Partial esterified isomerized alcohol block polyether, preparation and application in deinking of waste paper

A block polyether and isomeric alcohol technology, applied in chemical instruments and methods, pulp fat/resin/pitch/wax removal, transportation and packaging, etc., can solve the problems of poor foaming of deinking agent and achieve emulsification Strong dispersing ability, wide application range, enhanced compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Pump 2-ethylhexanol into the polymerization reactor, add catalyst KOH according to 0.5% of the total weight of 2-ethylhexanol, then heat the material to 150°C, vacuumize and pass through nitrogen protection, and pass through 572 kg The reaction control step is controlled by the feeding speed of ethylene oxide, the temperature does not exceed 150°C, and the pressure is 0.35MPa. Complete response;

[0044] Add 754 kilograms of propylene oxide, after the propylene oxide has been added, keep warm and reduce the pressure to 0.2MPa, so that the remaining raw materials react completely;

[0045] Add 572 kg of ethylene oxide. After the ethylene oxide is added, keep warm and reduce the pressure to 0.2 MPa, so that the remaining raw materials will react completely, and the isomeric alcohol block polyether will be produced after cooling down and discharging. The general structural formula is as formula (1), wherein: n=6, m=2, x=16, y=16, z=16;

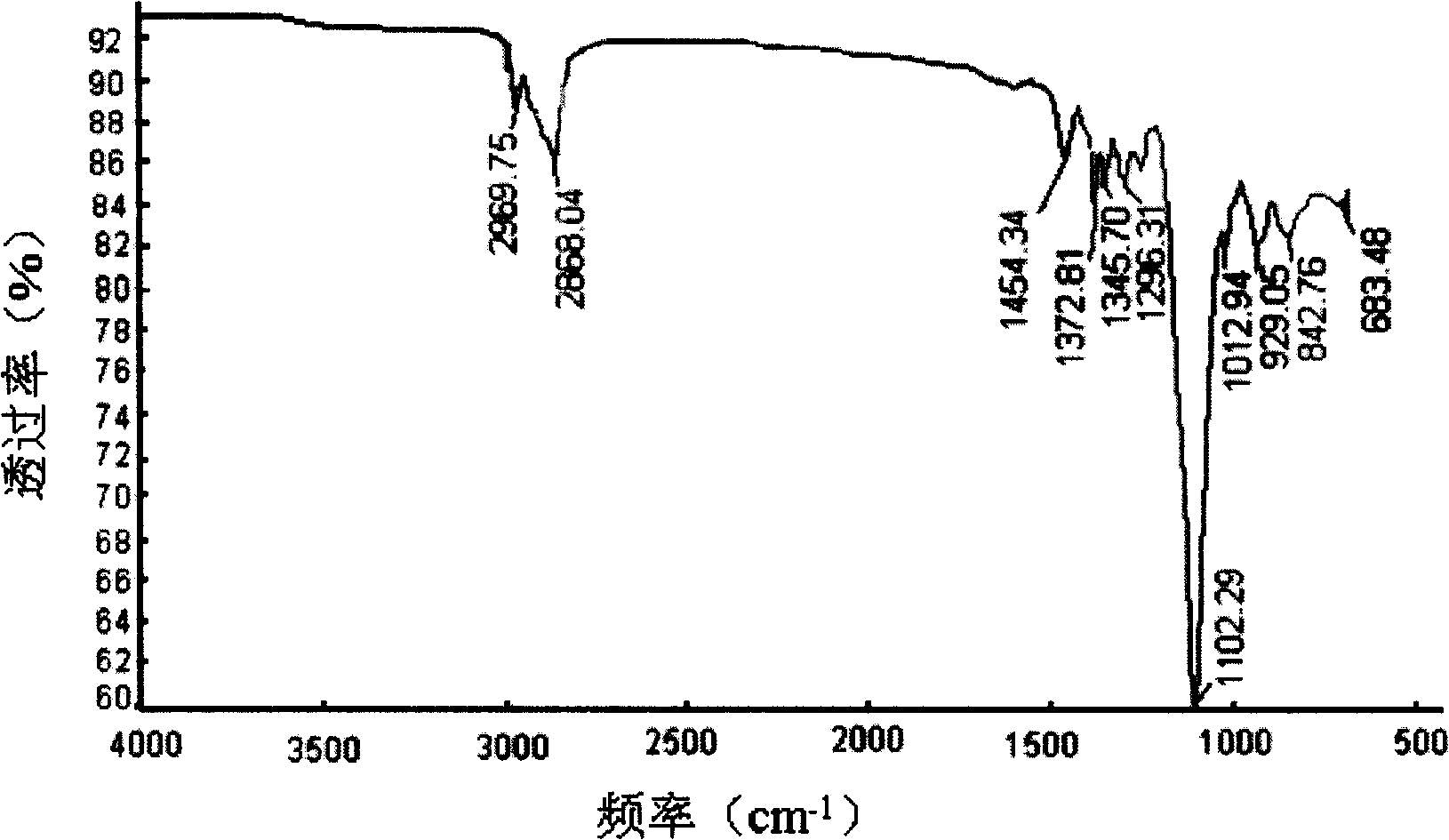

[0046] The structure of 2-ethylhe...

