Water-based composite deinking agent

A deinking agent, water-based technology, applied in the direction of chemical paint/ink remover, coating, papermaking, etc., can solve the problems of reduced whiteness of pulp, difficult to popularize and apply, poor foaming, etc., to improve the whiteness of pulp , Improve deinking effect, good emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

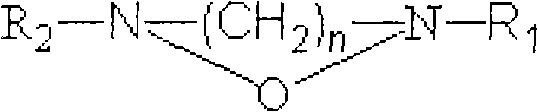

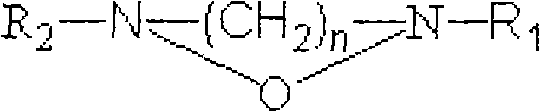

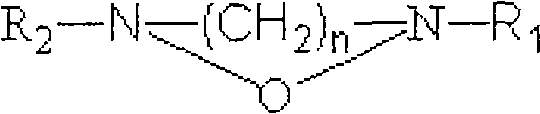

Method used

Image

Examples

Embodiment 1

[0040] Tear the paper pattern into 2cm×5cm pieces, mix them evenly, balance the water and set aside.

[0041] Water-based composite deinking agent body weight percentage:

[0042] Alkyl fatty alcohol polyoxypropylene polyoxyethylene ether phosphate 0.3%;

[0043] Sodium alkyl fatty alcohol polyoxyethylene ether sulfate 0.2%;

[0044] NaOH 1.5%;

[0045] NaSiO 3 3.0%;

[0046] h 2 o 2 1.5%;

[0047] 1,3-Dimethyl-2-imidazolinone 1.0%;

[0048] The rest is water.

[0049] Weigh a certain amount of dry sample and the above-mentioned proportioning water-based composite deinking agent solution and place it in a pulp disintegrator, adjust the weight content of the pulp to 15%, disintegrate at 60°C for 60 minutes, and dilute the pulp To a weight content of 0.8%, flotation by flotation machine for 4 minutes.

[0050] Use the laboratory ZCQ paper sheet former to copy the sheets, and the quantitative control is a...

Embodiment 2

[0052] Tear the paper pattern into 2cm×5cm pieces, mix them evenly, balance the water and set aside. Water-based composite deinking agent weight percent:

[0053] Alkyl fatty alcohol polyoxypropylene polyoxyethylene ether phosphate 0.3%;

[0054] Sodium alkyl fatty alcohol polyoxyethylene ether sulfate 0.2%;

[0055] NaOH 1.5%;

[0056] NaSiO 3 3.0%;

[0057] h 2 o 2 1.5%;

[0058] 1,3-Dimethyl-2-imidazolinone 1.5%;

[0059] The rest is water.

[0060] Weigh a certain amount of dry sample and the above-mentioned proportioning water-based composite deinking agent solution in a high-consistency pulp disintegrator, adjust the weight content of the pulp to about 15%, and disintegrate at a temperature of 60°C for 60 minutes to disintegrate the pulp Dilute it to a weight content of 1.2%, and float for 4 minutes through a flotation machine. Use the laboratory ZCQ paper sheet former to copy the sheets, and the q...

Embodiment 3

[0062] Tear the paper pattern into 2cm×5cm pieces, mix them evenly, balance the water and set aside. Water-based composite deinking agent weight percent:

[0063] Alkyl fatty alcohol polyoxypropylene polyoxyethylene ether phosphate 0.3%;

[0064] Sodium alkyl fatty alcohol polyoxyethylene ether sulfate 0.2%;

[0065] NaOH 1.5%;

[0066] NaSiO 3 3.0%;

[0067] h 2 o 2 1.5%;

[0068] 1,3-Dimethylpropylene imidazolinone 1.0%;

[0069] The rest is water.

[0070] Weigh a certain amount of dry sample and the above ratio water-based composite deinking agent solution in a high-consistency pulp disintegrator, adjust the pulp content to about 15%, disintegrate at 60°C for 60 minutes, and dilute the pulp To the content of 1%, flotation by flotation machine for 4 minutes. Use the laboratory ZCQ paper sheet former to copy the sheets, and the quantitative control is at 60 g / m 2 , and then dried and measured using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com