Patents

Literature

108results about How to "Good deinking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

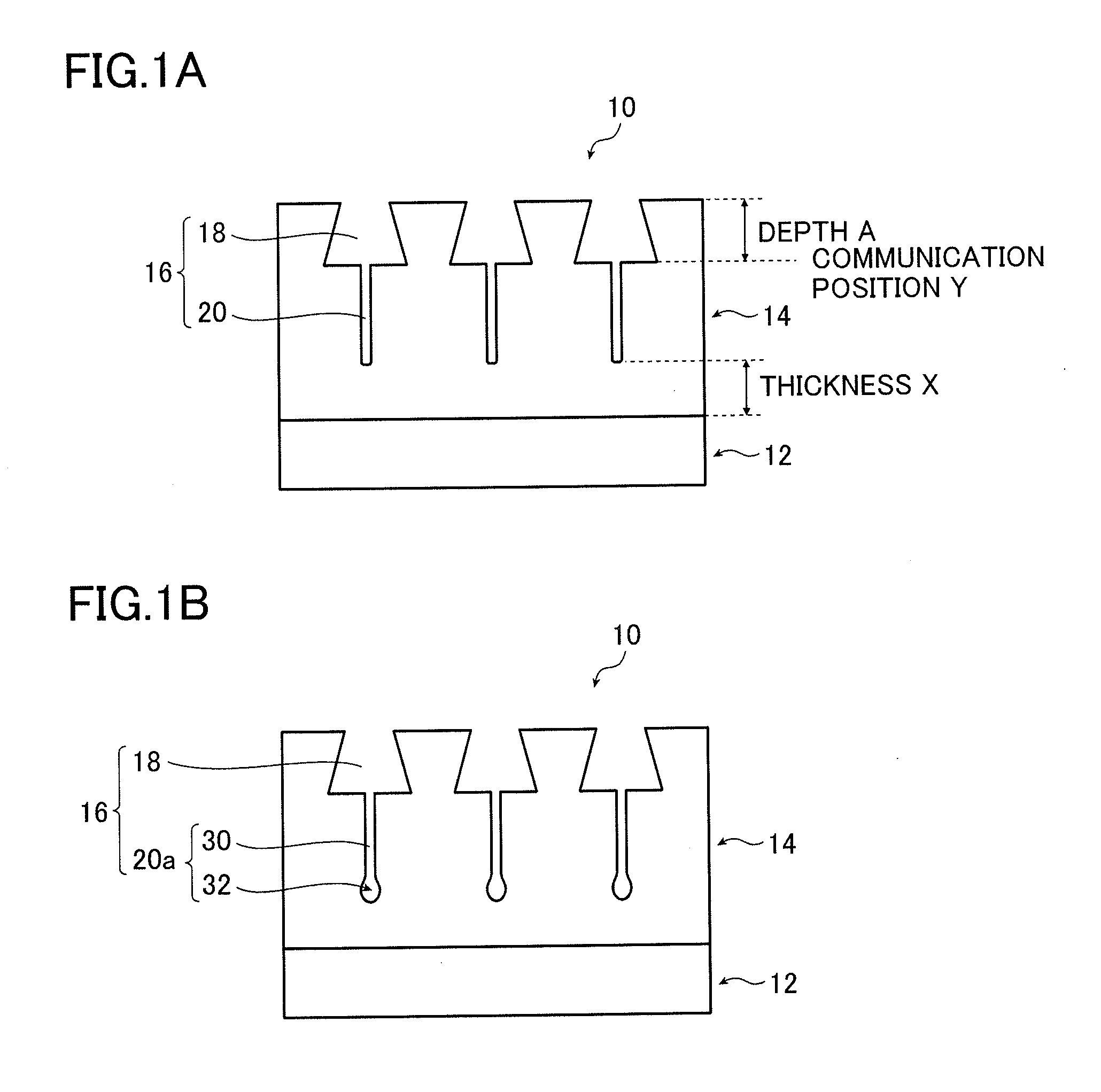

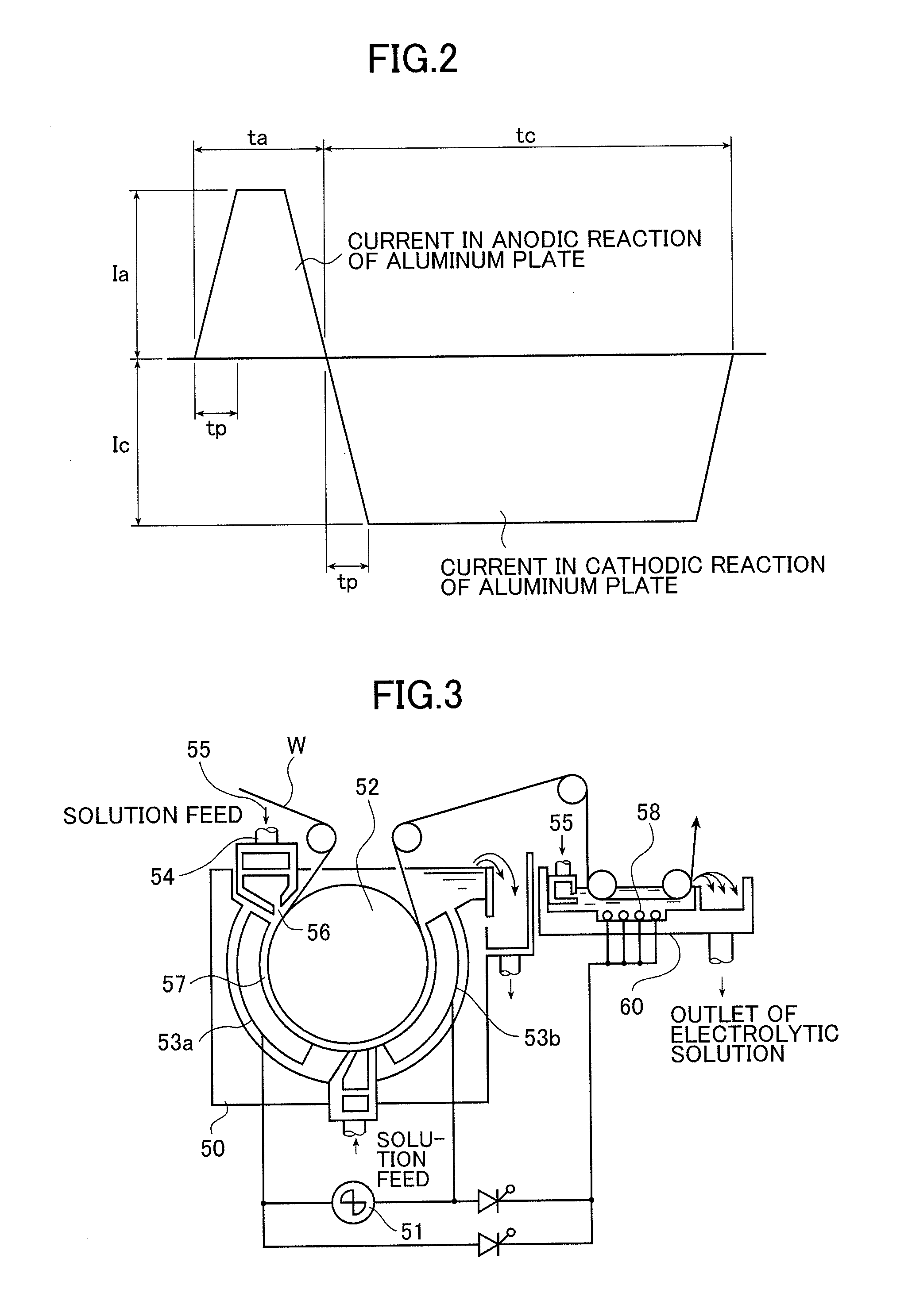

Support for planographic printing plate, method for producing support for planographic printing plate, and planographic printing original plate

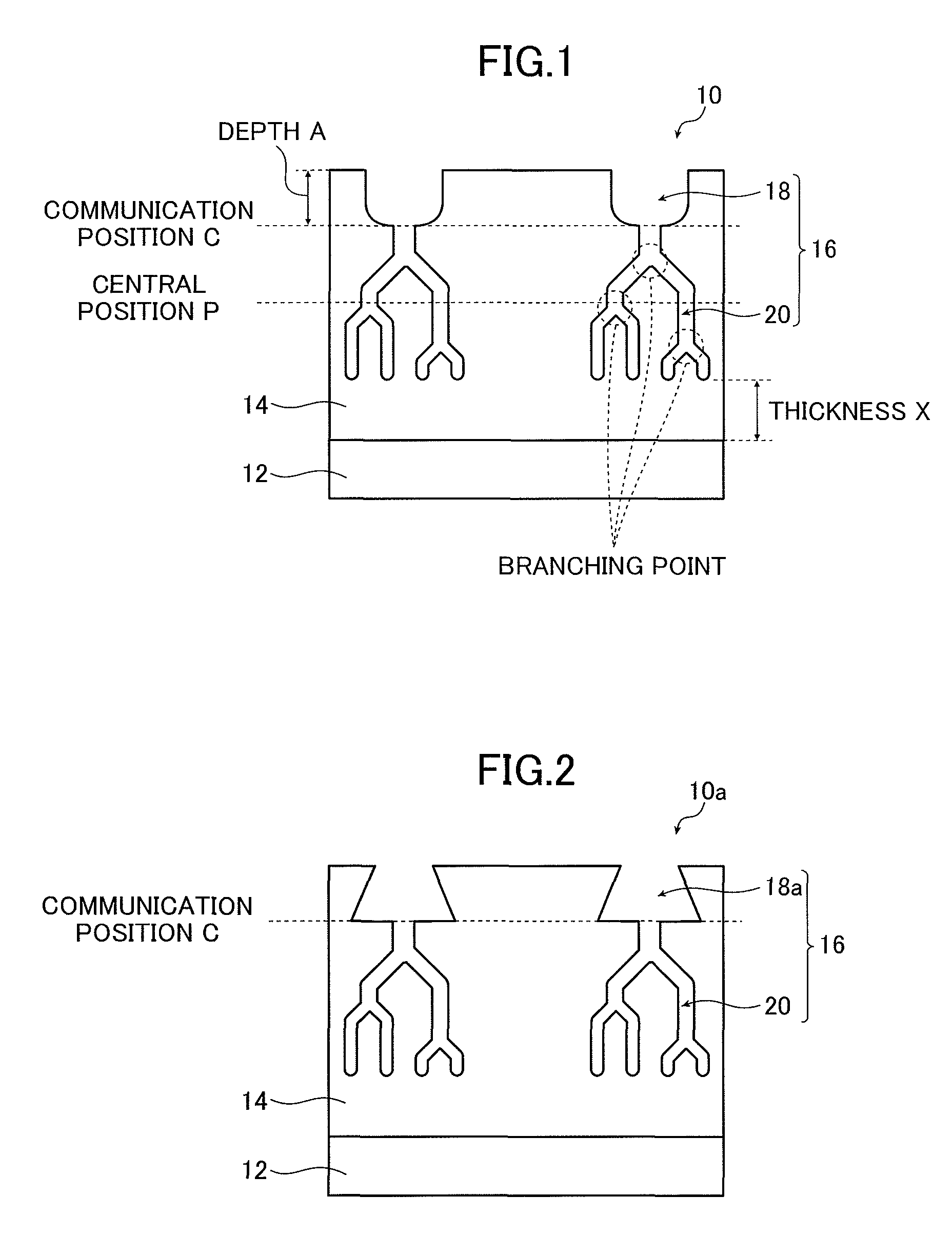

ActiveUS8783179B2Good deinking effectProlong lifeAnodisationDuplicating/marking methodsDepth directionPlanographic printing

Owner:FUJIFILM CORP

Lithographic printing plate support and presensitized plate

InactiveUS20110265673A1Improve scratch resistanceExcellent on-press developabilityAnodisationDuplicating/marking methodsEngineeringMechanical engineering