Embodiment 2

[0055] 2-Ethylhexanol is pumped into the polymerization reactor, and catalyst KOH is added by 0.5% of the weight of 2-Ethylhexanol, then the material is heated to 130° C., vacuumized and nitrogen protection is introduced, and 572 kg of Ethylene oxide, the reaction control step is controlled by the feeding speed of ethylene oxide, the temperature generally does not exceed 150°C, and the pressure is less than 0.35MPa. The response is complete.

[0056] Add 754 kilograms of propylene oxide, keep the temperature and reduce the pressure to 0.2MPa after the metered propylene oxide is added, so that the remaining raw materials react completely.

[0057] Add 572 kilograms of oxirane, keep the temperature and reduce the pressure to 0.2MPa after the metered oxirane is added, so that the remaining raw materials react completely.

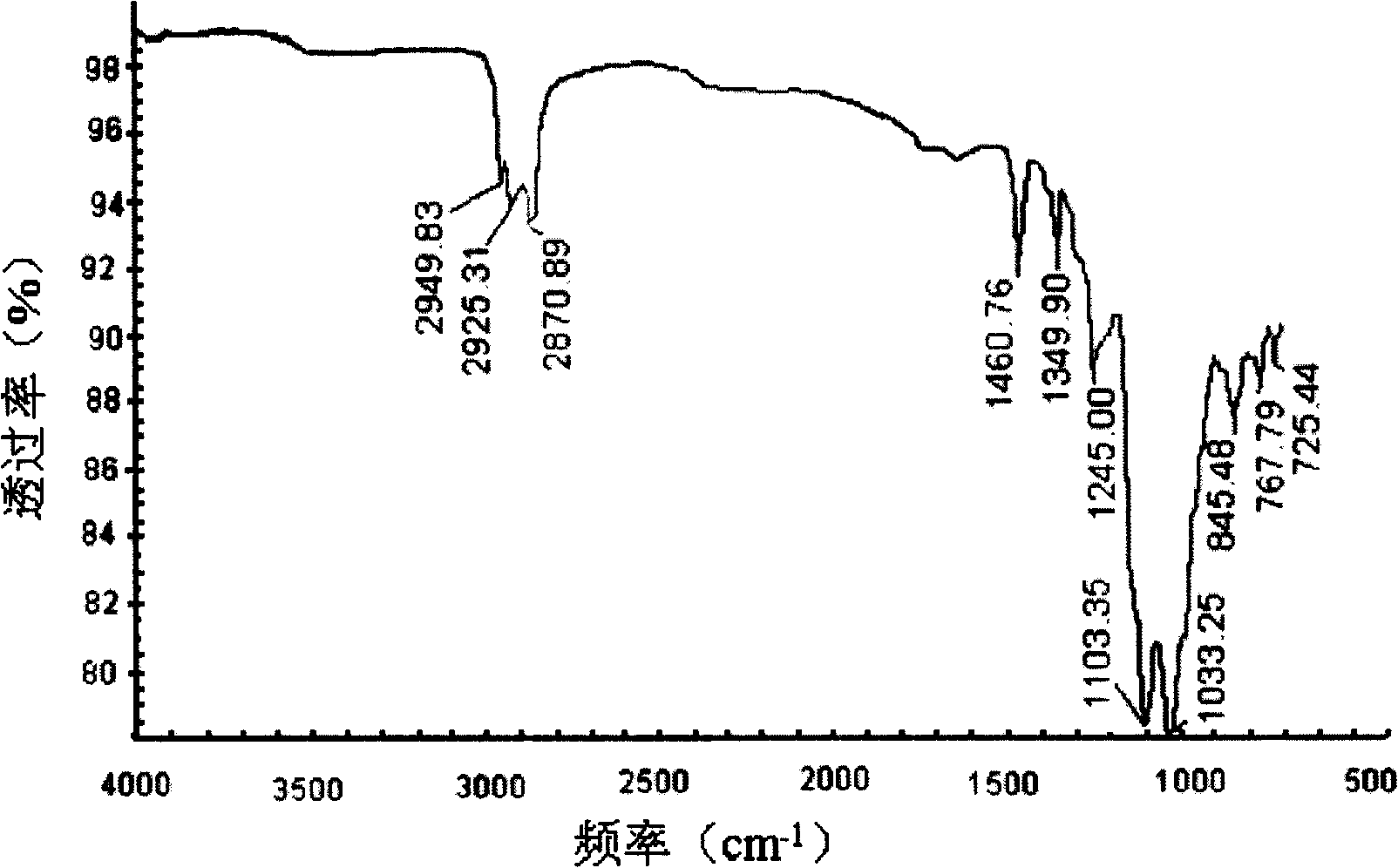

[0058] Put the fully reacted material into a reactor with a water separator, and add the P 2 o 5 , (weight ratio), the control reaction temperature is not m...

