Efficient deinking agent for mixed waste paper

A deinking agent and high-efficiency technology, applied in the field of high-efficiency deinking agent for mixed waste paper, can solve the problems of poor deinking effect and large environmental pollution, achieve good running performance, reduce environmental pollution, and avoid alkaline blackening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

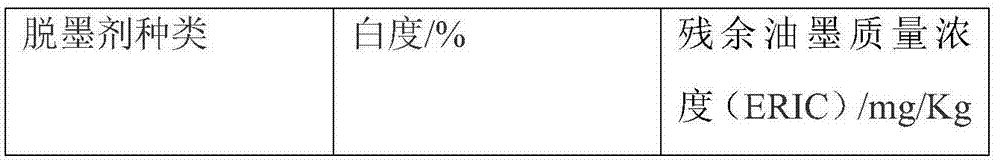

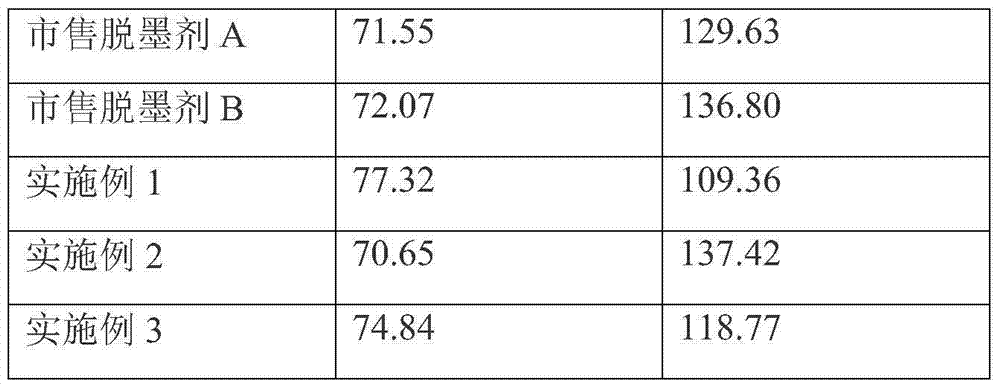

Examples

Embodiment 1

[0013] A kind of deinking agent, described deinking agent is made up of the composition of following parts by weight:

[0014] Sodium fatty alcohol polyoxyethylene ether sulfate (AES): 20 parts

[0015] Alkylphenol polyoxyethylene ether (OP-10): 20 parts

[0016] Tween-80: 10 servings

[0017] Sodium dodecylbenzenesulfonate: 28 parts

[0018] Attapulgite: 10 parts

[0019] Anhydrous sodium metasilicate (Na 2 SiO 3 ): 7 servings

[0020] Ethylenediaminetetraacetic acid (EDTA): 5 parts

[0021] Add the above substances in sequence, and stir for 5 minutes after each of the above substances is added.

Embodiment 2

[0023] A kind of deinking agent, described deinking agent is made up of the composition of following parts by weight:

[0024] Fatty alcohol polyoxyethylene ether sodium sulfate (AES): 15 parts

[0025] Alkylphenol polyoxyethylene ether (OP-10): 15 parts

[0026] Tween-80: 10 servings

[0027] Sodium dodecylbenzenesulfonate: 25 parts

[0028] Attapulgite: 15 parts

[0029] Anhydrous sodium metasilicate (Na 2 SiO 3 ): 10 copies

[0030] Ethylenediaminetetraacetic acid (EDTA): 10 parts

[0031] Add the above substances in sequence, and stir for 5 minutes after each of the above substances is added.

Embodiment 3

[0033] A kind of deinking agent, described deinking agent is made up of the composition of following parts by weight:

[0034] Sodium fatty alcohol polyoxyethylene ether sulfate (AES): 25 parts

[0035] Alkylphenol polyoxyethylene ether (OP-10): 15 parts

[0036] Tween-80: 10 servings

[0037] Sodium dodecylbenzenesulfonate: 30 parts

[0038] Attapulgite: 10 parts

[0039] Anhydrous sodium metasilicate (Na 2 SiO 3 ): 5 copies

[0040] Ethylenediaminetetraacetic acid (EDTA): 5 parts

[0041] Add the above substances in sequence, and stir for 5 minutes after each of the above substances is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com