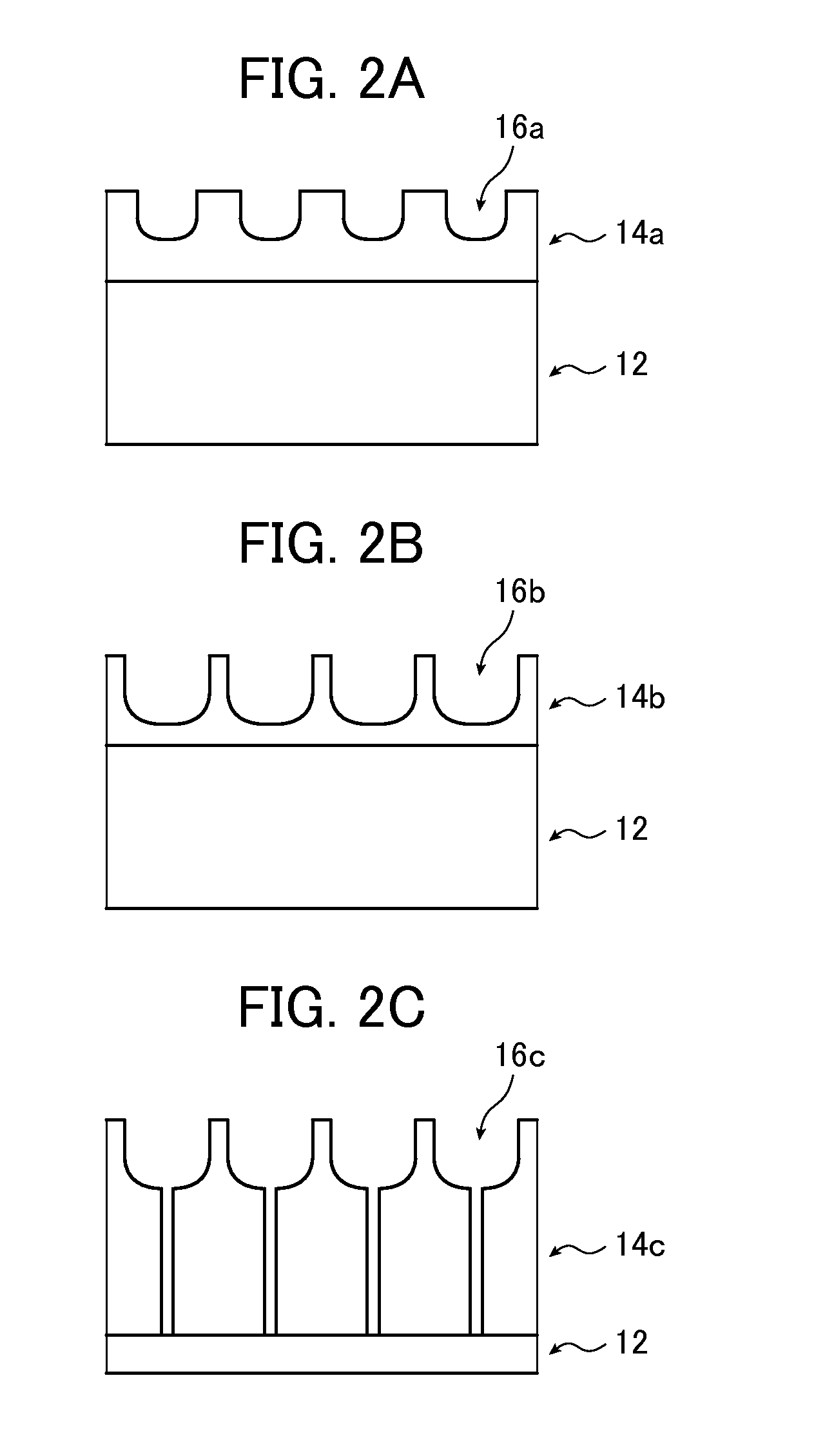

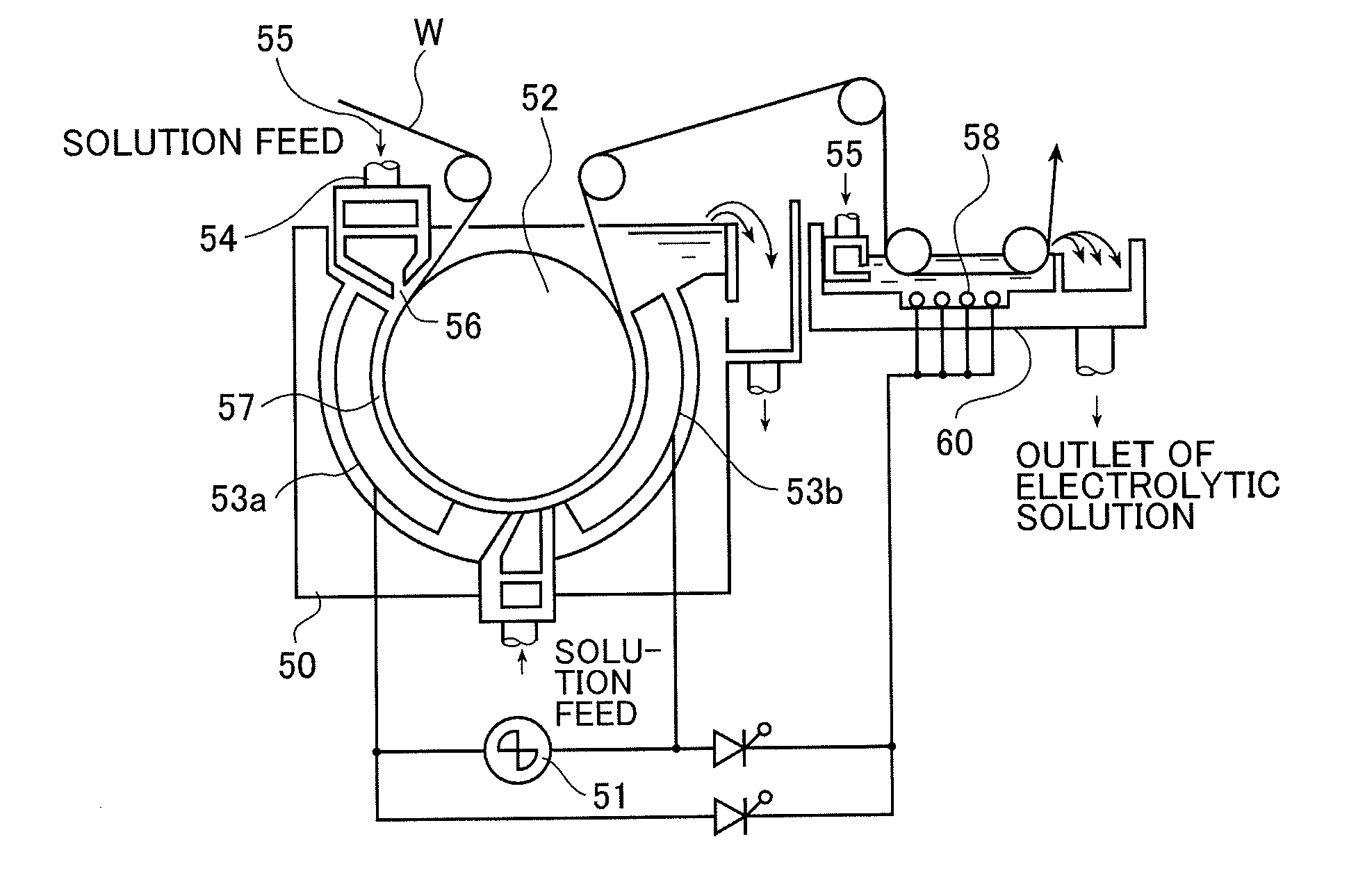

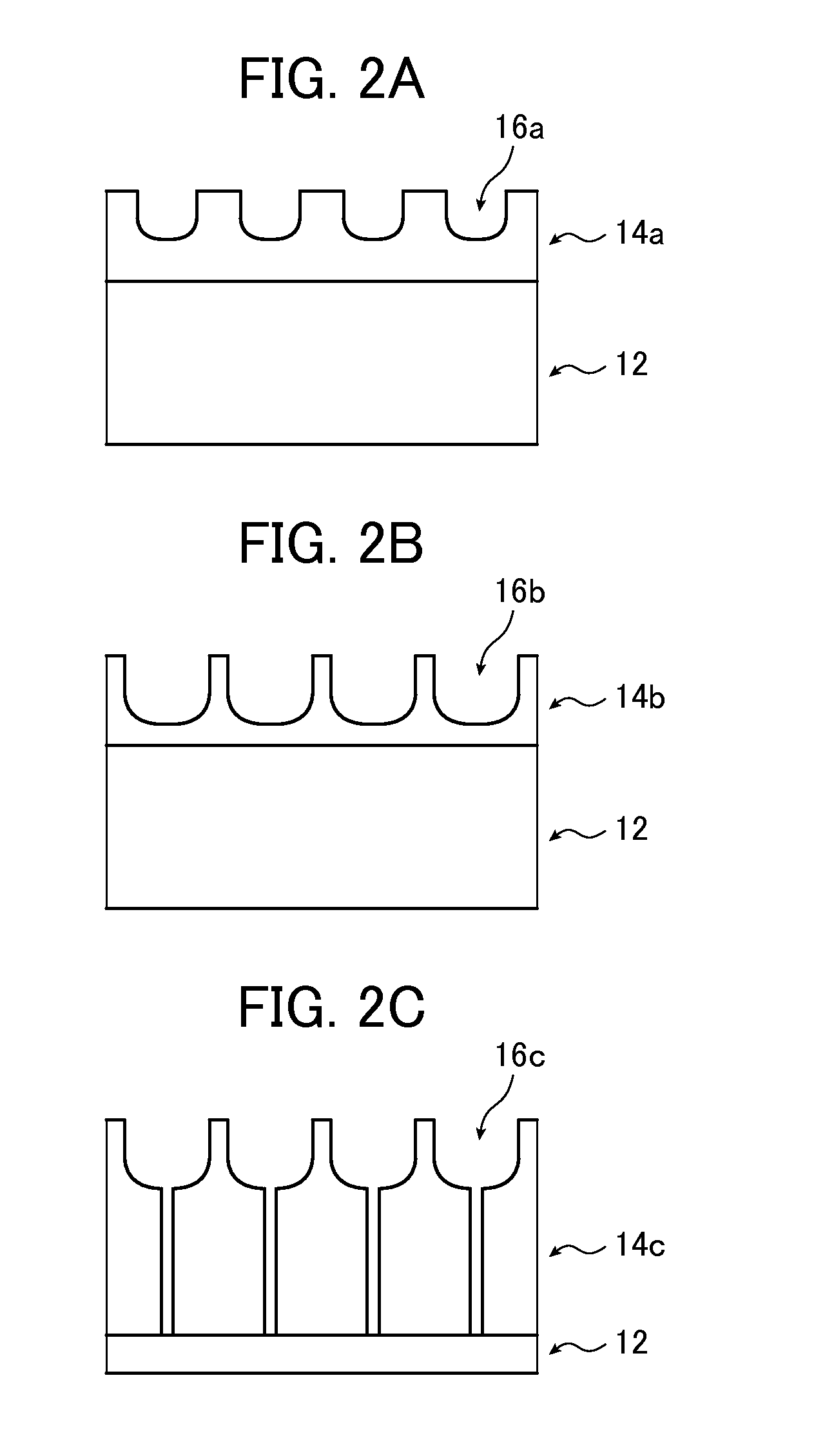

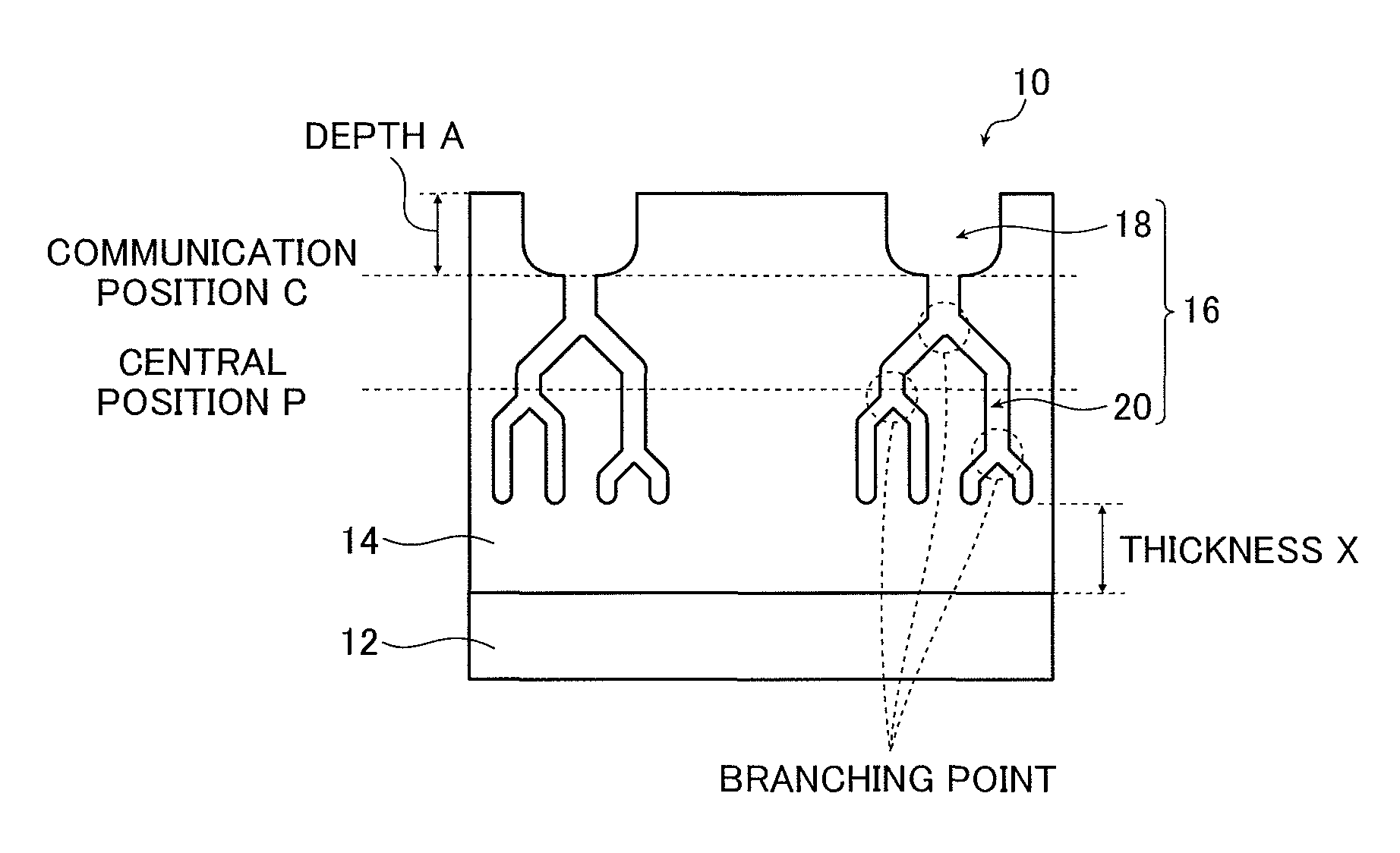

The lithographic printing plate support includes an aluminum plate and an anodized film formed on the aluminum plate and micropores extend in the anodized film in a depth direction from its surface opposite from the aluminum plate. Each of the micropores includes a large-diameter portion having a predetermined shape and a small-diameter portion having a predetermined shape. The lithographic printing plate support has excellent scratch resistance and is capable of obtaining a presensitized plate which exhibits excellent on-press developability and enables a lithographic printing plate formed therefrom to have a long press life, and excellent deinking ability in continued printing and after suspended printing.

Owner:FUJIFILM CORP

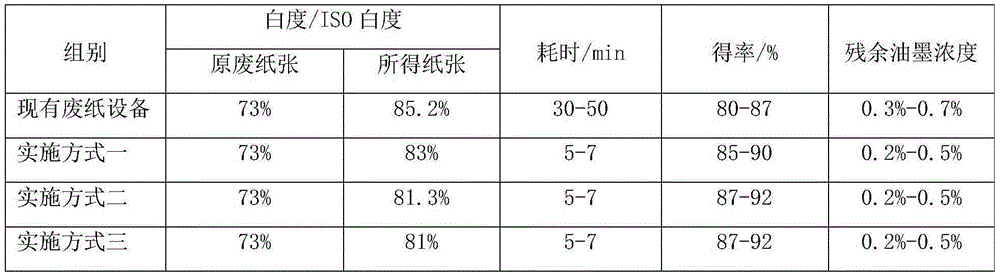

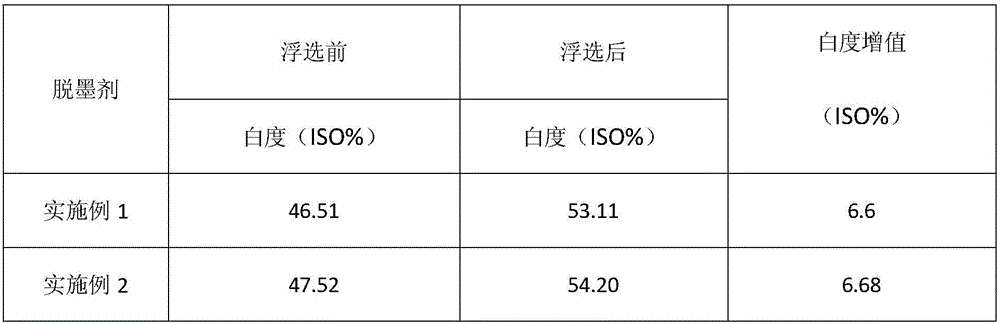

Method for improving removal effect of ink in waste paper pulp

InactiveCN101725069AGood removal effectGood deinking effectPaper recyclingPaper/cardboardDeinkingFiber

The invention discloses a method for improving a removal effect of ink in waste paper pulp. The method comprises the steps of: breaking waste paper, and diluting obtained pulp; then relative to the absolute dry mass of the paper pulp, adding 0.0025 to 0.5 percent of nonionic deinking agent into the pulp; at the same time, adding an anionic dispersant with a dispersion effect, wherein the consumption of the anionic dispersant is 0.001 to 0.3 percent of the absolute dry mass of the paper pulp; and floating at the temperature of between 40 and 50 DEG C after the mixture is stirred uniformly to remove the ink in the waste paper pulp, wherein the anionic dispersant is anionic polyacrylamide, or is one of polyacrylate and polymethacrylate. The method adopts the cheaper dispersant to compound the deinking agent with higher cost for floatation, which promotes deinking effect, and also solves the problems of cost increase caused by overhigh consumption of the deinking agent and the decrease of economic benefit caused by excessive fiber loss.

Owner:SOUTH CHINA UNIV OF TECH

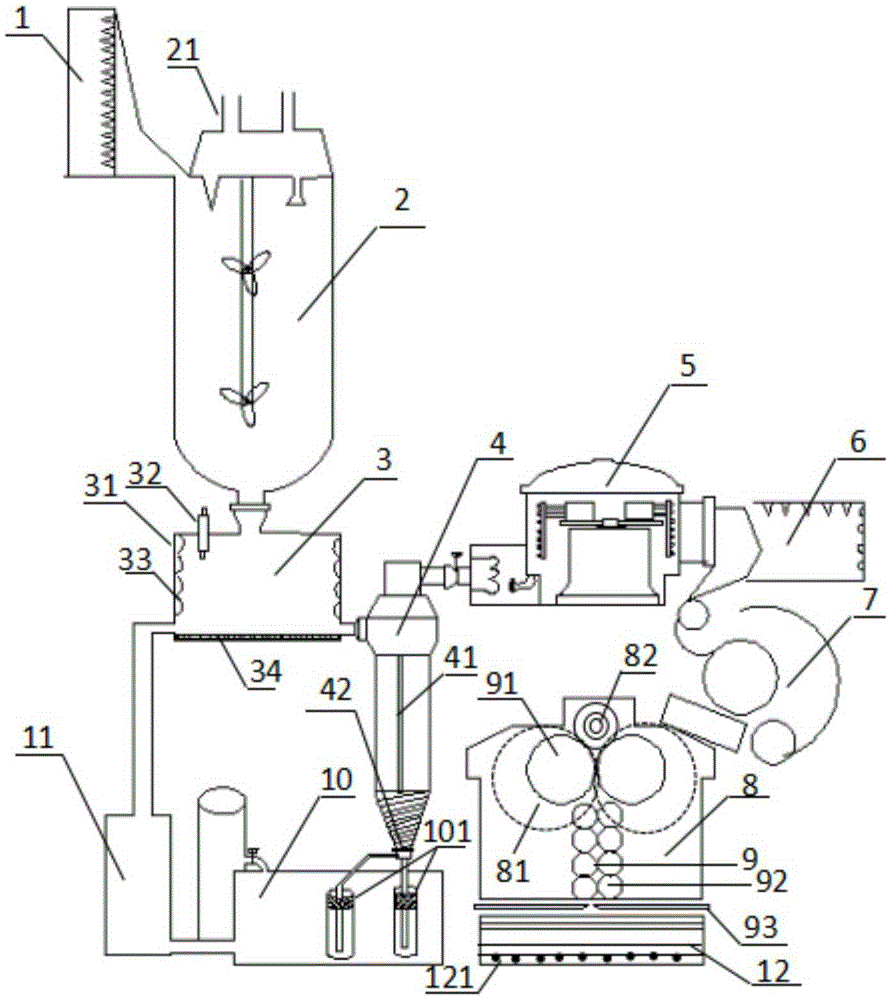

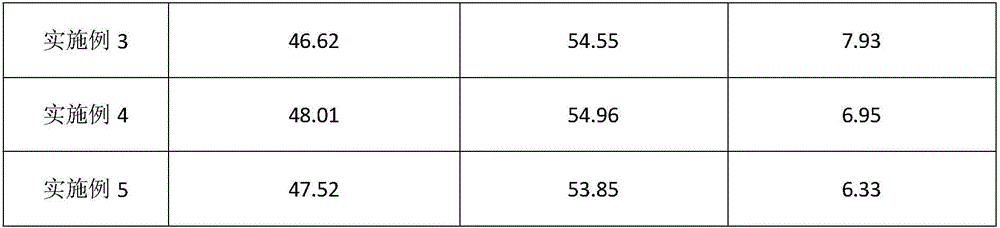

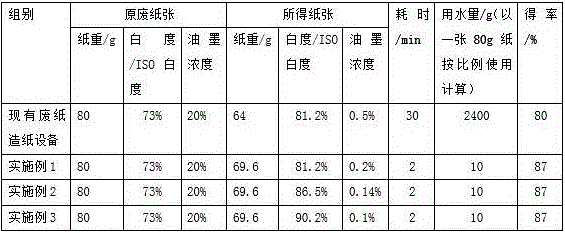

Custom environment-friendly paper machine for office and home use

ActiveCN105386349AImprove efficiencyShorten the timeWashing/displacing pulp-treating liquorsPaper recyclingPapermakingExtrusion

