Environment-friendly deinking agent for toughened glass and preparation method of environment-friendly deinking agent

A technology of deinking agent and section steel, which is applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of adverse health effects of environmental operators, large solvent volatilization, high energy consumption, etc., and achieve good deinking effect, Simple preparation process and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

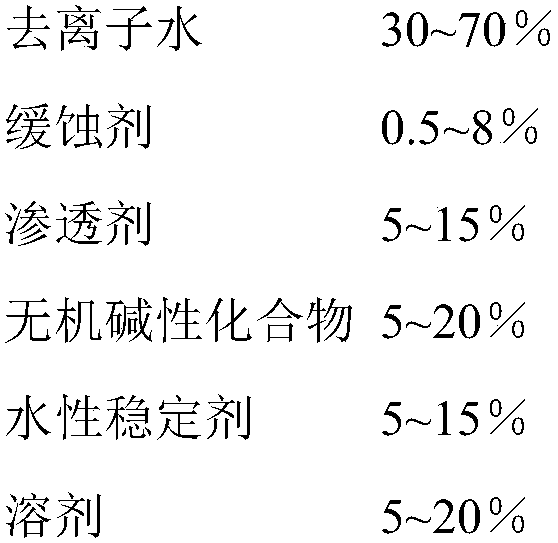

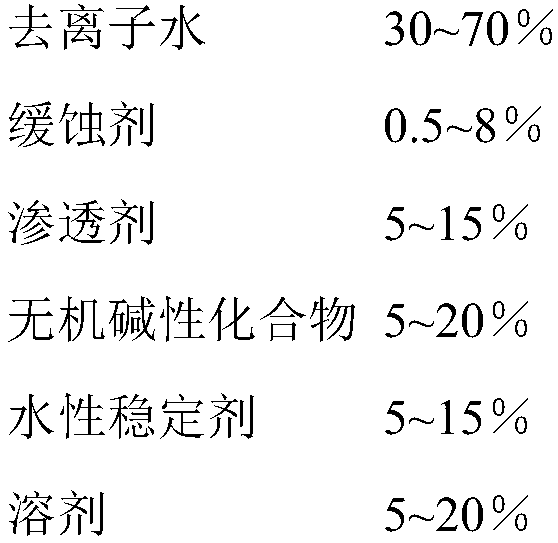

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of environment-friendly tempered glass deinking agent is as follows:

[0025] Step a, adding 180g of sodium hydroxide and 10g of diethanolamine into 400g of deionized water and stirring evenly, then cooling to 10-35°C;

[0026] Step b, take 30g of alkyl alcohol ether carboxylate and 60g of alkyl polyoxyethylene phosphate and mix to form a mixture, according to the mass ratio, configure the penetrating agent for N-methylpyrrolidone:isopropanol=2:3, and then to Add 100g of penetrant, 120g of diethylene glycol, and the mixture of the above-mentioned alkyl alcohol ether carboxylate and alkyl polyoxyethylene phosphate to the mixed solution of step a in sequence, and stir slowly until completely dissolved;

[0027] Step c. Add 100 g of water-soluble potassium gluconate to the mixed solution in step b, and continue to stir evenly to obtain the environment-friendly tempered glass deinking agent.

Embodiment 2

[0029] The preparation method of environment-friendly tempered glass deinking agent is as follows:

[0030] Step a, add 80g of sodium hydroxide, 40g of sodium carbonate, and 50g of glycerol into 500g of deionized water and stir evenly, then cool to 10-35°C;

[0031] Step b, take 40g of alkyl alcohol ether carboxylate and 30g of alkyl polyoxyethylene phosphate and mix to form a mixture, according to the mass ratio N-methylpyrrolidone: isopropanol = 1:1 to configure the penetrant, and then to Add 80g of penetrant, 100g of ethylene glycol monoethyl ether, and the mixture of the above-mentioned alkyl alcohol ether carboxylate and alkyl polyoxyethylene phosphate to the mixed solution in step a, and stir slowly until completely dissolved;

[0032] Step c. Add 80 g of water-soluble disodium ethylenediamine tetraacetate to the mixed liquid in step b, and continue to stir evenly to obtain the environment-friendly tempered glass deinking agent.

Embodiment 3

[0034] The preparation method of environment-friendly tempered glass deinking agent is as follows:

[0035] Step a, adding 80g of potassium hydroxide and 20g of triethanolamine into 600g of deionized water and stirring evenly, then cooling to 10-35°C;

[0036] Step b, take 10g of alkyl alcohol ether carboxylate and 50g of alkyl polyoxyethylene phosphate to form a mixture, configure the penetrating agent according to the mass ratio of N-methylpyrrolidone:isopropanol=3:1, and then add Add 120g of penetrant, 80g of diethylene glycol ether, and the mixture of the above-mentioned alkyl alcohol ether carboxylate and alkyl polyoxyethylene phosphate to the mixed solution of step a in sequence, and stir slowly until completely dissolved;

[0037] Step c. Add 50 g of disodium edetate to the mixed liquid in step b, and continue to stir evenly to obtain the environment-friendly tempered glass deinking agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com