Deinking method of waste paper alkaline enzyme

An alkaline enzyme and waste paper technology, applied in the processing of waste paper, papermaking, paper recycling, etc., can solve the problems of low activity, difficulty, single composition, etc., and achieve the effect of simplified steps, obvious effect, energy saving and water saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

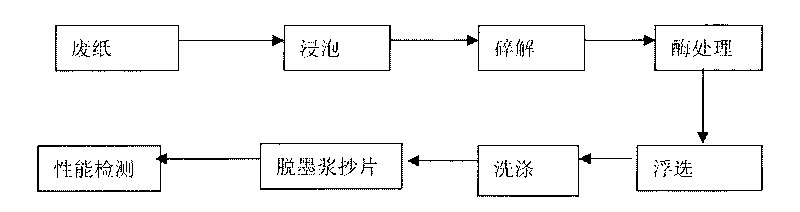

Method used

Image

Examples

Embodiment 1

[0027] Disposal of mixed office waste paper

[0028] After adding 15%wt of water required for slurry concentration into the beaker, put it in a constant temperature water bath at 60°C, and then add 0.20%-2.00%wt of surfactants such as fatty alcohol polyoxyethylene ether, alkylbenzenesulfonic acid Salt. Take 15g of absolute dry mixed office waste paper, in which the ratio of laser printing paper and electrostatic copy paper is 7:3, tear it into strips of 10×15cm and put it in a plastic beaker, soak for 3 to 5 minutes, start the strong constant Speed blender, stirring to shred the waste paper. and use CH 2 COOH or NaOH adjusts the pH of the pulp to 7-11. Then add required enzyme amount, xylanase 100-200μ / g absolute dry pulp, pectinase 70-120μ / g absolute dry pulp, amylase 50-100U / g absolute dry pulp. The reaction time is 10-30min. Dilute the slurry after enzyme treatment to 1%wt, then add 0.05%-0.20%wt anhydrous CaCl 2 , Carry out flotation in the flotation tank, the flot...

Embodiment 2

[0039] Embodiment 2 processes old newsprint

[0040] The treatment process is the same as in Example 1, except that the flotation process is omitted and the water is directly washed. After adding 15% of the water required for slurry concentration into the beaker, put it in a constant temperature water bath at 60°C, and then add 0.20%-1.50% of surfactants such as fatty alcohol polyoxyethylene ether, sodium alkylbenzene sulfonate, Take 15g of dry old newsprint, the waste paper is taken from Wuhan Chenming Paper Co., Ltd., it is imported American waste 8# and 10#, the ratio of 8# / 10# is 7 / 3, tear it into strips of 10×15cm Put it into a plastic beaker, soak for 3 to 5 minutes, start a powerful constant speed mixer, and stir to disintegrate the waste paper. And adjust the pH of the pulp to 7-11. Then add the required enzyme amount, xylanase 120-200μ / g, pectinase 80-100μ / g, amylase 60-120U / g. The reaction time is 15-30min. After the enzyme treatment, the obtained slurry was wash...

Embodiment 3

[0049] After adding 15% of the water required for slurry concentration into the beaker, put it in a constant temperature water bath at 60°C, and then add 0.24%-1.69% surfactants such as fatty alcohol polyoxyethylene ether, alkylbenzene sulfonate, Take 15g of absolute dry mixed office waste paper, in which the ratio of laser printing paper and electrostatic copy paper is 7:3, tear it into strips of 10×15cm and put it in a plastic beaker, soak for 3 to 5 minutes, start the strong constant Speed blender, stirring to shred the waste paper. and use CH 2 COOH or NaOH adjusts the pH of the pulp to 7-11. Then add the required amount of enzymes, xylanase 80-180μ / g dry pulp, pectinase 70-100μ / g dry pulp, amylase 50-100U / g dry pulp, and cellulase 30-100μ / g dry pulp, enzyme activator sodium chloride or sodium sulfate 0.5%-2.0%. The reaction time is 10-30min. Dilute the slurry after enzyme treatment to 1%wt, then add 0.05%-0.20%wt anhydrous CaCl 2 , Carry out flotation in the flotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com