Owner:李璇

Support for planographic printing plate, method for producing support for planographic printing plate, and planographic printing original plate

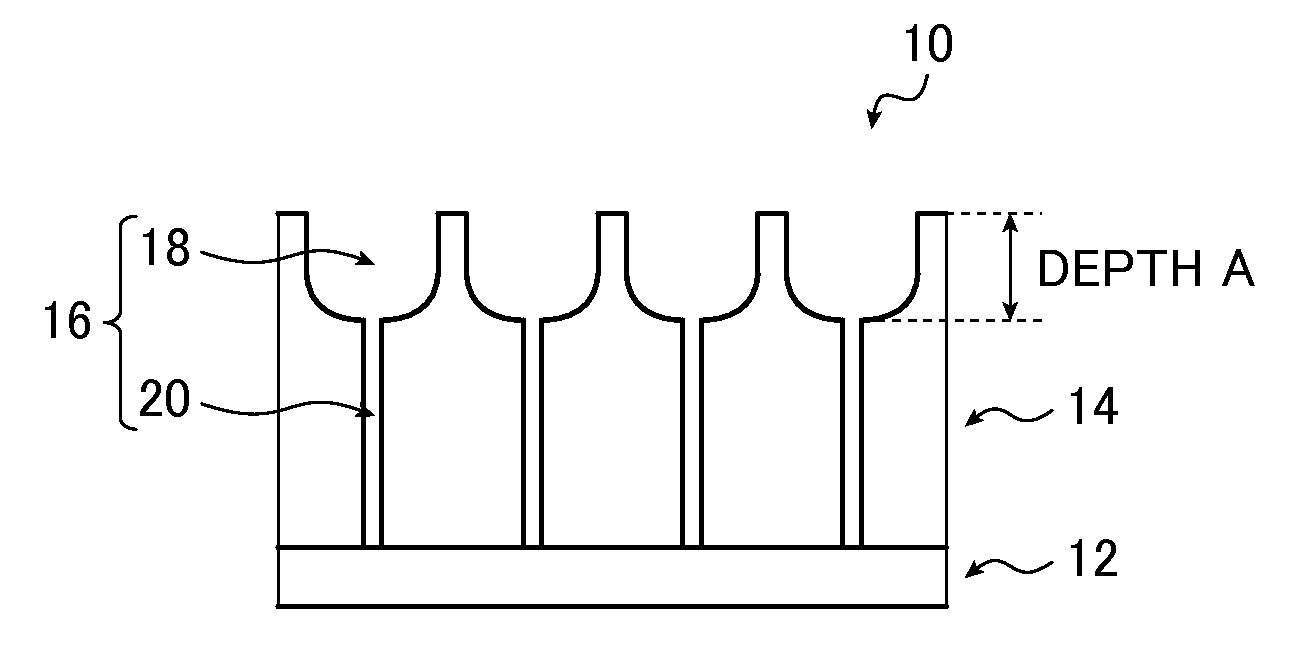

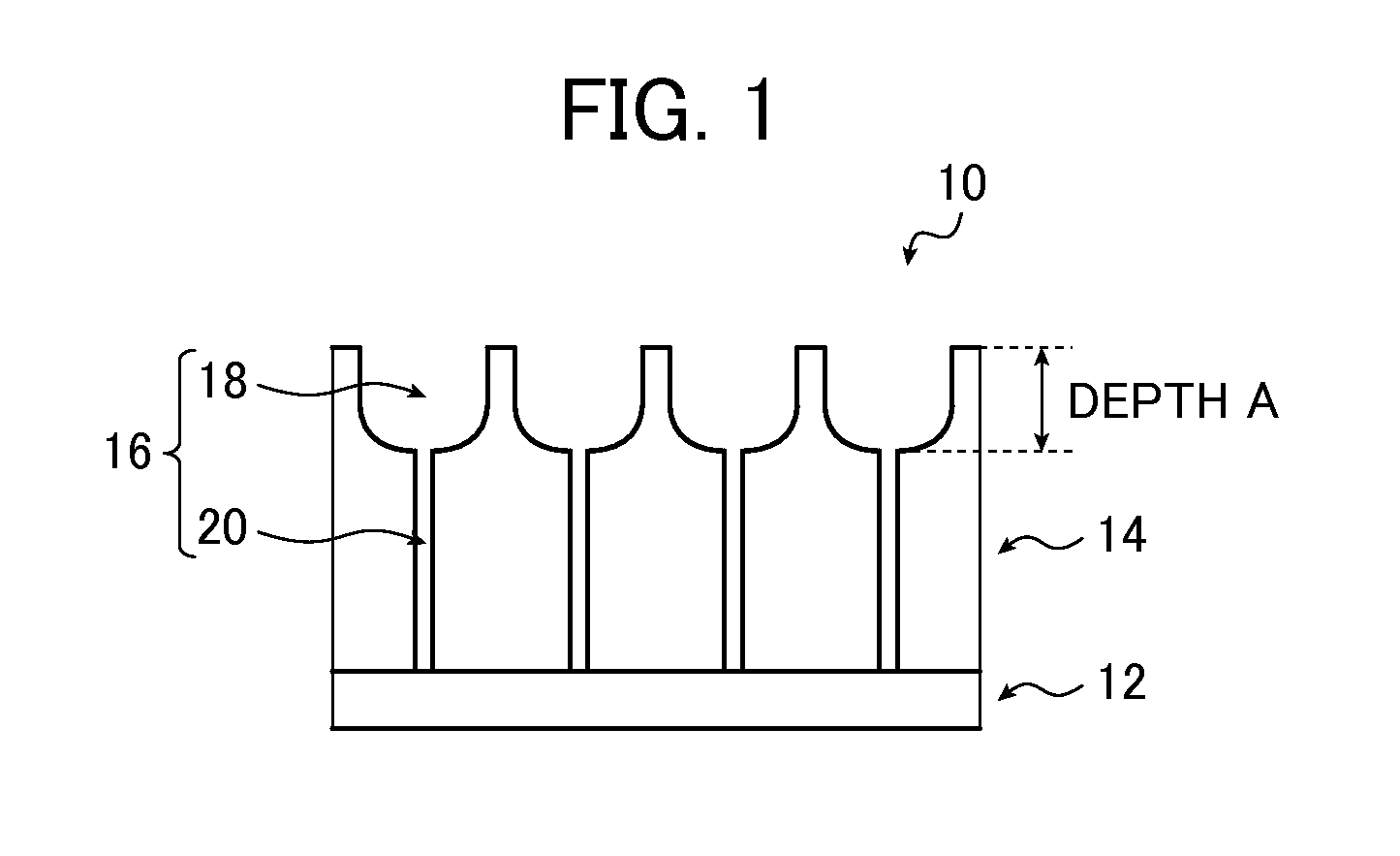

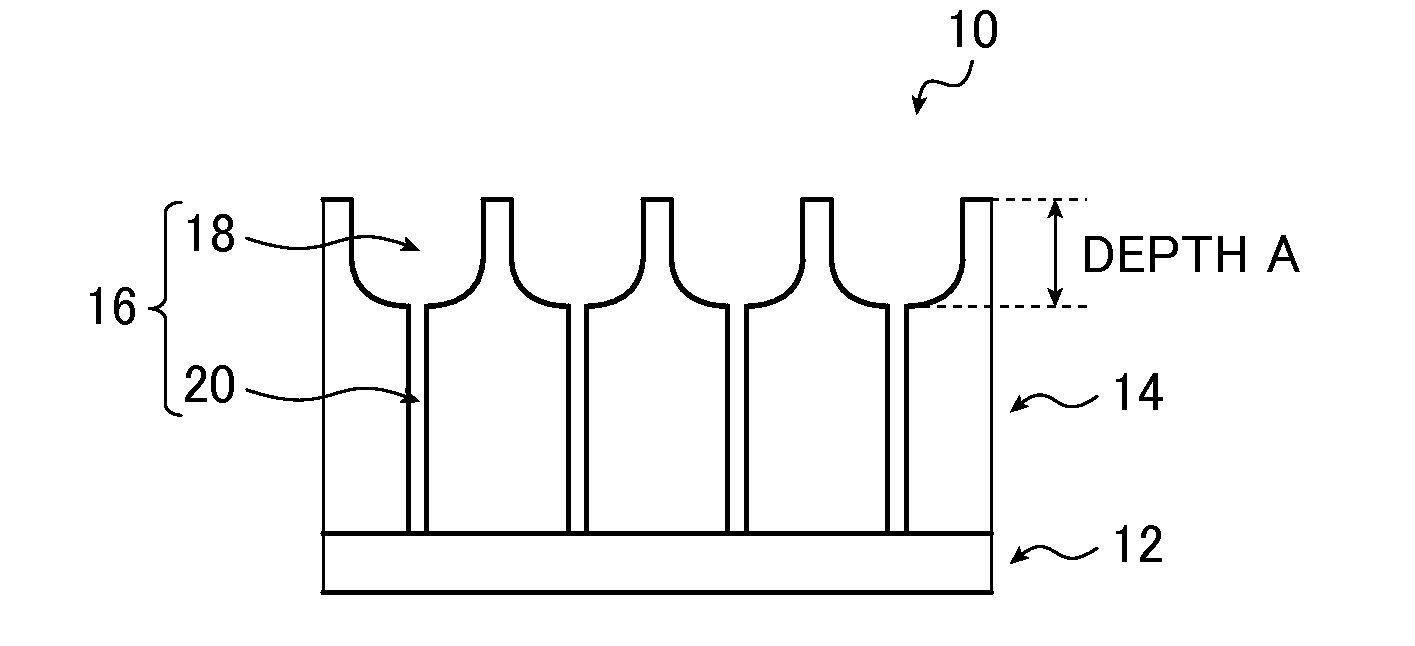

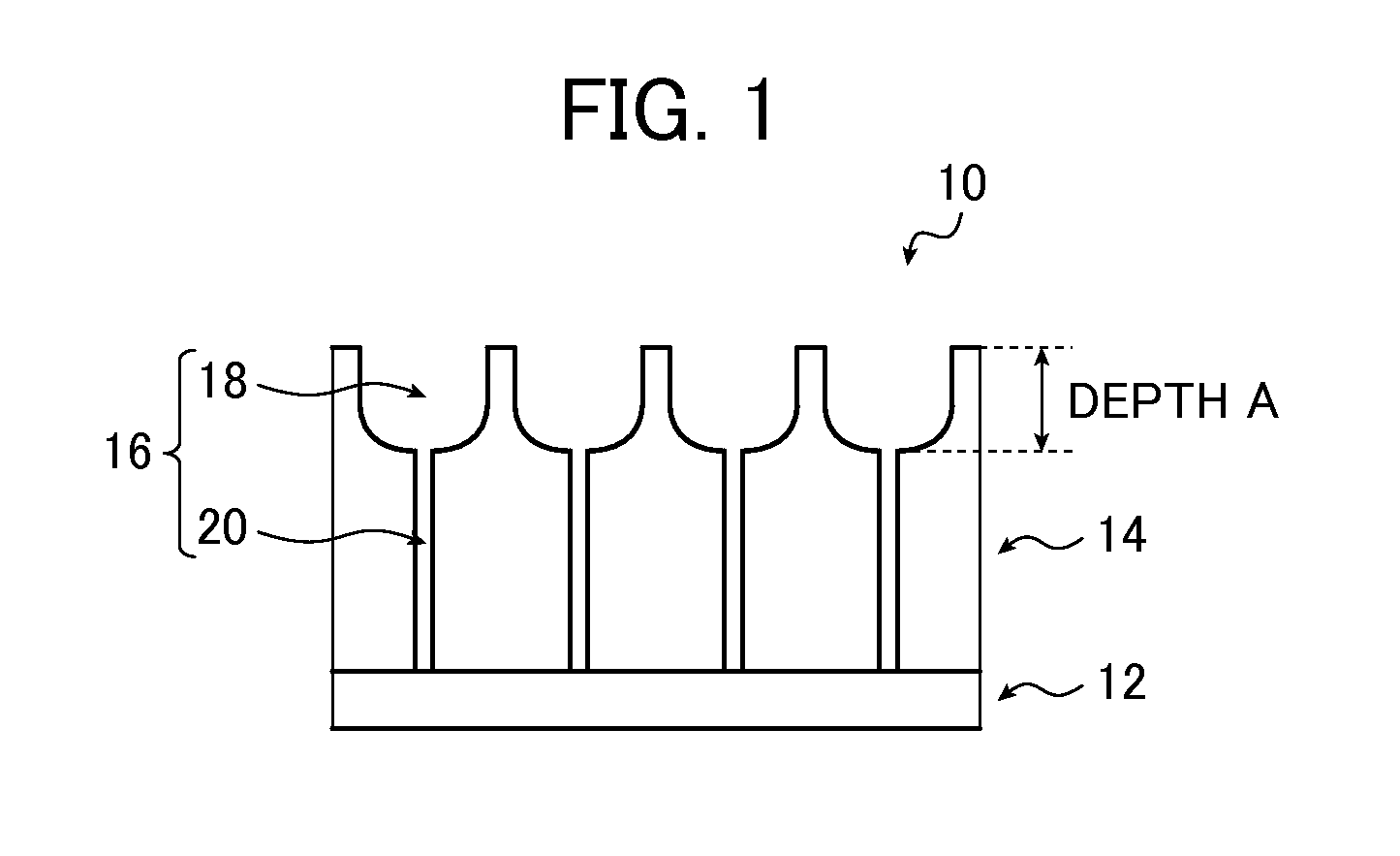

ActiveUS20120298001A1Good deinking effectProlong lifeAnodisationDuplicating/marking methodsEngineeringDepth direction

Provided is a lithographic printing plate support that has excellent scratch resistance and is capable of obtaining a presensitized plate which exhibits excellent on-press developability and enables a lithographic printing plate formed therefrom to have a long press life and excellent deinking ability after suspended printing. The lithographic printing plate support includes an aluminum plate, and an aluminum anodized film formed thereon and having micropores which extend in a depth direction of the anodized film from a surface of the anodized film opposite from the aluminum plate. Each micropore has a large-diameter portion which extends to a depth of 5 to 60 nm (depth A) from the anodized film surface, and a small-diameter portion which communicates with the bottom of the large-diameter portion, further extends to a depth of 900 to 2,000 nm from the communication position and has a predetermined average diameter.

Owner:FUJIFILM CORP

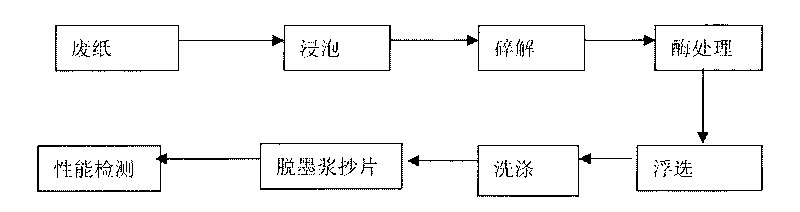

Lithographic printing plate support and presensitized plate

InactiveUS8978555B2Improve scratch resistanceExcellent developabilityDuplicating/marking methodsSurface reaction electrolytic coatingEngineeringDepth direction

A lithographic printing plate support includes an aluminum plate and an anodized film formed at a surface of the aluminum plate and having micropores which extend in a depth direction of the anodized aluminum film from a surface of the anodized film opposite from the aluminum plate. Each of the micropores includes a large-diameter portion and a dendritic small-diameter portion. The lithographic printing plate support has excellent scratch resistance and is capable of obtaining a presensitized plate which exhibits excellent on-press developability and enables a lithographic printing plate formed therefrom to have a long press life and excellent deinking ability after suspended printing.

