Biomass-base high-efficiency deinking agent, and preparation method and application thereof

A biomass and deinking agent technology, used in chemical paint/ink remover, recycling technology, coating, etc., can solve the problems of low product quality, insufficient foam quantity, poor foam stability, etc., and reduce pulp residues Ink, preparation method is efficient, and the effect of improving paper whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

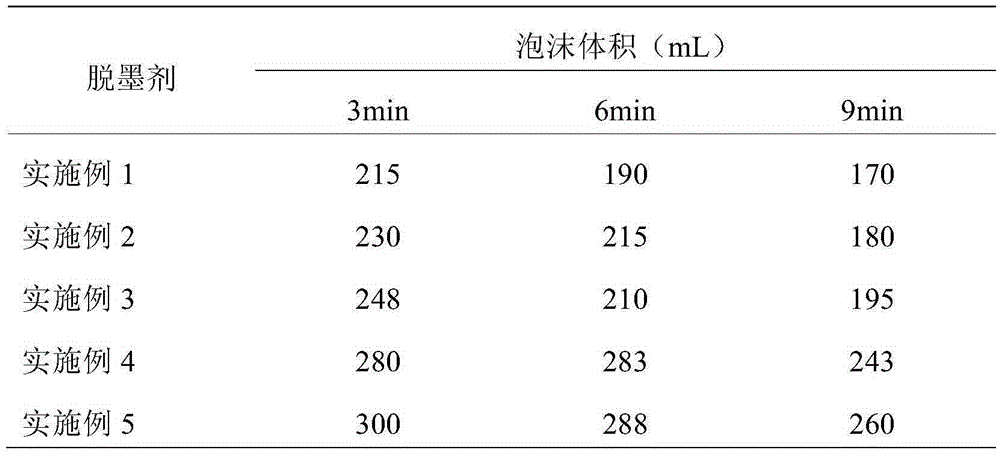

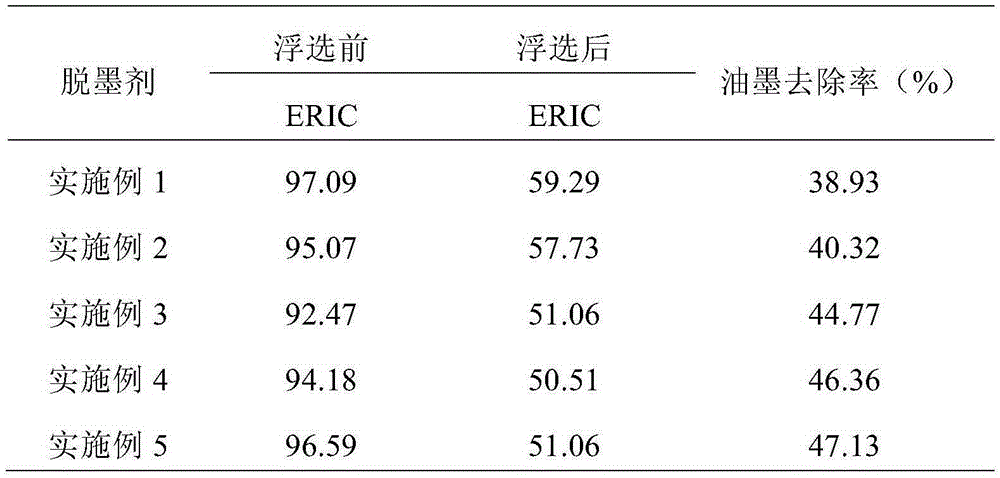

Examples

Embodiment 1

[0029] A preparation method of biomass-based high-efficiency deinking agent, comprising the following steps:

[0030] (1) Weigh 35g of rosin and place it in a round-bottomed flask, stir it to make it melt completely at 100°C, then add 45g of palmitic acid and 20g of vegetable oleic acid respectively, and mix the three raw materials evenly;

[0031] (2) Under constant stirring, a sodium hydroxide solution with a mass percent concentration of 10 wt % was added into a round bottom flask, and reacted at 85° C. for 1 h to obtain the biomass-based high-efficiency deinking agent.

Embodiment 2

[0033] A preparation method of biomass-based high-efficiency deinking agent, comprising the following steps:

[0034] (1) Weigh 35g of rosin and place it in a round-bottomed flask, stir it to make it melt completely at 105°C, then add 40g of palmitic acid and 25g of vegetable oleic acid respectively, and mix the three raw materials evenly;

[0035] (2) Under constant stirring, a sodium hydroxide solution with a mass percent concentration of 15 wt% was added into a round-bottomed flask, and reacted at 90° C. for 3 hours to obtain the biomass-based high-efficiency deinking agent.

Embodiment 3

[0037] A preparation method of biomass-based high-efficiency deinking agent, comprising the following steps:

[0038] (1) Weigh 32g of rosin and place it in a round-bottomed flask, stir it to melt it completely at 105°C, then add 43g of palmitic acid and 25g of vegetable oleic acid respectively, and mix the three raw materials evenly;

[0039] (2) Under continuous stirring, a sodium hydroxide solution with a mass percent concentration of 15 wt % was added into a round-bottomed flask, and reacted at 95° C. for 3 hours to obtain the biomass-based high-efficiency deinking agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com