Preparation method of waste paper deinking agent with excellent performance

An excellent technology for deinking of waste paper, applied in the field of preparation of deinking agent for waste paper, can solve the problems of intolerance to hard water, turbidity and delamination, affecting the natural food chain, etc., and achieve good deinking performance and strong oil solubilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

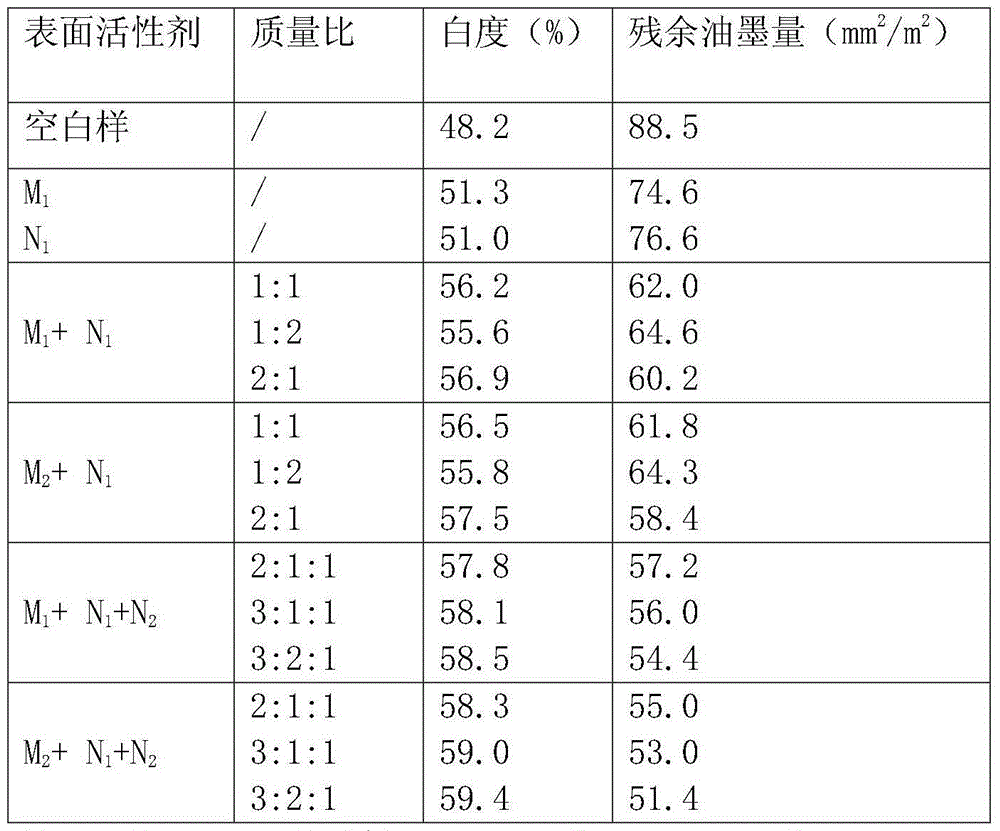

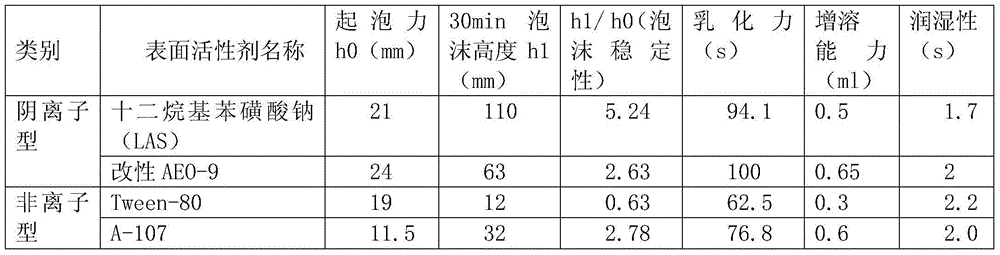

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of a waste paper deinking agent with excellent performance comprises the following steps: weighing carboxymethyl-modified AEO-9, AEO-9 and A-107, and mixing them uniformly to obtain the finished product. Wherein, the weight ratio of carboxymethyl-modified AEO-9:AEO-9:A-107 is 3:2:1.

[0024] A method for preparing carboxymethyl-modified fatty acid polyoxyethylene ether, a component of waste paper deinking agent, comprising the following steps: putting fatty acid polyoxyethylene ether and chloroacetic acid into a three-necked flask, keeping the reaction temperature at 25°C, and stirring After reacting for 0.5h, add sodium hydroxide in 2 times, continue to stir and react for 1.5h, then heat up to 70°C, stop the reaction until the pH value of the system drops to 6.8, adjust the pH value of the product to 5.8 with dilute sulfuric acid, and heat to At 80°C, the product was separated into two layers, which were separated with a separatory funnel, and the ...

Embodiment 2

[0028] A preparation method of a waste paper deinking agent with excellent performance comprises the following steps: weighing carboxymethyl-modified AEO-9, AEO-9 and A-107, and mixing them uniformly to obtain the finished product. Wherein, the weight ratio of carboxymethyl-modified AEO-9:AEO-9:A-107 is 4.5:2:1.

[0029] A method for preparing carboxymethyl-modified fatty acid polyoxyethylene ether, a component of waste paper deinking agent, comprising the following steps: putting fatty acid polyoxyethylene ether and chloroacetic acid into a three-necked flask, keeping the reaction temperature at 30°C, and stirring After reacting for 1 hour, add sodium hydroxide in 3 times, continue to stir and react for 1 hour, heat up to 80°C, stop the reaction when the pH value of the system drops to 7, adjust the pH value of the product to 6 with dilute sulfuric acid, and heat to 90°C , the product is divided into two layers, separated with a separatory funnel, and the upper layer solution...

Embodiment 3

[0032] A preparation method of a waste paper deinking agent with excellent performance comprises the following steps: weighing carboxymethyl-modified fatty acid polyoxyethylene ether, fatty acid polyoxyethylene ether and A-107, and mixing them uniformly to obtain the finished product. Wherein, the weight ratio of carboxymethyl-modified AEO-9:AEO-9:A-107 is 6:2:1.

[0033] A method for preparing carboxymethyl-modified fatty acid polyoxyethylene ether, a component of waste paper deinking agent, comprising the following steps: putting fatty acid polyoxyethylene ether and chloroacetic acid into a three-necked flask, keeping the reaction temperature at 35°C, and stirring After reacting for 1 hour, add sodium hydroxide in 3 times, continue to stir and react for 1.5 hours, heat up to 90°C, and stop the reaction until the pH value of the system drops to 7.5, adjust the pH value of the product to 6.3 with dilute sulfuric acid, and heat to 100 ℃, the product is divided into two layers, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com