Owner:FUJIFILM CORP

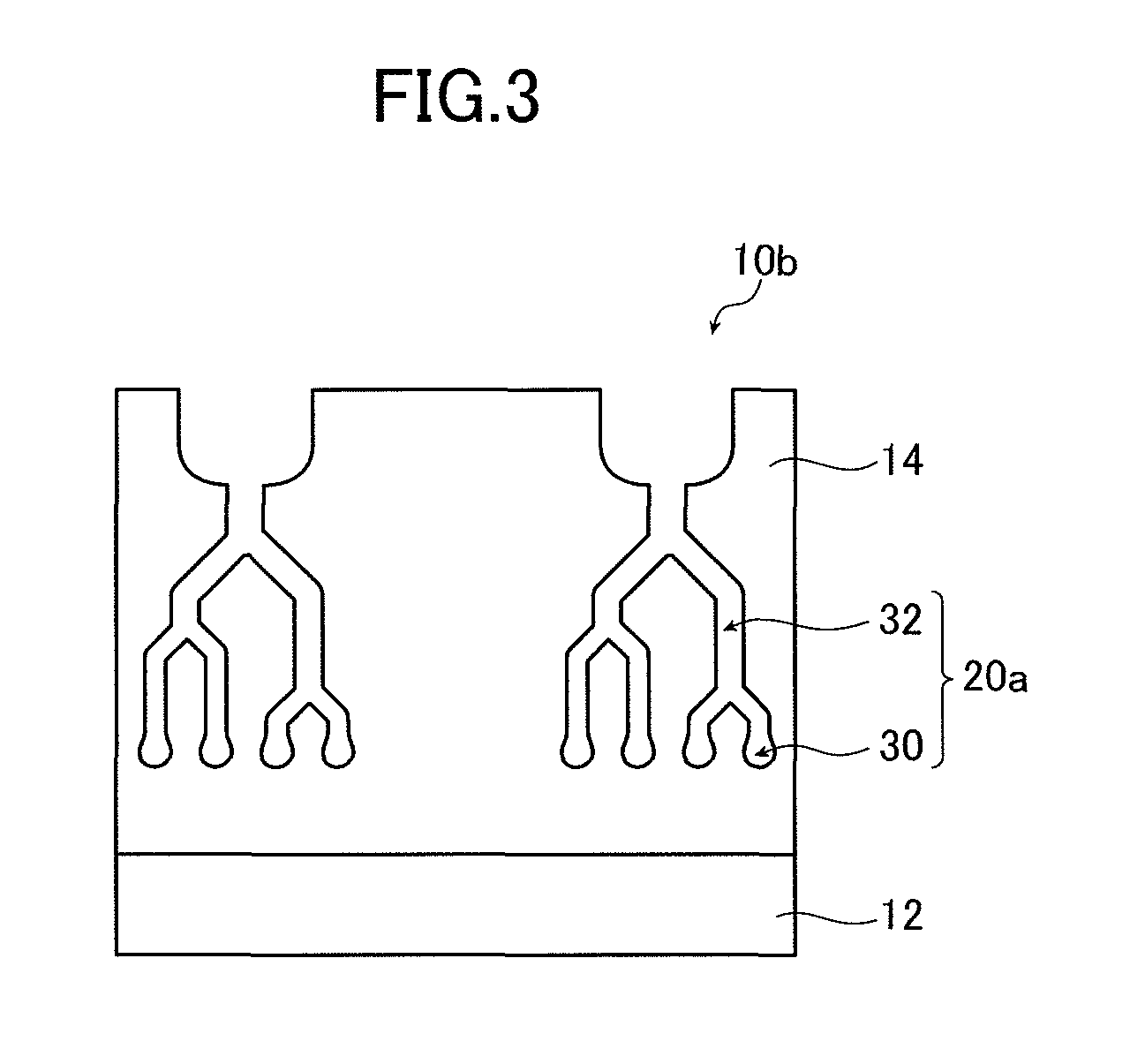

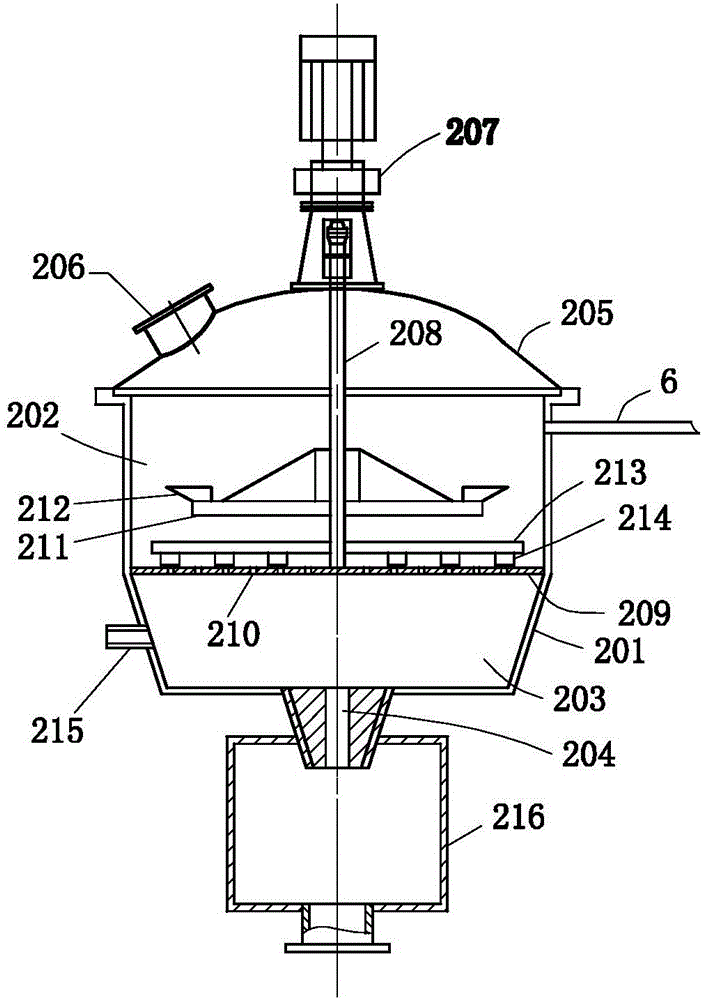

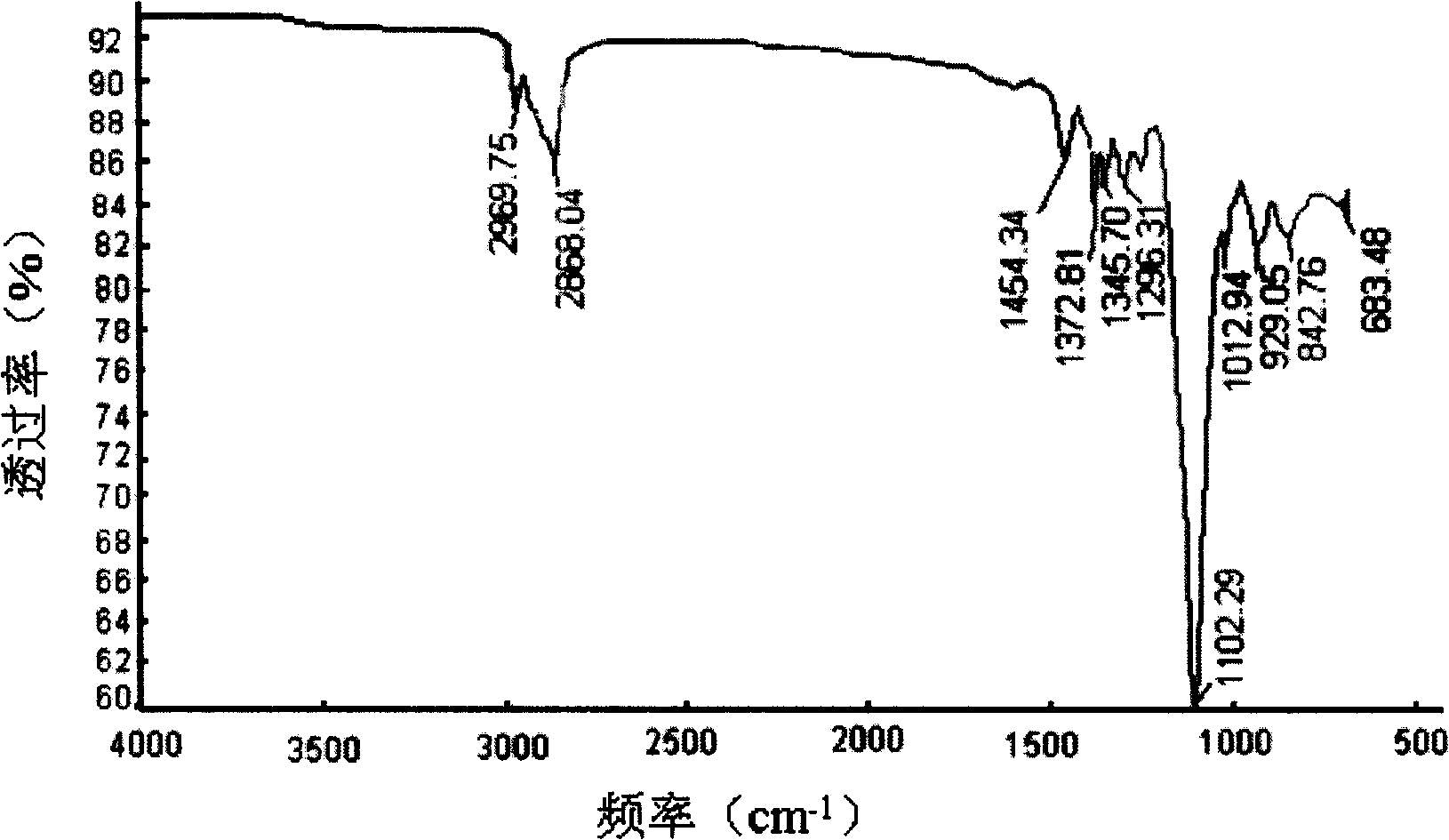

Neutral biological enzyme deinking agent and preparation method thereof

ActiveCN102532980AReduce dosageMild conditions for deinkingPaper recyclingChemical paints/ink removersPolypropylene glycolFatty acid

The invention discloses a neutral biological enzyme deinking agent and a preparation method thereof. The neutral biological enzyme deinking agent includes the following components by weight: 1% to 10% of lipase, 5% to 15% of fatty alcohol-polyoxyethylene ether, 5% to 15% of fatty acid polyoxyethylene ether, 5% to 15% of polyethylene glycol, 5% to 15% of polypropylene glycol and 30% to 79% of water. The preparation method includes sequentially adding water, the fatty alcohol-polyoxyethylene ether, the fatty acid polyoxyethylene ether, the polyethylene glycol and the polypropylene glycol into a reaction kettle, conducting stirring for 30 minutes to form solution with stirring speed as 100-150 turn / minute, adding the biological enzyme into the solution, stirring the solution for at least 10 minutes with the stirring speed as 100-150 turn / minute, and stirring the solution for at least 60 minutes with the stirring speed as 10-50 turn / minute. The neutral biological enzyme deinking agent cannot easily corrode equipment, is light in pollution and good in deinking effect.

Owner:ANHUI LEVEKING BIOTECH CO LTD

Waste paper deinking agent

ActiveCN101928485AEasy to produceReduce pollutionFats/resins/pitch/waxes removal in pulpChemical paints/ink removersDeinkingEconomic benefits

The invention relates to a waste paper deinking agent, which consists of surfactant, polyoxyethylene ether substance, penetrating agent, fatty acid sodium salt, caustic soda, sodium silicate, water and the like. All chemicals forming the waste paper deinking agent are common chemical products, and are easily purchased in a market. The components are innocuous and can be naturally degraded, namely the waste paper deinking agent meets the requirement of the current environment-friendly policy and has good environment friendliness. Meanwhile, a preparation process for the waste paper deinking agent is simple, easy in operation and good in finished product stability, can be applied to the deinking process of multiple waste papers and has ideal deinking effect; and the waste paper deinking agent is convenient to transport and store and is quickly dissolved in the deinking production process, namely the waste paper deinking agent has good economic benefit. Therefore, the waste paper deinking agent has remarkable environmental benefit and economic benefit.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

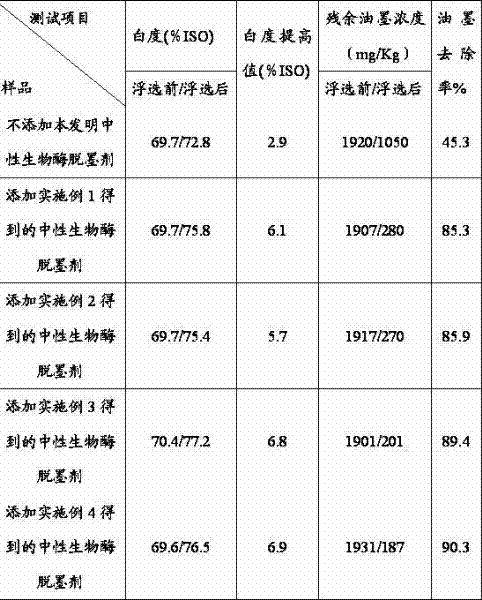

Deinking method of waste paper alkaline enzyme

InactiveCN101691699ASave the bleaching processLow costFats/resins/pitch/waxes removal in pulpPaper recyclingPectinaseDeinking

The invention discloses a deinking method of waste paper alkaline enzyme, comprising the following steps: carrying out soaking, disintegration, enzyme processing and washing on the waste paper to obtain the processed pulp; adding surface active agent when soaking at a usage amount of 0.10%-2.00%wt, wherein the enzyme processing is carried out under the conditions that the pH is 6-11, the temperature is 45-75 DEG C, and xylanase 30-150 mu / g of oven dry stock, pectinase 40-100 mu / g of oven dry stock and amylase 50-120 mu / g of oven dry stock are adopted to process the disintegrated waste paper for 10-30min. Cellulase can also be added in the enzyme processing procedure with an added quantity of 100 mu / g of oven dry stock. The processing effect is better if enzyme activator, such as sodium chloride is added in the enzyme processing procedure; and the alkaline enzyme can be bathed and used in a matching manner with a plurality of surface active agent, even with compounds with certain oxidation functions; and the process of waste paper deinking technology can be shortened and the bleaching process in deinking by the conventional enzyme method can be left out.

Owner:南京川平科技开发有限公司

Environment-friendly type deinking agent for mixing waste paper

InactiveCN101381534ALow freezing pointGood deinking effectChemical paints/ink removersDeinkingPhenyl Ethers

The invention relates to a deinking agent, in particular to an environment-friendly mixed waste paper deinking agent. The prior waste paper deinking agent can only deink one class of waste paper in general. The invention provides the environment-friendly mixed waste paper deinking agent with wider application range, which is characterized in that the weight percentage of every component is: 5 to 10 percent of polyoxyethylene nonyl phenyl ether, 25 to 30 percent of fatty alcohol polyoxyethylene ether sodium sulfide, 5 to 10 percent of fatty alcohol polyoxyethylene ether, 10 to 20 percent of sulfonic acid, 4 to 10 percent of ethanol and the balance being water. Compared with the prior deinking agent, the deinking agent of the invention has the advantages of wide application range, good deinking effect and the like, and is few in components and simple in method.

Owner:HANGZHOU KAIBO CHEM IND

Environment-friendly deinking agent for toughened glass and preparation method of environment-friendly deinking agent

The invention relates to the technical field of deinking agents, in particular to an environment-friendly deinking agent for toughened glass and a preparation method of the environment-friendly deinking agent. The deinking agent is prepared from 30%-70% of deionized water, 0.5%-8% of a corrosion inhibitor, 5%-15 % of a penetrant, 5%-20% of an inorganic basic compound, 5%-15 % of an aqueous stabilizer, 5%-20% of a solvent and 5%-15% of a mixture of alkyl alcohol ether carboxylate and alkyl polyoxyethylene phosphate. The raw materials of the deinking agent are all environment-friendly agents, and halogen, benzene and other toxic solvents are not contained; screen printing ink on the toughened glass of various tablets, touch screens and the like is removed under the synergistic effect among the components of the deinking agent, the deinking effect is good, and the deinking speed is high; besides, the homogeneous phase can be kept and a solution does not layer in a heating or high-temperature use process, and the chemical performance of the deinking agent is more stable.

Owner:广东星弛光电科技有限公司

Polyether surfactant as deinking agent of waste paper and its preparation method

InactiveCN101007248AThe composition is uniqueGood compatibilityFats/resins/pitch/waxes removal in pulpWashing/displacing pulp-treating liquorsDeinkingChemical structure

The invention discloses a polyether surfactant as wastepaper deinking agent and preparation method. Its chemical structure general formula as follows: R-(PO)n-(EO)m, among it R group is fatty alcohol start agent, m and n represents the polymerization degree of EO and PO in macromolecules respectively, n ranges 8-26 and m ranged 4-35. Preparation method steps as follows: 1) adding 3-20 wt% epoxypropane and 1- 3 wt % start agent mono-functional aliphatic alcohol into autoclave, while adding 0.1-0.2 wt% initiator; 2) evacuating the reactor and reacting the first step polymerization reaction under 70 ~ 120 DEG C; 3) after completing the first step reaction, evacuating the reactor again, adding 4~30 wt% epoxyethane under 50 ~ 100 degree C and reacting the second polymerization reaction; 4) after completing the first step reaction, taking-up the final product and neutralizing with acid until neutral under 20 ~ 60 degree C. The invention process is simple, efficient and environment-friendly, and has good characteristics such as less use, wide range of application and good deinking results, etc.

Owner:ZHEJIANG UNIV

Deinking of waste paper

InactiveUS20020179261A1Good deinking effectSpeed up the processPaper recyclingPulping with organic solventsStarch degradationEnzyme

In the production of pulp and paper from starch-containing paper, the deinking effect can be improved by including treatment with both a starch-degrading enzyme and a pectate lyase. The process comprises enzyme treatment during or after disintegration of the paper to produce pulp, followed by separation of ink particles.

Owner:NOVOZYMES AS +1

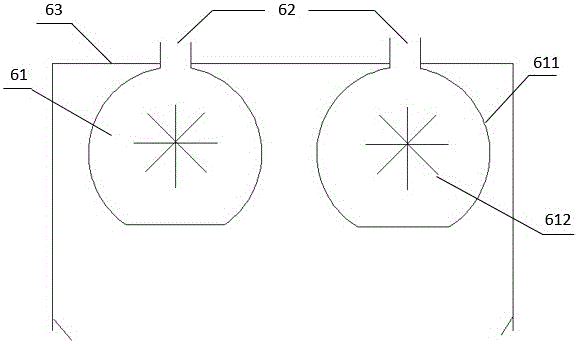

Deinking device

InactiveCN1727572ASimple structureNo power requiredFats/resins/pitch/waxes removal in pulpPaper recyclingWastewaterSewage

A deinking machine for treating the paper-making sewage is composed of a casing with liquid inlet and outlet, an ink collector with dregs outlet, and a millipore aerating unit with air inlet tube for blowing the air bubbles in the sewage by high-pressure air. When the air bubbles are diffused in the sewage, the ink in the sewage is adsorbed by them. When said air bubbles are broken on the surface of sewage, the ink is collected by the ink collector and then discharged via dregs outlet.

