Waste paper deinking method

A waste paper deinking and waste paper technology, applied in the field of papermaking, can solve the problem of low deinking effect in neutral deinking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The concrete operation of described waste paper deinking method is as follows:

[0028] Waste paper shredding: put 4000kg of office waste paper and 1000kg of book paper into the drum pulper, add 20m 3 Water, then add 2.5kg of lipase (0.05% of the total weight of waste paper), the temperature is 50-60°C, the drum pulper runs for 15-20min, the sieve plate aperture of the pulper is 4mm, and the waste paper slurry pH The value is 7.0~8.0;

[0029] Slurry purification: The slurry that has been preliminarily disintegrated by the drum pulper is passed into the conical desander, and the impurities heavier than the fibers are removed by centrifugal force, and then the slurry with heavy impurities is pumped to the pressure screen for removal. For light impurities such as paper and nylon paper with a diameter less than 0.12mm, the feeding concentration is 4-5%, the pressure is 0.25-0.30Mpa, and the sieve drum slot width of the pressure sieve is 0.12mm;

[0030] Ink dispersion: t...

Embodiment 2-12

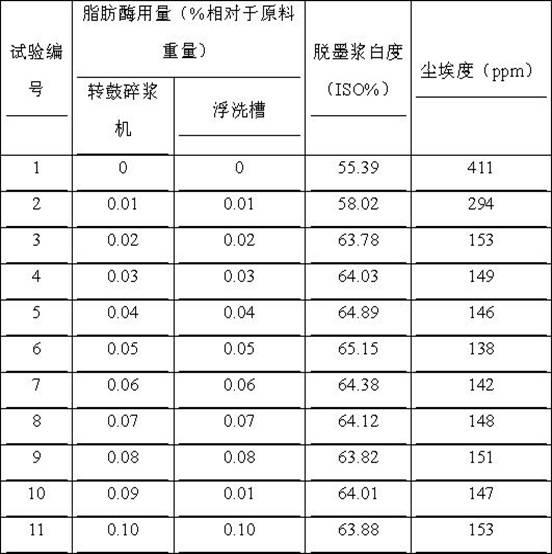

[0034] Carry out 11 tests repeatedly according to the method for embodiment 1, change the addition amount of lipase, other conditions are constant, each test is carried out continuously 72 hours, obtains the average value of deinking pulp into pulp whiteness and residual ink, the result is as shown in the table 1 (the embodiment number minus 1 is the test number).

[0035]

[0036] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com