Embodiment 3

[0069] Pump the isomeric dodecanol into the polymerization reactor, add catalyst KOH according to 0.8% of the total amount of isomeric dodecyl alcohol, then heat the material to 140°C, vacuumize and pass nitrogen protection, at the same time, open the metering pound, Feed 458 kg of ethylene oxide, the reaction control step is controlled by the feeding speed of ethylene oxide, the temperature generally does not exceed 150°C, and the pressure is less than 0.35MPa. , so that the remaining raw materials react completely.

[0070] Add 878 kilograms of propylene oxide, keep the temperature and reduce the pressure to 0.2MPa after the metered propylene oxide is added, so that the remaining raw materials react completely.

[0071] Add 512 kg of oxirane, keep the temperature and reduce the pressure to 0.2MPa after the metered oxirane is added, so that the remaining raw materials react completely.

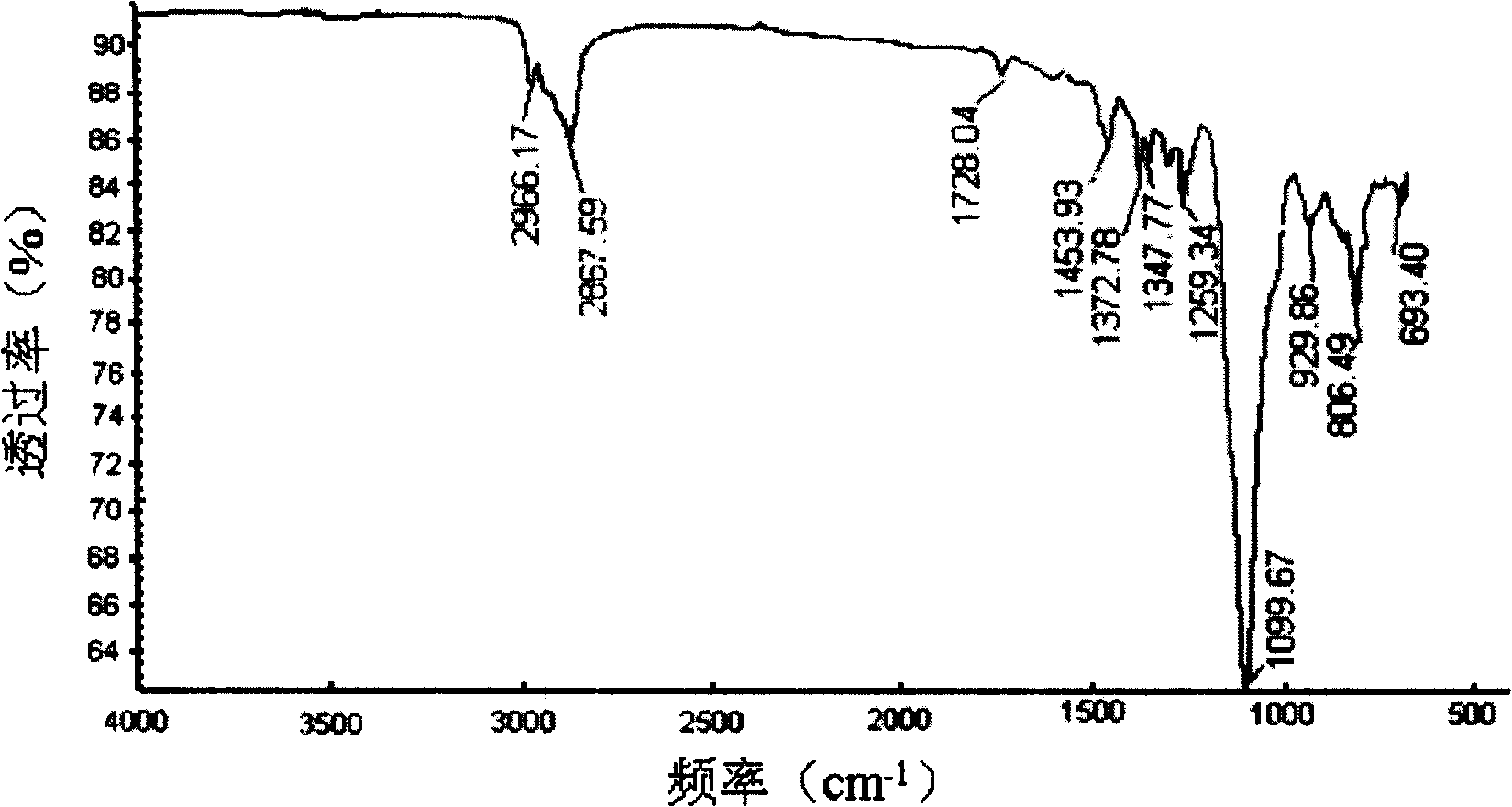

[0072] Put the fully reacted material into a reactor with a water separator, and add POC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com