Owner:李风宁

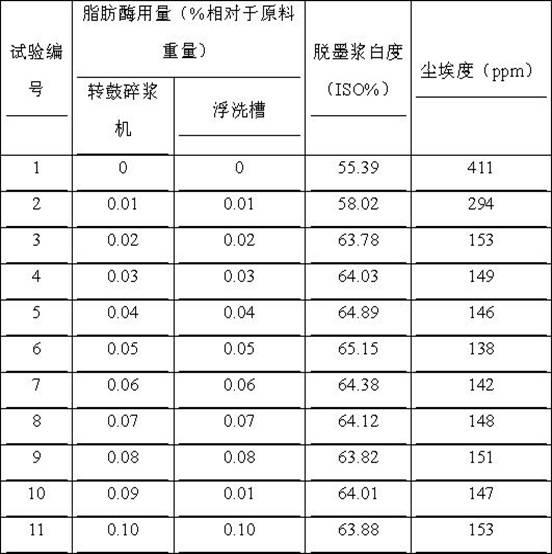

Waste paper deinking method

The invention belongs to the technical field of paper making and relates to a water paper deinking method, which aims to solve the problem of poor deinking effect in a neutral deinking process. The invention provides the water paper deinking method which comprises a pulping step of pulping by using a pulping machine and a flotation step of floating waste paper pulp by using a floatation groove. The water paper deinking method is characterized by further comprising a waste paper fiber rubbing step between the pulping step and the floatation step. The pulping step comprises a step of adding a deinking agent for the first time, and the floatation step comprises a step of adding the deinking agent for the second time. With the adoption of the above technical scheme disclosed by the invention, the technical problem can be effectively solved.

Owner:ZHEJIANG JINGXING PAPER

Biological deinking agent

ActiveCN105907162AReduce dosagePromote degradationChemical paints/ink removersDeinkingInorganic salts

The invention discloses a biological deinking agent. The biological deinking agent is prepared from, by weight, 8-25 parts of biomass raw materials, 2,000-150,000 U / g of biological enzymes, 15-40 parts of surface active agent, 1-5 parts of acid or alkali and 5-20 parts of inorganic salt electrolyte. The biological deinking agent is mainly formed by mixing the biomass raw materials, the biological enzymes and the surface active agent, a biological matrix is mainly adopted in the obtained biological deinking agent, the quantity of adopted chemical additives is small, the biological deinking agent is degradable, environmentally friendly and good in deinking effect, and the whiteness of paper obtained after deinking of the deinking agent is high.

Owner:苏州埃斯腾特生物科技有限公司

Water-saving, high-efficiency and environment-friendly paper machine for office and home use

InactiveCN106337308AAchieve reorganizationEliminate traces of usePaper recyclingCalendersHome useDeinking

A water-saving, high-efficiency and environment-friendly paper machine for an office and home use comprises a paper shredding unit, a repulping unit, an accelerating unit, a deinking unit, a dispersing unit, a fiber distributing unit, a fiber sticking unit, a conveying unit, a paper forming unit, a cutting unit and a pigment collecting unit. The water-saving, high-efficiency and environment-friendly paper machine adopts the coordination of laser clearance and physical fluid motion, reduces the chemical reagent used in the deinking process, and decreases the water consumption accordingly, thereby achieving the purpose of dry fiber processing. Compared with traditional handmade paper making and an existing small-sized paper machine for an office, the whole set of equipment has high production efficiency and a good paper deinking effect.

Owner:李璇

Deinking of waste paper

InactiveUS6576083B2Good deinking effectSpeed up the processChemical/biochemical paper treatmentPaper recyclingPulp and paper industryEnzyme

In the production of pulp and paper from starch-containing paper, the deinking effect can be improved by including treatment with both a starch-degrading enzyme and a pectate lyase. The process comprises enzyme treatment during or after disintegration of the paper to produce pulp, followed by separation of ink particles.

Owner:NOVOZYMES AS +1

Water-based composite deinking agent

InactiveCN101280133AEasy to prepareReduce depositionPaper recyclingChemical paints/ink removersWater basedDeinking

The invention provides a water-based compound deinking agent which has the following components based on weight percentage: 0.1-3% of alkyl poly propylene fatty alcohol polyoxyethylene ether phosphate, 0.1-5% of alkyl alcohol polyoxyethylene ether sulfate, 1-5% of NaOH, 2-8% of NaSiO3, 0.5-5% of H2O2, 0.5-8% of anti-ink deposition agent, and the remaining amount of water. The water-based compound deinking agent of the invention has the advantages that the invention has good emulsification, dispersion and catching performances and can reduce the re-deposition of printing ink particles in the deinking process, improve the pulp brightness, reduce the residual ink particles and improve the deinking effect so as to achieve high-efficient and environmental-friendly recycling of waste newspapers.

Owner:SHANGHAI UNIV OF ENG SCI +2

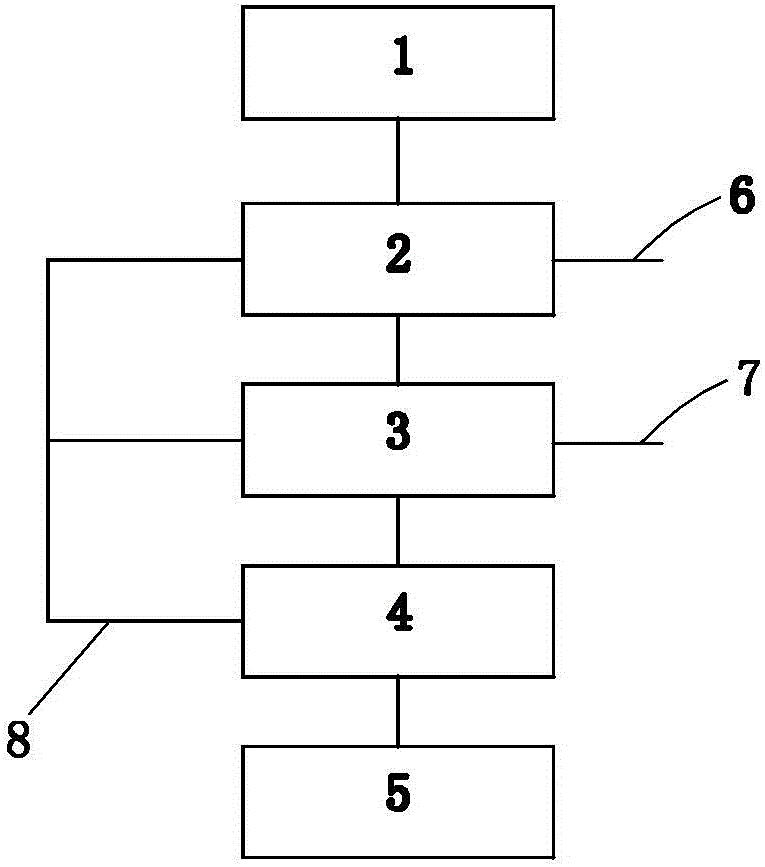

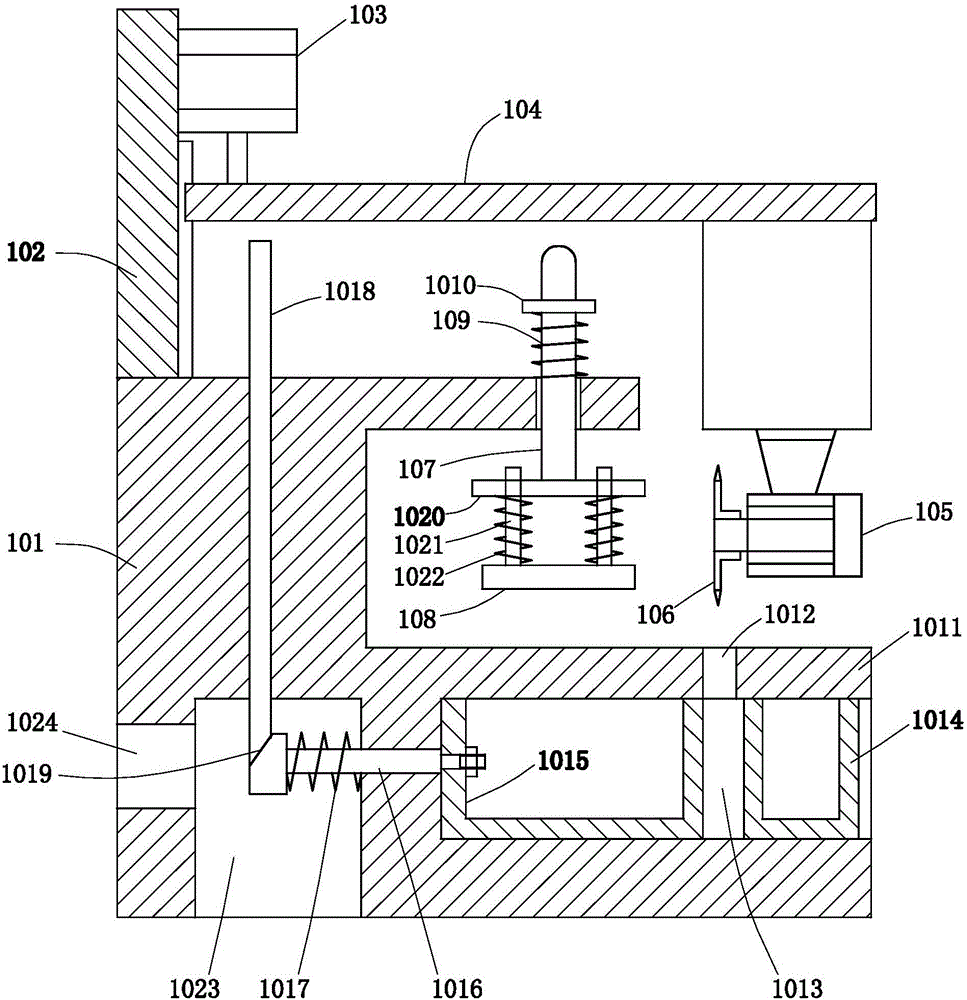

Treatment process and equipment of waste books

ActiveCN106149438AReduce power consumptionEmission reductionPaper recyclingPulp beating/refining methodsPulp and paper industryEnergy consumption

The invention discloses a treatment process and equipment of waste books and belongs to the technical field of waste paper recycling. The treatment process sequentially includes the steps, from top to bottom, of firstly, using an edge-cutting machine to cut off the edges, with glue or iron nails, of the waste books; secondly, using a hydrapulper to crush the waste books obtained after the first step, and using a ink-removing overflow pipe to discharge ink during the crushing; thirdly, using a pulping machine to make the crushed materials into pulp, performing ink removing while stirring during pulping, and discharging the removed ink through an ink discharge pipe; fourthly, using a concentrator to perform concentration; fifthly, storing the concentrated pulp in a pulp storage tank. The treatment process and equipment has the advantages that the process and equipment is simplified, energy consumption is lowered, the discharge of industrial waste liquid is reduced, the pulping efficiency and quality of the waste books are increased, and the process and equipment is widely applicable to waste paper treatment.

Owner:徐州市全鑫毛制品有限公司

Effective waste paper deinking agent

The invention discloses an effective waste paper deinking agent. The effective waster paper deinking agent is composed of, by weight, 38%-45% of surfactant, 38%-45% of enzyme-coated microcapsules and 20%-30% of auxiliaries. The effective waste paper deinking agent is suitable for being used for conducting deinking treatment on waste corrugated paper, waste news paper, color offset printing news paper, waste book and magazine paper, waste office paper and laser and electrostatic printing paper; lipase and cellulase are prepared into microcapsules through an emulsifying method, the preparation process is simple, stability is high, the activity of enzyme can be kept for a long time by adding the microcapsules into the chemical deinking agent, the chemical deinking agent is rich in ingredients and scientific in matching, the lipase and the cellulase are released slowly after waste paper pulp is added, deinking can be conducted through a chemical method and a biological method, the deinking effect on waste paper is good, whiteness is high, speckiness is low, the fiber is soft, reusability is high, the pollution degree caused by sewage generated in the later period is low, processing is simple, the cost is saved, and pollution to the environment is avoided.

Owner:HEFEI LONGFA PACKING CO LTD

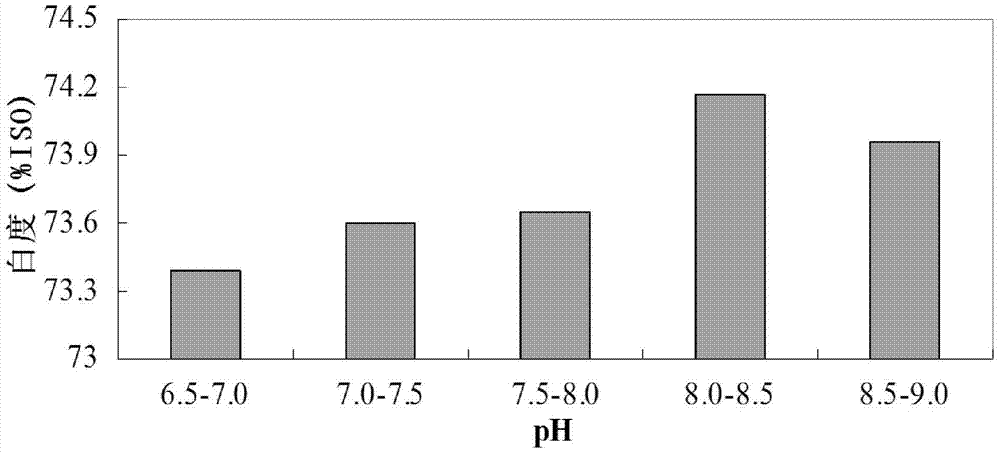

Method for deinking mixed office waste paper through composite biological enzyme

InactiveCN103485227APromote swellingReduce connectionsPaper recyclingWaste paper working-upPulp and paper industrySlurry

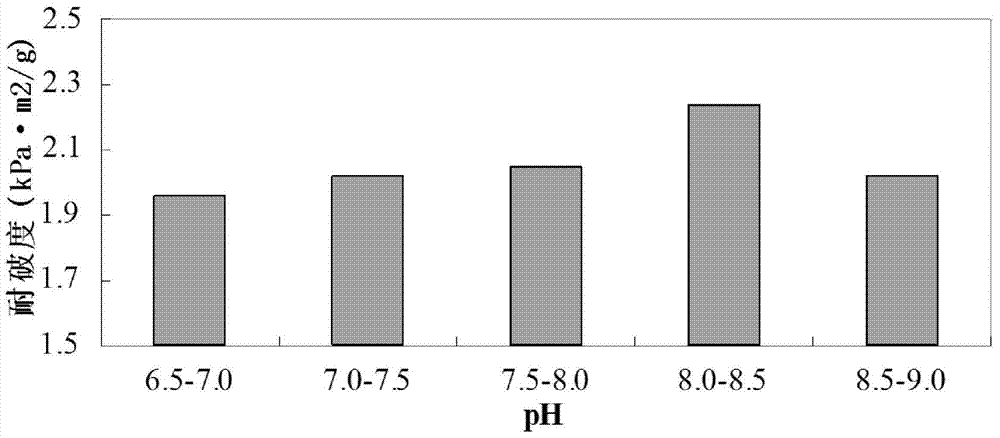

The invention discloses a method for deinking mixed office waste paper through composite biological enzyme. The method comprises the steps as follows: office waste paper is torn into 25*25 mm scraps with hands, and the scraps are soaked for 10 min and placed in a horizontal type hydrapulper for fluffing, so that standby pulp is obtained; the standby pulp is placed in the hydrapulper, water is added, the temperature is raised, the pH is adjusted, the composite biological enzyme and a surface active agent are added, and the mixture is mixed with the slurry; and finally, the slurry is poured into a flotation device, water is added for adjusting the slurry concentration to be 0.5%, the pH is adjusted to 8.0-8.5, an air pump and a slurry recycle switch of the flotation machine are switched on, and flotation is timed when a bubble pops out of a flotation tank; and after flotation, aeration and slurry recycle are stopped, and the slurry is poured into a filter bag to be squeezed, dried and dispersed for sheet making. According to the method, the waste paper dust degree is greatly reduced, the Eric value is decreased, and at the same time, the tensile index and the burst index of the paper are improved, so that the paper can have higher application values.

