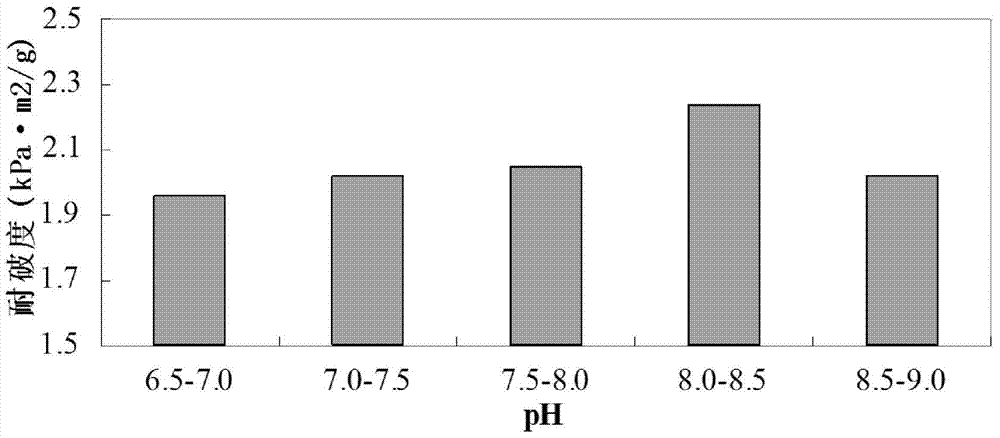

[0043] (2) Take the slurry obtained in step (1) with an absolute dry mass of 150g and add it to a pulper, add water to make a 9wt% slurry concentration, and add 6 drops of NaOH with a mass volume concentration of 0.05% after raising the temperature to 55°C. Concentration is 0.6% Na 2 SiO 3 Add 5 drops to adjust to pH 8.0-8.5;

[0044] (3) Add 200g / t dry-dried pulp quality co...

Embodiment 2

[0047] (1) The office waste paper (the main components are laser printing paper, electrostatic copy paper, color laser printing paper and waste ledgers, provided by Fujian Youlanfa Paper Group, the specific composition is: the weight percentage is 46% of laser printing paper, Electrostatic copy paper 51%, color laser printing paper 1.9%, waste ledger 1.1%) are manually torn into 25*25mm pieces, soaked for 10 minutes, placed in a horizontal hydraulic pulper for 20 minutes until the fibers are basically dissociated, and dried by drying Squeeze dry, disperse and store in plastic bags for later use;

[0048] (2) Take the slurry obtained in step (1) with an absolute dry mass of 150g and add it to a pulper, add water to make a 9wt% slurry concentration, and add 4 drops of NaOH with a mass volume concentration of 0.05% after the temperature is raised to 55°C. Concentration is 0.6% Na 2 SiO 3 Add 5 drops to adjust to pH 7.5-8.0;

[0049] (3) Add the compound biological enz...

Embodiment 3

[0052] (1) The office waste paper (the main components are laser printing paper, electrostatic copy paper, color laser printing paper and waste ledgers, provided by Fujian Youlanfa Paper Group, the specific composition is: the weight percentage is 46% of laser printing paper, Electrostatic copy paper 51%, color laser printing paper 1.9%, waste ledger 1.1%) are manually torn into 25*25mm pieces, soaked for 10 minutes, placed in a horizontal hydraulic pulper for 20 minutes until the fibers are basically dissociated, and dried by drying Squeeze dry, disperse and store in plastic bags for later use;

[0053] (2) Take the slurry obtained in step (1) with an absolute dry mass of 150g and add it to a pulper, add water to make a 9% slurry concentration, and add 6 drops of NaOH with a mass volume concentration of 0.05% after raising the temperature to 55°C. Concentration is 0.6% Na 2 SiO 3 Drop 5 drops to adjust to pH 8.5-9.0;

[0054] (3) Add the compound biological enzyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com