Owner:FUJIAN AGRI & FORESTRY UNIV

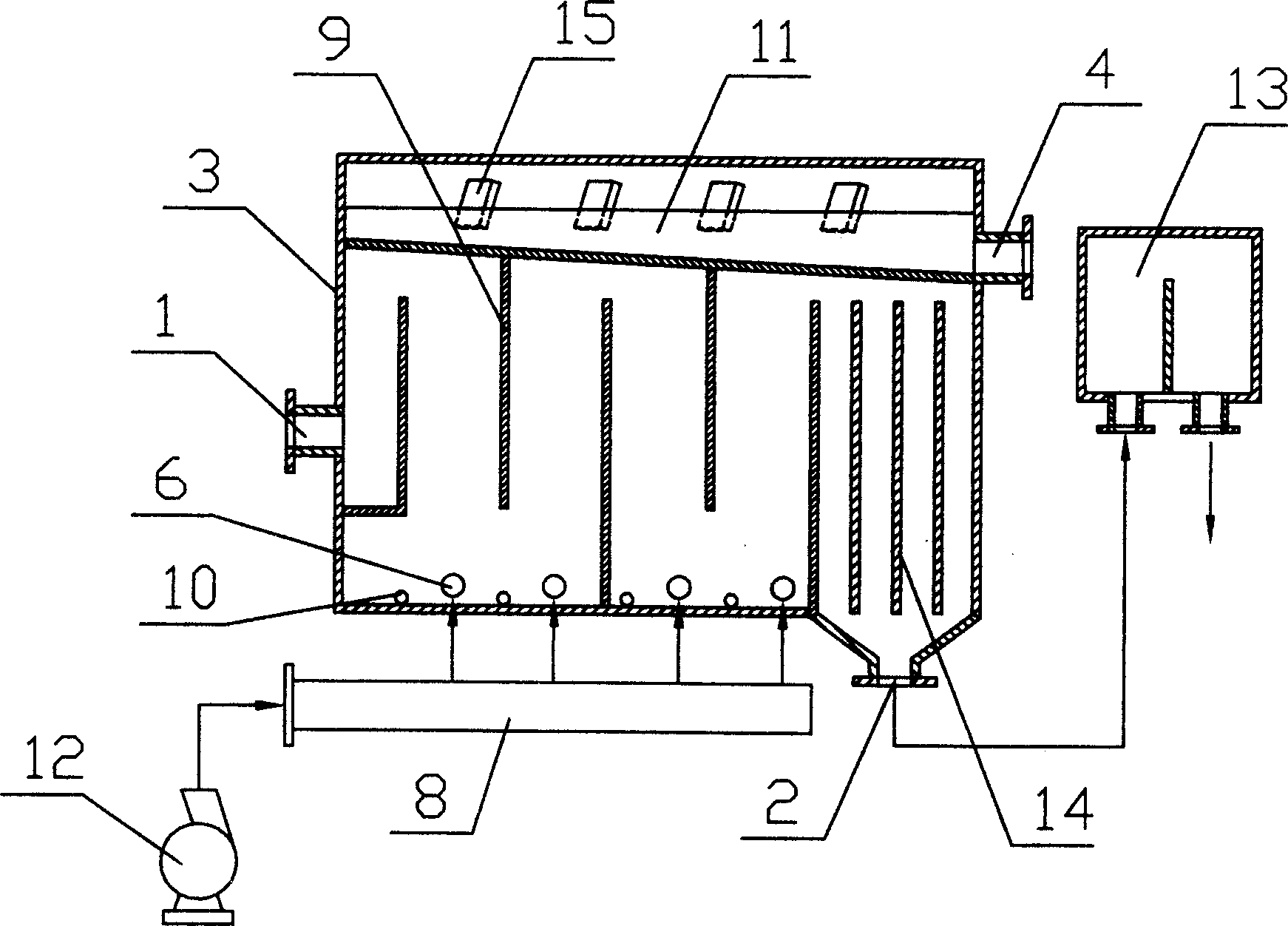

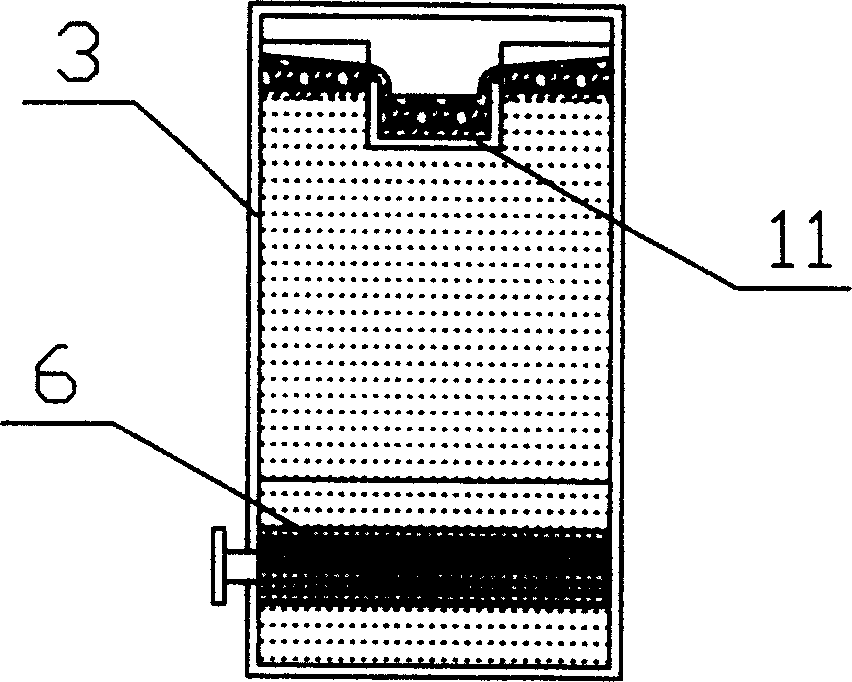

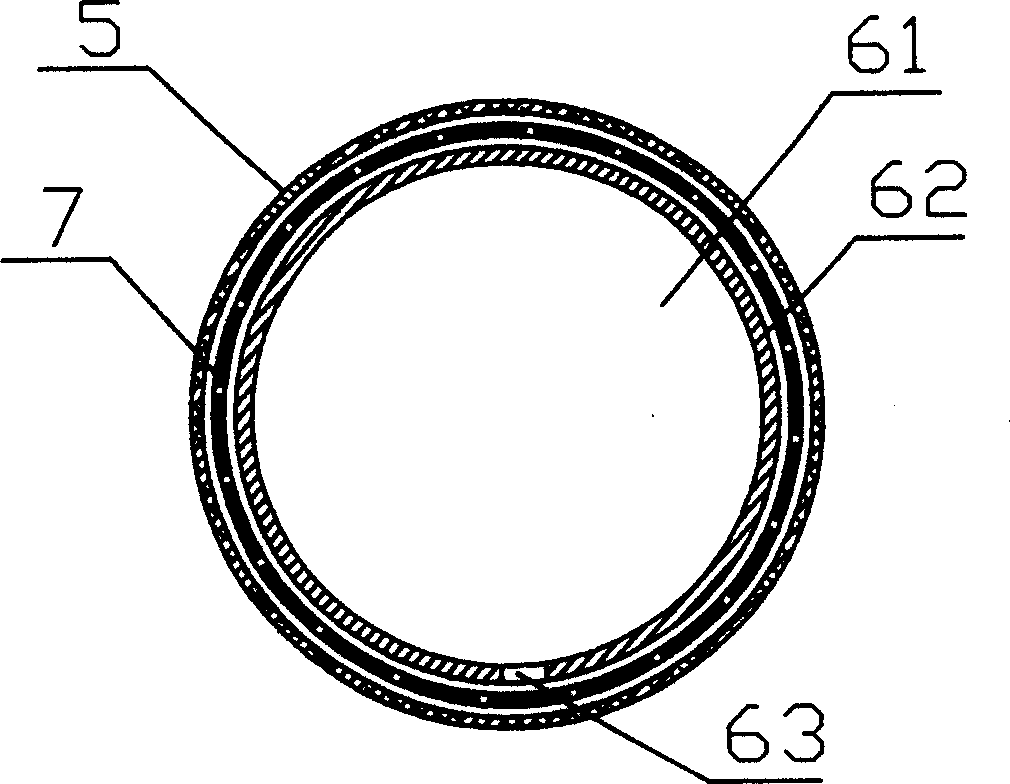

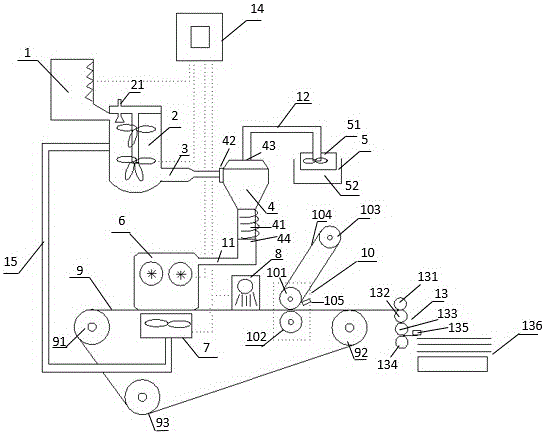

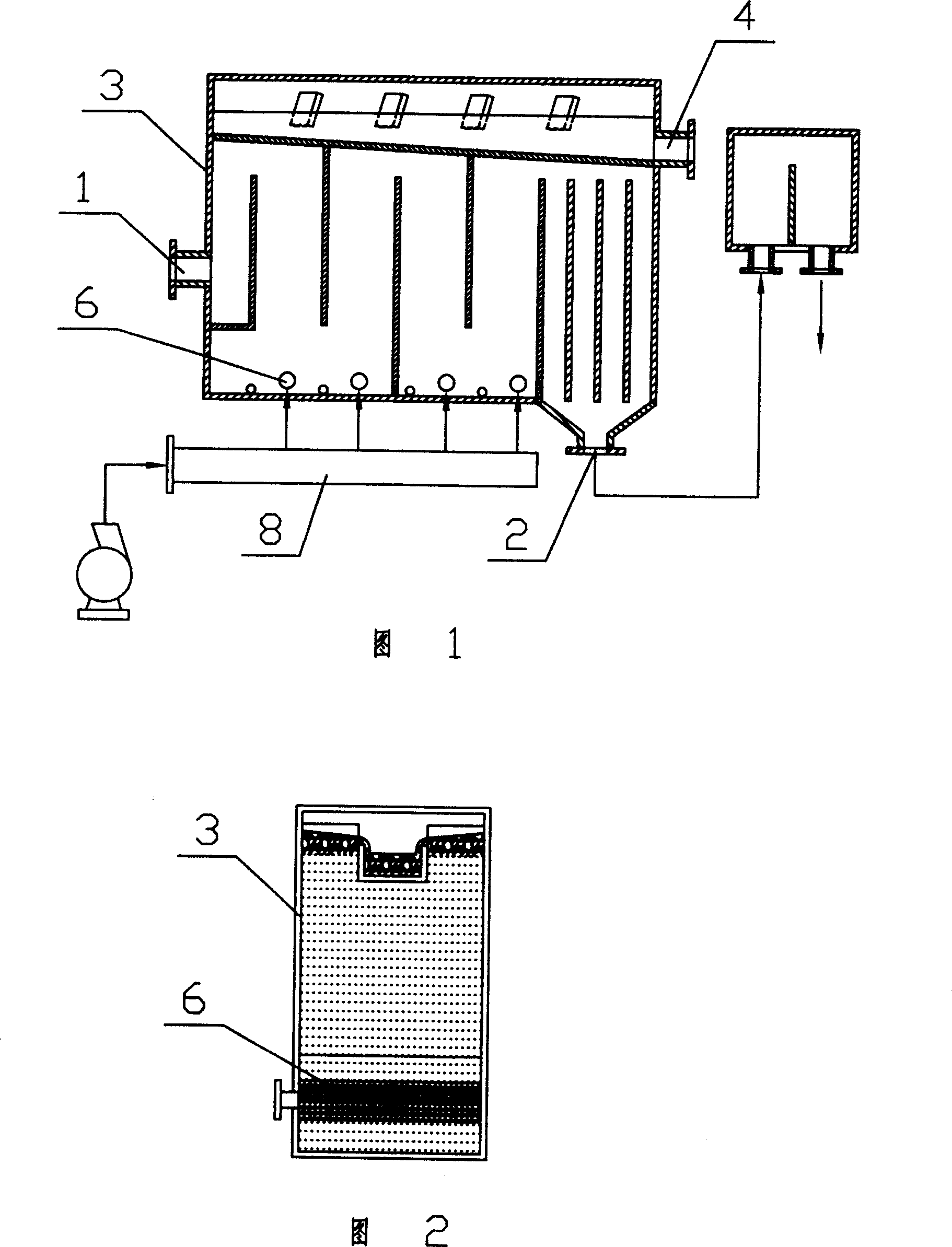

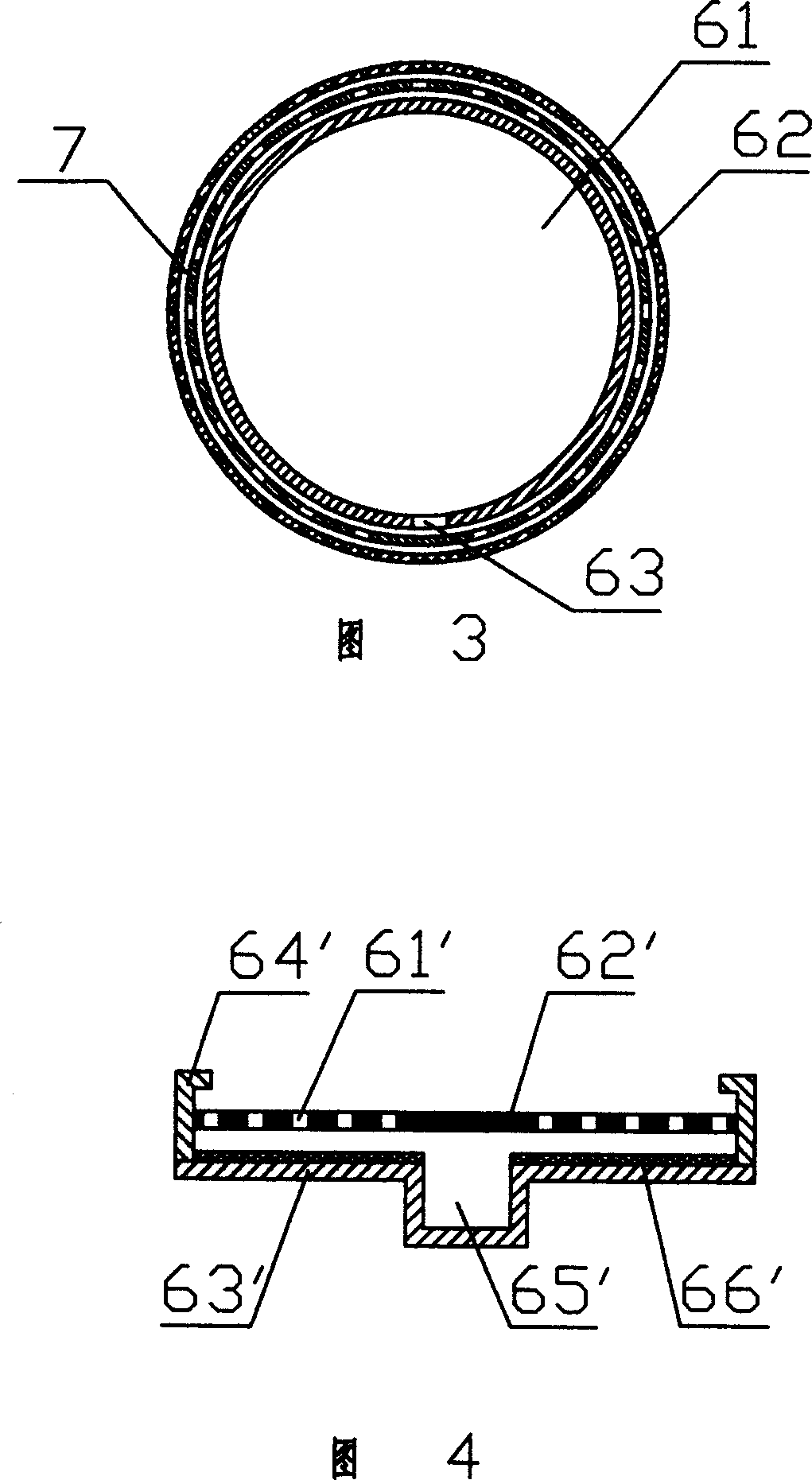

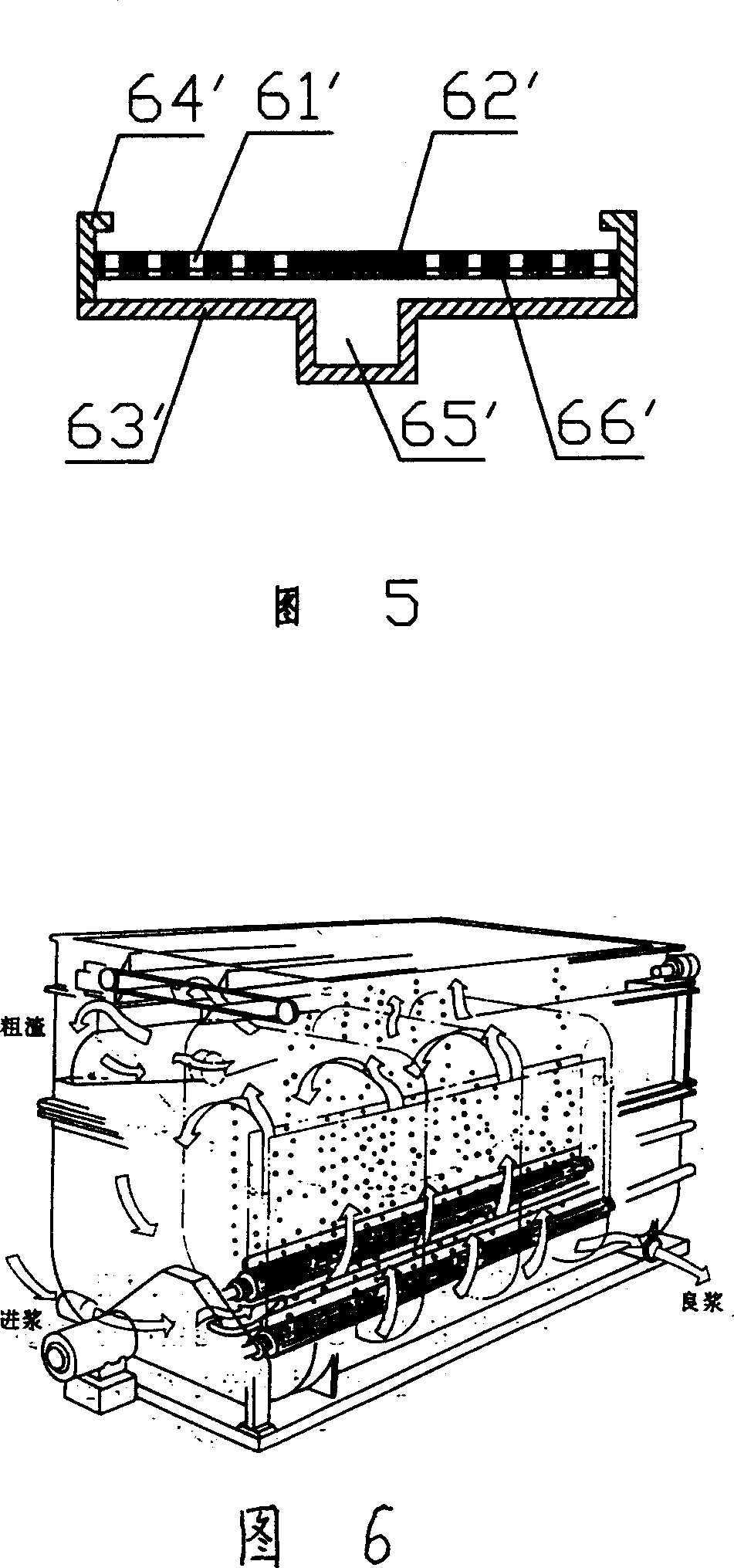

Floatation and ink removing machine

InactiveCN101086145AImprove qualityComplete deinkingCellulosic pulp after-treatmentPaper recyclingDeinkingSlag

The invention discloses a flotation deinking machine, it includes deinking machine shell, liquid feeding mouth installed on one side of deinking machine shell and liquid discharging mouth installed on another side of deinking machine shell, ink-gathering device installed in the upper of the cavity of deinking machine shell and the slag hole connected with the ink-gathering device, the bottom of said cavity of deinking machine shell is equipped with several micropore aeration device which can transmit flotation foam to the liquid in deinking machine shell, and air intake pipes connected with micropore aeration device, said several micropore aeration device is equipped with foam-generating hole which can generate foams in different diameter; due to the distribution of the diameter and the amount of flotation foam are matched with the size and the amount of the ink particles contained in the flotation pulp, ink particles in different diameters can be bright away by the flotation foam, the deinking is more thorough and the pulp quality is higher.

Owner:SHENZHEN DEWEI INTELLIGENT MFG TECH CO LTD

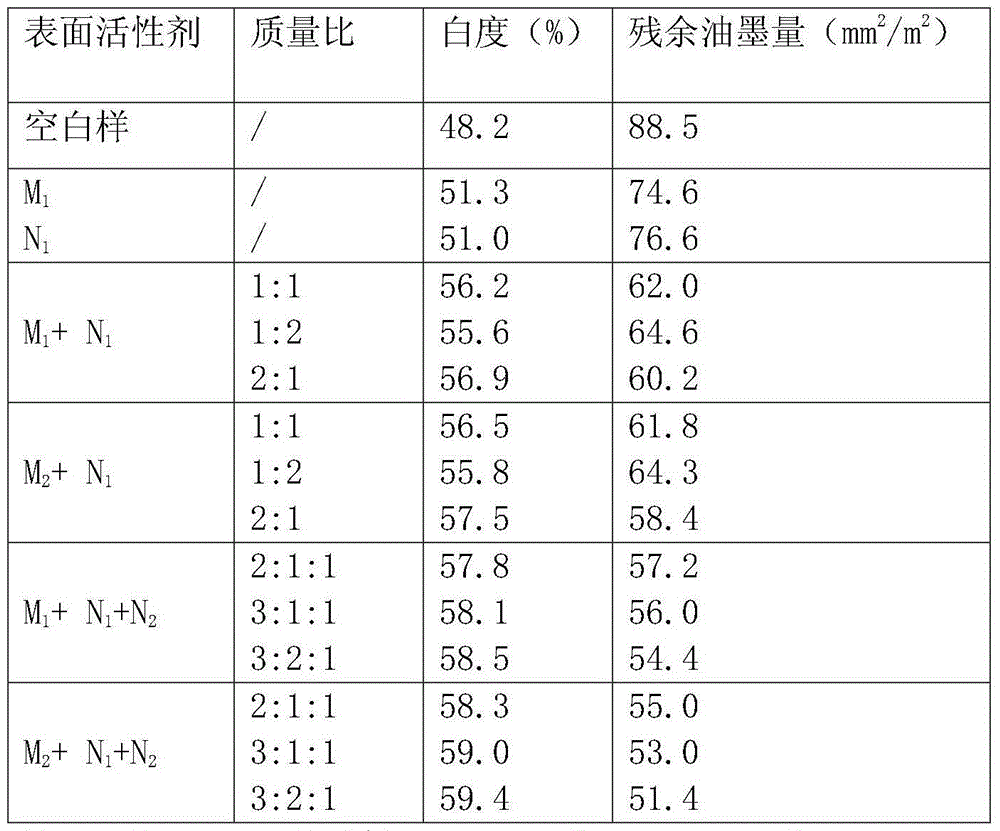

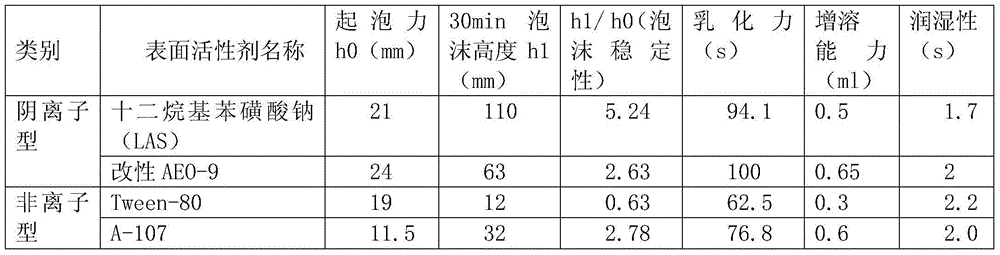

Preparation method of waste paper deinking agent with excellent performance

ActiveCN104693881AStrong oil solubilizationGood deinking performanceOrganic compound preparationCarboxylic acid esters preparationOrganic acidChemistry

The invention relates to a waste paper deinking agent with excellent performance. The waste paper deinking agent is prepared from the following ingredients by a certain weight ratio: carboxymethyl modified fatty-acid polyoxyethylene ether, fatty-acid polyoxyethylene ether and A-107. A preparation method of the deinking agent disclosed by the invention comprises the step of uniformly mixing carboxymethyl modified fatty-acid polyoxyethylene ether, fatty-acid polyoxyethylene ether and A-107, thereby obtaining the deinking agent. According to the deinking agent disclosed by the invention, the used synthesized organic-acid polyoxyethylene block ester product is an ether-ester type nonionic surfactant, so that the deinking agent has the advantages of strong oil-and-fat solubilization property, easiness in biodegradation, environment-friendliness and the like.

Owner:JIANGMEN POLYTECHNIC

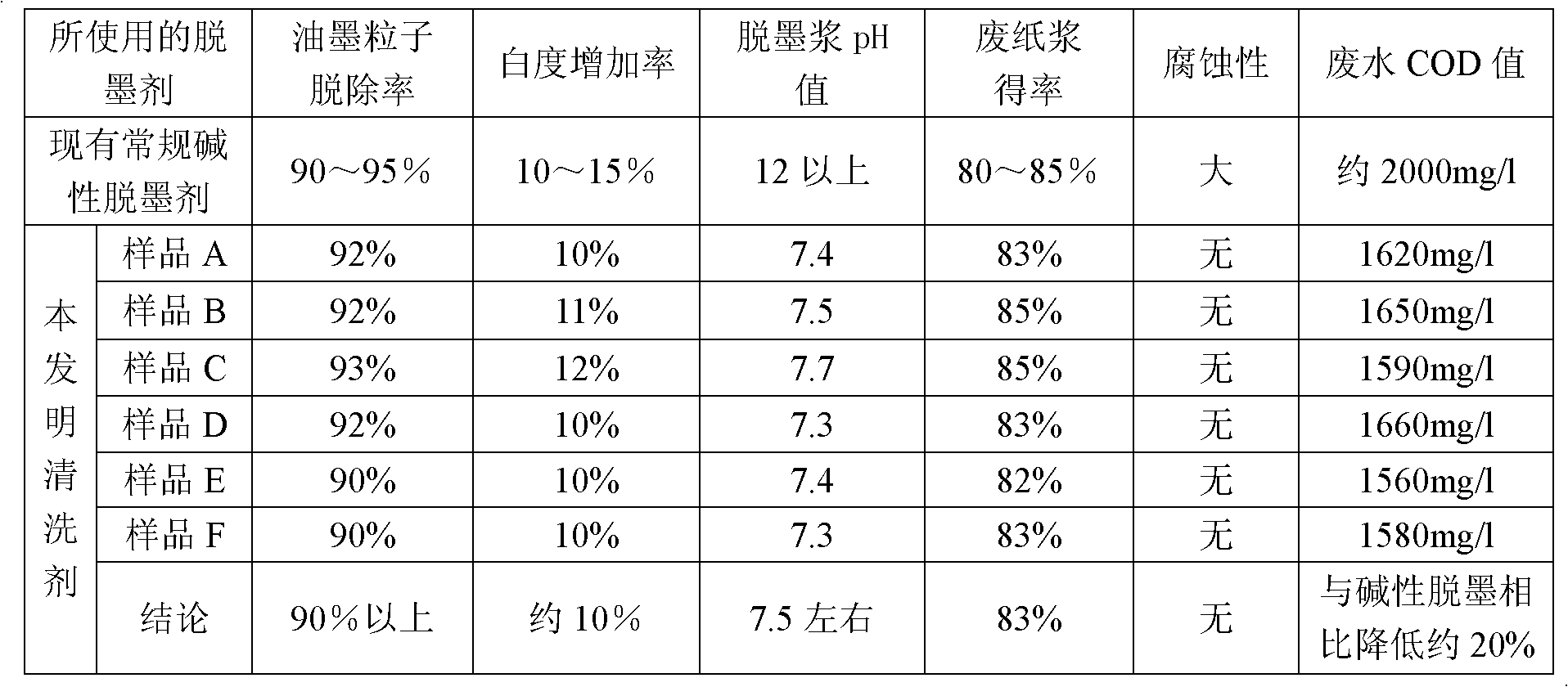

Waste newspaper-neutral deinking agent for waste book paper, preparation method and deinking method

InactiveCN102277763AReduce processing difficultySimple processPaper recyclingChemical paints/ink removersDeinkingSodium stearate

The invention relates to a neutral deinking agent for waste newspaper and waste book and periodical paper. The neutral deinking agent consists of the following components: sodium stearate, lauryl sodium sulfate, alkylphenol polyoxyethylene, fatty alcohol-polyoxyethylene ether and water. A preparation method for the neutral deinking agent comprises the following steps of: weighing the components, pouring the weighed water into a reaction kettle, adding the sodium stearate and stirring until the sodium stearate is dissolved completely, adding other components, keeping stirring, standing and naturally cooling, and thus obtaining the neutral deinking agent. A deinking method comprises the following steps of: shearing the waste newspaper and the waste book and periodical paper into blocks, mixing the blocks uniformly and placing the mixture into a container; and adding the neutral deinking agent, adding hot water to dilute the neutral deinking agent, and performing heat preservation, size degradation and flotation sequentially. By the neutral deinking agent for the waste newspaper and the waste book and periodical paper, the problems of high corrosiveness and environmental pollution caused by alkaline deinking agents in the prior art can be solved, and a deinking effect is good. The preparation method is simple in process and easy to implement. The deinking method has a good deinking effect and is environment-friendly and energy-saving.

Owner:XIAN UNIV OF TECH

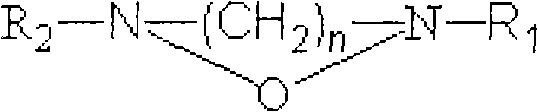

Partial esterified isomerized alcohol block polyether, preparation and application in deinking of waste paper

InactiveCN101319046AGood compatibilityStrong emulsifying and dispersing abilityFats/resins/pitch/waxes removal in pulpWashing/displacing pulp-treating liquorsAlcoholStructural formula

The invention discloses partially esterified isomerous alcohol block polyether, a method for manufacturing the same, and an application of the partially esterified isomerous alcohol block polyether in deinking of waste paper. The partially esterified isomerous alcohol three-block polyether reinforces the intermiscibility of a surfactant and ink on the basis of maintaining the surface activity, and has the advantages of low dosage, strong emulsifying and dispersing capacities, superior deinking effect and wide application range. Simultaneously, the partially esterified isomerous alcohol block polyether also has the characteristic of friendly environment. The chemical structural formula is as above.

Owner:SHANGHAI UNIV OF ENG SCI +2

Waste paper deinking and magnesium base hydrogen peroxide bleaching method

ActiveCN111424453AGood deinking effectHigh strengthWashing/displacing pulp-treating liquorsPulp beating methodsSodium silicateActive agent

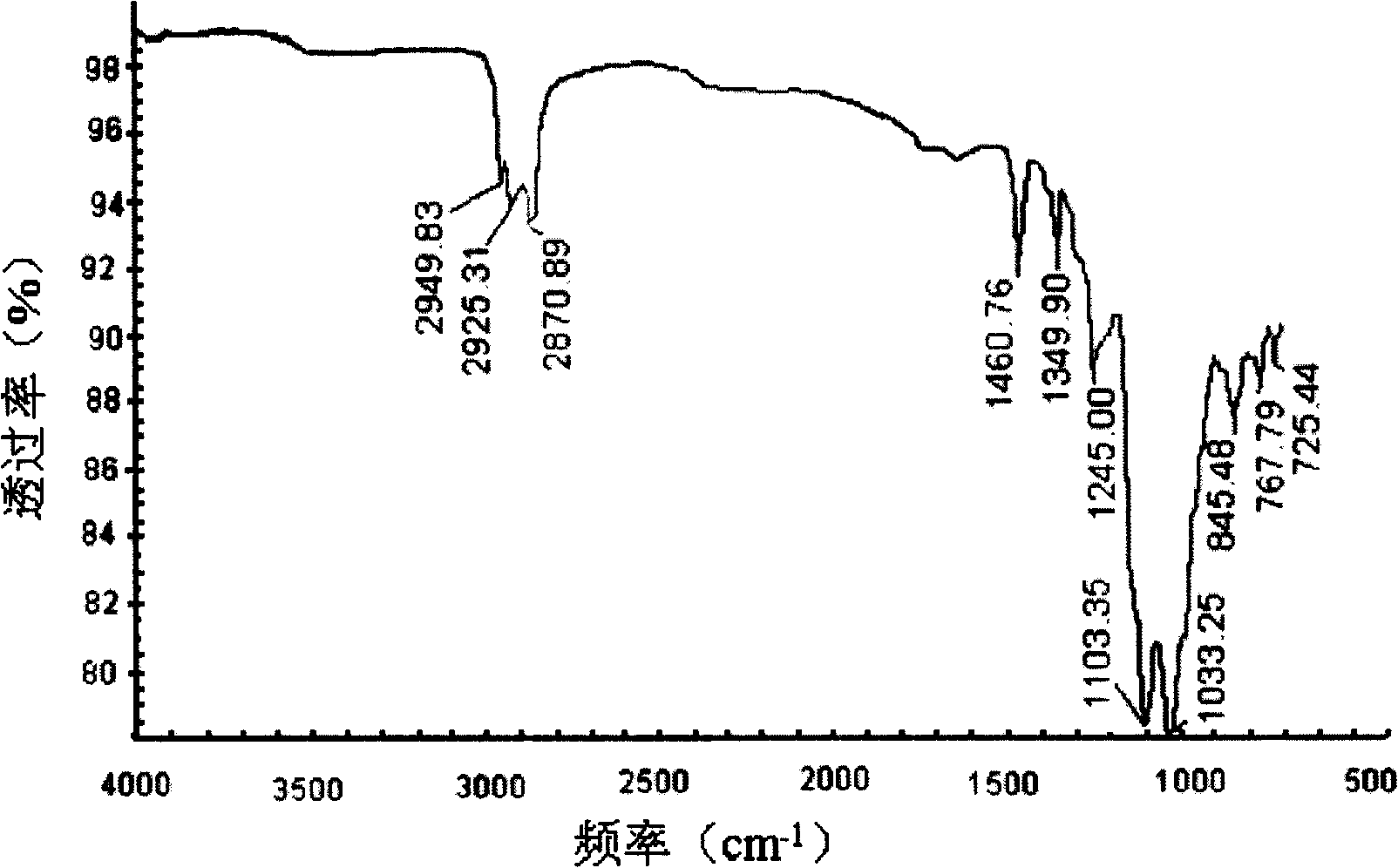

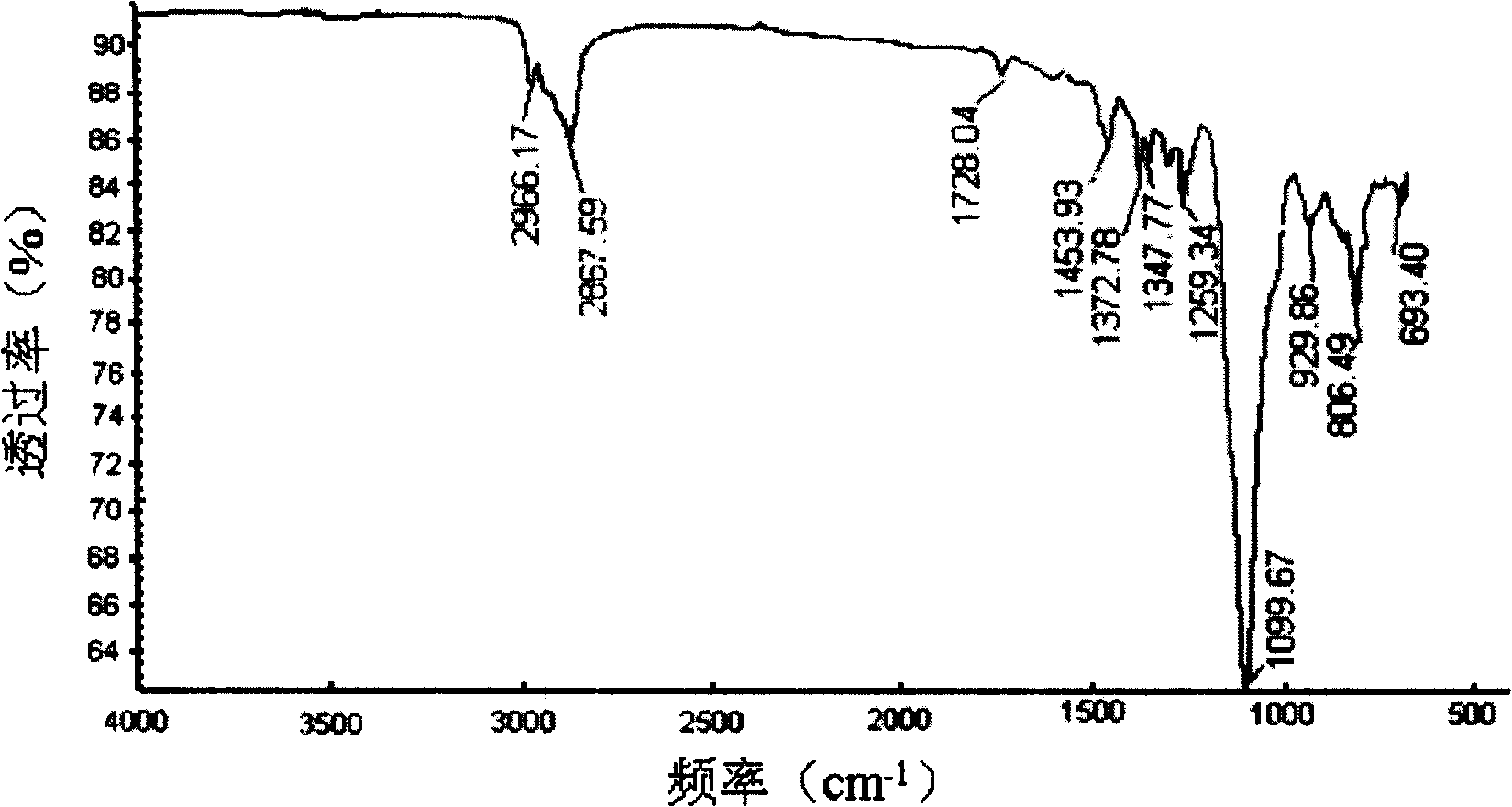

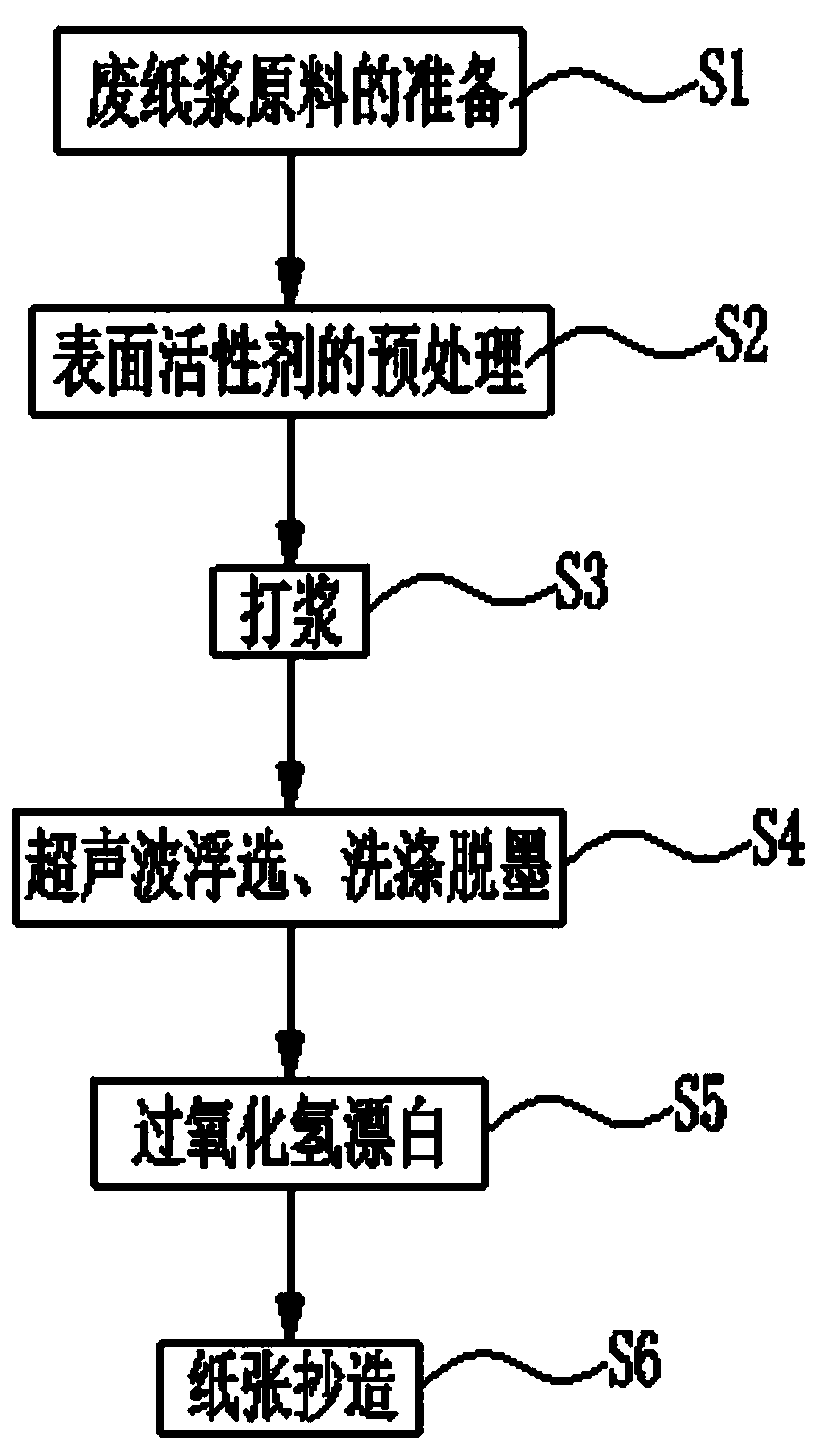

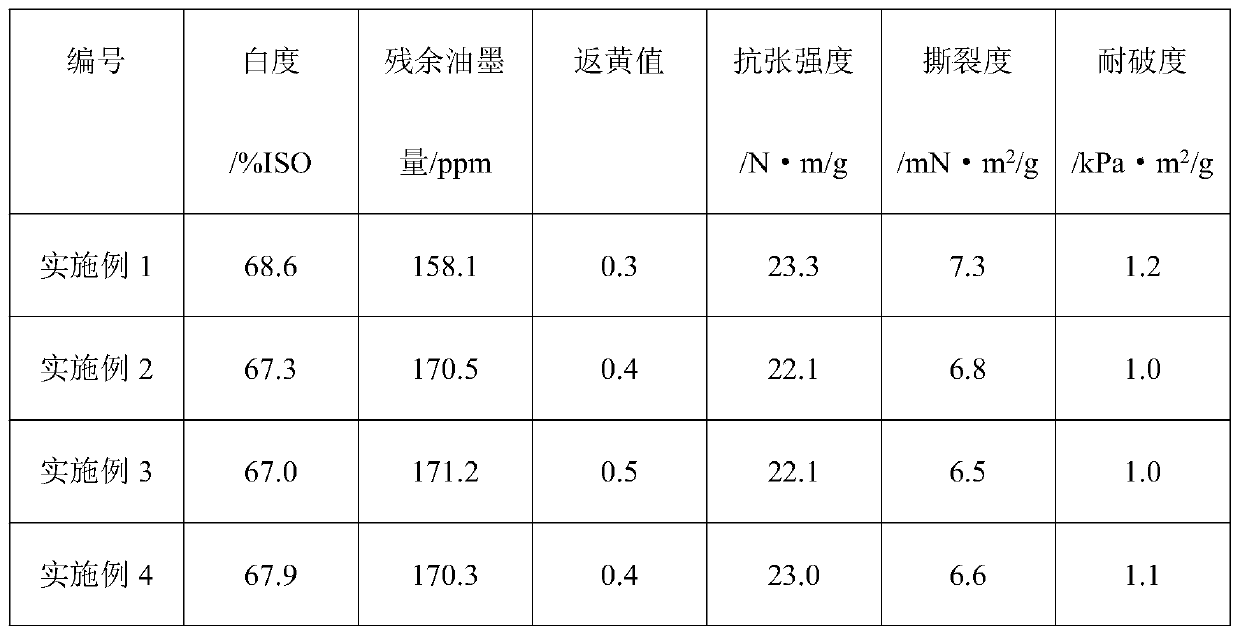

The invention belongs to the technical field of waste paper pulping and papermaking, and discloses a waste paper deinking and magnesium base hydrogen peroxide bleaching method. The method comprises the steps of waste paper pulp raw material preparation, surfactant pretreatment, pulping, ultrasonic flotation, washing deinking, hydrogen peroxide bleaching, paper making and the like. Through innovation and improvement of a deinking process, pretreatment of a surfactant is performed before pulping operation, and through the synergistic effect of the surfactant acrylic acid and isophorone diisocyanate, the subsequent waste paper deinking effect can be effectively enhanced, and the paper strength is enhanced. A hydrogen peroxide bleaching process is improved, laccase is used as a pre-bleaching agent, and magnesium sulfate, sodium silicate and sodium hydroxide are used as bleaching protective agents; hydrogen peroxide is used as a bleaching agent, and sodium isononanoyloxybenzenesulfonate isused as a bleaching aid, so the bleached waste paper deinking pulp is good in strength, high in whiteness and good in whiteness stability, and the COD value in bleaching waste liquid is remarkably reduced.

Owner:GUANGDONG IND TECHN COLLEGE

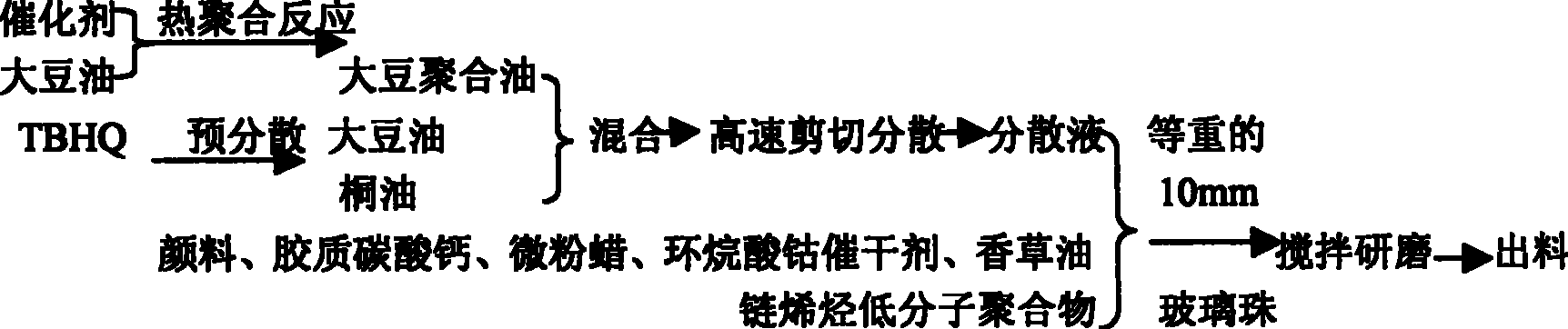

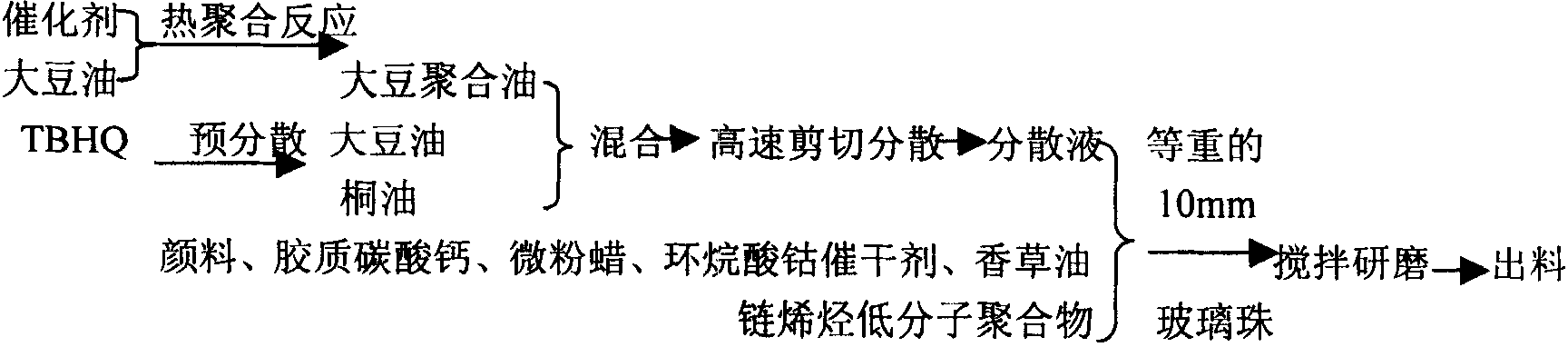

Environment-friendly type soya-bean ink and preparation technique thereof

The invention relates to the environment-friendly soybean oil ink and the preparation method. A container is put into a 65 to 70 degrees C water-bath and then the soybean oil is added in. Then the antioxidant TBHQ, the tung oil and the soybean heat-bodied oil are orderly added in. The mixture is dispersed by a high-speed shear dispersing mulser and then added in pigment, calcene, micro-pastille, olefine oligomer, cobalt naphthenate drier and herb oil. 10 mm beading with the same weight of the gross materials is added in after dispersing for half an hour by a blender. The pigment is grinded bythe friction of the beading surface, which enables the pigment to disperse evenly in bonding materials. The beading is separated after blending for 3 to 4 hours and the product can be obtained. The environment-friendly soybean oil ink has the advantages of fresh and pure color, low VOC content, good biological degradability, good working stability, good working quality after printing, good deink result of the presswork and low integrated printing cost, and thus can be biodegraded, avoiding environmental pollution.

Owner:TIANJIN UNIV OF SCI & TECH

Efficient deinking agent for mixed waste paper

InactiveCN104710853AAvoid \"alkaline blackening\"Avoid the phenomenon of \"returning yellow\"Chemical paints/ink removersEthylenediamineDeinking

The invention relates to an efficient deinking agent for mixed waste paper, and mainly solves the problems of poor deinking effect and serious environmental pollution in the prior art. The efficient deinking agent for the mixed waste paper comprises the following components in parts by weight: 15-25 parts of polyoxyethylene fatty alcohol sodium sulfate, 15-25 parts of alkylphenol polyoxyethylene, 10-15 parts of Twain-80, 25-30 parts of sodium dodecyl benzene sulfonate, 10-15 parts of attapulgite, 5-10 parts of anhydrous sodium metasilicate, 5-10 parts of ethylenediamine tetraacetic acid. By adopting the technical scheme, the problems are well solved, and the efficient deinking agent can be used for waste paper recycling.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waste paper deinking agent

InactiveCN105086583AEasy to prepareStrong stabilityPaper recyclingChemical paints/ink removersMicroencapsulationsSurface-active agents

The invention discloses a waste paper deinking agent. The waste paper deinking agent is composed of, by weight, 40%-50% of a non-ionic surface active agent, 35%-40% of lipase microcapsules and 20%-30% of auxiliary materials. The waste paper deinking agent is suitable for deinking treatment of waste corrugated paper, waste newsprint, colored offset newsprint, paper of waste books and magazines, office waste paper and laser and electrostatic copying paper. Microencapsulation is conducted on lipase, preparation is easy, the stability is strong, when the microcapisulazed lipase is added in a chemical deinking agent, the activity of the lipase is maintained, the chemical deinking agent is rich in components, and dosing is scientific; after waste paper pulp is added, the lipase is slowly released, deinking can be conducted by using a chemical method and a biological method simultaneously, the waste paper deinking effect is good, the whiteness is high, the dirt count is small, fibers are soft, the reutilization performance is strong, the degree of contamination of sewage in the later period is small, the treatment is easy, the cost is reduced, and the environment is protected.

Owner:HEFEI LONGFA PACKING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com